-

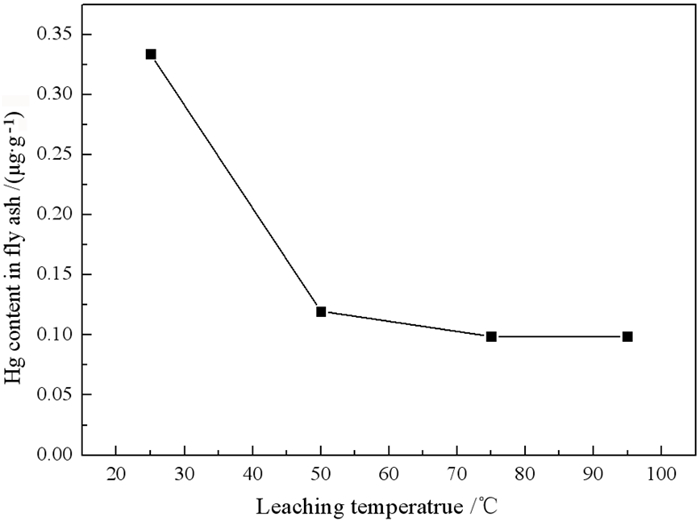

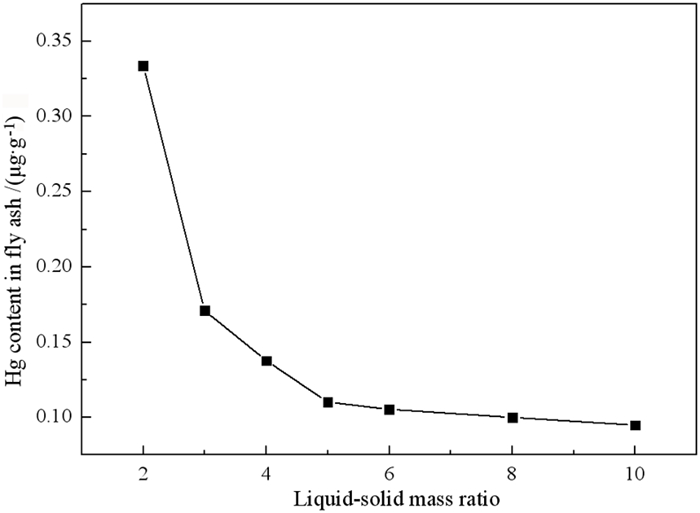

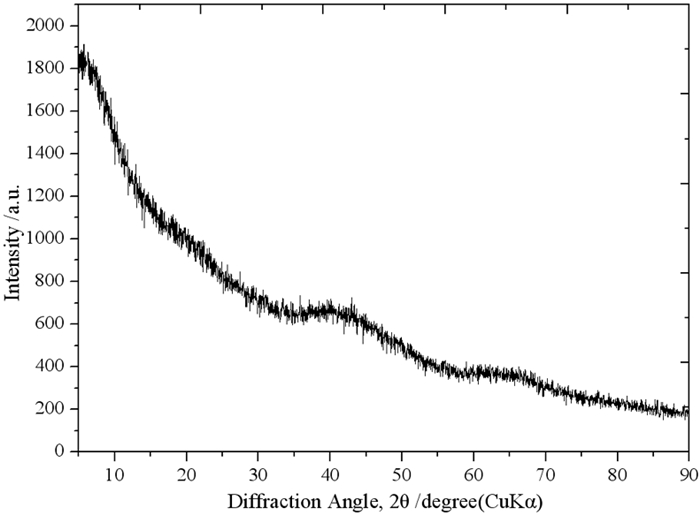

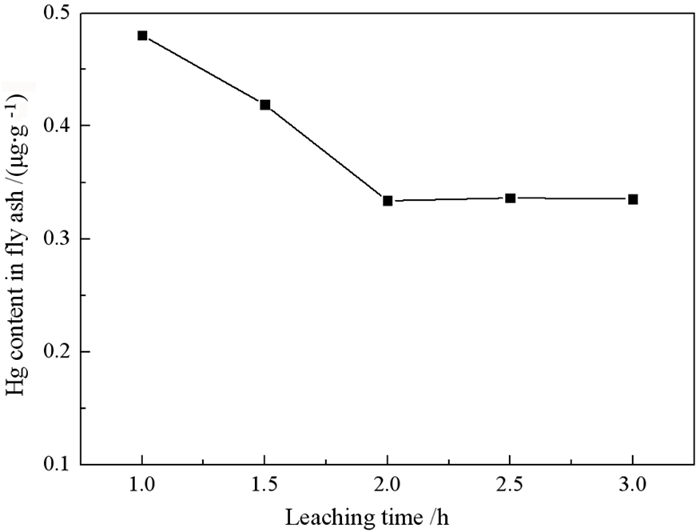

摘要: 粉煤灰中存在重金属汞,在环境中具有迁移的可能性,限制了粉煤灰在生态修复领域的利用。基于汞的赋存状态及其特性,提出了粉煤灰水浸脱汞新思路,采用单因素试验对脱汞新工艺进行了工艺条件的优化,并提出了原位合成水合氧化铝吸附剂的方法对脱汞废液进行净化。结果表明,在优化条件下,即温度为75℃、脱汞时间为2 h、液固比为5时,粉煤灰中汞的脱除率可达80%以上,汞含量可降至约0.1 μg/g,远低于土壤环境质量标准(GB 15618—2018)中土壤污染风险筛选值,大幅降低了粉煤灰生态利用的环境风险。原位合成的吸附剂对脱汞废液中汞的脱除率达到85%左右,净化液中汞的浓度降至2.267 μg/L,低于企业水污染物排放标准限值。Abstract: There is mercury in fly ash. The mercury in fly ash is easy to migrate in the environment, which limits the use of fly ash in the field of ecological restoration. Based on the occurrence states and characteristics of mercury, a new idea of removing mercury from fly ash by water leaching was proposed. Single factor experiments were used to optimize the process conditions of this new mercury removal process. And the method of in-situ synthesis of hydrated alumina adsorbent was proposed to purify the waste liquid of mercury removal. The results showed that under optimized process conditions, i.e. the temperature was 75 ℃, the mercury removal time was 2 h and the liquid-solid ratio was 5, the mercury removal rate can reach above 80% and the mercury content in fly ash can be reduced to about 0.1 μg/g. It was far below the risk screening value of soil pollution in GB 15618—2018, which greatly reduced the environmental risk of fly ash ecological utilization. The removal rate of mercury in waste liquid by the in-situ synthesized adsorbent reached about 85%. After purification, the concentration of mercury in the solution was reduced to 2.267 μg/L, which was lower than the limit value of enterprise water pollutant discharge standard.

-

Key words:

- fly ash /

- water leaching /

- mercury removal /

- adsorption

-

-

表 1 粉煤灰样品微波消解条件

Table 1. Conditions of fly ash microwave digestion

Serial number Power/W Temperature/℃ Heating time/min Hold time/min 1 700 150 10 5 2 700 180 5 5 3 700 210 5 20 表 2 净化前后废液中汞的含量及脱除率

Table 2. The content and removal rate of Hg in the original and purified wastewater

Item Mercury removal waste liquid/(μg·L-1) Purified liquid/(μg·L-1) Purification rate /% Hg 15.798 2.267 85.65 -

[1] 潘荔.第二届(2019)中国煤电固废生态治理与循环经济发展大会论文集[C].淮南: 中国循环经济协会粉煤灰专业委员会, 2019.

[2] 毕进红, 刘明华.粉煤灰资源综合利用[M].北京:化学工业出版社, 2017:38-139.

[3] 王亚玲, 王志鹏, 李述贤, 等.改性钢渣和粉煤灰对汞污染土壤稳定化修复影响[C]//2018中国环境科学学会科学技术年会论文集(第三卷).合肥: 中国环境科学学会, 2018.

[4] 刘振学, 周建芬.粉煤灰-硅肥料栽种花生研究报告[J].粉煤灰综合利用, 2005(2):12-13. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=fmhzhly200502005

[5] 武艳菊, 刘振学.减轻环境压力利用粉煤灰生产肥料[J].磷肥与复肥, 2005(2):58-59. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=lfyff200502021

[6] 关红飞, 张雷, 张瑞庆.粉煤灰在土壤改良和土地整治中的作用[J].农业工程, 2017, 7(5):86-89. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=nygch201705028

[7] 王晓钰.土壤环境重金属污染风险的综合评价模型[J].环境工程, 2013, 31(2):115-118. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=hjgc201302029

[8] Zhao S L, Duan Y F, Lu J C, et al. Chemical speciation and leaching characteristics of hazardous trace elements in coal and fly ash from coal-fired power plants[J]. Fuel, 2018, 232:463-469. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=36783100c10c1f52c3b1adc2fd3b56d2

[9] Li W H, Ma Z Y, Huang Q X, et al. Distribution and leaching characteristics of heavy metals in a hazardous waste incinerator[J]. Fuel, 2018, 233:427-441. http://cn.bing.com/academic/profile?id=1c7d51ae1729e18b4115b56827217dce&encoded=0&v=paper_preview&mkt=zh-cn

[10] Liu F L, Ma S H, Ren K, et al.Mineralogical phase separation and leaching characteristics of typical toxic elements in Chinese lignite fly ash[J]. Science of the Total Environment, 2020, http://doi:10.1016/j.scitotenv.2019.135095.

[11] 高正阳, 吕少昆, 陈嵩涛, 等.ESP对燃煤电站锅炉颗粒汞形态及热稳定性的影响[J].华北电力大学学报(自然科学版), 2015, 42(1):63-68. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=hbdldxxb201501011

[12] 任坤, 马淑花, 刘福立, 等.褐煤粉煤灰中汞的赋存状态[J].过程工程学报, 2020, 20(4):418-423. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=hgyj202004006

[13] 贾宇龙.铝溶胶的制备及结构性能[D].武汉: 武汉理工大学, 2012.

http://d.wanfangdata.com.cn/thesis/Y2099768 [14] 李晓云, 于海斌, 孙彦民, 等.活性氧化铝再水合制备拟薄水铝石的形态研究[J].电子显微学报, 2011, 30(6):517-520. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=dzxwxb201106007

[15] 顾景景, 安莹, 姚杰, 等.氢氧化铝吸附除磷性能及影响因素[J].净水技术, 2019, 38(12):93-98. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=jsjs201912017

-

| 引用本文: | 任坤, 金生祥, 张奇, 王六虎, 王晓辉, 张劲松, 马淑花. 粉煤灰中汞的水浸脱除研究[J]. 矿产保护与利用, 2020, 40(3): 85-89. doi: 10.13779/j.cnki.issn1001-0076.2020.03.014 |

| Citation: | Kun Ren, Shengxiang JIN, Qi ZHANG, Liuhu WANG, Xiaohui WANG, Jinsong ZHANG, Shuhua MA. Study on the Removal of Mercury from Fly Ash by Water Leaching[J]. Conservation and Utilization of Mineral Resources, 2020, 40(3): 85-89. doi: 10.13779/j.cnki.issn1001-0076.2020.03.014 |

- Figure 1. Changes of mercury content in fly ash with water leaching time

- Figure 2. Changes of mercury content in fly ash with water leaching temperature

- Figure 3. Changes of mercury content in fly ash with liquid-solid ratio

- Figure 4. X-ray diffraction analysis spectrum of the in-situ synthesized hydrated alumina

下载:

下载: