New Techniques and Concepts in Process Mineralogy

-

摘要:

近年来,基于扫描电镜的矿物自动分析仪如QEMSCAN(Quantitative Evaluation of Minerals by Scanning Electronic Microscopy)、MLA(Mineral Liberation Analyser)和AMICS(Advanced Mineral Identification and Characterization System)已经广泛应用于矿物的自动识别与测量;激光剥蚀等离子质谱仪(LA-ICP-MS)由于其在痕量上的检测优势,使元素赋存状态的研究更加准确与深入;飞行时间二次离子质谱仪(TOF-SIMS)的应用为研究矿物表面特性及其变化提供了便利和可靠的方法。部分大型矿山企业在地质勘查阶段就对不同区段的样品进行工艺矿物学研究,关注矿石性质的空间变化给选矿工艺及指标带来的影响,为及时优化改进工艺流程提供依据和指导。就目前研究成果而言,矿物自动测量与分析技术的不断完善,建立数学模型预测选矿指标以及矿物三维数据表征技术在工艺矿物学研究中的应用是其持续发展的新趋势和方向。

Abstract:In recent years, automated mineral analyzer based on SEM such as QEMSCAN, MLA, AMICS have been widely used in mineral automatic identification and measurement. Because of its advantages in trace detection, laser ablation plasma mass spectrometry (LA-ICP-MS) has made the study of the occurrence state of elements more accurate and thorough. Time of flight secondary ion mass spectrometry (TOF-SIMS) provides a convenient and reliable method for the study of the surface characteristics and change. In the geological exploration stage, based on the process mineralogy research of the sample in different sections, some large mining enterprises pay attention to the influence of the changes in the ore properties on the beneficiation process and indicators. In terms of the present research results, continuous improvement on automatic measurement and intelligent mineral analysis technology, mathematical model to forecast the index of mineral processing, and mineral 3D characterization technology in process mineralogy are the new trends of sustainable development and direction.

-

Key words:

- process mineralogy /

- automatic identification /

- occurrence state /

- surface analysis

-

-

表 1 矿石中金的元素平衡

Table 1. Element balance of gold in ore

名称 金矿物之间矿物量相对比例/% 金的分布率/% 碲金矿 5.67 3.66 碲金银矿 4.76 1.88 碲铜金矿 2.86 2.14 碲银矿(含Au) 22.14 0.69 铜金矿 0.29 0.41 自然金 64.28 91.22 总和 100.00 100.00 表 2 钪在不同矿物中的平均含量

Table 2. Average content of Sc in different minerals

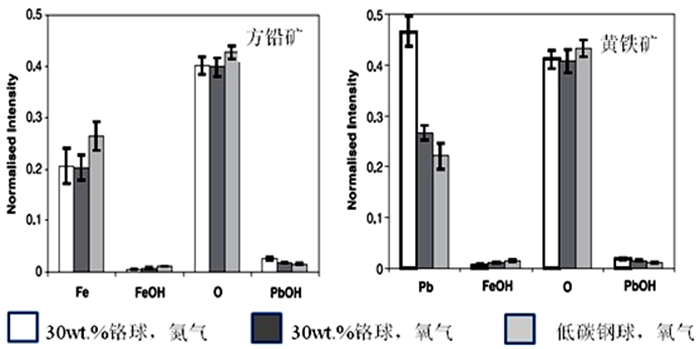

矿物名称 矿物中钪含量/10-6 矿物名称 矿物中钪含量/10-6 霓石 472.39 方解石 0.54 镁钠铁闪石 874.71 菱铁矿 28.99 透辉石 94.60 磁铁矿 0.72 透闪石 17.07 赤铁矿 22.99 石榴石 143.00 褐铁矿 28.00 黑云母 82.28 钛铁矿 464.70 金云母 12.86 氟碳铈矿类 0.61 绿泥石 9.59 独居石 0.37 斜长石 0.33 易解石 115.56 白云石 27.14 铌铁金红石 419.96 表 3 不同磨矿介质下方铅矿和黄铁矿浮选回收率

Table 3. Recovery rate of galena and pyrite n different igrinding medium

磨矿介质 方铅矿回收率/% 黄铁矿回收率/% 低碳钢球,充氧气 56 6 30%铬球,充氧气 72 9 30%铬球,充氮气 77 23 -

[1] Gu Y. Automated scanning electron microscope based mineral liberation analysis[J]. Journal of Minerals and Materials Characterization and Engineering, 2003, 2(1):33-41. doi: 10.4236/jmmce.2003.21003

[2] 贾木欣.国外工艺矿物学进展及发展趋势[J].矿冶, 2007, 16(2):95-99. http://industry.wanfangdata.com.cn/yj/Detail/Periodical?id=Periodical_ky200702025

[3] 高歌, 王艳.MLA自动检测技术在工艺矿物学研究中的应用[J].黄金, 2015(10):66-69. doi: 10.11792/hj201510015

[4] 彭明生, 刘晓文, 刘羽.工艺矿物学近十年的主要进展[J].矿物岩石地球化学通报, 2012, 31(3):210-217. http://www.cqvip.com/QK/84215X/201203/42308095.html

[5] Duncan M. Smythe, Annegret Lombard, LouisL. Coetzee. Rare earth element deportment studies utilising QEMSCAN technology[J]. Minerals Engineering, 2013, 52:52-61. doi: 10.1016/j.mineng.2013.03.010

[6] 庞建涛, 肖喆, 王灿霞, 等.MLA系统在磷块岩工艺矿物学研究中的应用[J].化工矿物与加工, 2015(10):19-21. http://www.cqvip.com/QK/92932X/201510/666449996.html

[7] 陈占华, 陈湘清, 李莎莎, 等.澳大利亚昆士兰州某铝土矿工艺矿物学研究[J].矿产综合利用, 2013(5):50-54. http://www.cnki.com.cn/Article/CJFDTOTAL-XKXB603.014.htm

[8] 方明山, 肖仪武, 童捷矢.山东某金矿中金的赋存状态研究[J].矿冶, 2012, 21(3):91-94. http://www.cqvip.com/QK/97765A/201203/43424457.html

[9] 方明山, 肖仪武, 童捷矢. 某金矿工艺矿物学研究[C]//矿山深部找矿理论与实践暨矿山工艺矿物学研究学术交流论文集. 北京: 冶金工业出版社, 2012: 341-347.

[10] Wei Terry Chen, Meifu Zhou, Xiaochun Li, et al. In-situ LA-ICP-MS trace elemental analyses of magnetite:Cu-(Au, Fe)deposits in the khetricopper belt in rajasthanprovince, NW India[J]. Ore Geology Reviews, 2015, 65:929-939. doi: 10.1016/j.oregeorev.2014.09.035

[11] 游俊富, 王虎, 赵海山.几种新型号二次离子质谱仪采用的新技术[J].现代仪器, 2005(1):39-41. https://www.wenkuxiazai.com/doc/45695868011ca300a6c3905e.html

[12] 余兴.激光剥蚀电感耦合等离子体质谱新进展[J].中国无机分析化学, 2012, 2(1):9-16. http://www.cqvip.com/QK/60072X/201201/41189347.html

[13] 章守成, 王文挺, 方德, 等.黄铁矿LA-ICP-MS原位测试与分析[J].现代矿业, 2016(9):195-198. http://www.cnki.com.cn/Article/CJFDTotal-KYKB201609063.htm

[14] 王岚, 杨理勤, 王亚平, 等.激光剥蚀电感耦合等离子体质谱微区分析进展评述[J].地质通报, 2012, 31(4):637. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=zgqydz201204020

[15] 沙克雷顿NJ.砷化铂和砷化钯的表面性质及其可浮性[J].国外金属矿选矿, 2008(5):19-27. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gwjskxk200805005

[16] 阿尔弗来德·贝宁豪文, 查良镇.飞行时间二次离子质谱-强有力的表面、界面和薄膜分析手段[J].真空, 2002(2):10-14. http://www.cnki.com.cn/Article/CJFDTOTAL-ZKZK200205002.htm

[17] 包泽民, 刘光达, 龙涛, 等.铜合金表面元素的飞行时间二次离子质谱微区原位分析[J].质谱学报, 2016, 37(3):229-235. doi: 10.7538/zpxb.2016.37.03.0229

[18] 皮安塔多西C.由飞行时间二次离子质谱法结果统计比较浮选精矿和尾矿中方铅矿和黄铁矿颗粒的疏水性和亲水性组分[J].国外金属矿选矿, 2002(10):37-43. http://kns.cnki.net/KCMS/detail/detail.aspx?filename=jsxk200210006&dbname=CJFD&dbcode=CJFQ

[19] 雷晓春, 林鹿, 李可成.XPS、AFM和TOF-SIMS的工作原理及在植物纤维表面分析中的应用[J].中国造纸学报, 2006, 21(4):97-101. https://www.wenkuxiazai.com/word/c3b35268ff00bed5b9f31ddf-1.doc

[20] Böttgera U, Pavlova SG, Deßmannb N, et al. Laser-induced alteration of ramanspectra for micron-sized solid particles[J].Planetary and Space Science, 2017, 138:25-32. doi: 10.1016/j.pss.2017.02.001

[21] Fornasiero D, Ralston J. Iron hydroxide complexes and their influence on the interaction between ethylxanthat and pyrite[J]. Colloid Interface Sci., 1992, 151:225-235. doi: 10.1016/0021-9797(92)90253-I

[22] Fornasiero D, Li F, Ralston J, et al. Oxidation of galena surfaces:Ⅰ. X-ray photoelectron spectroscopic and dissolution kinetics studies[J]. Colloid Interface Sci., 1994, 164:333-344. doi: 10.1006/jcis.1994.1175

[23] Fornasiero D, Li F, Ralston J, et al. Oxidation of galena:Ⅱ. electrokinetic study[J]. Colloid Interface Sci., 1994, 164:345-354. doi: 10.1006/jcis.1994.1176

[24] Yongjun Peng, Stephen Grano, Daniel Fornasiero, et al. Control of grinding conditions in the flotation ofgalena and its separation from pyrite[J]. Int. J. Miner. Process, 2003, 70:67-82. doi: 10.1016/S0301-7516(02)00153-9

[25] Carlo Philander, Abraham Rozendaal. The application of a novel geometallurgical template model tocharacterise the namakwasands heavy mineral deposit, west coast of South Africa[J]. Minerals Engineering, 2013, 52:82-94. doi: 10.1016/j.mineng.2013.04.011

[26] Philander C, Rozendaal A. A process mineralogy approach to geometallurgical model refinementfor the namakwasands heavy minerals operations, west coast of South Africa[J]. Minerals Engineering, 2014, 65:9-16. doi: 10.1016/j.mineng.2014.04.006

[27] Suazoa CJ, Kracht W, Alruiz OM. Geometallurgical modelling of the collahuasi-flotation circuit[J]. Minerals Engineering, 2010, 23:137-142. doi: 10.1016/j.mineng.2009.11.005

[28] Aparup Chattopadhyay, Stamen Dimov, Brian Hart, et al. Novel gold deportment technique-applications for complex copper-gold and refractory gold ores[C]. Quebec: XXVⅢ International Mineral Processing Congress, 2016.

[29] Lotter NO, Oliveira JF, Hannaford AL, et al. Flowsheet development for the kamoaproject-acase study[J]. Minerals Engineering, 2013, 52:8-20. doi: 10.1016/j.mineng.2013.02.014

[30] Dzvinamurungu T, Viljoen KS, Knoper MW. Geometallurgical characterisation of merenskyreef and UG2 at themarikanamine, bushveld complex, South Africa[J]. Minerals Engineering, 2013, 52:74-81. doi: 10.1016/j.mineng.2013.04.010

[31] Lotter NO, Kormos LJ, Oliveira J, et al. Modern process mineralogy:two case studies[J]. Minerals engineering, 2011, 24:638-650. doi: 10.1016/j.mineng.2011.02.017

[32] Baumgartner R, Dusci M, GressierJ, et al. Building a geometallurgical modelforearly-stage project development-A case study from the canahuire epithermal Au-Cu-Ag deposit, Southern Peru[J]. Proceedings 1st AUSIMM International Geometallurgical Conference, 2011:53-59.

[33] Gianni Schena, Luca Santoro, Stefano Favretto. Conceiving a high resolution and fast X-ray CT systemfor imaging fine multi-phase mineral particlesand retrieving mineral liberation spectra[J]. Miner. Process, 2007, 84:327-336. doi: 10.1016/j.minpro.2006.10.002

[34] Jan D. Miller, Chen Luh Lin, Lukasz Hupka, et al. Liberation-limited grade/recovery curves from X-ray micro CT analysis of feedmaterial for the evaluation of separation efficiency[J]. Miner. Process, 2009, 93:48-53. doi: 10.1016/j.minpro.2009.05.009

-

下载:

下载: