Research Progress of Iron Recovery from Red Mud

-

摘要:

赤泥是铝土矿生产氧化铝过程中产生的强碱性固体废渣,目前的堆存处理不但存在环境隐患,且未能对其中富含的金属资源进行利用。本文在概述赤泥的主要性质及处置现状基础上,针对其中含量最高的铁资源的回收技术进行详细介绍,从物理分选法、火法冶金和湿法冶金三方面对国内外最新的赤泥提铁技术进行综述,并对不同提铁方法的工艺路线和技术参数等进行说明及比较,评述了各种方法的优缺点及适用范围,并对各种方法的发展方向进行了展望。

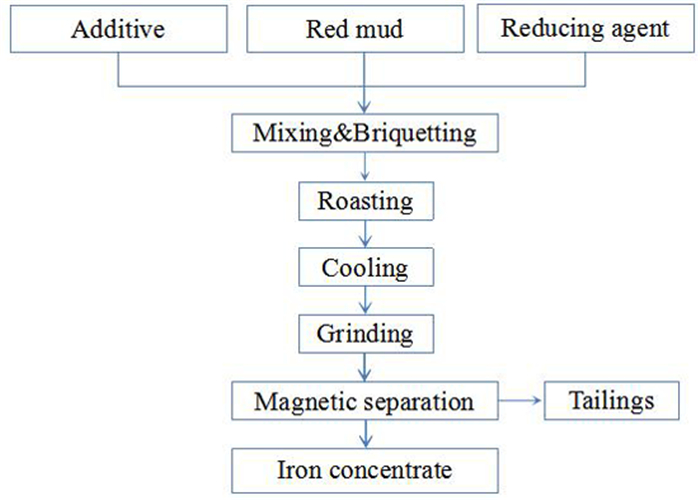

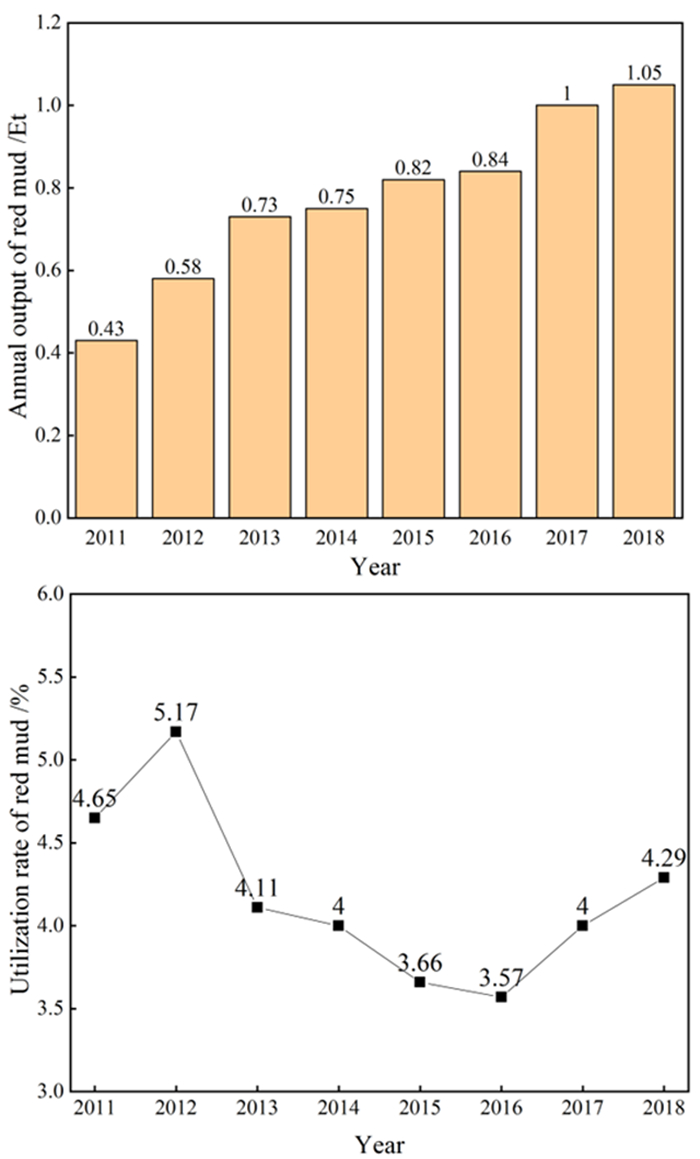

Abstract:Red mud is a strong alkaline solid waste produced in the process of alumina production from bauxite. At present there are not only environmental hazards in the stacking treatment, but also the failure to utilize the rich metal resources. On the basis of summarizing the main properties and disposal status of red mud, this paper introduces the recovery technology of iron resource with the highest content in red mud in detail. The latest iron extraction technology of red mud at home and abroad are summarizes from three aspects of physical separation, pyrometallurgy and hydrometallurgy. And and compares the process routes and technical parameters of different iron extraction methods are explains. The advantages, disadvantages and application scope of each method are reviewed, The development direction of each method is prospected.

-

Key words:

- red mud /

- iron concentrate /

- separation and recovery /

- magnetic separation /

- roasting /

- leaching

-

-

[1] 岳晶晶, 刘钟森, 程越迈, 等. 不同种植植物对赤泥盐离子迁移与分布的影响[J]. 矿产保护与利用, 2020, 40(3): 46-50. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=469c9825-6d92-4e92-afc8-55435ba92b9c

[2] 雷清源, 周康根, 何德文, 等. 赤泥中钪和钛的回收研究进展[J]. 矿产保护与利用, 2019, 39(3): 15-20. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=3b6acf78-e474-4117-8251-9502830cdeef

[3] ZHANG X, ZHOU K, CHEN W, et al. Recovery of iron and rare earth elements from red mud through an acid leaching-stepwise extraction approach[J]. Journal of Central South University, 2019, 26(2): 458-466. doi: 10.1007/s11771-019-4018-6

[4] 杨艳娟, 李建伟, 张茂亮, 等. 改性赤泥免烧砖的制备与放射性屏蔽机理分析[J]. 矿产保护与利用, 2019, 39(1): 95-99. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=969ed8fa-4b2b-439a-b459-97497b6df6cd

[5] 李彬, 王枝平, 曲凡, 等. 赤泥中有价金属的回收现状与展望[J]. 昆明理工大学学报(自然科学版), 2019, 44(2): 1-10. https://www.cnki.com.cn/Article/CJFDTOTAL-KMLG201902002.htm

[6] ZHANG X, ZHOU K, LEI Q, et al. Selective Removal of Iron from Acid Leachate of Red Mud by Aliquat 336[J]. JOM, 2019, 71(12): 4608-4615. doi: 10.1007/s11837-019-03801-4

[7] ARROYO F, LUNA-GALIANO Y, LEIVA C, et al. Environmental risks and mechanical evaluation of recycling red mud in bricks[J]. Environmental Research, 2020, 186: 109537. doi: 10.1016/j.envres.2020.109537

[8] IOANNIDI A, OULEGO P, COLLADO S, et al. Persulfate activation by modified red mud for the oxidation of antibiotic sulfamethoxazole in water[J]. Journal of Environmental Management, 2020, 270: 110820. doi: 10.1016/j.jenvman.2020.110820

[9] LI X, XIAO W, LIU W, et al. Recovery of alumina and ferric oxide from Bayer red mud rich in iron by reduction sintering[J]. Transactions of Nonferrous Metals Society of China, 2009, 19(5): 1342-1347. doi: 10.1016/S1003-6326(08)60447-1

[10] LIU X, GAO P, YUAN S, et al. Clean utilization of high-iron red mud by suspension magnetization roasting[J]. Minerals engineering, 2020, 157: 106553. doi: 10.1016/j.mineng.2020.106553

[11] LI G, LIU M, RAO M, et al. Stepwise extraction of valuable components from red mud based on reductive roasting with sodium salts[J]. Journal of Hazardous Materials, 2014, 280: 774-780. doi: 10.1016/j.jhazmat.2014.09.005

[12] 常军, 邵延海, 李硕, 等. 云南某赤泥还原焙烧-磁选试验研究[J]. 轻金属, 2017(8): 4-10. https://www.cnki.com.cn/Article/CJFDTOTAL-QJSS201708002.htm

[13] LEI Q, HE D, ZHOU K, et al. Separation and recovery of scandium and titanium from red mud leaching liquor through a neutralization precipitation-acid leaching approach[J]. Journal of Rare Earths, 2020. https://doi.org/10.1016/j.jre.2020.07.030 doi: 10.1016/j.jre.2020.07.030

[14] 顾汉念, 郭腾飞, 马时成, 等. 赤泥中铁的提取与回收利用研究进展[J]. 化工进展, 2018, 37(9): 3599-3608. https://www.cnki.com.cn/Article/CJFDTOTAL-HGJZ201809043.htm

[15] 齐川. 赤泥中有价金属提取的进展[J]. 轻金属, 2019(6): 6-10. https://www.cnki.com.cn/Article/CJFDTOTAL-QJSS201906003.htm

[16] 许金越. SLon脉动高梯度磁选技术在赤泥除铁的应用及理论研究[D]. 赣州: 江西理工大学, 2009.

[17] 廖国平, 钱枝花, 黄会春. SLon磁选机在氧化铝产业链中的应用[J]. 现代矿业, 2010, 26(8): 118-119. doi: 10.3969/j.issn.1674-6082.2010.08.039

[18] 李彬, 张宝华, 宁平, 等. 赤泥资源化利用和安全处理现状与展望[J]. 化工进展, 2018, 37(2): 714-723. https://www.cnki.com.cn/Article/CJFDTOTAL-HGJZ201802040.htm

[19] 武国娟. 赤泥中铁磁选回收方法的研究[J]. 科学与财富, 2019(27): 282.

[20] 周凯. 低温拜耳法赤泥磁选提铁试验研究[J]. 现代矿业, 2011, 27(1): 36-38. doi: 10.3969/j.issn.1674-6082.2011.01.008

[21] 徐淑安, 邵延海, 熊述清, 等. 疏水团聚-磁种法回收赤泥中微细粒铁矿试验[J]. 矿产综合利用, 2015(6): 62-66. doi: 10.3969/j.issn.1000-6532.2015.06.016

[22] 吕玉辰. 克钦邦铁锡矿选矿试验研究[D]. 昆明: 昆明理工大学, 2019.

[23] 顾汉念, 王宁, 刘世荣, 等. 烧结法赤泥的物质组成与颗粒特征研究[J]. 岩矿测试, 2012, 31(2): 312-317. doi: 10.3969/j.issn.0254-5357.2012.02.022

[24] 刘培坤, 姜兰越, 杨兴华, 等. 全重选法赤泥选铁富集性能试验研究[J]. 轻金属, 2017(6): 22-27. https://www.cnki.com.cn/Article/CJFDTOTAL-QJSS201706006.htm

[25] 张谌虎, 石开仪, 陈鹏, 等. 回收某赤泥中铁的选矿试验研究[J]. 矿业研究与开发, 2020, 40(7): 156-159. https://www.cnki.com.cn/Article/CJFDTOTAL-KYYK202007031.htm

[26] LI X, ZHOU Z, WANG Y, et al. Enrichment and separation of iron minerals in gibbsitic bauxite residue based on reductive Bayer digestion[J]. Transactions of Nonferrous Metals Society of China, 2020, 30(7): 1980-1990. doi: 10.1016/S1003-6326(20)65355-9

[27] 杜金明, 蔡冰冰, 胡波, 等. 分级重选—磁选—反浮选联合工艺处理某高泥赤铁矿[J]. 湖南有色金属, 2021, 37(1): 16-20. doi: 10.3969/j.issn.1003-5540.2021.01.005

[28] 陆扬. 一种从氧化铝赤泥中回收铁精矿和矿砂的工艺: 111589572A[P]. 2020.08.28.

[29] WEI D, JUN HUI X, YANG P, et al. Iron extraction from red mud using roasting with sodium salt[J]. Mineral processing and extractive metallurgy review, 2021, 42(3): 153-161. doi: 10.1080/08827508.2019.1706049

[30] LIU Y, ZUO K, YANG G, et al. Recovery of ferric oxide from bayer red mud by reduction roasting-magnetic separation process[J]. Journal of Wuhan University of Technology-Mater. Sci. Ed, 2016, 31(2): 404-407. doi: 10.1007/s11595-016-1383-y

[31] VALEEV D, ZINOVEEV D, KONDRATIEV A, et al. Reductive smelting of neutralized red mud for iron recovery and produced pig iron for heat-resistant castings[J]. Metals, 2020, 10(1): 32. http://www.researchgate.net/publication/338140043_Reductive_Smelting_of_Neutralized_Red_Mud_for_Iron_Recovery_and_Produced_Pig_Iron_for_Heat-Resistant_Castings

[32] SAMOUHOS M, TAXIARCHOU M, PILATOS G, et al. Controlled reduction of red mud by H2 followed by magnetic separation[J]. Minerals Engineering, 2017, 105: 36-43. doi: 10.1016/j.mineng.2017.01.004

[33] JIN J, LIU X, YUAN S, et al. Innovative utilization of red mud through co-roasting with coal gangue for separation of iron and aluminum minerals[J]. Journal of Industrial and Engineering Chemistry, 2021, 98: 298-307. doi: 10.1016/j.jiec.2021.03.038

[34] LONG Q, LI J, CHEN C, et al. Optimization of iron and aluminum recovery in bauxite[J]. Journal of Iron and Steel Research International, 2020, 27(3): 310-318. doi: 10.1007/s42243-019-00360-5

[35] 李恒, 刘晓明, 赵喜彬, 等. 生物质松木锯末中低温还原高铁拜耳法赤泥[J]. 工程科学学报, 2017, 39(9): 1331-1338. https://www.cnki.com.cn/Article/CJFDTOTAL-BJKD201709005.htm

[36] LIU Y, ZHAO B, TANG Y, et al. Recycling of iron from red mud by magnetic separation after co-roasting with pyrite[J]. Thermochimica Acta, 2014, 588: 11-15. doi: 10.1016/j.tca.2014.04.027

[37] LI X, XIAO W, LIU W, et al. Recovery of alumina and ferric oxide from Bayer red mud rich in iron by reduction sintering[J]. Transactions of Nonferrous Metals Society of China, 2009, 19(5): 1342-1347. doi: 10.1016/S1003-6326(08)60447-1

[38] LIU X, GAO P, YUAN S, et al. Clean utilization of high-iron red mud by suspension magnetization roasting[J]. Minerals Engineering, 2020, 157: 106553. doi: 10.1016/j.mineng.2020.106553

[39] GRUDINSKY P, ZINOVEEV D, PANKRATOV D, et al. Influence of Sodium Sulfate Addition on Iron Grain Growth during Carbothermic Roasting of Red Mud Samples with Different Basicity[J]. Metals, 2020, 10(12): 1571. doi: 10.3390/met10121571

[40] 杨帆, 张涛, 谢刚, 等. 不同添加剂对某铝土矿拜耳法溶出性能的研究[J]. 有色金属工程, 2018, 8(6): 51-55. doi: 10.3969/j.issn.2095-1744.2018.06.011

[41] CHUN T. Recovery of iron from red mud by high-temperature reduction of carbon-bearing briquettes[J]. Journal of the Southern African Institute of Mining and Metallurgy, 2017, 117(4): 361-364. doi: 10.17159/2411-9717/2017/v117n4a7

[42] LONG H, CHUN T, DI Z, et al. Preparation of metallic iron powder from pyrite cinder by carbothermic reduction and magnetic separation[J]. Metals, 2016, 6(4): 88. doi: 10.3390/met6040088

[43] 张洋洋, 吴雪兰, 陈意帆, 等. 某铁精矿浮选脱硫探究试验[J]. 科技视界, 2020(28): 115-118. https://www.cnki.com.cn/Article/CJFDTOTAL-KJSJ202028048.htm

[44] WANG K, LIU Y, ZHANG T, et al. Investigation of the smelting reduction mechanism and of iron extraction from high-iron red mud[J]. Materials Research Express, 2020, 7(12): 126514 (11pp). . doi: 10.1088/2053-1591/abd137

[45] 范艳青, 朱坤娥, 蒋训雄. 赤泥中铁资源的回收利用研究[J]. 有色金属(冶炼部分), 2019(9): 72-76. doi: 10.3969/j.issn.1007-7545.2019.09.013

[46] VALEEV D, ZINOVEEV D, KONDRATIEV A, et al. Reductive smelting of neutralized red mud for Iron recovery and produced pig Iron for heat-resistant castings[J]. Metals, 2020, 10(1): 32. http://www.researchgate.net/publication/338140043_Reductive_Smelting_of_Neutralized_Red_Mud_for_Iron_Recovery_and_Produced_Pig_Iron_for_Heat-Resistant_Castings

[47] PEPPER R A, COUPERTHWAITE S J, MILLAR G J. Comprehensive examination of acid leaching behaviour of mineral phases from red mud: Recovery of Fe, Al, Ti, and Si[J]. Minerals Engineering, 2016, 99: 8-18. doi: 10.1016/j.mineng.2016.09.012

[48] ZHANG X, ZHOU K, LEI Q, et al. Stripping of Fe(Ⅲ) from Aliquat 336 by NaH2PO4: implication for rare-earth elements recovery from red mud[J]. Separation science and technology, 2021, 56(2): 301-309. doi: 10.1080/01496395.2020.1713814

[49] ZHANG X, ZHOU K, WU Y, et al. Separation and recovery of iron and scandium from acid leaching solution of red mud using D201 resin[J]. Journal of Rare Earths, 2020, 38(12): 1322-1329. doi: 10.1016/j.jre.2019.12.005

[50] 薛真, 薛彦辉, 王力. 拜耳法赤泥中铝铁的盐酸浸出过程研究[J]. 矿产综合利用, 2018(6): 139-143. doi: 10.3969/j.issn.1000-6532.2018.06.029

[51] 宁凌峰, 何德文, 陈伟, 等. 赤泥中硫酸选择性浸出铁、钪及动力学研究[J]. 矿冶工程, 2019, 39(3): 81-84. doi: 10.3969/j.issn.0253-6099.2019.03.020

[52] YANG Y, WANG X, WANG M, et al. Recovery of iron from red mud by selective leach with oxalic acid[J]. Hydrometallurgy, 2015, 157: 239-245. doi: 10.1016/j.hydromet.2015.08.021

[53] ZHU X, NIU Z, LI W, et al. A novel process for recovery of aluminum, iron, vanadium, scandium, titanium and silicon from red mud[J]. Journal of Environmental Chemical Engineering, 2020, 8(2): 103528. doi: 10.1016/j.jece.2019.103528

-

下载:

下载: