Research Progress on Resource Utilization of Phosphorus Tailings, Phosphogypsum and Yellow Phosphorous Slag by Geological Polymerization

-

摘要:

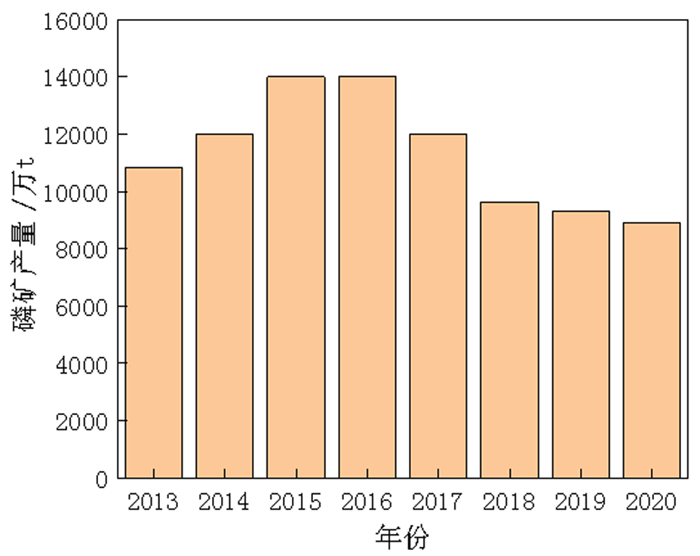

随着磷矿开采量的增大,磷矿固废的库存量也逐年增加,对自然环境造成了严重的危害。概述了磷尾矿、磷石膏和黄磷渣固废资源的利用现状,以及碱激发地质聚合反应机理,对比了碱激发地质聚合物混凝土和普通硅酸盐水泥混凝土,阐述了通过碱激发地质聚合反应资源化综合利用磷尾矿、磷石膏和黄磷渣的现状。

Abstract:With the increase of phosphate rock mining, the inventory of phosphate rock solid waste is also increasing year by year, which has caused serious harm to the natural environment. This paper summarizes the utilization status of phosphorus tailings, phosphogypsum and yellow phosphorus slag solid waste resources and the mechanism of alkali stimulated geological polymerization, compares alkali stimulated geological polymer concrete and ordinary portland cement concrete, and expounds the current situation of resource comprehensive utilization of phosphorus tailings, phosphogypsum and yellow phosphorus slag through alkali stimulated geological polymerization.

-

-

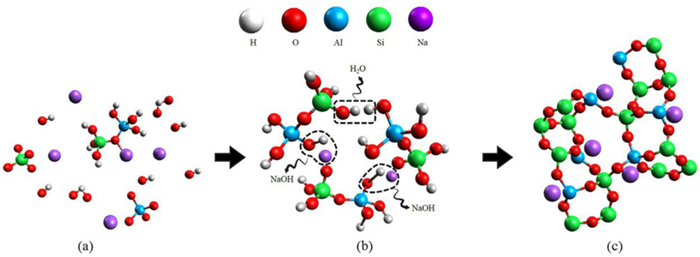

图 2 地质聚合反应示意图: (a)硅铝酸盐重组;(b)低聚物缩合形成凝胶;(c)聚合[14]

Figure 2.

表 1 磷石膏的杂质种类、存在形式及危害[9]

Table 1. Types, existing forms and hazards of impurities in phosphogypsum[9]

杂质种类 存在形式 危害 磷类 H3PO4、H2PO4-、HPO42-、共晶磷(CaHPO4·H2O)、磷酸络合物、未分解的磷灰石 水化预处理时,阻碍磷石膏水化,导致产品结构疏松,强度降低 氟类 F-、CaF2、SiF62-、NaAlF6、CaSiF6 可溶氟有促凝作用,当其质量分数超过0.3%时,会导致水化产物晶体粗化,结构疏松,强度减小 有机物类 固有的有机物、加入的有机添加剂(乙二醇甲醚乙酸酯、3-甲氧基正戊烷等) 加大磷石膏作为建材用途时的需水量,导致制品结构疏松,强度降低 其它 Na+、K+、硅、金属与磷酸盐形成的络合物、放射性元素(砷、氡、钍、汞、铅等) 钠、钾类碱金属盐使干燥后的石膏制品表面析晶;放射性元素对环境破坏大 -

[1] 刘志强, 郝梓国, 刘恋, 等. 我国尾矿综合利用研究现状及建议[J]. 地质论评, 2016(5): 1277-1282. https://www.cnki.com.cn/Article/CJFDTOTAL-DZLP201605016.htm

[2] 周亚敏. 以碳达峰与碳中和目标促我国产业链转型升级[J]. 中国发展观察, 2021(Z1): 56-58. https://www.cnki.com.cn/Article/CJFDTOTAL-FZGC2021Z1018.htm

[3] RAO F, LIU Q. Geopolymerization and Its Potential Application in Mine Tailings Consolidation: A Review[J]. Mineral Processing and Extractive Metallurgy Review, 2015, 36(6): 399-409. doi: 10.1080/08827508.2015.1055625

[4] YHM AMRAN, R ALYOUSEF, H ALABDULJABBAR, et al. Clean production and properties of geopolymer concrete: A review[J]. Journal of Cleaner Production, 2020, 251: 119679. doi: 10.1016/j.jclepro.2019.119679

[5] 李鹏毅, 张冬冬, 宁平, 等. 磷尾矿资源化利用研究[J]. 化工矿物与加工, 2019, 48(2): 66-70. https://www.cnki.com.cn/Article/CJFDTOTAL-HGKJ201902017.htm

[6] 张汉泉, 周峰, 许鑫, 等. 中国磷矿开发利用现状[J]. 武汉工程大学学报, 2020, 42(2): 159-164. https://www.cnki.com.cn/Article/CJFDTOTAL-WHHG202002008.htm

[7] 周倩倩, 周克清. 磷尾矿资源综合利用现状研究[J]. 化工矿物与加工, 2018, 47(9): 67-70. https://www.cnki.com.cn/Article/CJFDTOTAL-HGKJ201809017.htm

[8] 尹丽文. 中国磷矿资源分布及开发建议[J]. 资源与人居环境, 2009(10): 26-27. doi: 10.3969/j.issn.1672-822X.2009.10.012

[9] 朱志伟, 何东升, 陈飞, 等. 磷石膏预处理与综合利用研究进展[J]. 矿产保护与利用, 2019, 39(4): 19-25. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=3ed412be-d770-41ea-ba55-8534c228c014

[10] 张汉泉, 许鑫, 胡超杰, 等. 磷化工固体废弃物综合利用技术现状[J]. 中国矿业, 2021, 30(4): 50-55+63. doi: 10.3969/j.issn.1009-105x.2021.04.005

[11] K GNANDI, MHR BOROON, P EDORH. The geochemical characterization of mine effluents from the phosphorite processing plant of kpémé (southern togo)[J]. Mine Water and the Environment, 2009, 28(1): 65-73. doi: 10.1007/s10230-008-0058-0

[12] Zhang Z, Provis JL, Reid A, et al. Geopolymer foam concrete: An emerging material for sustainable construction[J]. Construction and Building Materials, 2014, 56(5): 113-127. http://www.onacademic.com/detail/journal_1000036073054810_8118.html

[13] A GHARZOUNI, E JOUSSEIN, B SAMET, et al. Effect of the reactivity of alkaline solution and metakaolin on geopolymer formation[J]. Journal of Non-Crystalline Solids, 2015, 410(5): 127-134. http://www.sciencedirect.com/science/article/pii/S0022309314006619

[14] SINGH NB, MIDDENDORF B. Geopolymers as an alternative to Portland cement: An overview[J]. Construction and Building Materials, 2020, 237(5): 117455. http://www.sciencedirect.com/science/article/pii/S0950061819329071

[15] DUAN P, YAN C, ZHOU W, et al. An investigation of the microstructure and durability of a fluidized bed fly ash–metakaolin geopolymer after heat and acid exposure[J]. Materials & Design, 2015, 74(6): 125-137. http://www.sciencedirect.com/science?_ob=ShoppingCartURL&_method=add&_eid=1-s2.0-S0261306915000928&originContentFamily=serial&_origin=article&_ts=1483808926&md5=986a21de1dfb7c1600ec23743d444982

[16] WAN Q, RAO F, SONG S, et al. Chemical forms of lead immobilization in alkali-activated binders based on mine tailings[J]. Cement and Concrete Composites, 2018, 92: 198-204. doi: 10.1016/j.cemconcomp.2018.06.011

[17] ATIŞ CD, GÖRVR EB, KARAHAN O, et al. Very high strength (120MPa) class F fly ash geopolymer mortar activated at different NaOH amount, heat curing temperature and heat curing duration[J]. Construction and Building Materials, 2015, 96(5): 673-678. http://www.sciencedirect.com/science/article/pii/S0950061815303020

[18] RASHAD AM. Insulating and fire-resistant behaviour of metakaolin and fly ash geopolymer mortars[J]. Construction Materials, 2019, 172(1): 34-77. http://www.onacademic.com/detail/journal_1000039956319810_ba99.html

[19] 李夕兵, 刘冰. 硬岩矿山充填开采现状评述与探索[J]. 黄金科学技术, 2018, 26(4): 492-502. https://www.cnki.com.cn/Article/CJFDTOTAL-HJKJ201804016.htm

[20] 刘建功, 王翰秋, 赵家巍. 煤矿固体充填采煤技术发展回顾与展望[J]. 煤炭科学技术, 2020, 48(9): 27-38. https://www.cnki.com.cn/Article/CJFDTOTAL-MTKJ202009003.htm

[21] EDRAKI M, BAUMGARTL T, MANLAPIG E, et al. Designing mine tailings for better environmental, social and economic outcomes: a review of alternative approaches. Journal of Cleaner Production, 2014, 84: 411-420. doi: 10.1016/j.jclepro.2014.04.079

[22] 吴洁, 饶峰, 印万忠. 通过地质聚合反应共同固结磷矿浮选尾矿与炉渣[J]. 金属矿山, 2020(8): 216-220. https://www.cnki.com.cn/Article/CJFDTOTAL-JSKS202008036.htm

[23] 刘冬梅, 刘玉娇, 彭艳周, 等. 固硫灰基磷尾矿充填体的性能及浸出液水质[J]. 非金属矿, 2020, 43(4): 11-15. doi: 10.3969/j.issn.1000-8098.2020.04.004

[24] SHI Y, CHENG L, TAO M, et al. Using modified quartz sand for phosphate pollution control in cemented phosphogypsum (PG) backfill[J]. Journal of Cleaner Production, 2020, 283(3): 124652. http://www.sciencedirect.com/science/article/pii/S0959652620346965

[25] LI M, CHEN Z. Strength Properties of Phosphogypsum Based Composite Filling Materials[C]. In Chinese Materials Conference. Springer, Singapore, 2017.

[26] ZHANG S, ZHAO Y, DING H, ET AL. Recycling flue gas desulfurisation gypsum and phosphogypsum for cemented paste backfill and its acid resistance[J]. Construction and Building Materials, 2021, 275(5): 122170. http://www.sciencedirect.com/science/article/pii/S0950061820341738

[27] XUE X, KE Y, KANG Q, et al. Cost-effective treatment of hemihydrate phosphogypsum and phosphorous slag as cemented paste backfill material for underground mine[J]. Advances in Materials Science and Engineering, 2019, 2019: 1-11. http://www.researchgate.net/publication/330843951_Cost-Effective_Treatment_of_Hemihydrate_Phosphogypsum_and_Phosphorous_Slag_as_Cemented_Paste_Backfill_Material_for_Underground_Mine

[28] CHEN Q, ZHANG Q, FOURIE A, et al. Utilization of phosphogypsum and phosphate tailings for cemented paste backfill[J]. Journal of Environmental Management, 2017, 201(5): 19-27. http://www.onacademic.com/detail/journal_1000040002576110_ec92.html

[29] JIANG G, WU A, WANG Y, et al. Low cost and high efficiency utilization of hemihydrate phosphogypsum: Used as binder to prepare filling material[J]. Construction and Building Materials, 2018, 167: 263-270. doi: 10.1016/j.conbuildmat.2018.02.022

[30] ZHOU S, LI X, ZHOU Y, et al. Effect of phosphorus on the properties of phosphogypsum-based cemented backfill[J]. Journal of hazardous materials, 2020, 399(5): 122993. http://www.sciencedirect.com/science/article/pii/S0304389420309821

[31] LI X, ZHOU S, ZHOU Y, et al. Durability Evaluation of Phosphogypsum-Based Cemented Backfill Through Drying-Wetting Cycles[J]. Minerals, 2019, 9(5): 321. doi: 10.3390/min9050321

[32] ZHENG K, ZHOU J, GBOZEE M. Influences of phosphate tailings on hydration and properties of Portland cement[J]. Construction and Building Materials, 2015, 98(5): 593-601. http://www.lsuic.com/wp-content/uploads/2016/03/Phosphate-Taillings.pdf

[33] 李家劲, 向兴, 尹亚, 等. 以磷尾矿作为填料制备泡沫混凝土的研究[J]. 混凝土, 2016(12): 151-153. doi: 10.3969/j.issn.1002-3550.2016.12.039

[34] 赵士豪, 王桂明, 孙涛, 等. 过硫磷石膏水泥砌筑用免烧砖的制备及养护制度研究[J]. 建材世界, 2017, 38(2): 18-21. https://www.cnki.com.cn/Article/CJFDTOTAL-GWJK201702005.htm

[35] 郭小雨, 樊传刚, 裴立宅, 等. 磷石膏免烧砖的性能及其重金属离子固定研究[J]. 新型建筑材料, 2020, 47(10): 127-131+152. doi: 10.3969/j.issn.1001-702X.2020.10.030

[36] ALLAHVERDI A, PILEHVAR S, MAHINROOSTA M. Influence of curing conditions on the mechanical and physical properties of chemically-activated phosphorous slag cement[J]. Powder Technology, 2016, 288: 132-139. doi: 10.1016/j.powtec.2015.10.053

[37] 张敏, 马倩敏, 郭荣鑫, 等. 磷渣-水泥复合及碱磷渣胶凝材料力学性能试验研究[J]. 硅酸盐通报, 2020, 281(2): 46-52+71. https://www.cnki.com.cn/Article/CJFDTOTAL-GSYT202002006.htm

[38] YANG R, YU R, SHUI Z, et al. Low carbon design of an Ultra-High Performance Concrete (UHPC) incorporating phosphorous slag[J]. Journal of Cleaner Production, 2019, 240: 118157. doi: 10.1016/j.jclepro.2019.118157

[39] WANG L, GUO F, LIN Y, et al. Comparison between the effects of phosphorous slag and fly ash on the C-S-H structure, long-term hydration heat and volume deformation of cement-based materials[J]. Construction and Building Materials, 2020, 250(5): 118807.

[40] 刘方华. 碱激发磷矿渣复合胶凝材料的水化特性[J]. 建筑材料学报, 2020, 23(5): 1038-1045. doi: 10.3969/j.issn.1007-9629.2020.05.007

[41] MAGHSOODLOORAD H, HAMIDREZA K, ALI A. Alkali-activated phosphorous slag performance under different curing conditions: Compressive strength, hydration products, and microstructure[J]. Journal of Materials in Civil Engineering, 2018, 30(1): 04017253. doi: 10.1061/(ASCE)MT.1943-5533.0002101

[42] 张建辉, 赵嘉鑫, 陈继才, 等. 碱激发磷渣基胶凝材料的性能及微观结构分析[J]. 硅酸盐通报, 2019, 276(9): 297-303. https://www.cnki.com.cn/Article/CJFDTOTAL-GSYT201909045.htm

[43] 廖国燕, 李夕兵, 赵国彦. 黄磷渣充填胶凝材料激发剂的选择与优化[J]. 金属矿山, 2010(3): 17-19+99. https://www.cnki.com.cn/Article/CJFDTOTAL-JSKS201003006.htm

-

下载:

下载: