A Review of Lithium Extraction from Lepidolite and Current Research Development of Fluorine Removal

-

摘要:

锂云母是我国重要的锂矿资源, 开发高效的提锂工艺对于保障锂行业可持续发展具有重要的研究意义。氟具有极强的电负性, 可以取代表界面羟基, 从而进入锂云母晶格, 在锂云母中含量可达5%~10%, 如何实现提锂过程中氟的深度脱除对于锂云母的清洁、高效提取具有重要意义。通过对典型的硫酸法、石灰石法、硫酸盐法、氯化焙烧法、压煮法和氟化学法等锂云母提锂工艺研究现状进行阐述, 充分探讨各主流提锂工艺的反应原理、工艺条件等, 客观分析总结工艺的优缺点, 并对目前脱氟技术的研究现状进行分析, 总结现有脱氟工艺的反应机理及脱氟装置改进方向。最后, 对锂云母整体提锂工艺的深度脱氟, 凝练出液相氟脱除的新思路, 旨在为锂云母清洁、高效提取提供重要的理论基础。

Abstract:Lepidolite is an important lithium resource in China. The development of efficient lithium extraction process is of great significance to ensuring the sustainable development of lithium industry. Due to the strong electronegativity of fluorine(F), about 5%~10% of F attacks the lepdolite lattice by taking interfacial hydroxyl groups. It is critical for the clean and effective utilisation lepidolite to accomplish the deep removal of fluorine during the lithium extraction process. Firstly, the typical methods to extract lithium from lepidolite were discussed such as sulfuric acid and limestone, sulfate, chloride roasting, pressure autoclave method and the fluorine chemical method. The reaction principle and technological conditions including the advantages and disadvantages of different methods were systematically discussed. Moreover, the current research development of defluorination was summarized such as the reaction mechanism and development of defluorination device. Finally, the deep fluorine removal, especially for fluorine in lithium containing liquid phase, was proposed as a new research direction, aiming at providing an important theoretical basis for clean and efficient lithium extraction of lepidolite.

-

Key words:

- lepidolite /

- roasting /

- fluorine removal /

- lithium extraction /

- comprehensive utilization

-

-

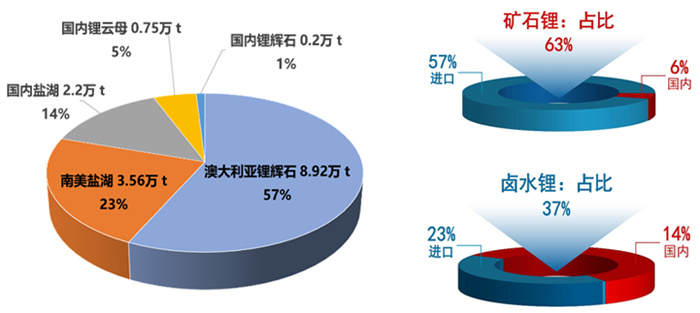

图 1 我国近年锂资源供应结构[3]

Figure 1.

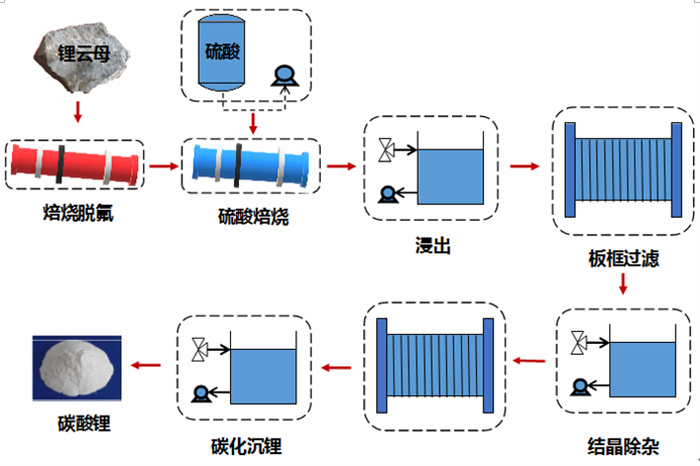

图 2 硫酸法工艺流程示意图[20]

Figure 2.

图 3 硫酸盐法工艺流程[58]

Figure 3.

图 4 氟化学法反应机理示意图[50]

Figure 4.

图 5 不同温度下LiF与水蒸气反应平衡组成[57]

Figure 5.

矿物种类 化学式 晶体结构 矿物的化学成分/% Li2O Na2O K2O SiO2 F FeO Al2O3 锂辉石 LiAl(SiO3)2 链状 8.03 0.55 0.48 63.6 _ _ 28.7 透锂长石 LiAlSi4O10 架片状 4.73 0.17 0.02 77.7 _ _ 17.1 锂云母 K(Li, Al)3(Al, Si, Rb)4O10(F, OH)2 层状 4.19 0.56 8.55 52.3 5.9 _ 28.8 锂霞石 KLiFeAl(AlSi3) O10(F, OH)2 粒、块状 2-5 0.19 10.1 42.8 6.1 11 21.7 锂磷铝石 LiAl(F, OH)PO4 短柱状 7.40 5.12 _ _ 9.4 _ 33.6 表 2 锂云母主流提锂工艺现状及优缺点

Table 2. Advantages and disadvantages of the current lithium extraction methods from lepidolite

工艺方法 应用现状 锂浸出率 优点 缺点 硫酸法[18-25] 工艺成熟、应用广泛,主要用于锂辉石矿提锂 92%~96% 生产效率高,固液相混合均匀,回收率高[21] 浸出液杂质含量高、工艺流程长、酸浸中和渣量大[23]、对设备防腐蚀性能要求高 硫酸盐法[26-33] 适用于处理江西宜春锂云母矿 90%~95% 能耗低,焙烧、浸出时间短[26] 钾盐用量大,铷铯浸出率低[28],易导致窑内结圈 石灰石法[34-38] 已被逐渐淘汰 85%~90% 工艺简单,原料成本低[34] 锂回收率低[35],能耗高 氯化焙烧法[39-44] 有一定应用 90%~95% 焙烧时间短、有价金属回收率高 浸出液含钙高,腐蚀设备严重[39] 压煮法[45-46] 江西赣锋锂业应用 75%~94% 工艺简单[45],浸出率高 对工艺条件及矿物种类要求苛刻[46] 氟化学法[47-54] 尚未工业化应用 93%~96% 流程较短、成本低,锂云母综合利用率高[47] 面临含氟溶液的净化和氟元素循环利用问题[54] -

[1] JOHN B G, YOUNGSIK K. Challenges for rechargeable Li batteries[J]. Chemistry of Materials, 2010, 22(3): 587-603. doi: 10.1021/cm901452z

[2] USGS. Mineral commodity summaries[DB/OL]. 2021-10-28. https://www.usgs.gov/centers/nmic/lithium-statistics-and-information.

[3] 姜贞贞, 刘高令, 卓玛曲西, 等. 我国锂资源供需现状下西藏盐湖锂产业现状及对策建议[J]. 盐湖研究, 2021, 29(3): 104-110. https://www.cnki.com.cn/Article/CJFDTOTAL-YHYJ202103013.htm

JIANG Z Z, LIU G L, ZHUOMA Q X, et al. Present situation and suggestions of saline lake lithium resource in Xizang under the current situation of supply and demand of lithium resources in China[J]. Journal of Salt Lake Research, 2021, 29(3): 104-110. https://www.cnki.com.cn/Article/CJFDTOTAL-YHYJ202103013.htm

[4] SWAIN B. Recovery and recycling of lithium: a review[J]. Separation and Purification Technology, 2016, 172: 388-403.

[5] 蒋晨啸, 陈秉伦, 张东钰, 等. 我国盐湖锂资源分离提取进展[J]. 化工学报, 2022, 73(2): 481-503. https://www.cnki.com.cn/Article/CJFDTOTAL-HGSZ202202001.htm

JIANG C X, CHEN B L, ZHANG D Y, et al. Progress in isolating lithium resources from China salt lake brine[J]. CIESC Journal, 2022, 73(2): 481-503. https://www.cnki.com.cn/Article/CJFDTOTAL-HGSZ202202001.htm

[6] 李丽娟. 高镁锂比盐湖卤水中锂资源高效利用和绿色分离的科学基础[D]. 西宁: 中国科学院青海盐湖研究所, 2019.

LI L J. Fundamental research for efficient utilization and green separation of lithium resources in salt lake brine with high magnesium lithium ratio[D]. Xining: Qinghai Instltute of Sale Lakes, Chinese Academy of Sciences, 2019.

[7] 张瑞, 钟静, 林森, 等. 盐湖铝系提锂吸附剂成型条件的影响研究[J]. 化工学报, 2021, 72(12): 6291-6297. https://www.cnki.com.cn/Article/CJFDTOTAL-HGSZ202112031.htm

ZHANG R, ZHONG J, LIN S, et al. Study on the influence of granulation conditions on Li/Al-LDHs for lithium recovery from low grade brine[J]. CIESC Journal, 2021, 72(12): 6291-6297. https://www.cnki.com.cn/Article/CJFDTOTAL-HGSZ202112031.htm

[8] 姚文贵, 马鸿文, 刘梅堂, 等. 锂辉石水热钾碱分解制取碳酸锂相平衡模拟与优化试验[J]. 有色金属(冶炼部分), 2021(4): 28-35. doi: 10.3969/j.issn.1007-7545.2021.04.005

YAO W G, MA H W, LIU M T, et al. Preparing lithium carbonate via hydrothermal of spodumene and potash: phase equilibrium simulation and optimization experiment[J]. Non-ferrous Metals (Smelting), 2021(4): 28-35. doi: 10.3969/j.issn.1007-7545.2021.04.005

[9] JEWELL S, SUZETTE M. Kimball mineral commodity summaries 2017[R]. Reston: U.S. Geological Survey, 2017: 100-101.

[10] 舒启溢. 锂云母浸取锂制备碳酸锂的工艺研究[D]. 南昌: 南昌大学, 2012.

SHU Q Y. Study of leaching lithium from lepidolite and preparation of lithium carbonate[D]. Nanchang: Nanchang University, 2012.

[11] 宋云峰, 赵中伟. 成矿地球化学特征与锂云母提锂技术方案[J]. 昆明理工大学学报(自然科学版), 2020, 45(1): 1-7. https://www.cnki.com.cn/Article/CJFDTOTAL-KMLG202001002.htm

SONG Y F, ZHAO Z Z. Metallogenic geochemical characteristics and technical schemes for extracting lithium from lepidolite[J]. Journal of Kunming University of Science and Technology (Natural Science), 2020, 45(1): 1-7. https://www.cnki.com.cn/Article/CJFDTOTAL-KMLG202001002.htm

[12] GUO H, LV M H, KUANG G, et al. Stepwise heat treatment for fluorine removal on selective leachability of Li from lepidolite using HF/H2SO4 as lixiviant[J]. Separation and Purification Technology, 2021, 259: 118194. doi: 10.1016/j.seppur.2020.118194

[13] 董栋, 程宏伟, 郭保万, 等. 锂辉石选矿技术现状及展望[J]. 矿产保护与利用, 2018(4): 130-134. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=e4589445-9f36-4131-b79b-2c19f2305e4a

DONG D, CHENG H W, GUO B W, et al. Research situation and prospect on the mineral processing technology of spodumene[J]. Conservation and Utilization of Mineral Resources, 2018(4): 130-134. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=e4589445-9f36-4131-b79b-2c19f2305e4a

[14] 苏慧, 朱兆武, 王丽娜, 等. 矿石资源中锂的提取与回收研究进展[J]. 化工学报, 2019, 70(1): 10-23. https://www.cnki.com.cn/Article/CJFDTOTAL-HGSZ201901002.htm

SU H, ZHU Z W, WANG L N, et al. Research progress in extraction and recovery of lithium from hard-rock ores[J]. CIESC Journal, 2019, 70(1): 10-23. https://www.cnki.com.cn/Article/CJFDTOTAL-HGSZ201901002.htm

[15] CAMILLE G, PAMELA H, MARION P, et al. Assessment of world lithium resources and consequences of their geographic distribution on the expected development of the electric vehicle industry[J]. Renewable and Sustainable Energy Reviews, 2012, 16(3): 1735-1744. doi: 10.1016/j.rser.2011.11.023

[16] WANG C G, ZHENG M P, ZHANG X F, et al. Geothermal‐type lithium resources in southern xizang, China[J]. Acta Geologica Sinica, 2021, 95(3): 860-872. doi: 10.1111/1755-6724.14675

[17] 田键, 李涛, 王明焱, 等. 典型锂矿石提锂技术研究进展[J]. 湖北大学学报(自然科学版), 2020, 42(1): 56-60. doi: 10.3969/j.issn.1000-2375.2020.01.009

TIAN J, LI T, WANG M Y, et al. Research progress on extraction process of lithium from lepidolite[J]. Journal of Hubei University(Natural Science), 2020, 42(1): 56-60. doi: 10.3969/j.issn.1000-2375.2020.01.009

[18] 丰丽琴, 王云帆, 覃文庆, 等. 江西某低品位锂云母矿浮选试验研究[J]. 非金属矿, 2019, 42(1): 60-62. doi: 10.3969/j.issn.1000-8098.2019.01.018

FENG L Q, WANG Y F, QIN W Q, et al. Experimental study on flotation of a low grade lepidolite ore from jiangxi[J]. Non-Metallic Mines, 2019, 42(1): 60-62. doi: 10.3969/j.issn.1000-8098.2019.01.018

[19] 张秀峰, 谭秀民, 刘维燥, 等. 矿石提锂技术现状与研究进展[J]. 矿产保护与利用, 2020, 40(5): 17-23. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=0587d20f-447f-49c5-a57e-a2b709569ea7

ZHANG X F, TAN X M, LIU W Z, et al. Current status and research progress of lithium extraction technology from ore[J]. Conservation and Utilization of Mineral Resources, 2020, 40(5): 17-23. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=0587d20f-447f-49c5-a57e-a2b709569ea7

[20] 曾小毛, 刘剑叶, 吴进方, 等. 关于利用硫酸和锂云母低温固相反应提取碱金属盐的方法研究[J]. 当代化工研究, 2020(15): 144-146. https://www.cnki.com.cn/Article/CJFDTOTAL-ZJTY202015067.htm

ZENG X M, LIU J Y, WU J F, et al. Study on the method of extracting alkali metal salts by solid-state reaction of sulfuric acid and lepidolite at low temperature[J]. Modern Chemical Research, 2020, 40(5): 17-23. https://www.cnki.com.cn/Article/CJFDTOTAL-ZJTY202015067.htm

[21] 伍习飞. 宜春锂云母提锂工艺及机理研究[D]. 长沙: 中南大学, 2012.

WU X F. Process and mechanism of lithium extraction from lepidolite in Yichun[D]. Changsha: Central South University, 2012.

[22] 赵寻, 杨静, 马鸿文, 等. 硫酸介质中锂云母分解反应动力学[J]. 中国有色金属学报, 2015, 25(9): 2588-2595. https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ201509035.htm

ZHAO X, YANG J, MA H W, et al. Kinetics of lepidolite decomposition reaction in sulfuric acid solution[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(9): 2588-2595. https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ201509035.htm

[23] 冯文平, 谢晶磊, 汤建良, 等. 硫酸浸取锂云母提锂方法的研究[J]. 精细化工中间体, 2016, 46(3): 66-69. https://www.cnki.com.cn/Article/CJFDTOTAL-HNHG201603022.htm

FENG W P, XIE J L, TANG J L, et al. Study on the extraction of lithium from lepidolite[J]. Fine Chemical Intermediates, 2016, 46(3): 66-69. https://www.cnki.com.cn/Article/CJFDTOTAL-HNHG201603022.htm

[24] 何明明. 锂云母机械化学活化提锂工艺研究[D]. 北京: 中国科学院大学(中国科学院过程工程研究所), 2018.

HE M M. Study on leaching process of lithium from lepidolite through mechanochemical activation treatment[D]. Beijing: University of Chinese Academy of Sciences, 2018.

[25] 张秀峰, 伊跃军, 张利珍, 等. 锂云母精矿的硫酸熟化研究[J]. 矿产保护与利用, 2018(4): 59-62. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=238375e4-5f3f-4eaf-9b5a-ef1567661fee

ZHANG X F, YI Y J, ZHANG L Z, et al. Study on sulfuric acid curing of lepidolite concentrate[J]. Conservation and Utilization of Mineral Resources, 2018(4): 59-62. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=238375e4-5f3f-4eaf-9b5a-ef1567661fee

[26] 舒启益, 胡炜华, 邱祖民. 用硫酸盐法从锂云母中提取锂[J]. 南昌大学学报(工科版), 2011, 33(4): 325- 327. doi: 10.3969/j.issn.1006-0456.2011.04.005

SHU Q Y, HU Y H, QIU Z M. Extraction of lithium from lithium mica by sulfate method[J]. Journal of Nanchang University (Engineering Edition), 2011, 33(4): 325- 327. doi: 10.3969/j.issn.1006-0456.2011.04.005

[27] ZHANG X F, CHEN Z C, Rohani S, et al. Simultaneous extraction of lithium, rubidium, cesium and potassium from lepidolite via roasting with iron(Ⅱ) sulfate followed by water leaching[J]. Hydrometallurgy, 2022, 208: 105820. doi: 10.1016/j.hydromet.2022.105820

[28] VIECELI N, Nogueira C A, Pereira M F C, et al. Optimization of lithium extraction from lepidolite by roasting using sodium and calcium sulfates[J]. Mineral Processing and Extractive Metallurgy Review, 2017, 38(1): 62-72. doi: 10.1080/08827508.2016.1262858

[29] 郭春平, 周健, 文小强, 等. 锂云母硫酸盐法提锂研究[J]. 无机盐工业, 2014, 46(3): 41-44. doi: 10.3969/j.issn.1006-4990.2014.03.011

GUO C P, ZHOU J, WEN X Q, et al. Extraction of lithium from lepidolite by sulfate process[J]. Inorganic Salt Industry, 2014, 46(3): 41-44. doi: 10.3969/j.issn.1006-4990.2014.03.011

[30] 王盘喜, 海东婧, 卞孝东, 等. 卢氏锂辉石-锂云母型稀有多金属矿石工艺矿物学研究[J]. 矿产保护与利用, 2015(3): 41-45. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=7962e9ec-4ed8-40af-b02d-69c03dd6ce43

WANG P X, HAI D J, BIAN X D, et al. Processing mineralogy of spodumene-lepidolite pattern rare polymetal ore in lushi[J]. Conservation and Utilization of Mineral Resources, 2015(3): 41-45. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=7962e9ec-4ed8-40af-b02d-69c03dd6ce43

[31] 汪建岭, 王继民, 朱建春, 等. 硫酸盐法从锂云母制取碳酸锂的研究[J]. 新疆有色金属, 1996(1): 85-89. https://www.cnki.com.cn/Article/CJFDTOTAL-XJYS199601023.htm

WANG J L, WANG J M, ZHU J C, et al. Preparation of lithium carbonate from lithium mica by sulfate process[J]. Xinjiang Nonferrous Metals, 1996(1): 85-89. https://www.cnki.com.cn/Article/CJFDTOTAL-XJYS199601023.htm

[32] NICHOLSON C M. Production of lithium compounds: US Patent 2413644[P]. 1946-12-31.

[33] 王丁, 陈树. 锂云母-氧化钙高压蒸汽法提锂工艺研究[J]. 应用化工, 2020, 49(12): 3043-3045. doi: 10.3969/j.issn.1671-3206.2020.12.019

WANG D, CHEN S. Study on the process of extracting lithium from lepidolite-calcium oxide by high pressure steam[J]. Applied Chemical Industry, 2020, 49(12): 3043-3045. doi: 10.3969/j.issn.1671-3206.2020.12.019

[34] GUO H, LV M H, KUANG G, et al. Enhanced lithium extraction from α-spodumene with fluorine-based chemical method: a stepwise heat treatment for fluorine removal[J]. Minerals Engineering, 2021, 174: 107246. doi: 10.1016/j.mineng.2021.107246

[35] 孙友润. 锂云母-石灰石法烧成工艺最佳条件的选择[J]. 稀有金属, 1984(5): 11-15. https://www.cnki.com.cn/Article/CJFDTOTAL-ZXJS198405002.htm

SUN Y R. Selection of optimum conditions for calcining process of limica-limestone[J]. Rare Metals, 1984(5): 11-15. https://www.cnki.com.cn/Article/CJFDTOTAL-ZXJS198405002.htm

[36] HIEN-DINH T T, LUONG V T, GIERE R, et al. Extraction of lithium from lepidolite via iron sulphide roasting and water leaching[J]. Hydrometallurgy, 2015, 153: 154-159. doi: 10.1016/j.hydromet.2015.03.002

[37] 石颖. 石灰石法锂云母综合冶炼工艺流程[J]. 稀有金属, 1982(3): 7-11. https://www.cnki.com.cn/Article/CJFDTOTAL-ZXJS198203001.htm

SHI Y. Comprehensive lithium extraction from lepidolite by limestone process[J]. Rare Metals, 1982(3): 7-11. https://www.cnki.com.cn/Article/CJFDTOTAL-ZXJS198203001.htm

[38] LUONG V T, KANG D J, AN J W, et al. Factors affecting the extraction of lithium from lepidolite[J]. Hydrometallurgy, 2013, 134/135: 54-61. doi: 10.1016/j.hydromet.2013.01.015

[39] OGORODOVA L P, KISELEVA I A, MELCHAKOVA L V, et al. Thermodynamic properties of lithiummica: lepidolite[J]. Thermochimica Acta, 2005, 435(1): 68-70. doi: 10.1016/j.tca.2005.04.026

[40] YAN Q X, LI X H, WANG Z X, et al. Extraction of lithium from lepidolite using chlorination roasting-water leaching process[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(7): 1753-1759. doi: 10.1016/S1003-6326(11)61383-6

[41] BARBOSA L I, VALENTE G, OROSCO R P, et al. Lithium extraction from β-spodumene through chlorination with chlorine gas[J]. Minerals Engineering, 2014, 56: 29-34. doi: 10.1016/j.mineng.2013.10.026

[42] YAN Q X, LI X H, WANG Z X, et al. Extraction of valuable metals from lepidolite[J]. Hydrometallurgy, 2012, 124(8): 117-118.

[43] 徐盛明, 汪锡孝. 锂云母焙烧矿的氯化铵压煮过程的研究[J]. 稀有金属与硬质合金, 1993(4): 22-27. https://www.cnki.com.cn/Article/CJFDTOTAL-XYJY199304004.htm

XU S M, WANG X X. Study on pressure leaching process for the calcine of lepidolite by ammonium chloride[J]. Rare Metals and Cemented carbides, 1993(4): 22-27. https://www.cnki.com.cn/Article/CJFDTOTAL-XYJY199304004.htm

[44] 陈亚, 廖婷, 陈白珍. 纯碱压煮法从锂辉石中提取锂的研究[J]. 有色金属(冶炼部分), 2011(9): 21- 32. doi: 10.3969/j.issn.1007-7545.2011.09.006

CHEN Y, LIAO T, CHEN B Z. Extraction of lithium from spodumene by sodium carbonate autoclave process[J]. Non-ferrous Metals(Smelting), 2011(9): 21-32. doi: 10.3969/j.issn.1007-7545.2011.09.006

[45] 仇世源, 张景怀, 阚素荣, 等. 宜春锂云母食盐压煮法制取碳酸锂新工艺[J]. 新疆有色金属, 1996(1): 44-48. https://www.cnki.com.cn/Article/CJFDTOTAL-XJYS199601007.htm

CHOU S Y, ZHANG J H, KAN S R, et al. New technology of preparation of lithium carbonate by autoclave process of yichun lepidolite and salt[J]. Xinjiang Nonferrous Metals, 1996(1): 44-48. https://www.cnki.com.cn/Article/CJFDTOTAL-XJYS199601007.htm

[46] JANDOV J, DVOFAK P, FORMANEK J, et al. Recovery of rubidium and potassium alums from lithium-bearing minerals[J]. Hydrometallurgy, 2012, 119/120: 73-76. doi: 10.1016/j.hydromet.2012.02.010

[47] 旷戈, 林诚, 王占前, 等. 锂云母氟化学提锂工艺: CN201010235150.2[P]. 2010-11-17.

KUANG G, LIN C, WANG Z Q, et al. Lithium extraction from lepidolite with fluorine chemical method: CN201010235150.2[P]. 2010-11-17.

[48] KUANG G, CHEN Z B, GUO H, et al. Lithium extraction mechanism from a-spodumene by fluorine chemical method[J]. Advanced Materials Research, 2012, 524/525/526/527: 2011-2016.

[49] 刘绪凯, 亓亮, 姜信德, 等. 锂云母提锂新工艺[J]. 中国有色金属, 2014(12): 66-67. https://www.cnki.com.cn/Article/CJFDTOTAL-YSGY201412021.htm

LIU X K, QI L, JIANG X D, et al. New technology of lithium extraction from lithium mica[J]. China Nonferrous Metals, 2014(12): 66-67. https://www.cnki.com.cn/Article/CJFDTOTAL-YSGY201412021.htm

[50] GUO H, KUANG G, WAN H, et al. Enhanced acid treatment to extract lithium from lepidolite with a fluorine-based chemical method[J]. Hydrometallurgy, 2019, 183: 9-19. doi: 10.1016/j.hydromet.2018.10.020

[51] GUO H, KUANG G, LI H, et al. Enhanced lithium leaching from lepidolite in continuous tubular reactor using H2SO4+H2SiF6 as lixiviant[J]. Transactions of Nonferrous Metals Society of China, 2021, 31(7): 2165-2173. doi: 10.1016/S1003-6326(21)65646-7

[52] GUO H, YU H Z, ZHOU A A, et al. Kinetics of leaching lithium from α-spodumene in enhanced acid treatment using HF/H2SO4 as medium[J]. Transactions of Nonferrous Metals Society of China, 2019, 29(2): 407-415. doi: 10.1016/S1003-6326(19)64950-2

[53] GUO H, KUANG G, YANG J X, et al. Fundamental research on a new process to remove Al3+ as potassium alum during lithium extraction from lepidolite[J]. Metallurgical and Materials Transactions, B, 2016, 47: 3557-3564. doi: 10.1007/s11663-016-0774-y

[54] GUO H, KUANG G, WANG H D, et al. Investigation of enhanced leaching of lithium from α-spodumene using hydrofluoric and sulfuric Acid[J]. Minerals, 2017, 7(11): 205. doi: 10.3390/min7110205

[55] 李军, 朱庆山, 李洪钟. 典型含锂矿物焙烧提锂研究进展[J]. 中国科学: 化学, 2017, 47(11): 1273-1283. https://www.cnki.com.cn/Article/CJFDTOTAL-JBXK201711005.htm

LI J, ZHU Q S, LI H Z. Progress of lithium extraction from typical lithium bearing minerals by roasting[J]. Scientia Sinica China, 2017, 47(11): 1273-1283. https://www.cnki.com.cn/Article/CJFDTOTAL-JBXK201711005.htm

[56] 颜群轩. 锂云母中有价金属的高效提取研究[D]. 长沙: 中南大学, 2012.

YAN Q X. Extraction of valuable metals from lepidolite[D]. Changsha: Central South University, 2012.

[57] 高贵彦. 典型含锂矿物焙烧提锂研究进展[J]. 当代化工研究, 2018(10): 92-93. doi: 10.3969/j.issn.1672-8114.2018.10.056

GAO G Y. Research progress on roasting and extracting lithium from typical lithium-containing minerals[J]. Chenmical Intermediate, 2018(10): 92-93. doi: 10.3969/j.issn.1672-8114.2018.10.056

[58] 李根, 杨洁, 杨静. 锂云母分解及溶出锂工艺的研究进展评述[J]. 硅酸盐通报, 2017, 36(5): 1599-1604. https://www.cnki.com.cn/Article/CJFDTOTAL-GSYT201705024.htm

LI G, YANG J, YANG J. Literature review of extracting lithium from lepidolite[J]. Bulletin of the Chinese Ceramic Society, 2017, 36(5): 1599-1604. https://www.cnki.com.cn/Article/CJFDTOTAL-GSYT201705024.htm

[59] OGORODOVA L P, KISELEVA l A, MELCHAKOVA L V. Thermodynamic properties of lithium micas[J]. Geochemistry International, 2010, 48(4): 415-418. doi: 10.1134/S0016702910040117

[60] 胡赞. 典型矿石提锂工艺介绍及经济效益分析[J]. 盐科学与化工, 2019, 48(3): 5-8. https://www.cnki.com.cn/Article/CJFDTOTAL-HHYH201903005.htm

HU Z. Analysis of typical lithium extraction from mines and its economic benefit[J]. Journal of Salt Science and Chemical Industry, 2019, 48(3): 5-8. https://www.cnki.com.cn/Article/CJFDTOTAL-HHYH201903005.htm

[61] 雷祖伟, 钟宏, 王帅, 等. 含铷、铯锂云母矿的复合盐焙烧-浸出性能及机理[J]. 矿产综合利用, 2019(3): 152-156. doi: 10.3969/j.issn.1000-6532.2019.03.033

LEI Z W, ZHONG H, WANG S, et al. Composite salt roasting - leaching performance and mechanism of lepidolite containing rubidium and cesium[J]. Conservation and Utilization of Mineral Resources, 2019(3): 152-156. doi: 10.3969/j.issn.1000-6532.2019.03.033

[62] MESHRAM P, PANDEY B D, MANKHAND T R. Extraction of lithium from primary and secondary sources by pre-treatment, leaching and separation: a comprehensive review[J]. Hydrometallurgy, 2014, 150: 192-208. doi: 10.1016/j.hydromet.2014.10.012

[63] 谭秀民, 张永兴, 张利珍, 等. 能源金属锂资源开发利用现状及发展建议[J]. 矿产保护与利用, 2017(5): 87-92. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=73769145-b053-4be2-a7d1-dc8e7f39d3e3

TAN X M, ZHANG Y X, ZHANG L Z, et al. Utilization status of lithium resources and development suggestions[J]. Conservation and Utilization of Mineral Resources, 2017(5): 87-92. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=73769145-b053-4be2-a7d1-dc8e7f39d3e3

[64] 董栋, 程宏伟, 郭保万, 等. 锂辉石选矿技术现状及展望[J]. 矿产保护与利用, 2018(4): 130-134. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=316a5a09-cb41-4c2b-9fb2-67435bd13475

DONG D, CHENG H W, GUO B W, et al. Research situation and prospect on the mineral processing technology of spodumene[J]. Conservation and Utilization of Mineral Resources, 2018(4): 130-134. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=316a5a09-cb41-4c2b-9fb2-67435bd13475

[65] 刘子潇, 张家靓, 杨成, 等. 热力学研究在锂离子电池回收中的应用[J]. 化工进展, 2021, 40(10): 5325-5336. https://www.cnki.com.cn/Article/CJFDTOTAL-HGJZ202110008.htm

LIU Z X, ZHANG J L, YANG C, et al. Applications of thermodynamic research in recycling of lithium ion battery[J]. Chemical Industry and Engineering Progress, 2021, 40(10): 5325-5336. https://www.cnki.com.cn/Article/CJFDTOTAL-HGJZ202110008.htm

[66] 解海兵. 从锂云母中提取碳酸锂的研究[D]. 上海: 华东理工大学, 2012.

XIE H B. Preparation of the lithium carbonate from lepidolite[D]. Shanghai: East China University of Science and Technology, 2012.

[67] 徐盛明, 汪锡孝, 张传福. 宜春锂云母焙烧过程的研究[J]. 矿冶工程, 1994(14): 56-58. https://www.cnki.com.cn/Article/CJFDTOTAL-KYGC401.012.htm

XU S M, WANG X X, ZHANG C F. A study on the roasting process of yichun lepidolite[J]. Mining and Metallurgical Engineering, 1994(14): 56-58. https://www.cnki.com.cn/Article/CJFDTOTAL-KYGC401.012.htm

[68] 马小红, 葛伟. HF回收技术在氟化工行业的应用[J]. 有机氟工业, 2012(1): 34-39. https://www.cnki.com.cn/Article/CJFDTOTAL-YJFG201201010.htm

MA X H, GE W. Application of HF recovery technology in fluorine chemical industry[J]. Organo- Fluorine Industry, 2012(1): 34-39. https://www.cnki.com.cn/Article/CJFDTOTAL-YJFG201201010.htm

[69] 易长福. 科技打造"亚洲锂都"[J]. 科技创新与品牌, 2012(3): 83-85. https://www.cnki.com.cn/Article/CJFDTOTAL-KJCX201203028.htm

YI C F. "Lithium capital of Asia" by science and technology[J]. Science and Technology Innovation and Brand, 2012(3): 83-85. https://www.cnki.com.cn/Article/CJFDTOTAL-KJCX201203028.htm

[70] 高照国, 曹耀华, 刘红召, 等. 某含铷和锂的云母粗精矿焙烧和浸出试验研究[J]. 矿产保护与利用, 2017(5): 64-66. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=14b7932d-3f71-4b4d-8f76-58659bc09bd7

GAO Z G, CAO Y H, LIU H Z, et al. Investigations on roasting and leaching of a mica rough concentrate containing rubidium and lithium[J]. Conservation and Utilization of Mineral Resources, 2017(5): 64-66. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=14b7932d-3f71-4b4d-8f76-58659bc09bd7

[71] 马小红, 葛伟, 李勇. 氟化工废热回收与高效用水技术探讨[J]. 有机氟工业, 2012(3): 15-19. https://www.cnki.com.cn/Article/CJFDTOTAL-YJFG201203008.htm

MA X H, GE W, LI Y. Discussion on waste heat recovery and efficient water use technology of fluorine chemical industry[J]. Organo-Fluorine Industry, 2012(3): 15-19. https://www.cnki.com.cn/Article/CJFDTOTAL-YJFG201203008.htm

[72] 胡光华, 吴剑. 宜春新法提取碳酸锂国际领先[N]. 江西日报, 2011-03-24.

HU G H, WU J. Yichun new method leads the world in extracting lithium carbonate[N]. Jiangxi Daily, 2011-03-24.

[73] 许开成, 黄财林, 陈梦成. 锂云母渣作为掺合料的可行性研究[J]. 混凝土, 2015(8): 84-86. https://www.cnki.com.cn/Article/CJFDTOTAL-HLTF201508027.htm

XU K C, HUANG C L, CHEN M Z. Feasibility research of lepidolite slag as mineral admixture[J]. Concrete, 2015(8): 84-86. https://www.cnki.com.cn/Article/CJFDTOTAL-HLTF201508027.htm

[74] 吕子虎, 赵登魁, 沙惠雨, 等. 阴阳离子组合捕收剂浮选锂云母的试验研究[J]. 矿产保护与利用, 2017(2): 81-84. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=2d98af83-8e4c-48ba-aef9-bf45bc9d50f5

LU Z H, ZHAO D K, SHA H Y, et al. Experimental study on lepidolite flotation with anion-cation combined collectors[J]. Conservation and Utilization of Mineral Resources, 2017(2): 81-84. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=2d98af83-8e4c-48ba-aef9-bf45bc9d50f5

[75] 马智敏, 李思, 陈兴华. 无传动微泡浮选槽在高海拔地区某锂辉石矿的工业试验[J]. 矿产保护与利用, 2016(4): 33-36. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=14c6f8f2-425e-401b-b668-cd372769d0f2

MA Z M, LI X, CHEN X H. Industrial test research of no drive micro bubble flotation column for spodumene separation in high attitude area[J]. Conservation and Utilization of Mineral Resources, 2016(4): 33-36. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=14c6f8f2-425e-401b-b668-cd372769d0f2

[76] 旷戈, 候彭, 汤军军, 等. 锂云母循环流化床焙烧脱氟的方法: CN107934980B[P]. 2019-12-17.

KAUNG G, HOU P, TANG J J, et al. Defluorination of lepidolite by roasting in circulating fluidized bed: CN107934980B[P]. 2019-12-17.

[77] EDGAR G, ROBERT P. Processing of spodumene concentrates in fluidized-bed systems[J]. Minerals Engineering, 2020, 148: 15-23.

[78] LI J, KONG J, ZHU Q S, et al. Enhanced roasting of lepidolite for high defluorination efficiency in a fluidized bed reactor[J]. Particuology, 2020, 52: 28-35.

[79] 旷戈, 林诚, 臧运凯, 等. 锂云母浸取液除杂工艺: CN201010561193. X[P]. 2012-04-11.

KAUNG G, LIN C, ZANG Y K, et al. Separation and purification of leaching solution from lepidopite: CN201010561193. X[P]. 2012-04-11.

[80] OGORDOVA L P, KISELEVA 1 A, MEL'CHAKOVA L V, et al. Thermodynamic properties of the lithium mica polylithionite[J]. Geochemistry International, 2006, 44(11): 1151-1153.

[81] LI J, KONG J, ZHU Q S, et al. In-situ capturing of fluorine with CaO for accelerated defluorination roasting of lepidolite in a fluidized bed reactor[J]. Powder Technology, 2019, 353(C): 498-504.

[82] 旷戈, 郭慧, 刘善军, 等. 锂云母矿石提锂浸取液体系中除铝的研究[J]. 稀有金属, 2014, 38(1): 102-107. https://www.cnki.com.cn/Article/CJFDTOTAL-ZXJS201401016.htm

KAUNG G, GUO H, LIU S J, et al. Aluminum recovery in leaching solution of lepidolite after lithium extraction[J]. Chinese Journal of Rare Metals, 2014, 38(1): 102-107. https://www.cnki.com.cn/Article/CJFDTOTAL-ZXJS201401016.htm

[83] 祝宏帅. 氟循环酸解锂云母选择性浸出锂工艺的研究[D]. 石家庄: 河北科技大学, 2018.

ZHU H S. Study on selectively leaching lithium from lepidolite by fluorine recycling and acid leaching method[D]. Shijiazhuang: Hebei University of Science and Technology, 2018.

[84] 郭慧. 锂云母氟化学法提锂反应机理及浸取液硫酸盐体系成矾除铝的研究[D]. 福州: 福州大学, 2014.

GUO H. The investigation on reaction mechanism fluorine chemical method to extract lithium from lepidolite and separation technology to recover aluminum in the leaching solution abstract[D]. Fuzhou: Fuzhou University, 2014.

[85] WANG H D, ZHOU A A, GUO H, et al. Kinetics of leaching lithium from lepidolite using mixture of hydrofluoric and sulfuric acid[J]. Journal of Central South University, 2020, 27: 27-36.

-

下载:

下载: