Preparation and Mechanical Properties of Non-burning Bricks with Coal Gangue as Main Raw Materials

-

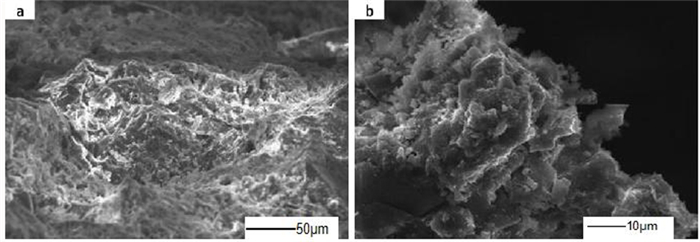

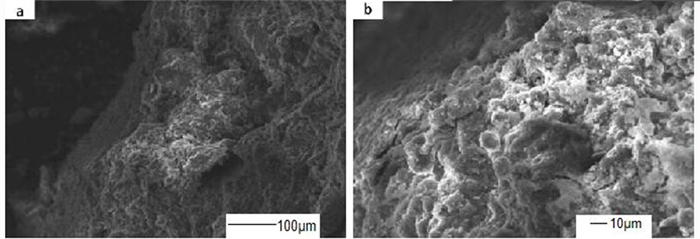

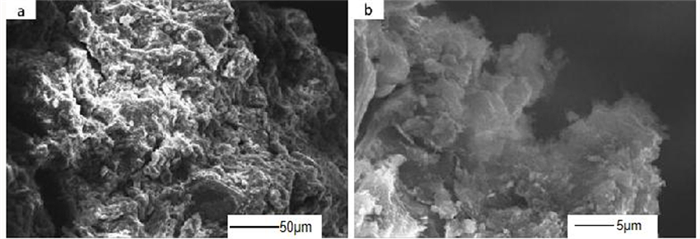

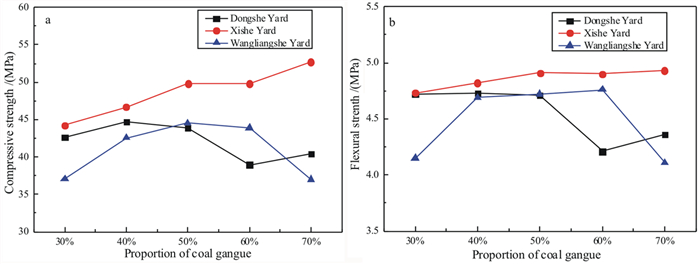

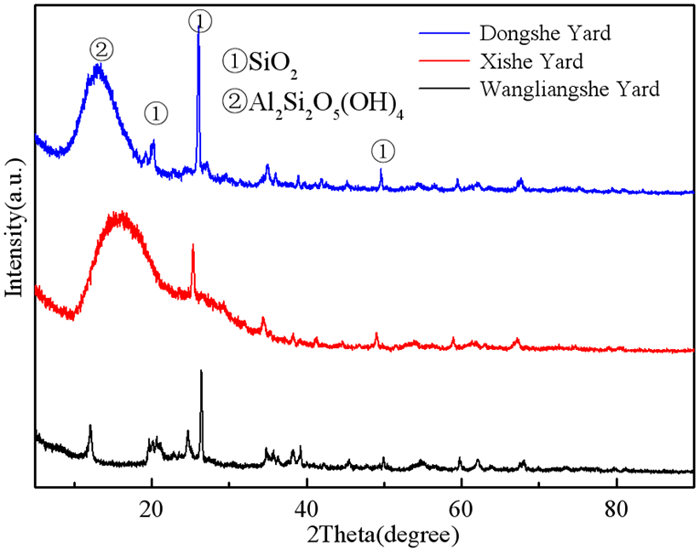

摘要: 为了有效地提高煤矸石资源化利用水平,针对抚顺矿区的煤矸石资源,在分析其化学成分和矿物组成基础上,采用煤矸石作为主要原料,辅以水泥、天然砂、粉煤灰及添加剂研究制备免烧砖。通过调整原料配比和成型压力,研究不同制备条件下免烧砖的微观结构特征和物理性能差异,如密度、含水率、抗压强度和抗折强度。通过正交试验获得优化原料质量配比和工艺参数分别为:东舍场煤矸石40%,天然砂42%;西舍场煤矸石70%,天然砂12%;汪良舍场煤矸石50%,天然砂32%;其它相同参数分别为粉煤灰5.14%、水泥12.86%、减水剂0.05%、水10%,成型压力20 MPa,常温养护28 d。获得的煤矸石基免烧砖性能符合JC/T 422—2007《非烧结垃圾尾砖》MU25标准要求,其中最高抗压强度和抗折强度分别为52.70 MPa和4.93 MPa。Abstract: In order to improve the utilization level of coal gangue resources, non-burning bricks had been prepared in this work with coal gangue in Fushun area as main raw materials and cement, natural sand, fly ash and additives as supplementary materials based on the analysis of chemical composition and mineral composition of coal gangue. The differences in microstructure characteristics and physical properties of non-burning bricks were investigated under different preparation conditions, such as density, moisture content, compressive strength and flexural strength. After the orthogonal experiment, an optimized raw material ratio and process parameters were obtained: coal gangue of Dongshe yard 40%, natural sand 42%; coal gangue of Xishe yard 70%, natural sand 12%; coal gangue of Wangliangshe yard 40%, natural sand 32%. The rest same parameters were as follows: fly ash 5.14% cement 12.86%, superplasticizer 0.05%, water 10%, molding pressure 20 MPa, curing at room temperature for 28 days. The obtained coal gangue-based bricks were in compliance with the MU15 standard of JC/T 422—2007 "non-burning waste tail bricks", wherein the highest compressive strength was 52.70 MPa and flexural strength was 4.93 MPa, respectively.

-

Key words:

- coal gangue /

- non-burning bricks /

- raw material ratio /

- molding pressure /

- compressive strength

-

-

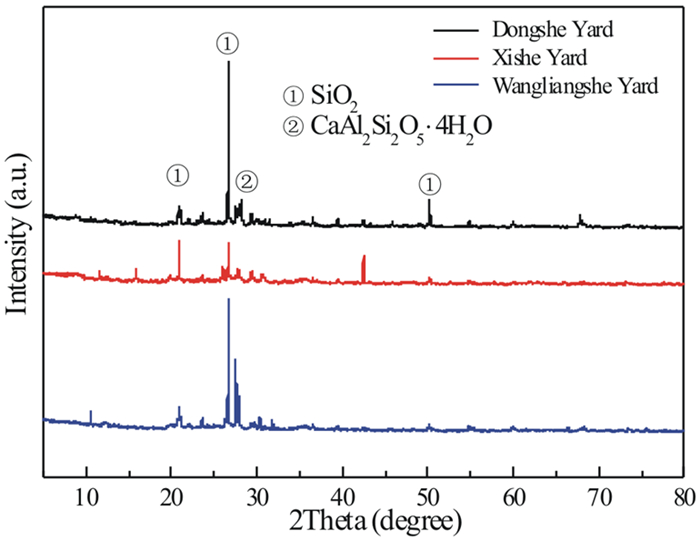

表 1 抚顺各舍场煤矸石化学成分

/% Table 1. Chemical composition of coal gangue from Fushun

Raw material Al2O3 SiO2 Fe2O3 Na2O TiO2 MgO CaO Dongshe Yard 18.41 43.88 6.18 0.01 0.89 1.88 1.01 Xishe Yard 15.98 43.76 7.62 2.00 0.78 3.70 3.48 Wangliangshe Yard 15.44 32.45 5.79 1.04 1.37 1.29 1.09 表 2 P.O42.5水泥化学成分组成

/% Table 2. Chemical composition of P.O42.5 cement

SiO2 Al2O3 CaO Fe2O3 SO3 MgO Loss on ignition 21.5 5.53 61.91 3.92 2.56 1.75 1.73 表 3 煤矸石基免烧砖原料配比

/% Table 3. Material ratio of non-burning brick

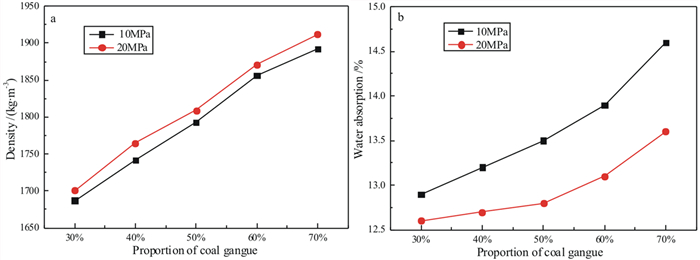

Sample Coal gangue Fly ash Nature sand Cement Water Admixture A 30 5.14 52 12.86 10 0.05 B 40 5.14 42 12.86 10 0.05 C 50 5.14 32 12.86 10 0.05 D 60 5.14 22 12.86 10 0.05 E 70 5.14 12 12.86 10 0.05 表 4 不同成型压力免烧砖样品密度

/(kg·m-3) Table 4. Sample density of non-burning bricks under different forming pressure

Content pressure 30% 40% 50% 60% 70% 10 MPa 1687 1742 1793 1856 1892 20 MPa 1701 1765 1809 1871 1912 表 5 不同成型压力免烧砖样品吸水率

/% Table 5. Absorption rate of non-burning brick samples under different forming pressure

Content pressure 30% 40% 50% 60% 70% 10 MPa 12.9 13.2 13.5 13.9 14.6 20 MPa 12.6 12.7 12.8 13.1 13.6 表 6 各组配方下免烧砖自然养护28 d后尺寸偏差

Table 6. Size deviation of non-burning bricks after natural curing for 28 days under different formulations

Sample Diameter/mm Thickness/mm Cracks A 0.73 0.43 No B 0.68 0.52 No C 0.71 0.48 No D 0.65 0.54 No E 0.74 0.45 No 表 7 不同含量煤矸石制备的免烧砖样品抗压强度

/MPa Table 7. Compressive strength of samples prepared from different materials

Content pressure 30% 40% 50% 60% 70% 10 MPa 30.81 32.16 34.80 33.57 35.67 20 MPa 37.07 42.56 44.51 43.88 37.01 表 8 不同舍场煤矸石制备的免烧砖样品抗压强度/MPa(成型压力为20 MPa)

Table 8. Compressive strength of samples prepared from different materials /MPa(molding pressure is 20 MPa)

Content sample 30% 40% 50% 60% 70% Dongshe Yard 42.63 44.73 43.84 38.97 40.42 Xishe Yard 44.24 46.67 49.80 49.81 52.70 Wangliangshe Yard 37.07 42.56 44.51 43.88 37.01 表 9 不同舍场煤矸石制备的免烧砖样品在抗折强度/MPa(成型压力为20 MPa)

Table 9. Flexural strength of samples prepared from different materials /MPa(molding pressure is 20 MPa)

Content sample 30% 40% 50% 60% 70% Dongshe Yard 4.72 4.73 4.71 4.21 4.36 Xishe Yard 4.73 4.82 4.91 4.90 4.93 Wangliangshe Yard 4.15 4.69 4.72 4.76 4.11 -

[1] 王长明, 邓军, 王进德.抚顺市煤矸石对生态环境的影响及综合利用[J].中国煤田地质, 2005, 17(1):12-15 http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=zgmtdz200501010

[2] 王晋麟.利用劣质煤矸石生产烧结砖的特点[J].砖瓦世界, 2019(6):6-9. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=jcgyxx201911003

[3] 王云, 潘云, 张军营.煤矸石烧结砖的热值利用与节能测算模型研究[J].山东科技大学学报:自然科学版, 2011(6):25-29. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=sdkjdxxb201106005

[4] 许红亮, 程维高, 武予宁, 等.煤矸石烧结砖厂废气凝结物的研究[J].环境工程, 2013(1):77-80. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=hjgc201301021

[5] Del Coz Diaz J. J., Garcia Nieto P.J., Betegon Biempica C, et al. Analysis and optimization of the heat-insulating light concrete hollow brick walls design by the finite element method[J]. Applied Thermal Engineering, 2008, 27(8-9):1445-1456. http://cn.bing.com/academic/profile?id=914afafda313fae12b7a4826a63664f4&encoded=0&v=paper_preview&mkt=zh-cn

[6] Oti J E, Kinuthia J M. Stabilised unfired clay bricks for environmental and sustainable use[J]. Applied Clay Science, 2012, 58:0-59. http://cn.bing.com/academic/profile?id=89358cadba29f0fafb0d63abb87b3ce7&encoded=0&v=paper_preview&mkt=zh-cn

[7] 王鹏涛.煤矸石综合利用的现状及存在的问题研究[J].科学技术创新, 2019(16):182-183. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=hljkjxx201916115

[8] 庄红峰.浅论煤矸石制砖[J].砖瓦世界, 2017(2):57-58. http://d.wanfangdata.com.cn/periodical/jcgyxx201702016

[9] 孙春宝, 董红娟, 张金山, 等.煤矸石资源化利用途径及进展[J].矿产综合利用, 2016(6):1-7. http://www.cnki.com.cn/Article/CJFDTotal-KCZL201606001.htm

[10] 刘莉君, 于伟, 王怡丹, 等.煤矸石制备烧结砖的方法和性能研究[J].煤炭技术, 2017(10):279-281. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=mtjs201710110

[11] 邓代强.中国西南地区煤矸石利用现状与展望[J].矿产保护与利用, 2019, 39(2):136-141. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=101ea103-40be-4449-98ad-7b62be8338d9

[12] 郭伟.煤矸石的活性激发及活性评价方法的探讨[D].南京: 南京工业大学, 2005.

http://cdmd.cnki.com.cn/Article/CDMD-10291-2007021469.htm [13] 闫书科.铸坯热送保温材料的研究使用[J].中华民居, 2012(7):832-833. http://d.wanfangdata.com.cn/periodical/zhmj201207648

[14] 程海, 陈昕.水泥体积安定性浅析[J].科教导刊(电子版), 2015(29):142-142. http://d.wanfangdata.com.cn/periodical/kjdkdz-zx201510114

[15] 胡普华, 张高展.高掺量粉煤灰轻质节能免烧砖的研制[J].硅酸盐通报, 2012(4):984-987. http://www.cnki.com.cn/Article/CJFDTotal-GSYT201204051.htm

[16] 丁星, 蒲心诚.水泥活性矿物掺料增强效应统计模型研究[J].硅酸盐学报, 1999(4):400-407. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=gsyxb199904003

-

下载:

下载: