Research on Mechanical Properties and Hydration Characteristics of Pyrite Tailings Foam Concrete

-

摘要:

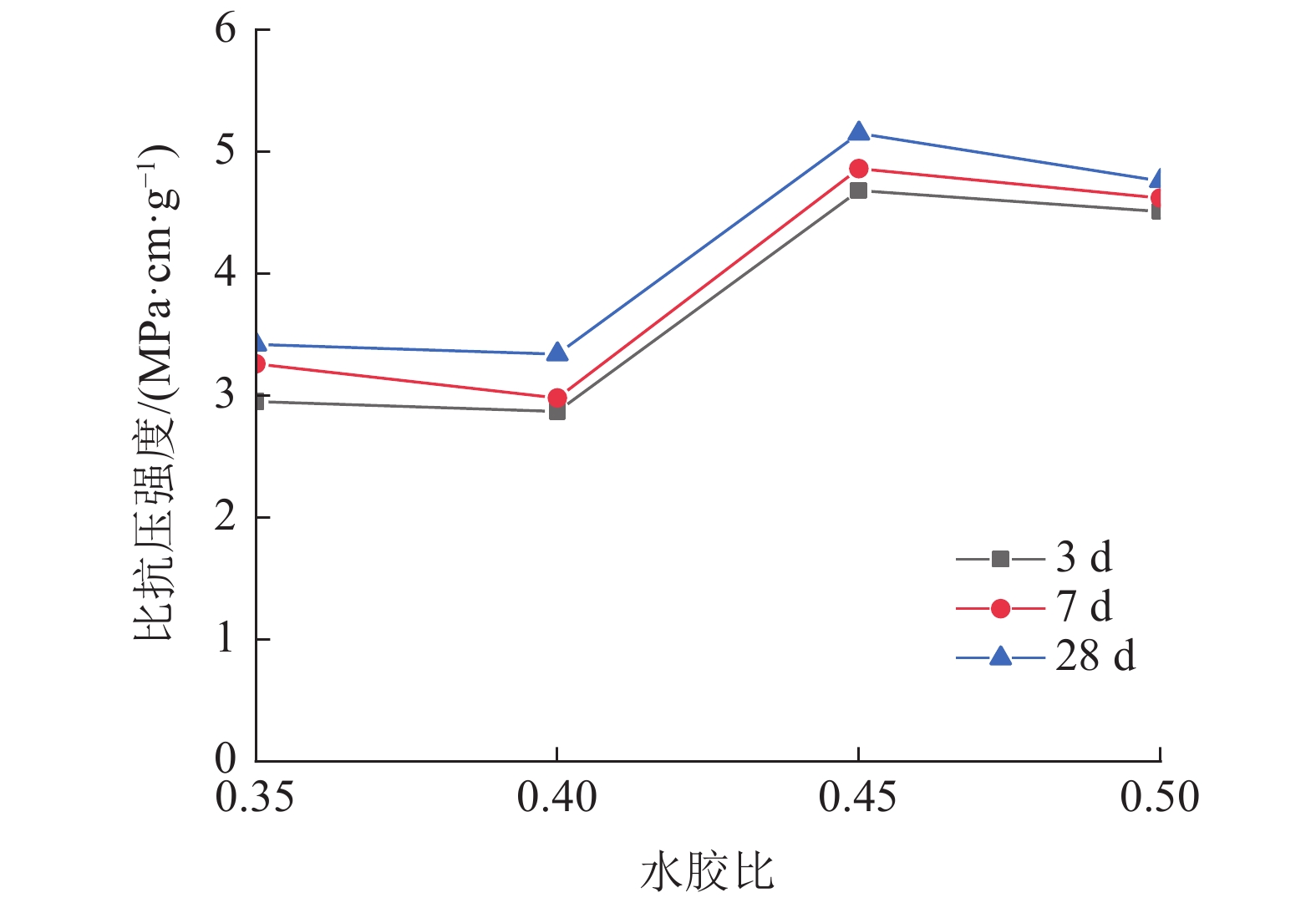

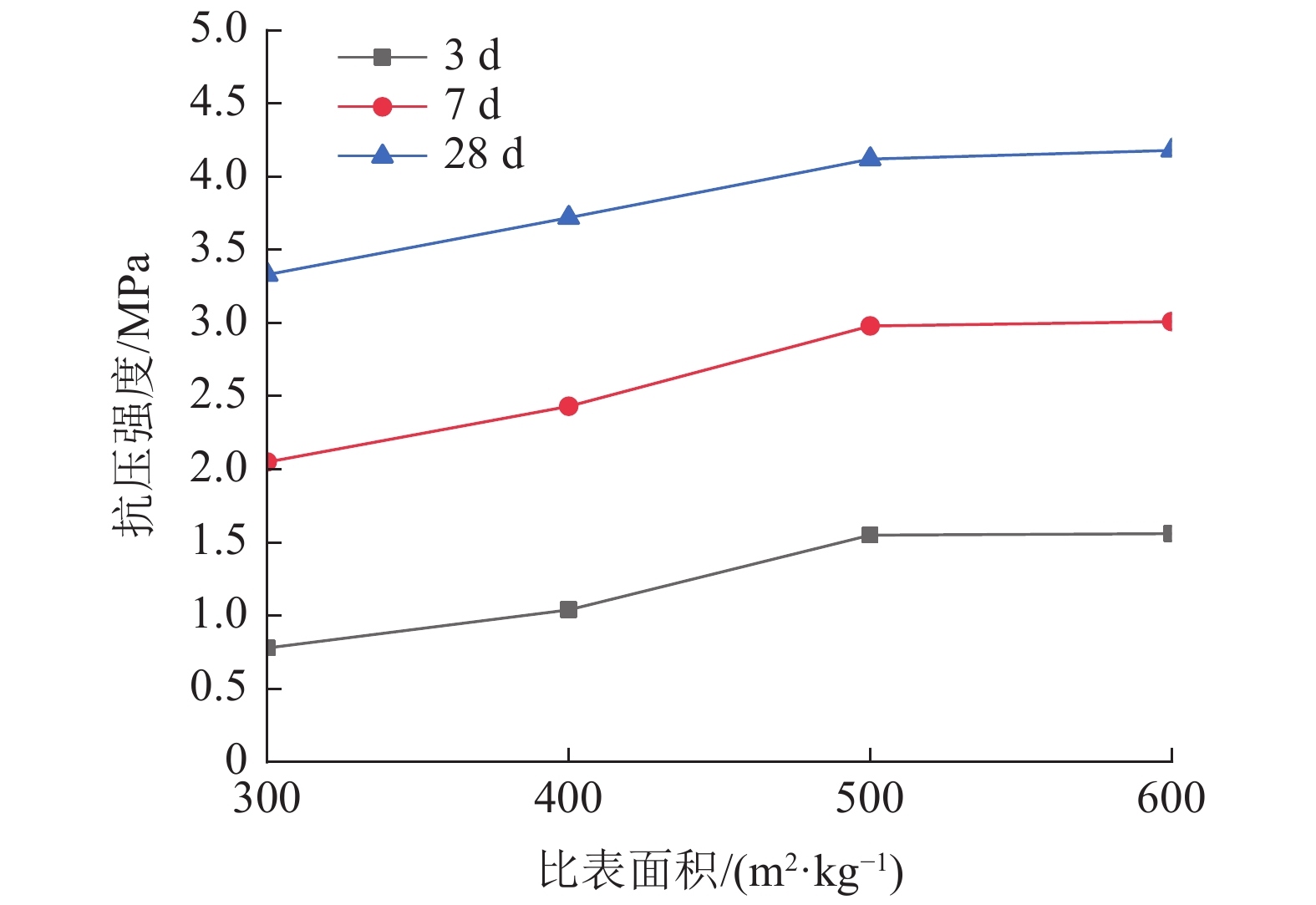

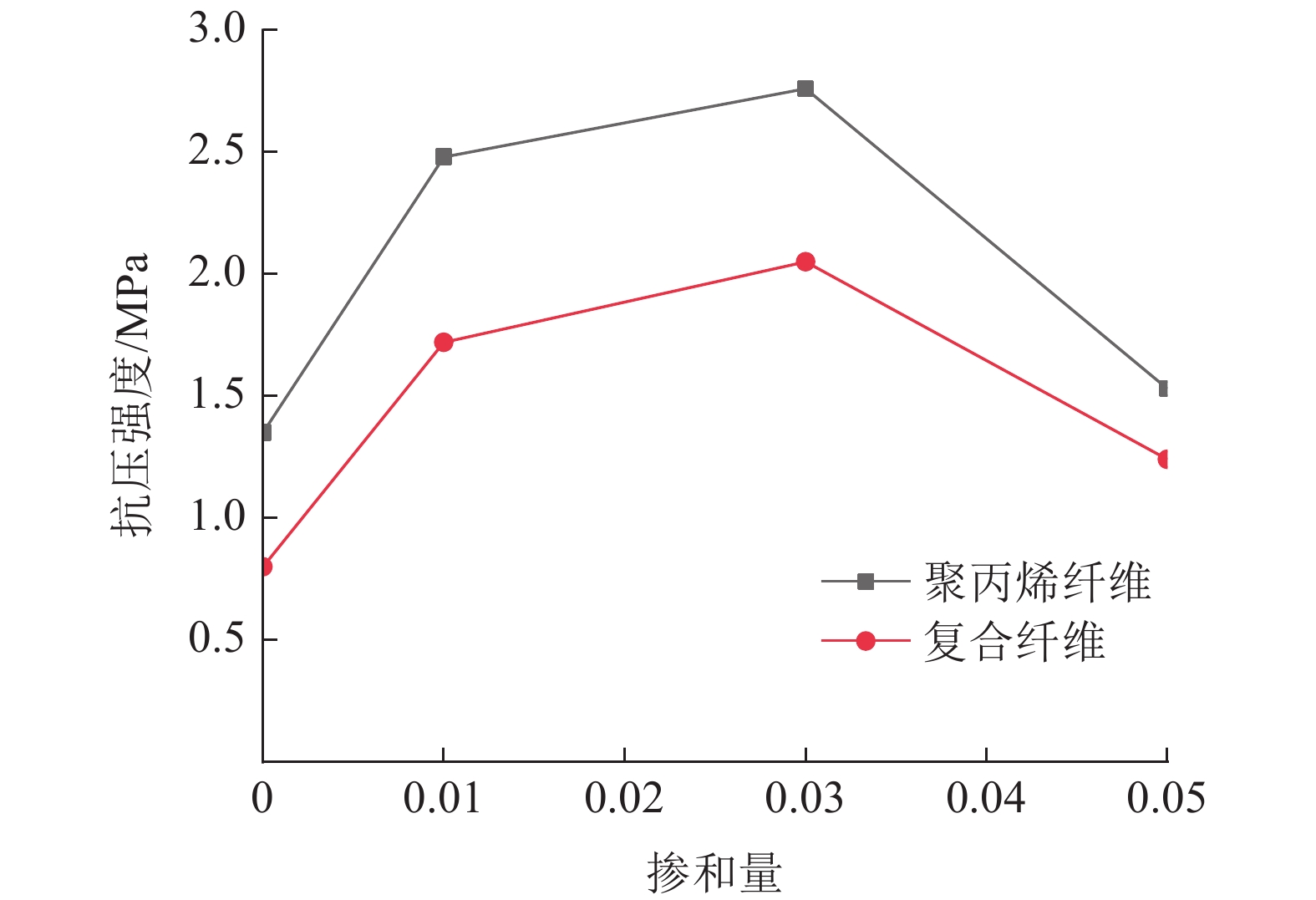

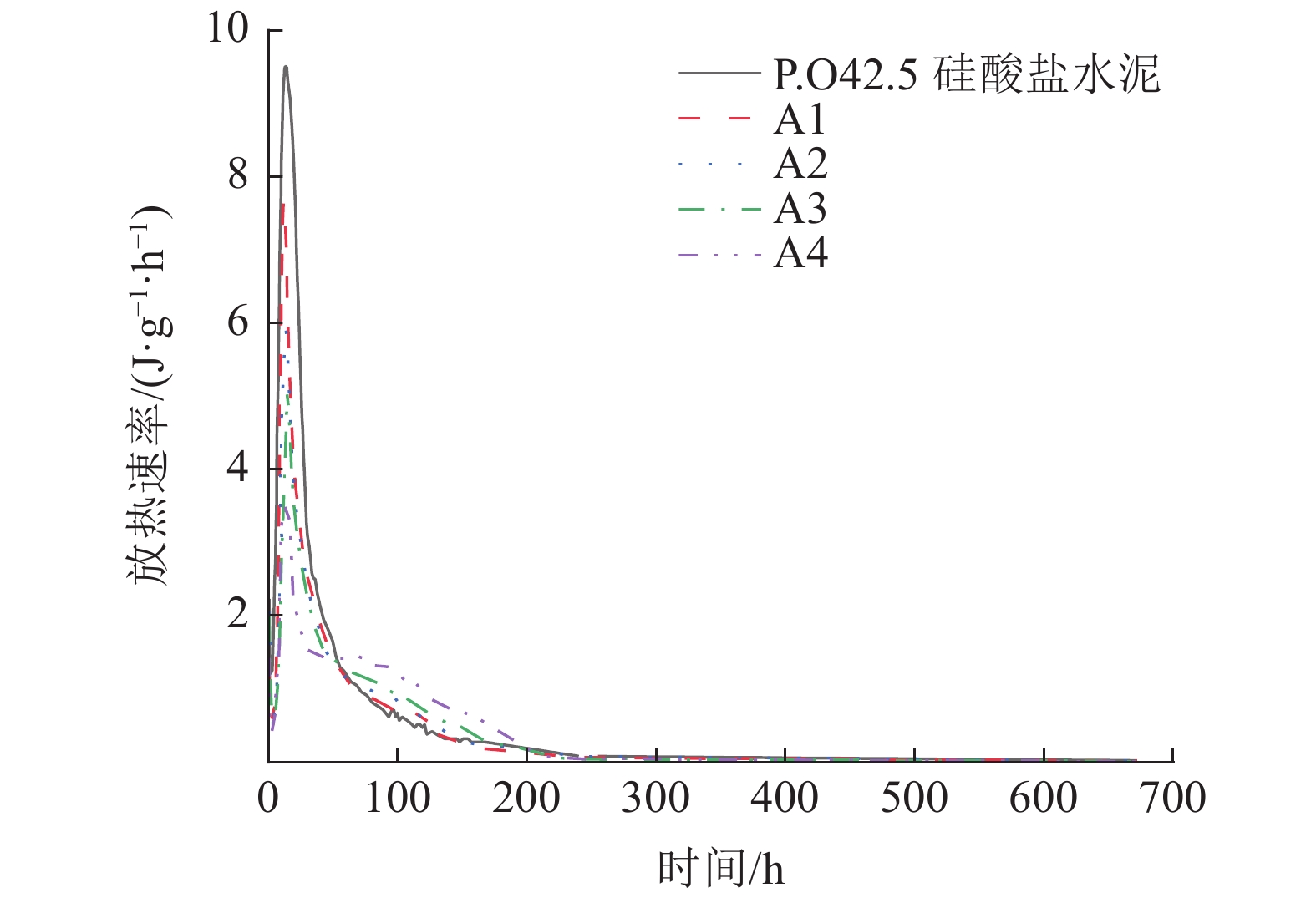

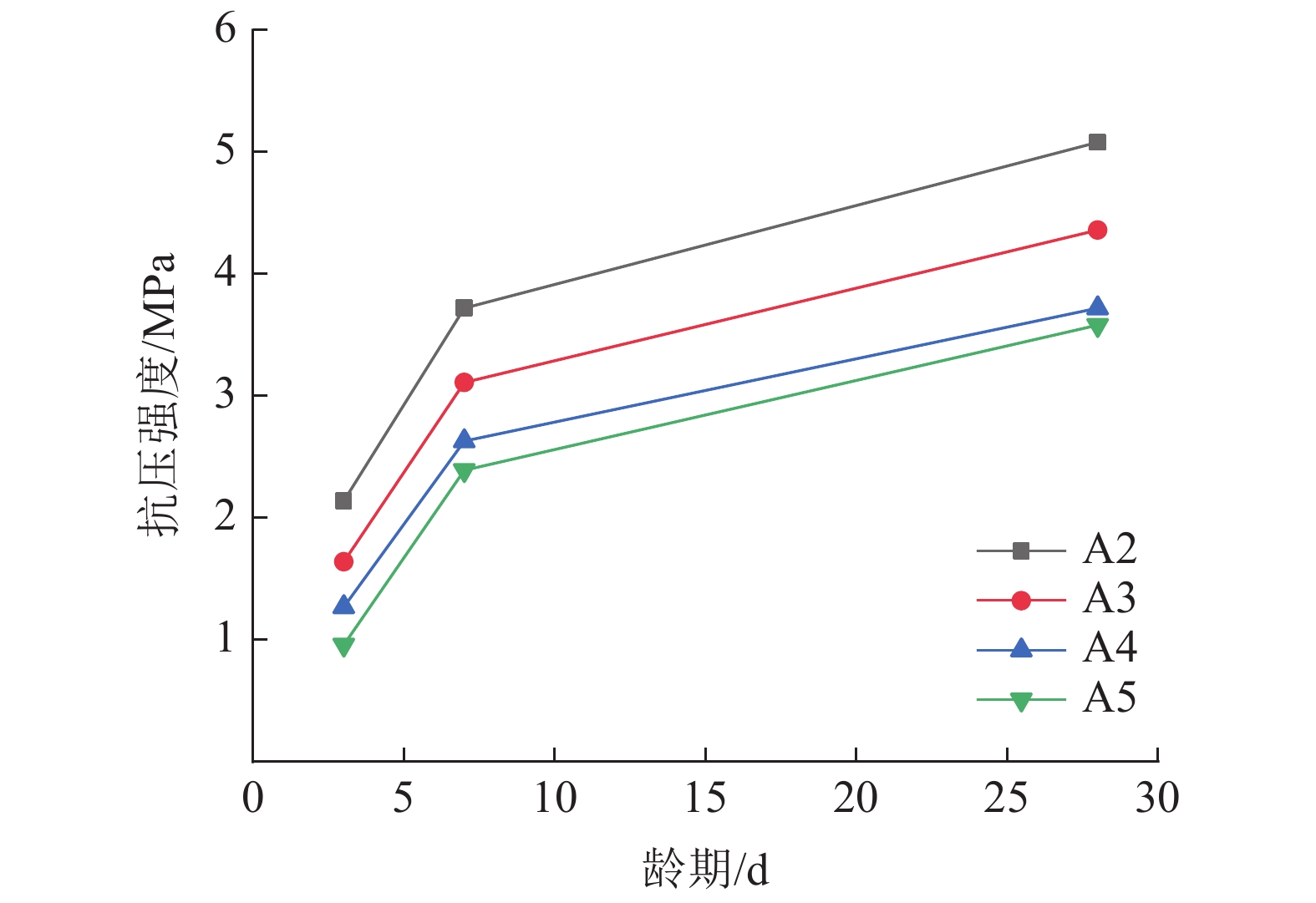

为了探究发泡剂、水胶比、比表面积以及纤维的添加对由黄铁矿尾矿制备的泡沫混凝土力学特性的影响,对泡沫混凝土进行了抗压强度实验,最终得出了以上配料的较优种类和配比,为后续研究黄铁矿尾矿掺量对泡沫混凝土力学特性的影响打下基础。黄铁矿尾矿掺入量对泡沫混凝土的影响黄铁矿实验结果表明:随着黄铁矿尾矿掺量的不断增加,泡沫混凝土的抗压强度逐渐下降,且掺入量在10%~20%之间强度的衰减幅度较大。通过DSC-TG测试发现,黄铁矿尾矿掺入量的增大会导致水化产物的减少,进而降低泡沫混凝土的力学性能; IR光谱分析表明,随着黄铁矿尾矿掺入量的增加会导致OH-、Si-O和Al-O键数量减少,这代表了水化产物生成量的减少,从而减小其抗压强度;水化热测试结果表明,黄铁矿尾矿掺入量的增加会导致其抗压强度降低,实验还发现在保护龄期50 h后,黄铁矿尾矿可提高泡沫混凝土的强度,在泡沫混凝土加入适量的黄铁矿尾矿矿能够适当改善其养护后期的力学特性。

Abstract:In order to explore the influence of foaming agent, water-binder ratio, tailings specific surface area and fiber on pyrite tailings foamed concrete the compressive strength tests of concrete were carried out and the optimal types and proportions of the above ingredients were obtained for the subsequent exploration of the influence of the amount of pyrite tailings on the strength of foam concrete. The test results show that with the increase in the amount of pyrite tailings the compressive strength of the foam concrete gradually decrease, and when the amount is 20%-30% the compressive strength of foam concrete decreases most. In the DSC-TG tests it is found that the increase in the amount of pyrite tailings will lead to the reduction of hydration products, thereby reducing the compressive strength of the foamed concrete. Through IR tests found that an increase in the amount of doping will lead to a decrease in OH-, Si-O bonds and Al-O bonds. This represents the reduction of hydration products C-S-H gel and wollastonite Thereby its compressive strength was reduced; the heat of hydration tests not only found that the increase in the amount of doping will decline its mechanical properties. It is also found that the strength provided by pyrite tailings to foamed concrete is mainly after the protection age of 50 h. Therefore, adding appropriate amount of pyrite tailings to foamed concrete can improve its compressive strength.

-

Key words:

- Pyrite tailings /

- Foamed concrete /

- Hydration reaction /

- Compressive strength.

-

-

表 1 化学组成/%

Table 1. Chemical composition

名称 SiO2 CaO Al2O3 MgO Fe2O3 SO3 FeO MnO P2O5 K2O Na2O 黄铁矿原矿 25.84 28.21 5.4 9.8 23.3 5.7 - 0.18 0.05 0.41 0.58 矿渣 32.46 41.28 22.64 2.3 0.28 - 1.59 0.32 0.07 0.37 0.47 表 2 混凝土配合比

Table 2. Concrete mix ratio

编号 黄铁矿尾矿渣/g 矿渣/g 脱硫石膏/g 发泡剂量/mL 水量/g A1 100 770 130 1000 450 A2 200 670 130 1000 450 A3 300 570 130 1000 450 A4 400 470 130 1000 450 -

[1] 李林, 姜涛, 陈超, 等. 攀西钒钛磁铁矿尾矿制备储水泡沫陶瓷的研究[J]. 矿产综合利用, 2020(6):7-13. doi: 10.3969/j.issn.1000-6532.2020.06.002

LI L, JIANG T, CHEN C, et al. Study on preparation of water-retaining foam ceramics from vanadium-titanium magnetite tailings[J]. Multipurpose Utilization of Mineral Resources, 2020(6):7-13. doi: 10.3969/j.issn.1000-6532.2020.06.002

[2] 刘俊杰, 梁钰, 曾宇, 等. 利用铁尾矿制备免烧砖的研究[J]. 矿产综合利用, 2020(5):136-141. doi: 10.3969/j.issn.1000-6532.2020.05.021

LIU J J, LIANG Y, ZENG Y, et al. Preparation of baking-free bricks by iron tailings[J]. Multipurpose Utilization of Mineral Resources, 2020(5):136-141. doi: 10.3969/j.issn.1000-6532.2020.05.021

[3] 李猛, 黄寅生, 张少波, 等. 泡沫混凝土的研究进展及展望[J]. 材料导报, 2016, 30(S1):402-405.

LI M, HUANG Y S, ZHANG S B, et al. Research progress and prospect of foamed concrete[J]. Materials Review, 2016, 30(S1):402-405.

[4] 荣辉, 张静, 张磊, 等. 泡沫混凝土用生物基发泡剂的研制及其性能研究[J]. 硅酸盐通报, 2020, 39(1):90-95.

RONG H, ZHANG J, ZHANG L, et al. Development and performance research of bio-based foaming agent for foamed concrete[J]. Bulletin of Silicate, 2020, 39(1):90-95.

[5] 姬军. 钢铁渣基泡沫混凝土制备及其水化特征研究[D]. 北京: 北京科技大学, 2020.

JI J. Preparation and hydration characteristics of steel slag-based foam concrete [D]. Beijing: University of Science and Technology Beijing, 2020.

[6] 马旭明, 倪文, 刘轩. 钢渣粉性能优化及制备无熟料混凝土的实验研究[J]. 材料导报, 2016, 30(16):135-140.

MA X M, NI W, LIU X. Experimental study on performance optimization of steel slag powder and preparation of clinker-free concrete[J]. Materials Review, 2016, 30(16):135-140.

[7] 白光, 田义, 余林文, 等. 聚乙烯醇纤维对碱矿渣泡沫混凝土性能的影响[J]. 材料导报, 2018, 32(12):2096-2099. doi: 10.11896/j.issn.1005-023X.2018.12.029

BAI G, TIAN Y, YU L W, et al. Effects of polyvinyl alcohol fibers on the properties of alkali slag foamed concrete[J]. Materials Review, 2018, 32(12):2096-2099. doi: 10.11896/j.issn.1005-023X.2018.12.029

[8] 陈华, 李辉. 特殊钢尾渣粉在泡沫混凝土制备中的作用机理[J]. 建筑材料学报, 2019, 22(3):446-450. doi: 10.3969/j.issn.1007-9629.2019.03.017

CHEN H, LI H. Mechanism of special steel tailings powder in the preparation of foamed concrete[J]. Journal of Building Materials, 2019, 22(3):446-450. doi: 10.3969/j.issn.1007-9629.2019.03.017

-

下载:

下载: