The Study of Minerology of Qingshui Zisha Clay Mineral and the Microstructure of Sintering Products

-

摘要:

中国宜兴拥有独特的紫砂泥矿产资源,但是对宜兴紫砂矿料及其烧成品的科学系统研究还鲜少报道,不利于对紫砂矿产的保护和利用。宜兴清水泥被作为经典代表来研究,采用XRD、XRF、SEM、压汞计和EDS方法,分析了其成分和烧成品的微观形貌。结果表明,清水泥紫砂矿料样品主要由57.0%石英、12.3%赤铁矿、14.3%高岭石、13.0%伊利石以及3.4%蒙脱石组成,其烧成样品的微观结构显示出大量的多级次孔道结构。该种微观形貌的形成是由紫砂烧结过程中的液相量不足以及液相中含有大量的铁离子共同所致。紫砂陶瓷孔道的形成研究为宜兴紫砂矿产资源在多孔陶瓷材料领域的应用指出了方向。

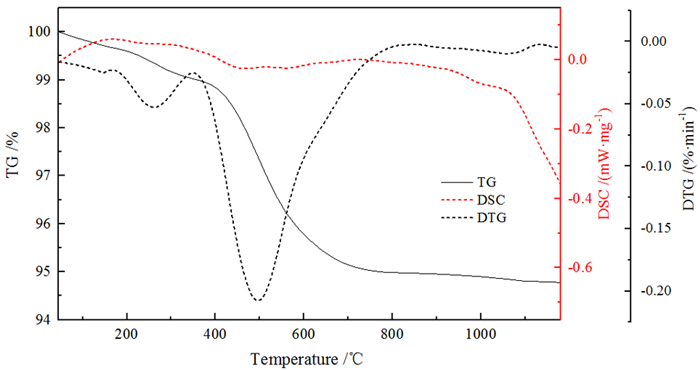

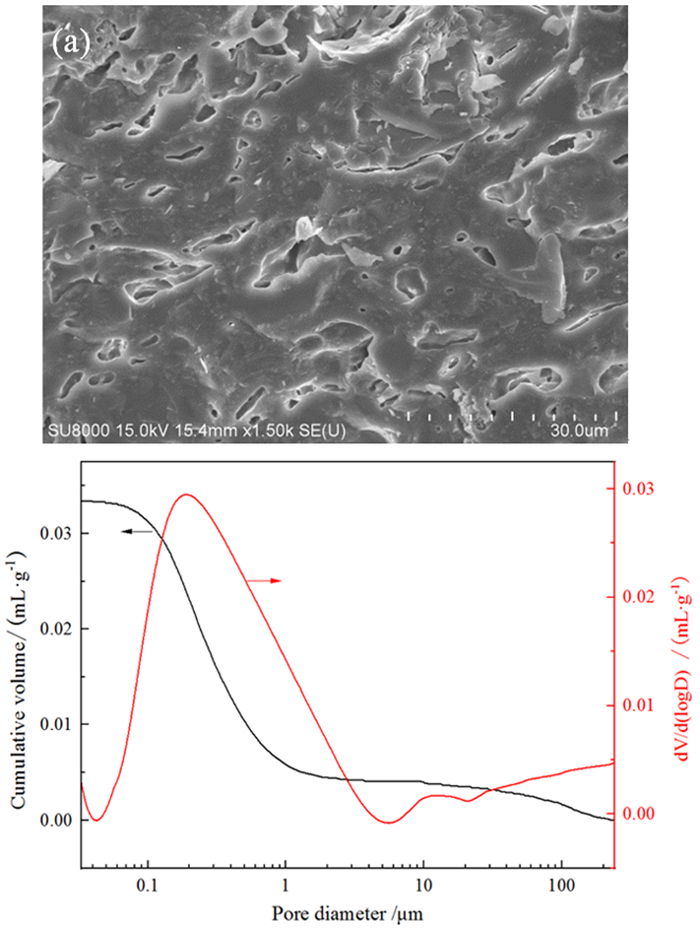

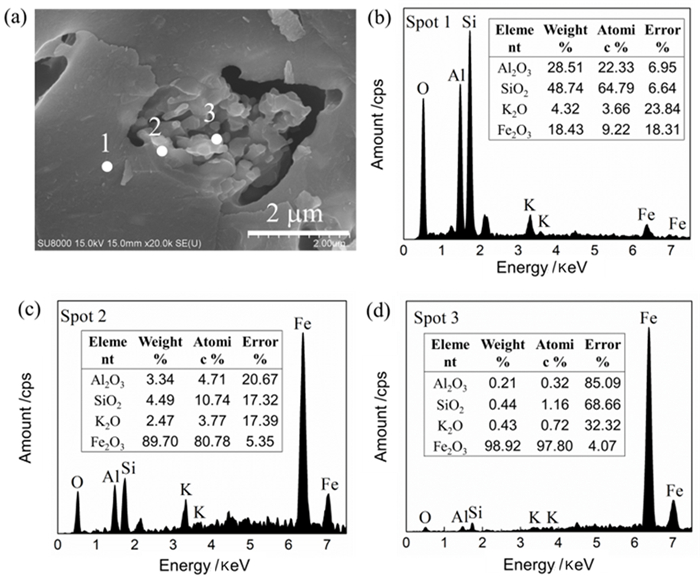

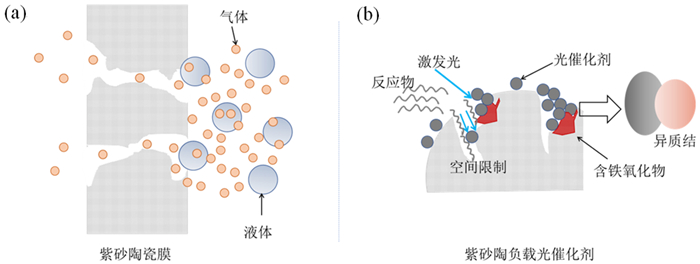

Abstract:It is well known that there are unique Zisha clay mineral resources in Yixing, China. However, until now, very few works have been reported on them and the corresponding sintering products. This is unfavorable to the protection and application of the Zisha clay mineral resources. Yixing Qingshui Zisha clay has been studied as an example. The composition of the Qingshui Zisha clay and the microstructures of the corresponding sintering products were analyzed by XRD, XRF, SEM, mercury porosimetry, and EDS. The results show that Qingshui Zisha clay is comprised of 57.0% quartz, 12.3% hematite, 14.3% kaolinite, 13.0% illite, and 3.4% montmorillonite, and the sintering Qingshui Zisha pottery has rich hierarchical pore structures. It is demonstrated that the microstructures of Zisha pottery result from a lack of liquid and the high content of Fe ions in liquid during the sintering of Qingshui Zisha clay. The study of formation mechanism of Zisha pore structures indicates the future application in porous ceramics of Yixing Zisha clay mineral resources.

-

Key words:

- Yixing /

- Zisha /

- Qingshui clay /

- mineral /

- microstructure

-

-

表 1 清水泥的矿物定量分析结果

Table 1. The quantitative results of mineral composition of Qingshui Zisha clay

/% 矿物相 石英 赤铁矿 伊利石 高岭石 蒙脱石 含量 57.0 12.3 13.0 14.3 3.4 表 2 清水泥的矿物化学成分分析结果

Table 2. The chemical composition of Qingshui Zisha clay

/% 成分 SiO2 Al2O3 Fe2O3 MgO CaO Na2O K2O MnO TiO2 P2O5 烧失量 含量 58.78 17.22 12.74 0.88 0.37 0.11 2.12 0.04 1.06 0.10 6.58 表 3 清水泥成品的物相组成

Table 3. The phase composition of the sintering product of Qingshui Zisha clay

/% 物相 石英 莫来石 赤铁矿 方石英 非晶相 含量 23.7 14.0 10.1 1.2 51.0 表 4 清水泥成品的孔道性质数据

Table 4. The pore properties of the sintering product of Qingshui Zisha clay

压汞法 BET法 孔隙率/% 孔容/(mL·g-1) 比表面积/(m2·g-1) 孔容/(mL·g-1) 比表面积/(m2·g-1) 8.466 0.031 0.628 0.018 1.328 -

[1] 刘玉林, 戴银法. 阳羡茗砂土[M]. 南京: 江苏美术出版社, 2013.

LIU Y l, DAI L f. Yangxian Zisha clays[M]. Nanjing: Jiangsu Fine Art Press, 2013.

[2] 朱泽伟, 沈亚琴. 宜兴紫砂矿料[M]. 北京: 地质出版社, 2009.

ZHU Z W, SHEN Y Q. Yixing purple sand mineral[M]. Beijing: Geology Press, 2009.

[3] LEE V, ATTINGER D. Thermodynamics and historical relevance of a jetting thermometer made of Chinese zisha ceramic[J]. Scientific Report, 2016, 6: 1-10. doi: 10.1038/s41598-016-0001-8

[4] ZHU J, MACDONALD B L, HANG T, et al. Compositional characterization of zisha clay from the Yixing area (Jiangsu, China) by neutron activation analysis[J]. Microchemical Journal, 2019, 147: 1117-1122. doi: 10.1016/j.microc.2019.04.031

[5] WU J, HOU T, ZHANG M L, et al. An analysis of the chemical composition, performance and structure of China Yixing Zisha pottery from 1573 A.D. to 1911 A.D. [J]. Ceramic International, 2013, 39: 2589-2595. doi: 10.1016/j.ceramint.2012.09.021

[6] CHUNG T Y, KUO P C, LIAO Z H, et al. Analysis of lipophilic compounds of tea coated on the surface of clay teapots[J]. Journal of Food and Drug Analysis, 2015, 23: 71-81. doi: 10.1016/j.jfda.2014.05.005

[7] LIAO Z H, CHEN Y J. TZEN J T, et al. Effect of teapot materials on the chemical compositions of oolong tea infusion[J]. Journal of the Science of Food and Agriculture, 2018, 98: 751-757. doi: 10.1002/jsfa.8522

[8] LIN Y, HU C, DING D, et al. The Compositions and pore structures of Benshanzhu Zisha ceramics[J]. Journal of Ceramic Science and Technology, 2021, 4: 1-8.

[9] 白秀莲. 夕雨红榴拆, 新秋绿芋肥——浅析紫砂"捷报丰收壶"[J]. 江苏陶瓷. 2020, 53(1): 85-86. https://www.cnki.com.cn/Article/CJFDTOTAL-JSTC202001057.htm

BAI X L. Xiyu Hongliu Chai, Xinqiu Lvyu Fei——the study of Zisha "Jiebao Fengshou teapot"[J]. Jiangsu Ceramics, 2020, 53(1): 85-86. https://www.cnki.com.cn/Article/CJFDTOTAL-JSTC202001057.htm

[10] 范国祥. 浅论紫砂泥及"五色土"的工艺特性[J]. 艺术品鉴, 2017(5): 454. https://www.cnki.com.cn/Article/CJFDTOTAL-YSPJ201705424.htm

FAN G X. Study of properties of the Zisha clay and "Five-Color clay"[J]. Appreciation, 2017(5): 454. https://www.cnki.com.cn/Article/CJFDTOTAL-YSPJ201705424.htm

[11] 范泽锋, 闵仲明, 杨伯军. 宜兴"五色土"基本特性探讨[J]. 中国陶瓷, 2010, 6: 55-58. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGTC201006017.htm

FAN Z F, MIN Z M, YANG B J. Discussion on characteristic of Yixing Five-Color clay[J]. China Ceramics, 2010, 6: 55-58. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGTC201006017.htm

[12] KAKALI G, PERRAKI T, TSIVILIS S, et al. Thermal treatment of kaolin: the effect of mineralogy on the pozzolanic activity[J]. Applied Clay Science, 2001, 20: 73-80. doi: 10.1016/S0169-1317(01)00040-0

[13] KAY A, CESAR I, GRATZEL M. New benchmark for water photooxidation by nanostructured alpha-Fe2O3 films[J]. Journal of the American Chemical Society, 2006, 128: 15714-15721. doi: 10.1021/ja064380l

[14] 王小莉, 郭俊刚, 马驰, 等. 一种伊利石仿独山玉的宝石学研究[J]. 矿产保护与利用, 2018(6): 70-76. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=6a966677-a431-431c-a21e-53d603aa0b68

WANG X L, GUO J G, MA C, et al. Study on the gemological characteristics of an Illite-imitated Dushan Jade[J]. Conservation and Utilization of Mineral Resources, 2018(6): 70-76. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=6a966677-a431-431c-a21e-53d603aa0b68

[15] MAGAGNIN D, SANTOS C M F D, WANDERLIND A, et al. Effect of kaolinite, illite and talc on the processing properties and mullite content of porcelain stoneware tiles[J]. Materials Science and Engineering A, 2014, 618: 533-539. doi: 10.1016/j.msea.2014.09.049

[16] CHIN C L, AHMAD Z A, SOW S S. Relationship between the thermal behaviour of the clays and their mineralogical and chemical composition: example of ipoh, kuala rompin and mersing (Malaysia)-sciencedirect[J]. Applied Clay Science, 2017, 143: 327-335. doi: 10.1016/j.clay.2017.03.037

[17] AZIZ M A, OTHMAN M, HASHIM N A, et al. Fabrication and characterization of mullite ceramic hollow fiber membrane from natural occurring ball clay[J]. Applied Clay Science, 2019, 177: 51-62. doi: 10.1016/j.clay.2019.05.003

[18] SANCHEZ-SOTO P J, PEREZ-RODRIGUEZ J L. Influence of grinding in pyrophyllite-mullite thermal transformation assessed by 29Si and 27Al MAS NMR spectroscopies[J]. Chemistry of Materials, 1997, 9: 677-684. doi: 10.1021/cm960224+

[19] MCCONVILLE C J, LEE W E. Microstructural development on firing illite and smectite clays compared with that in kaolinite[J]. Journal of the American Ceramic Society, 2005, 88: 2267-2276. doi: 10.1111/j.1551-2916.2005.00390.x

[20] CHMIELOVA M, MARTINEC P, WEISS Z, et al. Almandine-pyrope-grossular garnets: a method for estimating their composition using X-ray powder diffraction patterns[J]. European Journal of Mineralogy, 1997, 9: 403-409. doi: 10.1127/ejm/9/2/0403

[21] LIU B, SHIOYAMA H, AKITA T, et al. Metal-organic framework as a template for porous carbon synthesis[J]. Journal of the American Chemical Society, 2008, 130: 5390-5391. doi: 10.1021/ja7106146

[22] FUKASAWA T, DENG Z Y, ANDO M. Synthesis of porous silicon nitride with unidirectionally aligned channels using freeze-drying process[J]. Journal of the American Ceramic Society, 2002, 85: 2151-2155. doi: 10.1111/j.1151-2916.2002.tb00426.x

[23] LAO X B, XU X Y, JIANG W H, et al. Influences of impurities and mineralogical structure of different kaolin minerals on thermal properties of cordierite ceramics for high-temperature thermal storage[J]. Applied Clay Science, 2020, 187: 105485. doi: 10.1016/j.clay.2020.105485

[24] NASKAR M K, CHATTERJEE M. A novel process for the synthesis of cordierite (Mg2Al4Si5O18) powders from rice husk ash and other sources of silica and their comparative study[J]. Journal of the European Ceramic Society, 2004, 24: 3499-3508. doi: 10.1016/j.jeurceramsoc.2003.11.029

[25] ZHU P, WANG L Y, HONG D, et al. A study of cordierite ceramics synthesis from serpentine tailing and kaolin tailing[J]. Science of Sintering, 2012, 44: 129-134. doi: 10.2298/SOS1202129Z

[26] 董洋. 水中溶解气体CO2、CH4和13CH4原位光谱分析仪的研制[D]. 合肥: 中国科学技术大学, 2020.

DONG Y. In-situ spectroscopic gas analyzer for dissolved CH4, CO2 and 13CH4 in water[D]. Hefei: University of Science and Technology of China, 2020.

[27] 李想. 海水关键溶解气体高灵敏激光原位分析方法研究[D]. 合肥: 中国科学技术大学, 2020.

LI X. Dissolved gases measurements in seawater using high sensitivity laser spectrometer technology[D]. Hefei: University of Science and Technology of China, 2020.

[28] DYRDA K M, GRINSCHEK F, RABSCH G, et al. Development of a microsieve based micro contactor for gas/liquid phase separation[J]. Separation and Purification Technology, 2019, 220: 238-249. doi: 10.1016/j.seppur.2019.03.016

[29] 石超, 陈步欣. 新型高效节能软基加固设备施工方法[J]. 节能与环保, 2021, 4: 59-60. https://www.cnki.com.cn/Article/CJFDTOTAL-HBJC202104030.htm

SHI C, CHEN B X. Novel energy-efficient method to soft foundation reinforcement[J]. Energy Saving and Environment Protection, 2021, 4: 59-60. https://www.cnki.com.cn/Article/CJFDTOTAL-HBJC202104030.htm

[30] 董海伟, 宋旭龙, 王劼. 水气分离无砂法与传统真空预压技术的研究[J]. 海河水利, 2020(6): 38-40. https://www.cnki.com.cn/Article/CJFDTOTAL-HHSL202006018.htm

DONG H W, SONG X L, WANG J. Study of sand-free gas-liquid separation and traditional vacuum preloading[J]. Haihe Hydraulic Engineering, 2020(6): 38-40. https://www.cnki.com.cn/Article/CJFDTOTAL-HHSL202006018.htm

[31] BHATTACHARYYA T, PAL D K, DESHPANDE S B. On kaolinitic and mixed mineralogy classes of shrink-swell soils[J]. Australian Journal of Soil Research, 1997, 35(6): 1245-1252. doi: 10.1071/S96115

[32] ROBEL I, SUBRAMANIAN V, KUNO M, et al. Quantum dot solar cells harvesting light energy with CdSe nanocrystals molecularly linked to mesoscopic TiO2 films[J]. Journal of the American Chemical Society, 2006, 128(7): 2385-2393. doi: 10.1021/ja056494n

[33] 张建琳. 陶瓷膜分离与MnO2催化臭氧氧化耦合技术对污水深度处理的研究[D]. 大连: 大连理工大学, 2017.

ZHANG J L. Study on advanced wastewater treatment by ceramic membrane separation coupled with MnO2catalytic ozonation[D]. Dalian: Dalian University of Technology, 2017.

[34] HOU W, CRONIN S B. A Review of surface plasmon resonance-enhanced photocatalysis[J]. Advanced Functional Materials, 2013, 23(13): 1612-1619. doi: 10.1002/adfm.201202148

-

下载:

下载: