Preparation and Characterization of Sericite Modified by Macromolecular Coupling Agent KH570-g-PLA

-

摘要:

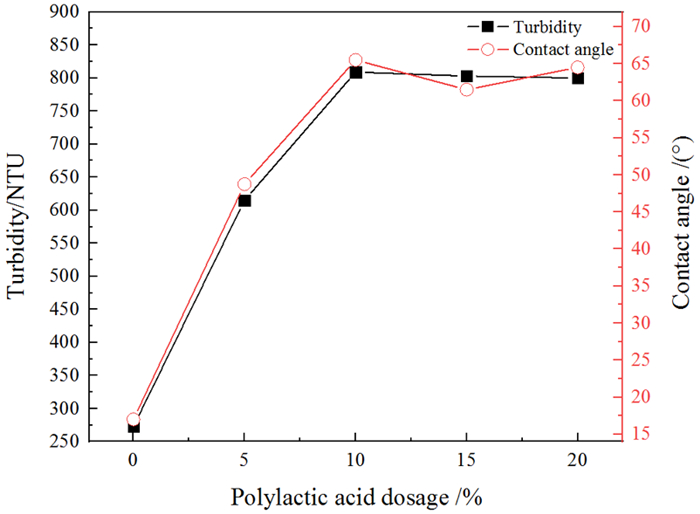

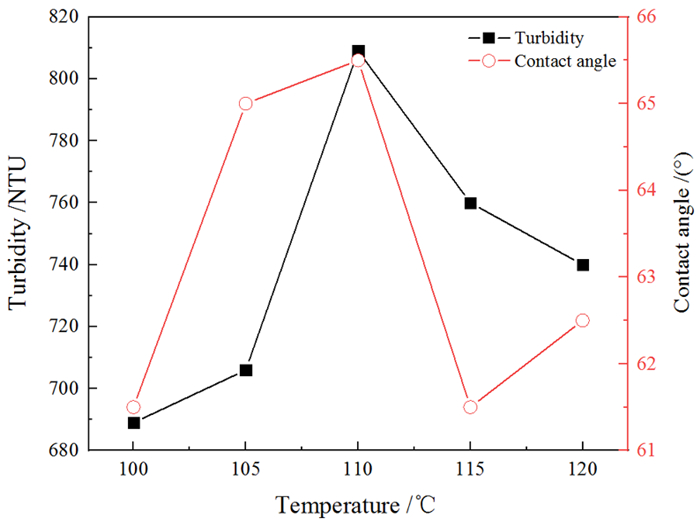

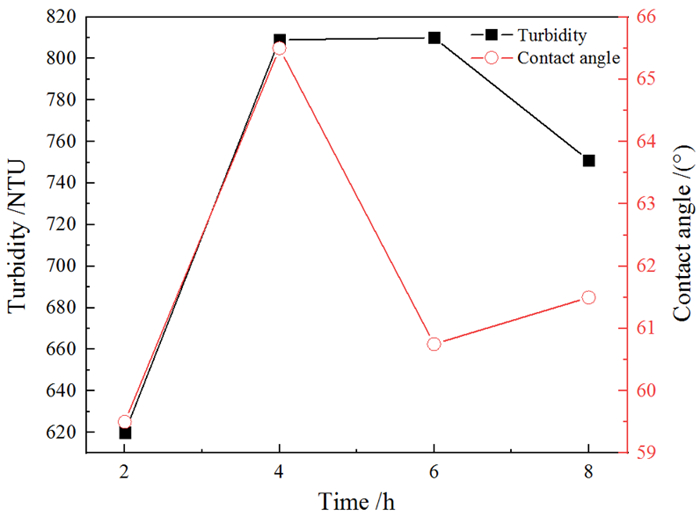

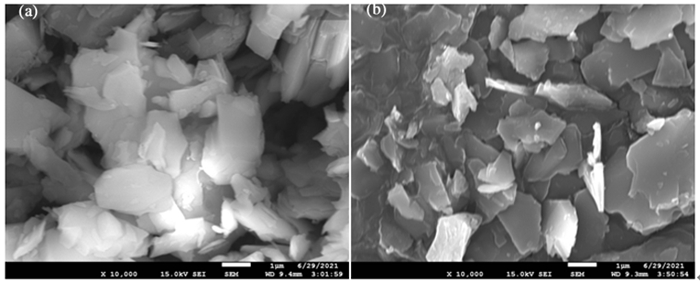

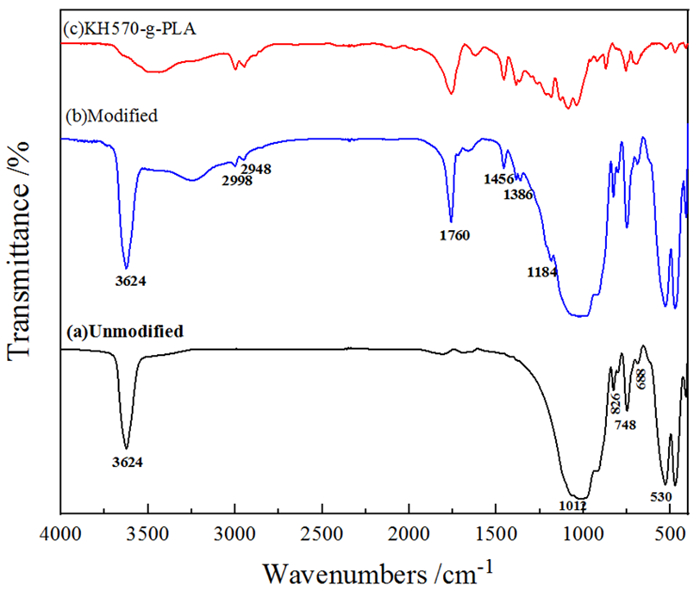

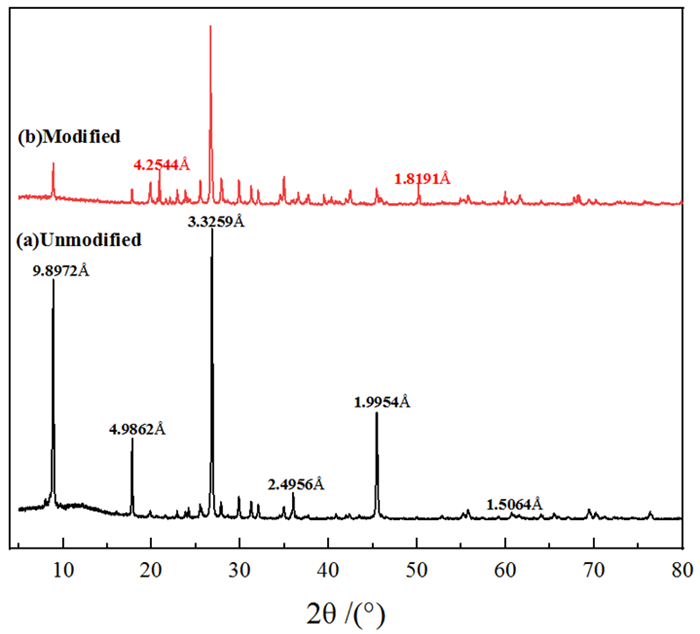

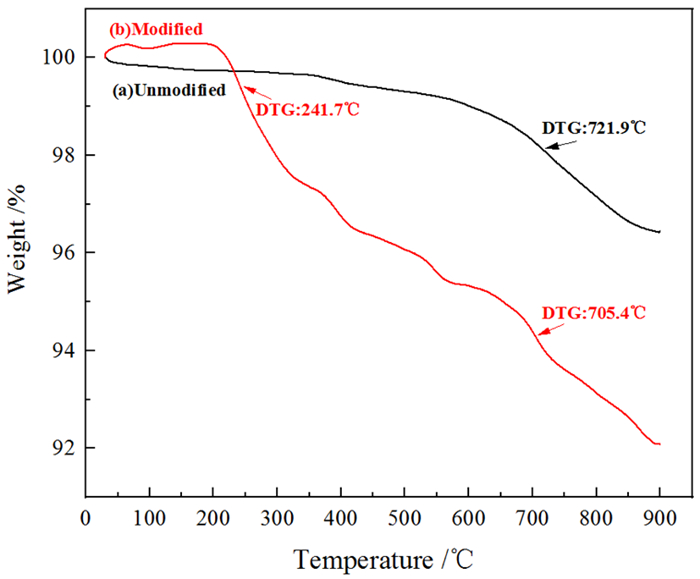

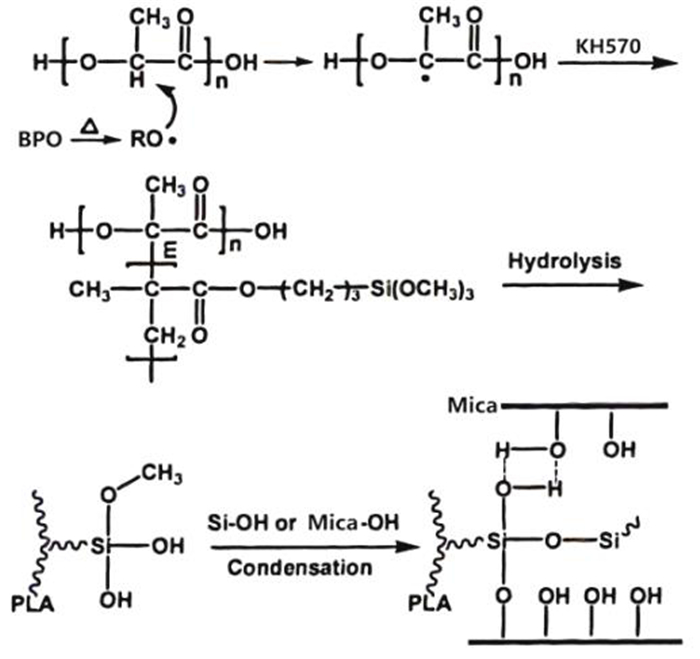

采用"一步法"复合改性工艺制备大分子偶联剂KH570-g-PLA改性绢云母,以改性前后绢云母的浊度和接触角为参数对绢云母表面改性工艺进行优化,考察了改性剂用量、反应时间和反应温度对绢云母表面改性效果的影响。试验结果表明,KH570-g-PLA改性绢云母的最佳工艺条件为聚乳酸(PLA)用量10%、反应温度110℃、反应时间4 h,此时其浊度为809 NTU,接触角为66°。相比未改性绢云母,浊度提高196%,接触角提高285%。测试分析表明,大分子偶联剂KH570-g-PLA被成功偶联到绢云母表面,KH570-g-PLA改性绢云母的晶体片径变小,团聚现象减弱,分散性和疏水性提高,结晶度降低,耐热温度约为705℃。

Abstract:The macromolecular coupling agent KH570-g-PLA modified sericite were prepared by one-step composite modification process. The effects on the sericite surface modification efficiency of modifier dosage, reaction time and reaction temperature were investigated with the parameters of turbidity, and contact angle of sericite before and after modification, and the optimizational surface modification conditions of sericite were obtained.The optimal technological conditions of KH570-g-PLA modified sericite were that the 10% of PLA was reacted with sericite at 110℃ for 4 h. The turbidity is 809 NTU and the contact Angle is 66°. Compared with unmodified sericite, its turbidity increased by 196%, and contact angle increased by 285%. The coupling agent KH570-G-PLA was successfully coupled to the surface of sericite. And the KH570-g-PLA modified sericite had a smaller crystal size, seldom agglomeration phenomenon, better dispersibility and hydrophobicity, lower crystallinity and the higher heat resistance temperature (about 705℃).

-

Key words:

- sericite /

- polylactic acid /

- KH570 /

- KH570-g-PLA /

- graft copolymerization /

- coupling effect

-

-

表 1 绢云母改性前后粒度分析

Table 1. Size analysis of sericite before and after modification

Size analysi d50/μm d90/μm Middiameter/μm BET/(m2·g-1) Unmodified 27.10 72.74 5.908 0.133 Modified 23.76 67.59 4.853 0.157 -

[1] LIANG Y, YANG D, YANG T, et al. The stability of intercalated sericite by cetyl trimethylammonium ion under different conditions and the preparation of sericite/polymer nanocomposites[J]. Polymers, 2019, 11(5): 900-911. doi: 10.3390/polym11050900

[2] 岳晋充. 云母表面改性方法综述[J]. 科技创新与应用, 2015, 1(31): 7-8. https://www.cnki.com.cn/Article/CJFDTOTAL-CXYY201531003.htm

YUE J C. Review on surface modification methods of mica[J]. Science & Technology Innovation and Application, 2015, 1(31): 7-8. https://www.cnki.com.cn/Article/CJFDTOTAL-CXYY201531003.htm

[3] 兰黄鲜. 云母粉在高分子材料改性中的研究进展[J]. 当代化工, 2011, 40(2): 177-179. doi: 10.3969/j.issn.1671-0460.2011.02.022

LAN H X. Research progress of mica powder in the modification of polymer materials[J]. Contemporary Chemical Industry, 2011, 40(2): 177-179. doi: 10.3969/j.issn.1671-0460.2011.02.022

[4] LISICHKIN G, OLENIN A. Hydrophobization of inorganic materials by chemical modification of the surface[J]. Russian Journal of Applied Chemistry, 2020, 93(1): 1-13.

[5] 尚丽娜, 王如寅, 关庆文, 等. 聚乳酸纳米填充改性的研究进展[J]. 化工新型材料, 2009, 37(9): 21-23+51. doi: 10.3969/j.issn.1006-3536.2009.09.007

SHANG L N, WANG R Y, GUAN Q W, et al. Research progress of polylactic acid nanofilling modification[J]. New Chemical Materials, 2009, 37(9): 21-23+51. doi: 10.3969/j.issn.1006-3536.2009.09.007

[6] JAIN S, MISRA M, MOHANTY A, et al. Thermal, mechanical and rheological behavior of poly(lactic acid)/talc composites[J]. Journal of Polymers and the Environment, 2012, 20(4): 1027-1037. doi: 10.1007/s10924-012-0500-z

[7] HE H, LIU B, XUE B, et al. Study on structure and properties of biodegradable PLA/PBAT/organic-modified MMT nanocomposites[J]. Journal of Thermoplastic Composite Materials, 2019, 2: 1-18.

[8] JIA S, WANG Z, ZHU Y, et al. Composites of poly(lactic) acid/thermoplastic polyurethane/mica with compatibilizer: morphology, miscibility and interphase[J]. RSC Advances, 2015, 5(120): 98915-98924. doi: 10.1039/C5RA17938F

[9] 钟振彪. 绢云母的表面改性及其高分子复合材料性能研究[D]. 合肥: 合肥工业大学, 2011.

Zhong Z B. Study on surface modification of sericite and properties of polymer composites[D]. Hefei: Hefei University of Technology, 2011.

[10] CHEN K, LI P, LI X, et al. Effect of silane coupling agent on compatibility interface and properties of wheat straw/polylactic acid composites[J]. International Journal of Biological Macromolecules, 2021, 182: 2108-2116. doi: 10.1016/j.ijbiomac.2021.05.207

[11] 杨琳强, 金立维. 聚乳酸接枝硅烷偶联剂的制备及对聚乳酸/木粉复合材料的影响[J]. 高分子材料科学与工程, 2016, 32(7): 125-130. https://www.cnki.com.cn/Article/CJFDTOTAL-GFZC201607024.htm

YANG L Q, JIN L W. Preparation of poly (lactic acid) grafted silane coupling agent and its effect on poly (lactic acid)/wood powder composites[J]. Polymer Materials Science and Engineering, 2016, 32(7): 125-130. https://www.cnki.com.cn/Article/CJFDTOTAL-GFZC201607024.htm

[12] DUAN J, FAN C, LI Y, et al. Preparation and characterization of the covalent-integrated poly(lactic acid) and scrap leather fiber composites[J]. Journal of Shanghai Jiaotong University (Science), 2012, 17(5): 586-592.

[13] 韩金光, 李珠, 王亮, 等. 膨胀珍珠岩的复合改性工艺及其对混凝土性能的影响[J]. 新型建筑材料, 2016, 43(10): 98-101. https://www.cnki.com.cn/Article/CJFDTOTAL-XXJZ201610030.htm

HAN J G, LI Z, WANG L, et al. Composite modification process of expanded perlite and its effect on concrete properties[J]. New Building Materials, 2016, 43(10): 98-101. https://www.cnki.com.cn/Article/CJFDTOTAL-XXJZ201610030.htm

[14] 赵志鸿, 张廷友, 吕召胜, 等. 超高分子量聚乙烯加工改性研究进展[J]. 工程塑料应用, 2012, 40(1): 99-102. https://www.cnki.com.cn/Article/CJFDTOTAL-ACSN201201024.htm

ZHAO Z H, ZHANG T Y, LU Z S, et al. Progress in processing and modification of ultra-high molecular weight polyethylene. Engineering Plastics Application, 2012, 40(1): 99-102. https://www.cnki.com.cn/Article/CJFDTOTAL-ACSN201201024.htm

[15] 汪磊, 周艳, 贾德民. 橡胶/有机蒙脱土纳米复合材料的研究——不同改性工艺的影响[J]. 弹性体, 2002, 1(4): 20-23. https://www.cnki.com.cn/Article/CJFDTOTAL-TXTZ200204009.htm

WANG L, ZHOU Y JIA D M. Study on rubber/organic montmorillonite nanocomposites: Influence of different modification processes[J]. Elastomers, 2002, 1(4): 20-23. https://www.cnki.com.cn/Article/CJFDTOTAL-TXTZ200204009.htm

[16] REN H, ZHU J, BI Y, et al. One-step fabrication of transparent hydrophobic silica aerogels via in situ surface modification in drying process[J]. Journal of Sol-Gel Science and Technology, 2016, 80(3): 1-7.

[17] 易宁波, 姜波, 黄玉东, 等. 绢云母改性及其在高分子材料中的应用进展[J]. 化学与黏合, 2010, 32(5): 47-49. https://www.cnki.com.cn/Article/CJFDTOTAL-HXYZ201005015.htm

YI N B, JIANG B, HUANG Y D, et al. Modification of sericite and its Application in polymer Materials[J]. Chemistry and Adhesives, 2010, 32(5): 47-49. https://www.cnki.com.cn/Article/CJFDTOTAL-HXYZ201005015.htm

[18] PENG L. Polymer modified clay minerals: A review[J]. Applied Clay Science, 2007, 38(1/2): 64-76.

-

下载:

下载: