An experimental study of dynamic parameters of unit cell of deep mixed column-reinforced soft clay under dynamic loading

-

摘要:

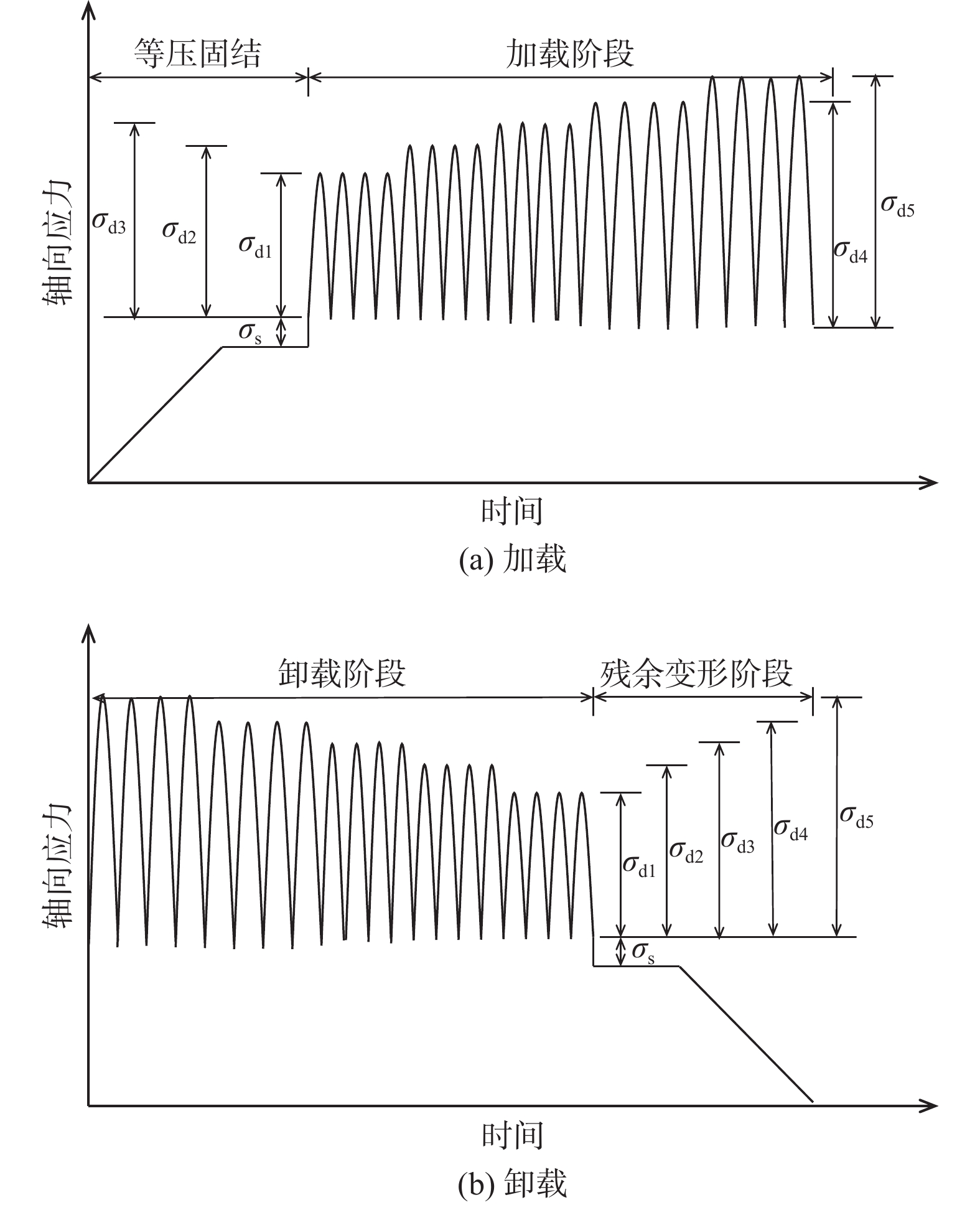

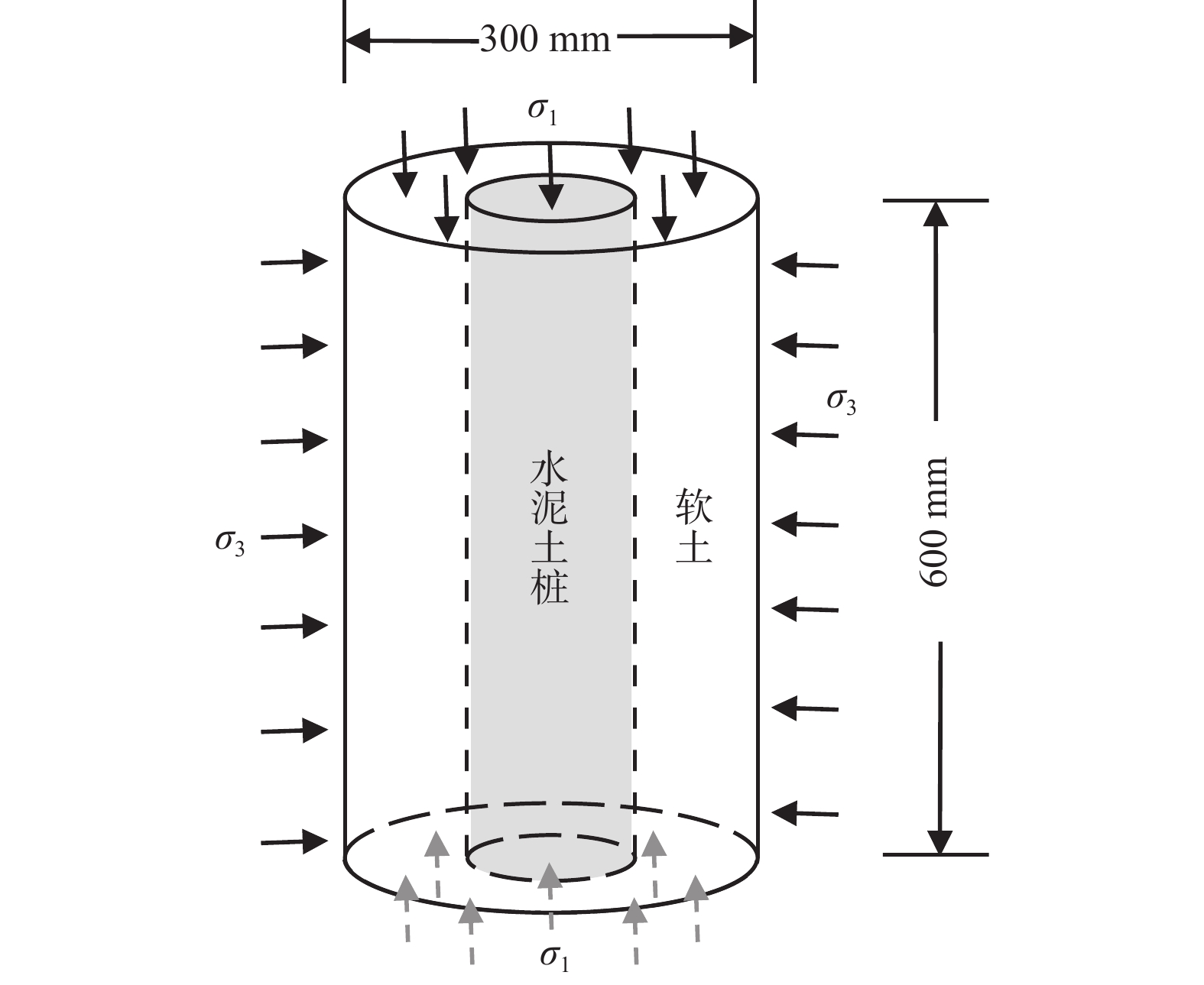

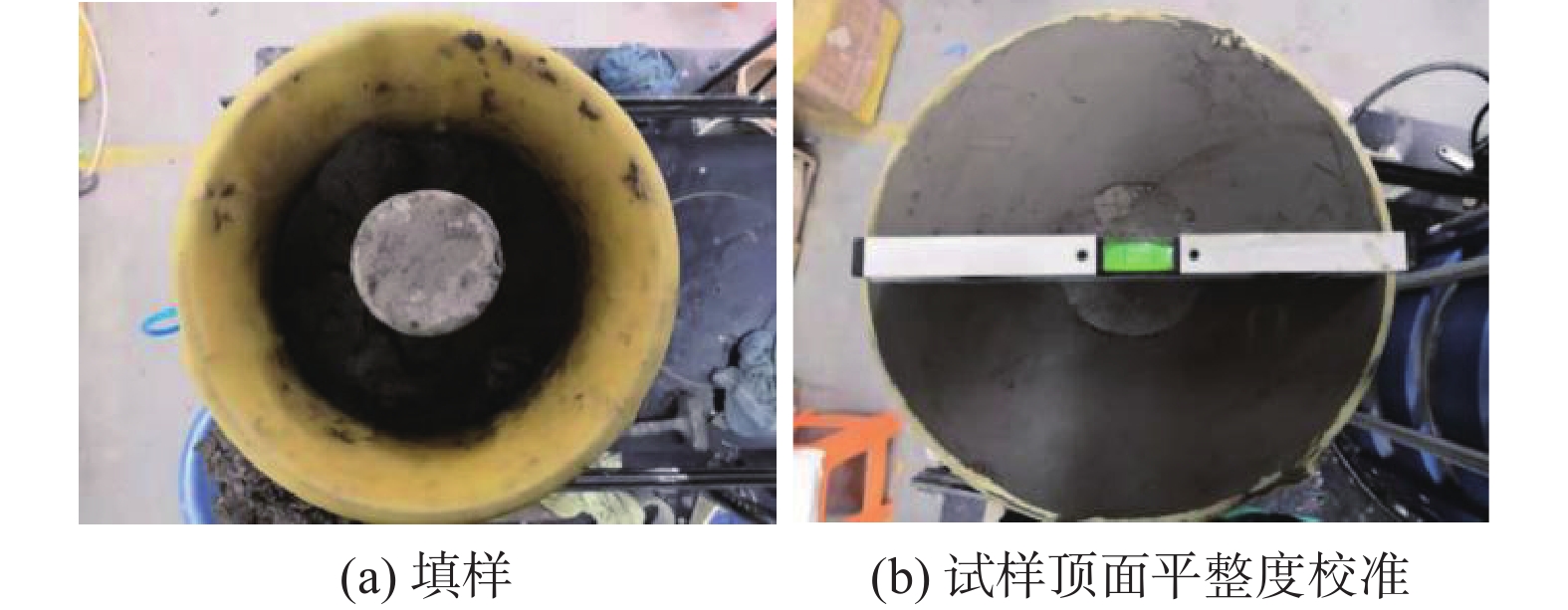

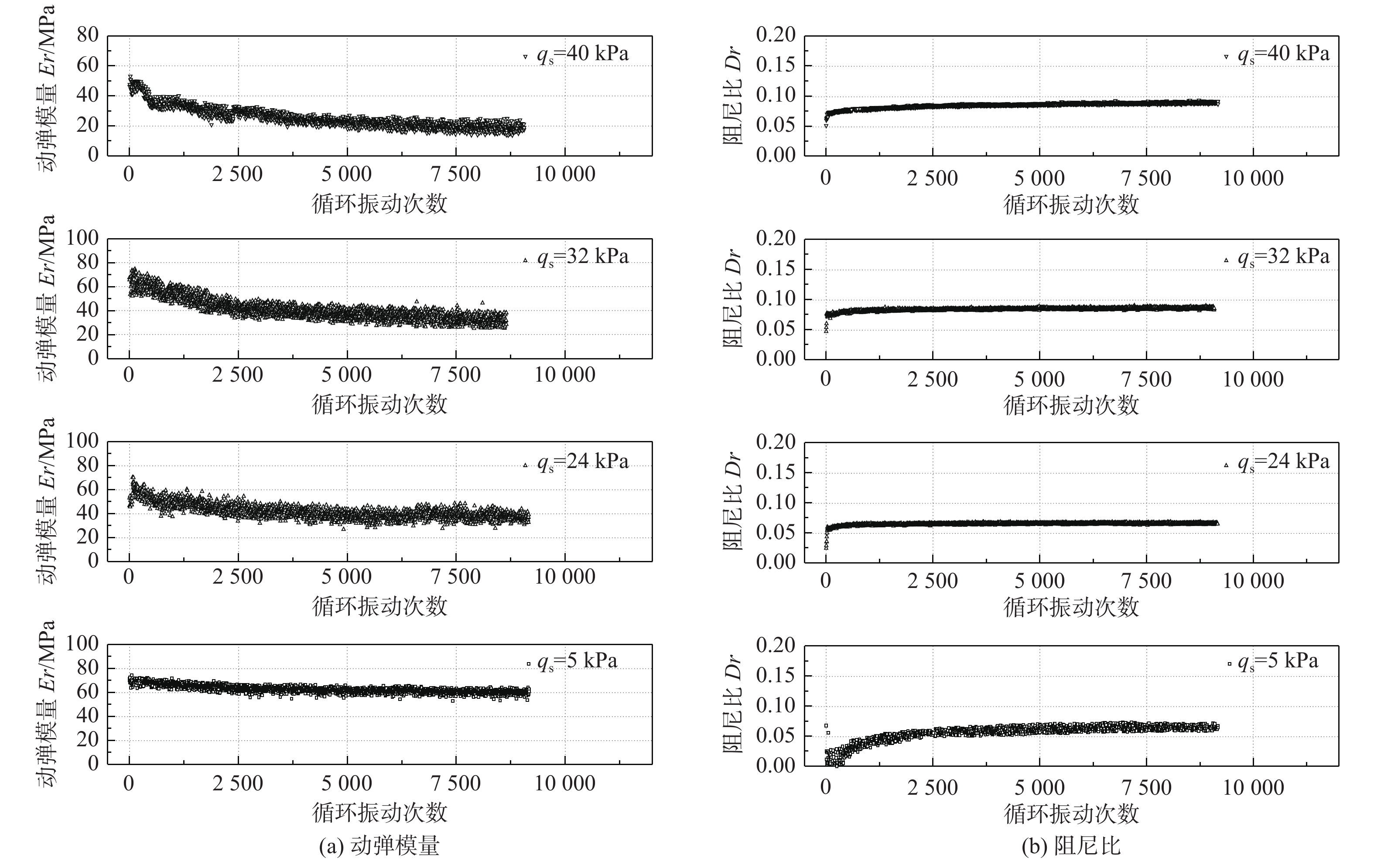

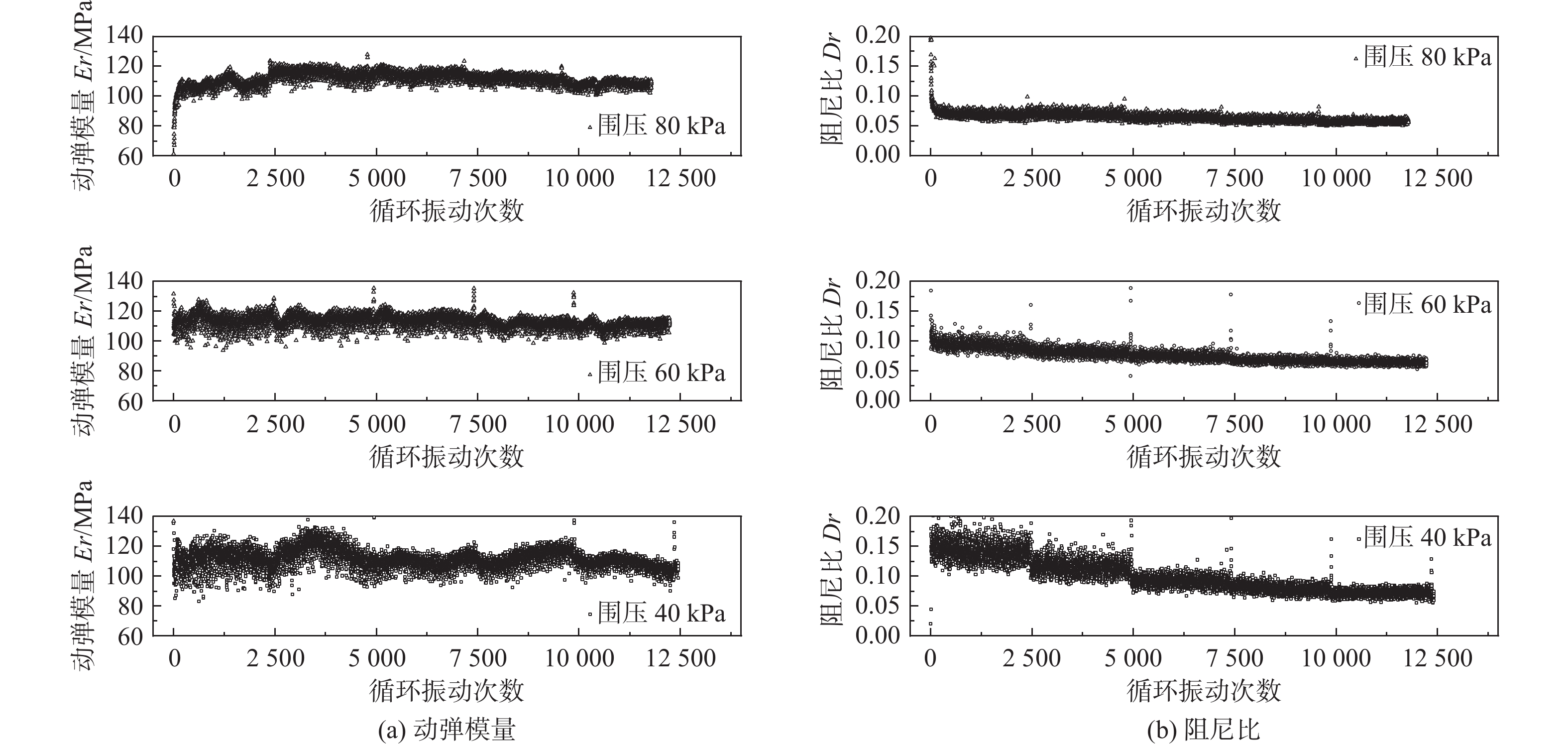

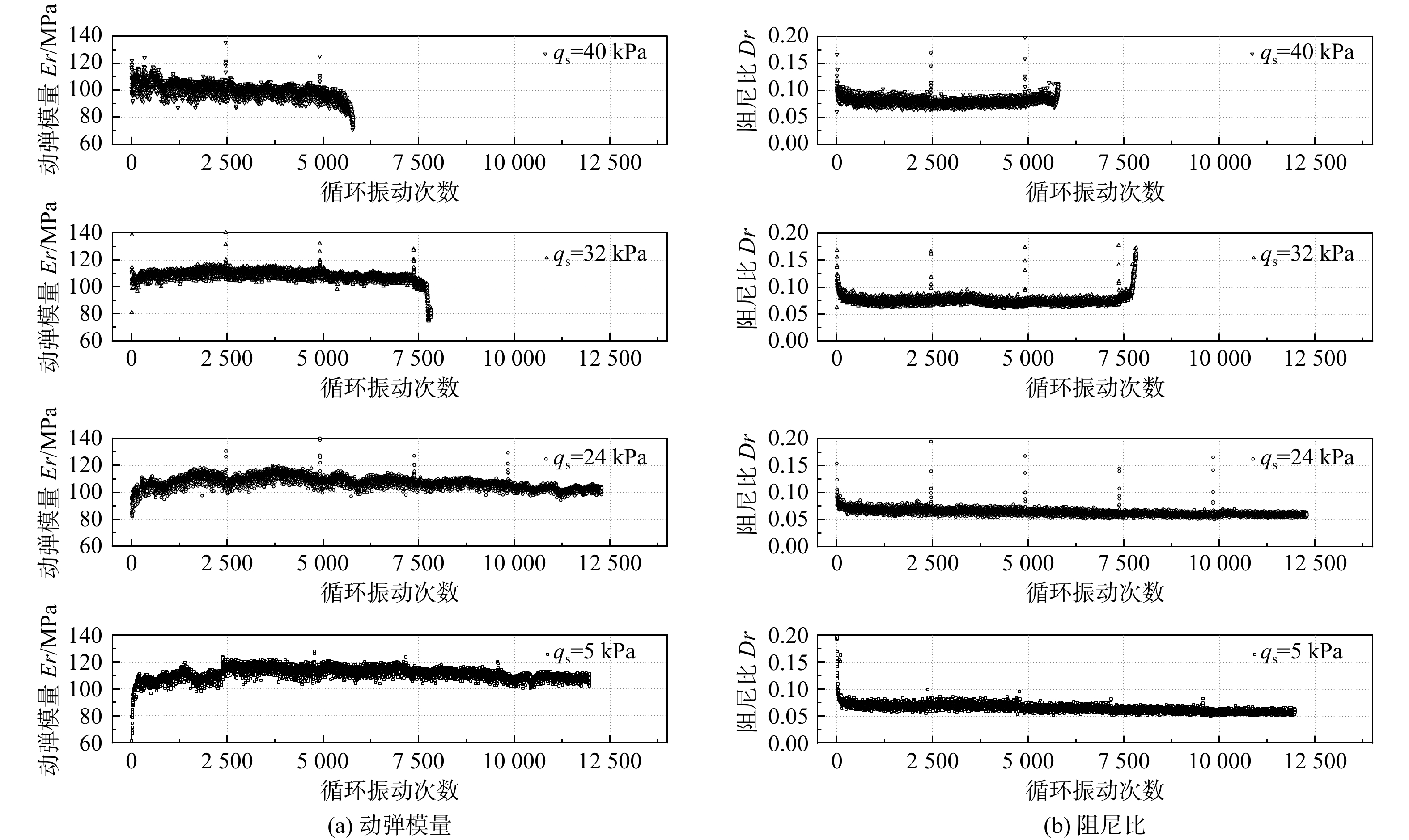

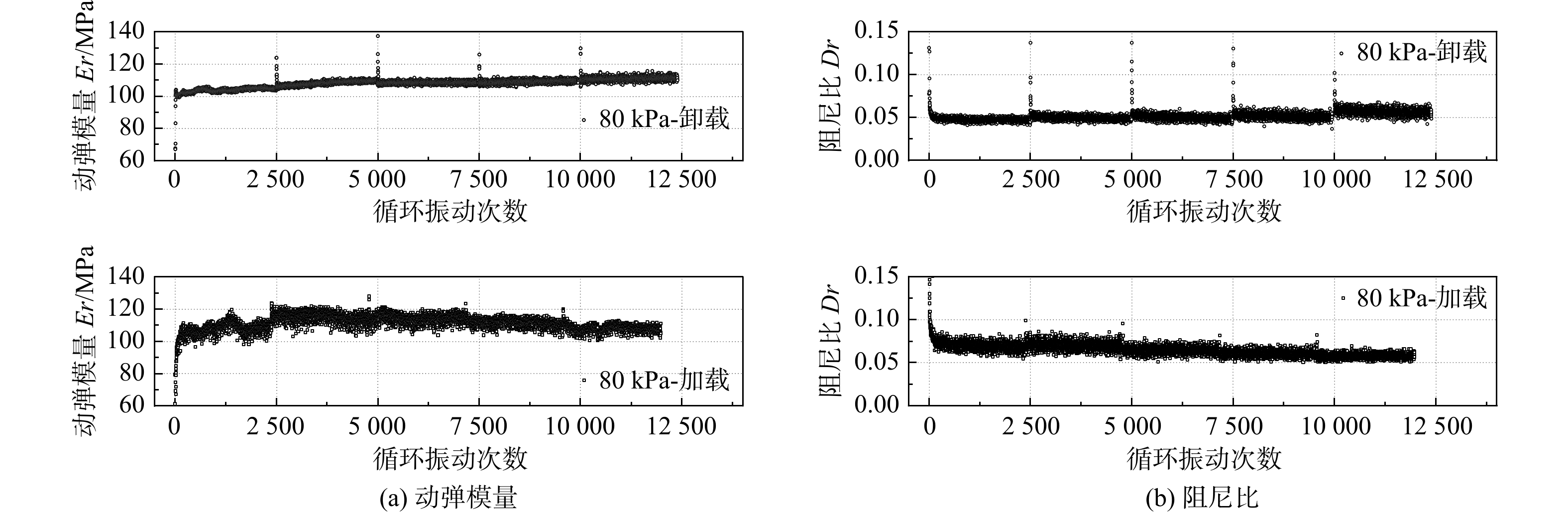

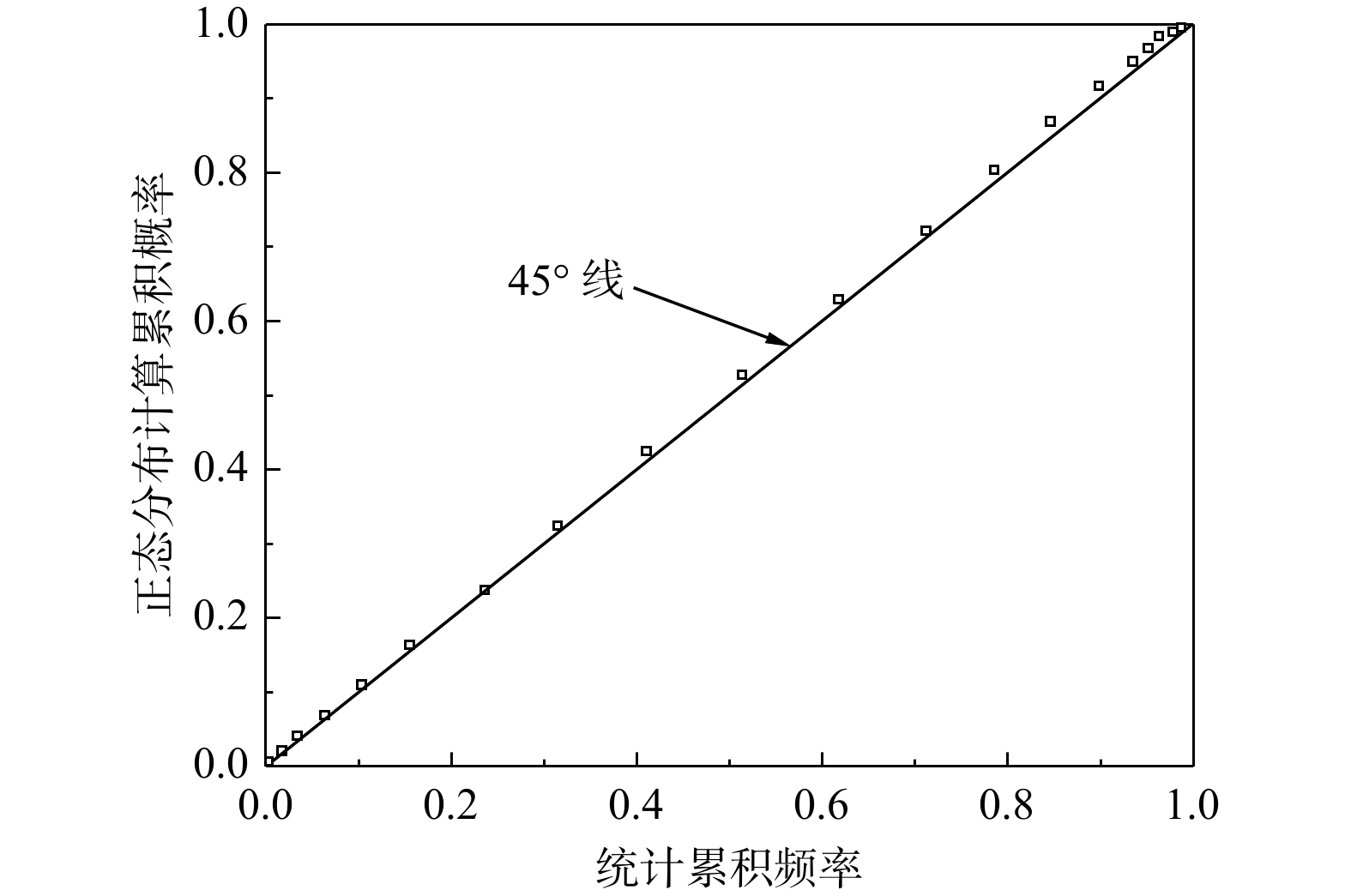

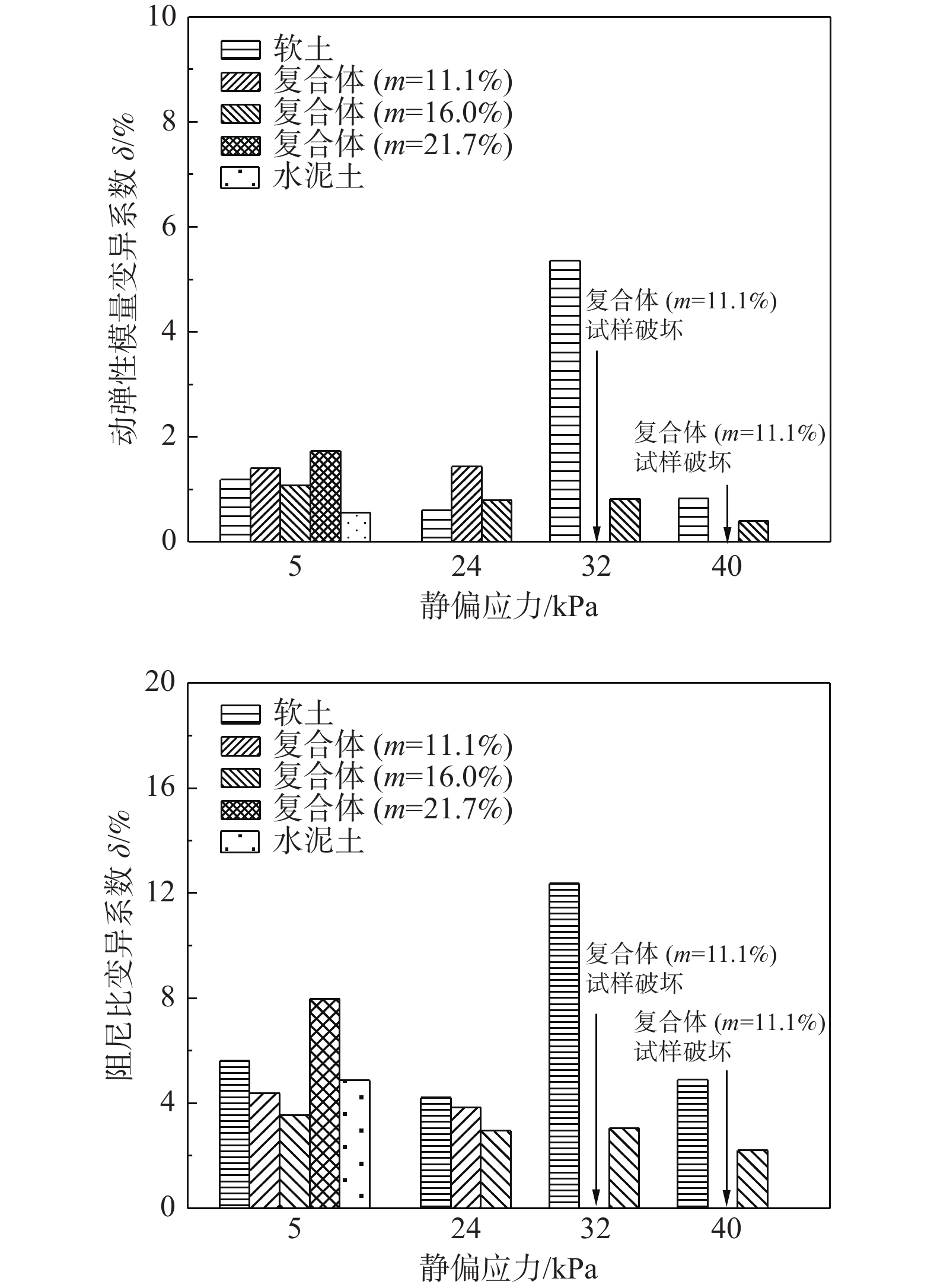

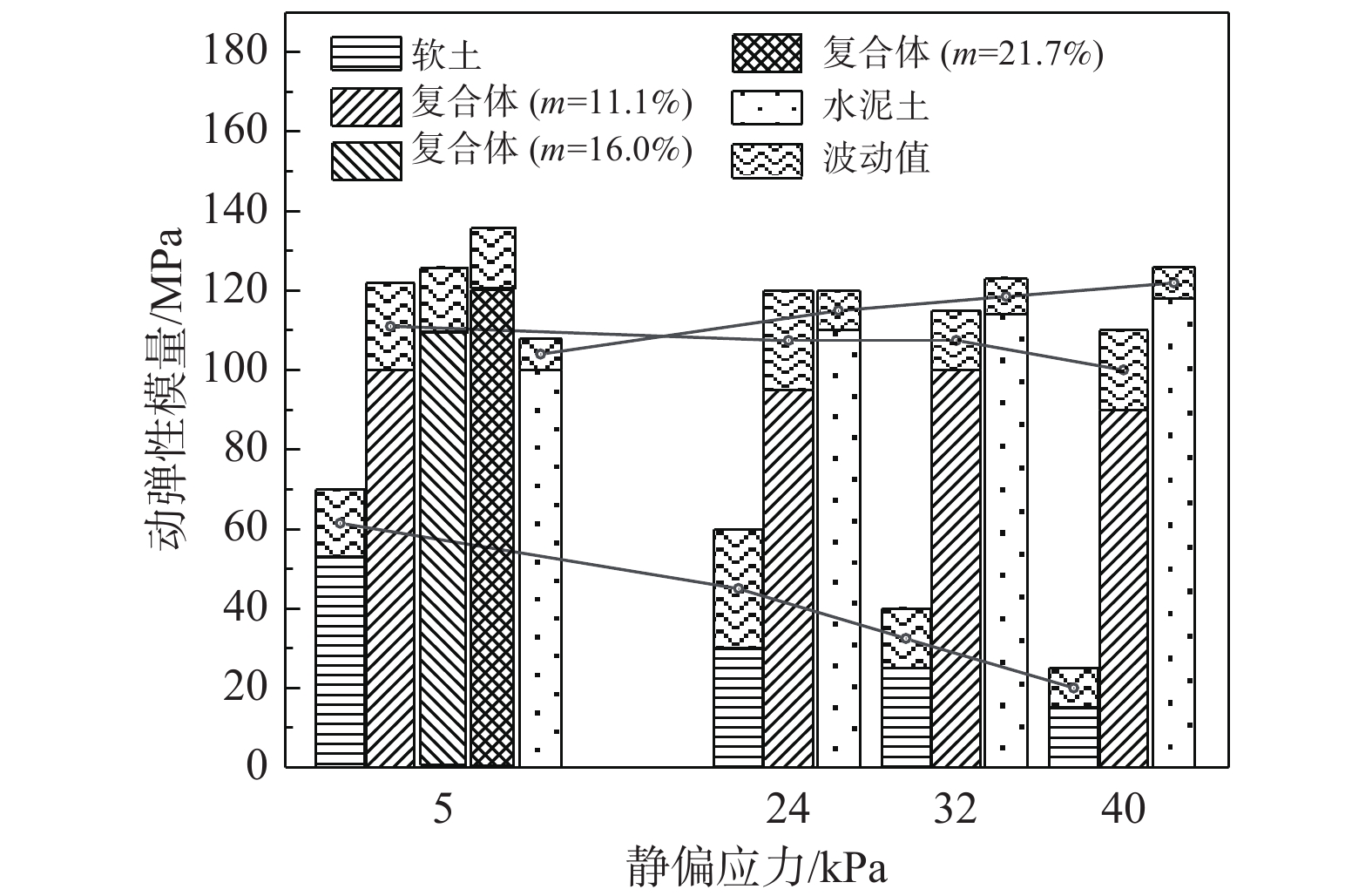

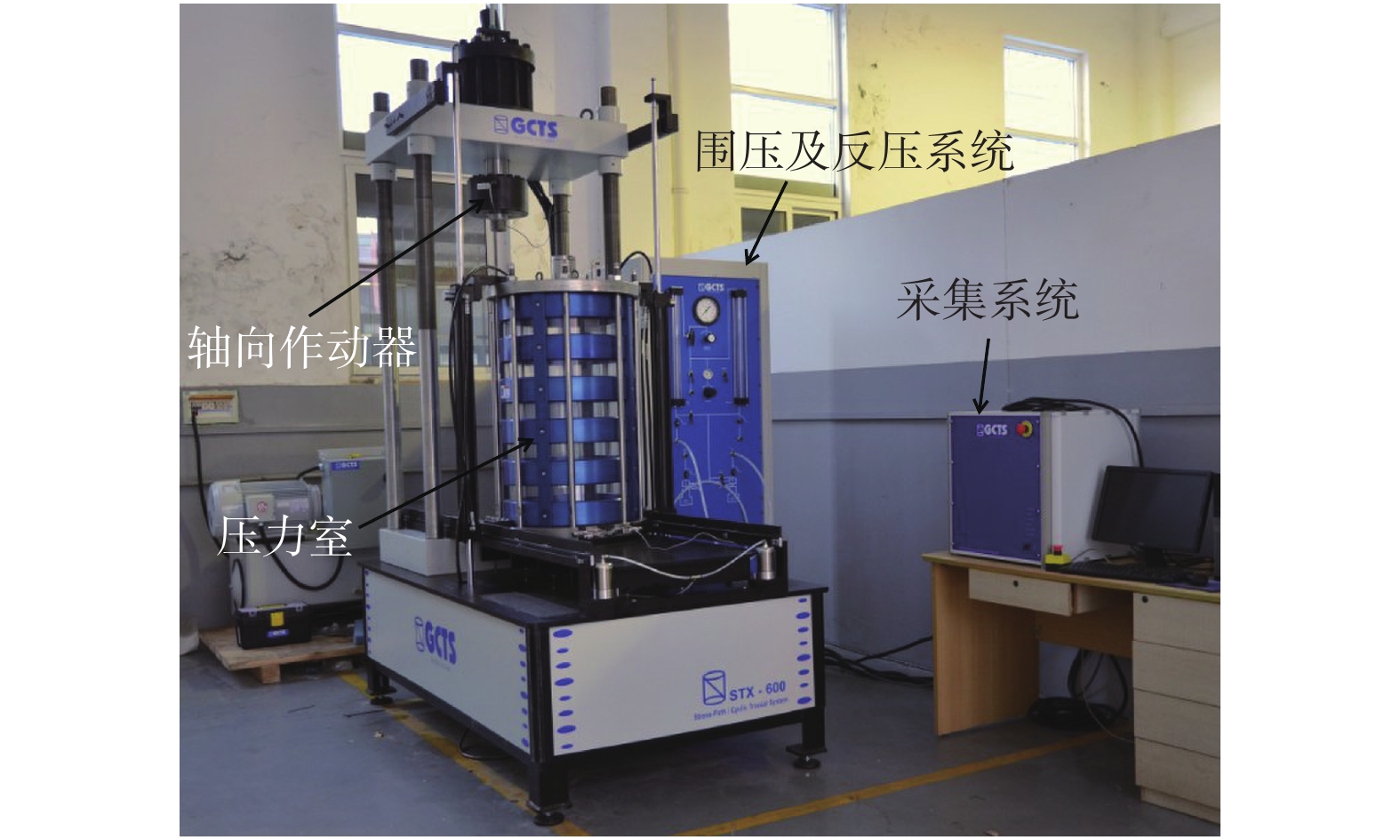

水泥土桩被广泛应用于软土路基加固工程中。然而,人们对水泥桩与桩间土形成的加固体的动力特性尚缺乏认识,无法合理评价水泥土桩复合地基的长期性能。基于此,本文开展水泥土桩复合体大型动三轴试验,研究围压、静偏应力、置换率及分级加卸载路径对其动力参数的影响,并分析了动力参数的波动性。试验结果表明:随着静偏应力增加,复合单元体的动弹模量减小,阻尼比增大,临界动应力比减小。随着置换率增加,动弹模量略有增加,阻尼比略有减小。逐级卸载造成复合单元体的动力参数劣化。阻尼比具有较强的波动性,复合单元体阻尼比的变异系数是动弹模量的2.8~7.0倍。相比于软土,复合体动弹模量提高了2~6倍,静偏应力越大,提高系数越大。

Abstract:Composite soil with deep mixed column is widely used in strengthening soft soil subgrade. However, there is still a lack of understanding the dynamic characteristics of composite soil with deep mixed column and evaluating unreasonably the long-term performance of composite soil with deep mixed column. Based on above, this study conducted a series of large-scale triaxial test to investigate the influence factors of static deviator stress, replacement ratio and incremental loading/unloading on the dynamic parameters of unit cell of deep mixed column-reinforced soft soil. The results show that with the increase of the static deviator stress, the dynamic elastic modulus increases, the damping ratio decreases, and the critical dynamic stress ratio decreases. With the increase of the area replacement ratio, the dynamic elastic modulus increases slightly and the damping ratio decreases slightly. The staged unloading can deteriorate the dynamic properties of the unit cell. The damping ratio is of strong volatility, and the variation coefficient of damping ratio is 2.8 to 7.0 times that of the dynamic elastic modulus. The dynamic elastic modulus of the unit cell of the composite soil is 2 to 6 times that of the soft soil, and the improvement factor increases with the increase of the static deviator stress.

-

-

表 1 试验方案

Table 1. Test scheme

项目 试验编号 围压

/kPa动应力比 置换率

/%静偏应力

/kPa水泥土桩复合体

(大型动三轴试验)DC1 80 0.25~0.45 11.1 5 DC2 80 0.25~0.45 11.1 24 DC3 80 0.25~0.45 11.1 32 DC4 80 0.25~0.45 11.1 40 DC1 80 0.25~0.45 11.1 5 DC5 80 0.25~0.45 16.0 5 DC6 80 0.25~0.45 21.7 5 DC7 40 0.25~0.45 11.1 5 DC8 60 0.25~0.45 11.1 5 DC1 80 0.25~0.45 11.1 5 DC9 80 0.45~0.25 11.1 5 水泥土(动三轴试验) DC10 80 0.25~0.45 100 5 DC11 80 0.25~0.45 100 24 DC12 80 0.25~0.45 100 32 DC13 80 0.25~0.45 100 40 软土(动三轴试验) DC14 80 0.15 0 5 DC15 80 0.15 0 24 DC16 80 0.15 0 32 DC17 80 0.15 0 40 表 2 不同材料的动力参数取值范围

Table 2. Value ranges of dynamic elastic modulus of different materials

试验材料 试验内容 动力参数 动弹性模量Er/MPa 阻尼比Dr 软土 静偏应力−5kPa 53 ~ 70 0.056 ~ 0.070 静偏应力−24kPa 30 ~ 60 0.064 ~ 0.068 静偏应力−32kPa 25 ~ 455 0.084 ~ 0.090 静偏应力−40kPa 15 ~ 25 0.086 ~ 0.093 复合体

m=11.1%静偏应力−5kPa 100 ~ 22 0.050 ~ 0.079 静偏应力−24kPa 95 ~ 120 0.056 ~ 0.075 静偏应力−32kPa 100 ~ 115 0.062 ~ 0.085 静偏应力−40kPa 90 ~ 110 0.065 ~ 0.100 复合体

m=16.0%静偏应力−5kPa 110 ~ 125 0.052 ~ 0.075 复合体

m=21.7%静偏应力−5kPa 120 ~ 135 0.027 ~ 0.059 水泥土 静偏应力−5kPa 100 ~ 108 0.032 ~ 0.075 静偏应力−24kPa 110 ~ 120 0.039 ~ 0.069 静偏应力−32kPa 114 ~ 123 0.049 ~ 0.054 静偏应力−40kPa 118 ~ 126 0.040 ~ 0.055 -

[1] 黄春霞, 韩爱民, 隋志龙, 等. 水泥土搅拌桩复合地基承载力的确定[J]. 水文地质工程地质,2009,36(3):99 − 102. [HUANG Chunxia, HAN Aimin, SUI Zhilong, et al. Determination of bearing capacity for composite foundation of cement-soil mixing piles[J]. Hydrogeology & Engineering Geology,2009,36(3):99 − 102. (in Chinese with English abstract) doi: 10.3969/j.issn.1000-3665.2009.03.021

[2] 叶观宝, 叶书麟. 水泥土搅拌桩加固软基的试验研究[J]. 同济大学学报(自然科学版),1995,23(3):270 − 275. [YE Guanbao, YE Shulin. Field study of improved soft soil by cement-soil mixed piles[J]. Journal of Tongji University (Natural Science),1995,23(3):270 − 275. (in Chinese with English abstract)

[3] 刘松玉, 朱志铎, 席培胜, 等. 钉形搅拌桩与常规搅拌桩加固软土地基的对比研究[J]. 岩土工程学报,2009,31(7):1059 − 1068. [LIU Songyu, ZHU Zhiduo, XI Peisheng, et al. Comparison between T-shaped deep mixing method and traditional deep mixing method for soft ground improvement[J]. Chinese Journal of Geotechnical Engineering,2009,31(7):1059 − 1068. (in Chinese with English abstract) doi: 10.3321/j.issn:1000-4548.2009.07.012

[4] 叶观宝, 蔡永生, 张振. 加芯水泥土桩复合地基桩土应力比计算方法研究[J]. 岩土力学,2016,37(3):672 − 678. [YE Guanbao, CAI Yongsheng, ZHANG Zhen. Research on calculation of pile-soil stress ratio for composite foundation reinforced by stiffened deep mixed piles[J]. Rock and Soil Mechanics,2016,37(3):672 − 678. (in Chinese with English abstract)

[5] 白顺果, 侯永峰, 张鸿儒. 循环荷载作用下水泥土桩复合地基的临界循环应力比和永久变形分析[J]. 岩土工程学报,2006,28(1):84 − 87. [BAI Shunguo, HOU Yongfeng, ZHANG Hongru. Analysis on critical cyclic stress ratio and permanent deformation of composite foundation improved by cement-soil piles under cyclic loading[J]. Chinese Journal of Geotechnical Engineering,2006,28(1):84 − 87. (in Chinese with English abstract) doi: 10.3321/j.issn:1000-4548.2006.01.017

[6] KIM A R, CHANG I, CHO G C, et al. Strength and dynamic properties of cement-mixed Korean marine clays[J]. KSCE Journal of Civil Engineering,2018,22(4):1150 − 1161. doi: 10.1007/s12205-017-1686-3

[7] LIU F Y, ZHU K, HU X Q, et al. Experimental simple shear study of composite soil with cemented soil core[J]. Marine Georesources & Geotechnology,2019,37(8):960 − 971. DOI:10.1080/1064119X.2018.1513614.

[8] CAI Y Q, LIANG X. Dynamic properties of composite cemented clay[J]. Journal of Zhejiang University Science,2004,5(3):309 − 316. doi: 10.1631/jzus.2004.0309

[9] 曾国红, 白晓红, 张卫平, 等. 增强体复合土动弹性模量影响因素的研究[J]. 水利学报,2009,40(5):576 − 582. [ZENG Guohong, BAI Xiaohong, ZHANG Weiping, et al. Experimental study on factors influencing the dynamic elastic modulus of composite soil with different reinforcements[J]. Journal of Hydraulic Engineering,2009,40(5):576 − 582. (in Chinese with English abstract) doi: 10.3321/j.issn:0559-9350.2009.05.010

[10] 吕程伟. 水泥土动力特性的共振柱试验研究[D]. 武汉: 湖北工业大学, 2016.

LYU Chengwei. Resonant column experimental study on dynamic properties of cemented clay[D]. Wuhan: Hubei University of Technology, 2016. (in Chinese with English abstract)

[11] KAZEMIAN S, HUAT B B K, MOAYEDI H. Undrained shear characteristics of tropical peat reinforced with cement stabilized soil column[J]. Geotechnical and Geological Engineering,2012,30(4):753 − 759. doi: 10.1007/s10706-012-9492-7

[12] CAI Y, XU L R, LIU W Z, et al. Field Test Study on the dynamic response of the cement-improved expansive soil subgrade of a heavy-haul railway[J]. Soil Dynamics and Earthquake Engineering,2020,128:105878. doi: 10.1016/j.soildyn.2019.105878

[13] CHAI J C, SHRESTHA S, HINO T. Failure of an embankment on soil-cement column–improved clay deposit: investigation and analysis[J]. Journal of Geotechnical and Geoenvironmental Engineering,2019,145(9):05019006. doi: 10.1061/(ASCE)GT.1943-5606.0002118

[14] 温日琨, 王常晶, 陈云敏. 交通荷载引起的静偏应力对饱和软粘土变形影响[J]. 岩土力学,2009,30(增刊2):119 − 122. [WEN Rikun, WANG Changjing, CHEN Yunmin. Effect of traffic loading induced static deviator stress on deformation of saturated soft clay[J]. Rock and Soil Mechanics,2009,30(Sup2):119 − 122. (in Chinese with English abstract)

[15] HYODO M, YASUHARA K. Analytical procedure for evaluation pore water pressure and deformation of saturated clay ground subjected to traffic loads[J]. Numerical Methods In Geomechanics,1988,6(1):653 − 658.

[16] ZHUANG Y, LI S B. Three-dimensional finite element analysis of arching in a piled embankment under traffic loading[J]. Arabian Journal of Geosciences,2015,8(10):7751 − 7762. doi: 10.1007/s12517-014-1748-5

[17] PHAM H V, DIAS D, DUDCHENKO A. 3D modeling of geosynthetic-reinforced pile-supported embankment under cyclic loading[J]. Geosynthetics International,2020,27(2):157 − 169. doi: 10.1680/jgein.18.00039

-

下载:

下载: