Extraction of Amorphous Silicon from Fly Ash and High Value Utilization of Silicon Products

-

摘要:

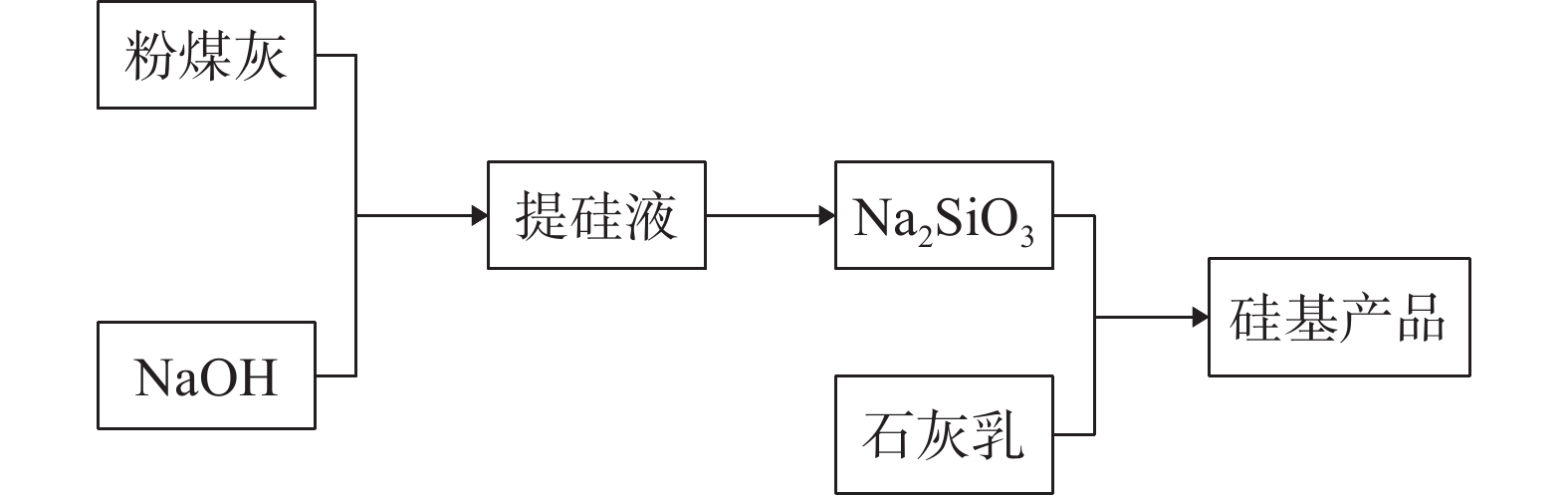

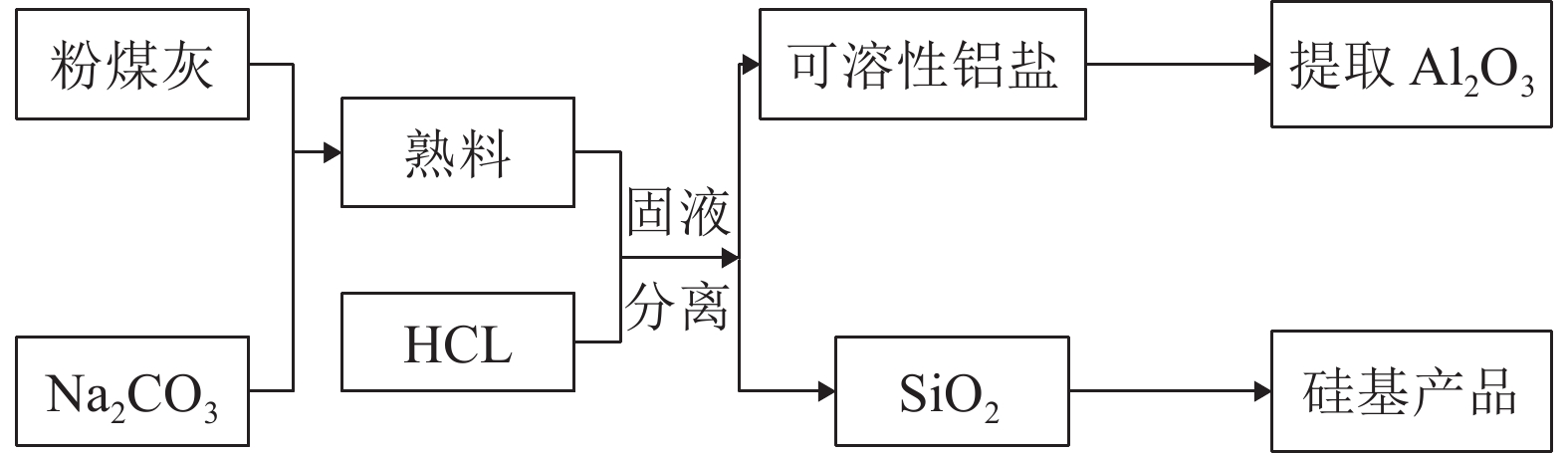

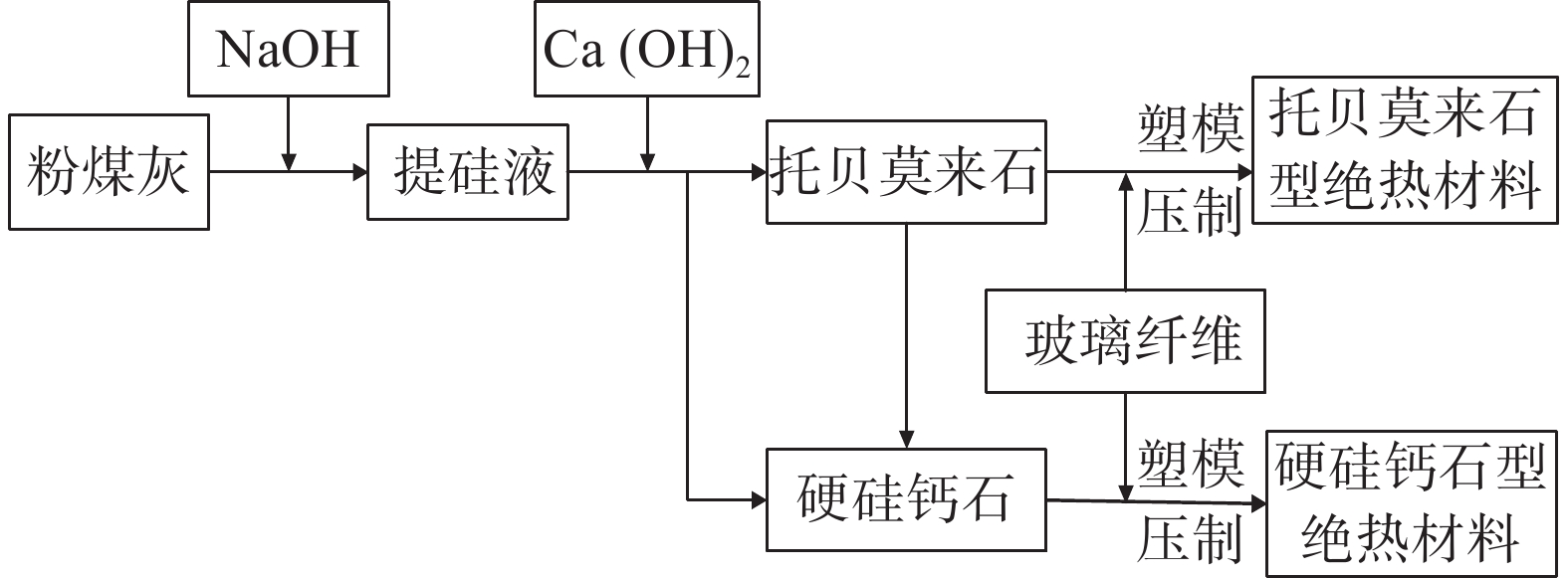

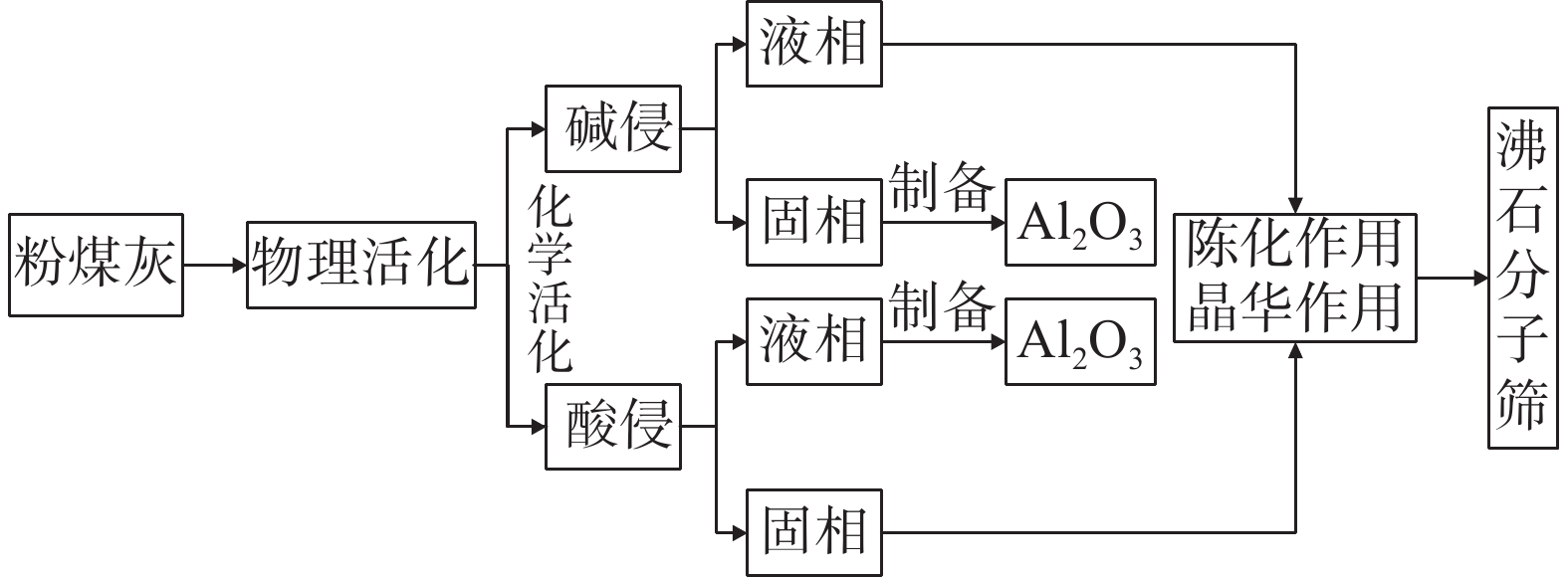

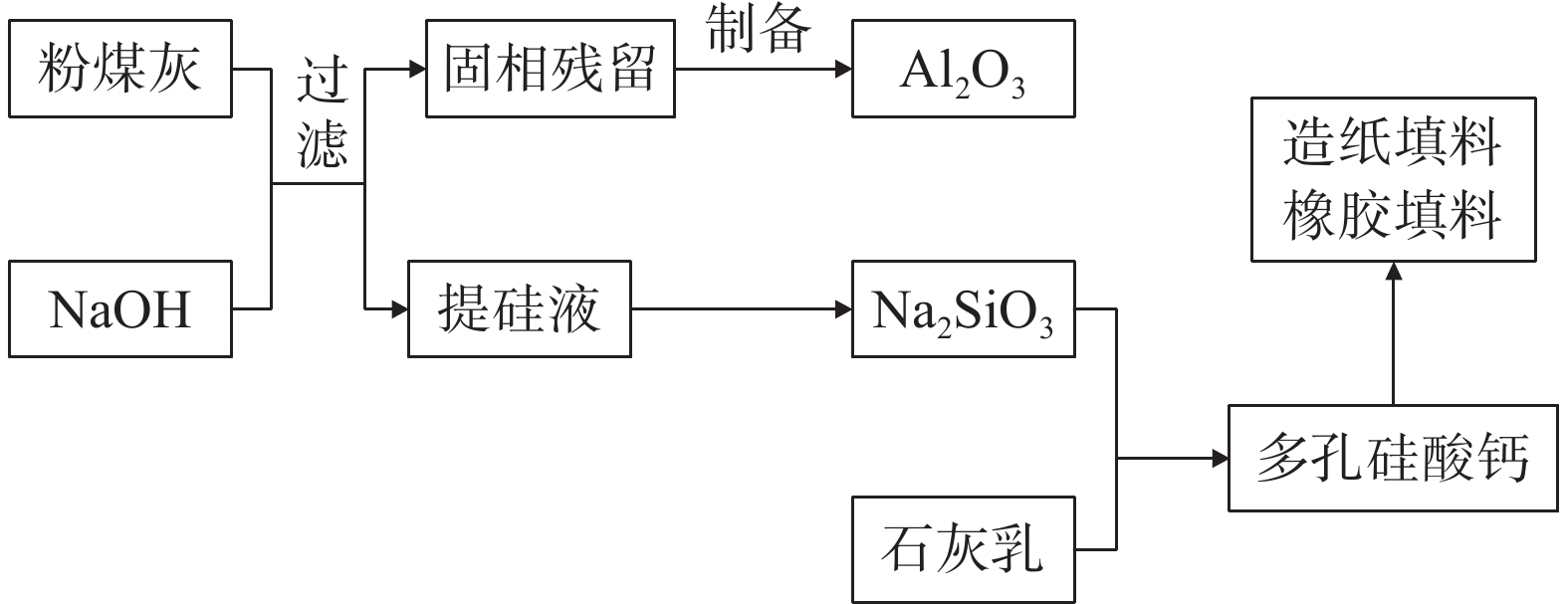

我国以煤炭为主的能源结构,在保障着我国能源供给的同时也带来了大量的粉煤灰,尤其在我国西北地区,由于较低的粉煤灰利用率,造成了严重的环境污染及耕地占用等问题。目前有用组分的提取已然成为粉煤灰高值化利用的研究热点,特别是粉煤灰中非晶态硅的提取是提升粉煤灰资源化利用价值的重要手段。本文论述了碱浸法和酸浸法两种从粉煤灰中提取非晶态硅的工艺,剖析其原理及工艺特点,并探讨了提硅产物在绝热保温材料、白炭黑、分子筛、造纸填塑等方面的应用情况。相较于传统硅基产品的制备,利用粉煤灰提硅产物制备各种硅基制品具有产品性能好、成本低、应用广泛等优点,不失为一条实现粉煤灰高值化、精细化、梯级化利用的有效途径。

Abstract:Coal-based energy structure of China has not only guaranteed energy supply, but also brought a lot of fly ash, because of the low utilization rate of fly ash has caused serious environmental pollution and farmland occupation problems, especially in Northwest China. At present, the extraction of useful components has become a research hotspot of high-value utilization of fly ash, especially the extraction of amorphous silicon in it an important means to improve the value of resource utilization of fly ash. In this paper, two main processes of extracting amorphous silicon from fly a share described, namely alkali leaching and acid leaching. The principle and characteristics of the process are analyzed and the application of products by silicon extraction in the insulation material, silica black, molecular sieve, filling of paper and rubber is discussed. Compared with the products of traditional silicon-based, the various of silicon-based products prepared by fly ash have the advantages of better performance, lower cost and more wider application, which can be regarded as an effective way to realize the high-value, fine and cascade utilization of fly ash.

-

Key words:

- Fly ash /

- Amorphous silicon /

- Extract /

- Silicon product

-

-

图 9 粉煤灰基多孔硅酸钙微观形貌[33]

Figure 9.

表 1 粉煤灰的化学成分/%

Table 1. Chemical composition of fly ash

SiO2 Al2O3 CaO MgO Fe2O3 K2O Na2O SO3 33~65 15~40 0.8~17 0.6~29 1.5~19 0.6~2.9 0.2~4.2 0~6 50.6 28 2.8 1.2 7.1 1.3 1.2 0.8 -

[1] 2020年12月份能源生产情况[N]. 国家统计局, 2021.

Energy production in December 2020[N]. National Bureau of Statistics, 2021.

[2] 刘梦茹, 杨亚东, 杨素洁, 等. 粉煤灰资源综合利用现状研究[J]. 化工矿物与加工, 2020(4):1-5. doi: 10.16283/j.cnki.hgkwyjg.2021.04.010

LIU M R, YANG Y D, YANG S J, et al. Research on status of comprehensive utilization of fly ash[J]. Industrial Minerals & Processing, 2020(4):1-5. doi: 10.16283/j.cnki.hgkwyjg.2021.04.010

[3] 宋明铭. 高碳粉煤灰综合利用技术研究[J]. 矿产综合利用, 2021(3):93-98. doi: 10.3969/j.issn.1000-6532.2021.03.015

SONG M M. Study on comprehensive utilization technology of high carbon fly ash[J]. Multipurpose Utilization of Mineral Resources, 2021(3):93-98. doi: 10.3969/j.issn.1000-6532.2021.03.015

[4] 卓庆奉, 巴蕾, 王奇峰. 掺粉煤灰的混合充填骨料配比优化实验[J]. 矿产综合利用, 2021(3):187-192. doi: 10.3969/j.issn.1000-6532.2021.03.030

ZHUO Q F, BA L, WANG Q F. Optimum experiment of aggregate proportion for mixed filling with fly ash[J]. Multipurpose Utilization of Mineral Resources, 2021(3):187-192. doi: 10.3969/j.issn.1000-6532.2021.03.030

[5] Yao Z T, Ji S, Sarker P K, et al. A comprehensive review on the applications of coal fly ash[J]. Earth Science Reviews, 2015, 141:105-121. doi: 10.1016/j.earscirev.2014.11.016

[6] 王莺歌, 陈懿辉, 梁川. 大型燃煤电站粉煤灰的特性及综合利用[J]. 东北电力技术, 2011, 11:41-45. doi: 10.3969/j.issn.1004-7913.2011.07.013

WANG Y G, CHEN Y H, LIANG C. The characteristics and comprehensive utilization of large-scale coal-fired power plants fly ash[J]. Northeast Electric Power Technology, 2011, 11:41-45. doi: 10.3969/j.issn.1004-7913.2011.07.013

[7] 肖永丰. 粉煤灰提取氧化铝方法研究[J]. 矿产综合利用, 2020(4):156-162. doi: 10.3969/j.issn.1000-6532.2020.04.027

XIAO Y F. Study on the methods of leaching alumina from fly ash[J]. Multipurpose Utilization of Mineral Resources, 2020(4):156-162. doi: 10.3969/j.issn.1000-6532.2020.04.027

[8] 孙应龙, 梁振凯, 祁光霞, 等. 高铝粉煤灰脱硅反应工艺优化及机理探讨[J]. 环境科学研究, 2016, 29(5):753-760. doi: 10.13198/j.issn.1001-6929.2016.05.18

SUN Y L, LIANG Z K, QI G X. et al. Optimization of reaction conditions and mechanism of desilication of high-alumina fly ash[J]. Research of Environmental Sciences, 2016, 29(5):753-760. doi: 10.13198/j.issn.1001-6929.2016.05.18

[9] 王腾飞, 张金山, 李侠, 等. 碱法提取高铝粉煤灰中氧化铝的研究进展[J]. 矿产综合利用, 2019(1):16-21. doi: 10.3969/j.issn.1000-6532.2019.01.004

WANG T F, ZHANG J S, LI X, et al. Research progress of extracting alumina in alkali method from high- alumina coal fly ash[J]. Multipurpose Utilization of Mineral Resources, 2019(1):16-21. doi: 10.3969/j.issn.1000-6532.2019.01.004

[10] 李晓光, 丁书强, 卓锦德, 等. 粉煤灰提取二氧化硅技术及工业化发展现状[J]. 无机盐工业, 2018, 50(12):1-4.

LI X G, DING S Q, ZHUO J D, et al. Progress of research and industrialization of extraction technologies of SiO2 from fly ash[J]. Inorganic Chemicals Industry, 2018, 50(12):1-4.

[11] WANG M W, YANG J, MA H W, et al. Extraction of aluminum hydroxide from coal fly ash by pre-desilication and calcination methods[J]. Advanced Materials Research, 2012:2536.

[12] 刘晓婷, 王宝冬, 肖永丰, 等. 高铝粉煤灰碱溶预脱硅过程研究[J]. 中国粉体技术, 2016, 19(6):24-27.

LIU X T, WANG B D, XIAO Y F, et al. Pre-desilication process of alumina-rich fly ash in alkali solution[J]. China Powder Science and Technology, 2016, 19(6):24-27.

[13] GUO Y X, ZHAO Z, ZHAO Q, et al. Novel process of alumina extraction from coal pre-desilicating—Na2CO3 activation—Acid leaching technique[J]. Hydrometallurgy, 2017, 169:418-425. doi: 10.1016/j.hydromet.2017.02.021

[14] Shemi A, Ndlovu S, Sibanda V. et al. Extraction of alumina from coal fly ash using an acid leach-sinter-acid leach technique[J]. Hydrometallurgy, 2015, 157:348-355. doi: 10.1016/j.hydromet.2015.08.023

[15] 柳丹丹. 粉煤灰酸法提铝过程SiO2强化分离及硅基材料制备研究[D]. 太原: 山西大学, 2019.

LIU D D. Separation and utilization of silica from alumina extraction process of coal fly ash with acid leaching [D]. Taiyuan: Shanxi University, 2019.

[16] ZHANG J B, LI S P, LI H Q, et al. Acid activation for pre-desilicated high-alumina fly ash[J]. Fuel Processing Technology, 2016:151.

[17] BAI G H, QIAO Y H, SHEN B, et al. Thermal decomposition of coal fly ash by concentrated sulfuric acid and alumina extraction process based on it[J]. Fuel Processing Technology, 2011, 92(6).

[18] 王宏宾, 杜艳霞. 粉煤灰盐酸法提取氧化铝技术研究[J]. 现代化工, 2020, 40(8):194-197. doi: 10.16606/j.cnki.issn0253-4320.2020.08.041

WANG H B, DU Y X. Research on extracting alumina from fly ash through hydrochloricacid leaching method[J]. Modern Chemical Industry, 2020, 40(8):194-197. doi: 10.16606/j.cnki.issn0253-4320.2020.08.041

[19] 杨志杰, 叶俊沛, 孙俊民, 等. 煤基固废协同利用制备硅酸钙板的试验研究[J]. 混凝土与水泥制品, 2014(10):90-92. doi: 10.3969/j.issn.1000-4637.2014.10.022

YANG Z J, YE J P, SUN J M et al. Experimental study on preparation of calcium silicate plate by synergistic utilization of coal based solid waste[J]. China Concrete and Cement Products, 2014(10):90-92. doi: 10.3969/j.issn.1000-4637.2014.10.022

[20] 邱明华, 李强, 念保义, 等. 白炭黑表面改性研究现状及进展[J]. 矿产综合利用, 2020(3):40-47. doi: 10.3969/j.issn.1000-6532.2020.03.007

QIU M H, LI Q, NIAN B Y, et al. Research status and development of precipitated silica surface modification[J]. Multipurpose Utilization of Mineral Resources, 2020(3):40-47. doi: 10.3969/j.issn.1000-6532.2020.03.007

[21] 吴艳, 翟玉春, 李来时, 等. 新酸碱联合法以粉煤灰制备高纯氧化铝和超细二氧化硅[J]. 轻金属, 2007(9):24-27. doi: 10.3969/j.issn.1002-1752.2007.09.007

WU Y, ZHAI Y C, LI L S, et al. Preparationof High-purity Al2O3 and Superfine SiO2 from fly ash by the new acid and alkali combination method[J]. Light Metals, 2007(9):24-27. doi: 10.3969/j.issn.1002-1752.2007.09.007

[22] 徐洁明, 谢吉民, 朱建军. 粉煤灰气相法制备纳米白炭黑研究[J]. 无机盐工业, 2006, 38(7):54-56.

XU J M, XIE J M, ZHU J J. Study on preparing nanosized SiO2·xH2O from fly ash by gas-phase method[J]. Inorganic Chemicals Industry, 2006, 38(7):54-56.

[23] C T Kresge, M E Leonowicz, W. J. Roth, et al. Ordered mesoporous molecular sieves synthesized by a liquid-crystal template mechanism[J]. Letters to Nature, 1992:359.

[24] 于成龙, 熊楠, 宋杰, 等. 近20年来中国利用粉煤灰合成分子筛研究进展[J]. 矿产综合利用, 2020(4):26-35. doi: 10.3969/j.issn.1000-6532.2020.04.005

YU C L, XIONG N, SONG J, et al. Development of molecular sieves composition from fly ash in China in the last two decades[J]. Multipurpose Utilization of Mineral Resources, 2020(4):26-35. doi: 10.3969/j.issn.1000-6532.2020.04.005

[25] 邹萍. 粉煤灰水热合成法制备4A型分子筛研究进展[J]. 矿产综合利用, 2020(3):33-39.

ZOU P. Research development of 4A zeolite preparation from coal fly ash by hydrothermal synthesis method[J]. Multipurpose Utilization of Mineral Resources, 2020(3):33-39.

[26] 侯芹芹, 李昌晔, 郭凡凯, 等. 粉煤灰制备ZSM-5分子筛及其应用[J]. 应用化工, 2020, 49(9):2270-2274. doi: 10.3969/j.issn.1671-3206.2020.09.029

HOU Q Q, LI C H, GUO F K, et al. Preparation and application of ZSM-5 molecularsieve from fly ash[J]. Applied Chemical Industry, 2020, 49(9):2270-2274. doi: 10.3969/j.issn.1671-3206.2020.09.029

[27] Juliana de C Izidoro, Denise Alves Fungaro, Fernando S dos Santos, et al. Characteristics of Brazilian coal fly ashes and their synthesized zeolites[J]. Fuel Processing Technology, 2012, 97:38-44. doi: 10.1016/j.fuproc.2012.01.009

[28] Marion Gross-Lorgouilloux, Michel Soulard, Philippe Caullet, et al. Conversion of coal fly ashes into faujasite under soft temperature and pressure conditions: Influence of additional silica[J]. Microporous and Mesoporous Materials, 2009, 127(1).

[29] Ariela M Cardosoa, Martha B Hornb, Lizete S. Ferret Integrated synthesis of zeolites 4A and Na–P1 using coal fly ash for application in the formulation of detergents and swine wastewater treatment[J]. 2015, 287: 69-77.

[30] 魏雅娟, 王群英, 李小江. 不同种类粉煤灰对丁苯橡胶补强性能的对比研究[J]. 矿产综合利用, 2019(1):88-91. doi: 10.3969/j.issn.1000-6532.2019.01.019

WEI Y J, WANG Q Y, LI X J. Study on performance of styrene butadiene rubber reinforced by different type fly ash[J]. Multipurpose Utilization of Mineral Resources, 2019(1):88-91. doi: 10.3969/j.issn.1000-6532.2019.01.019

[31] 刘俊华, 张美云, 陆赵情, 等. 粉煤灰提取新型硅酸盐填料在造纸上的应用研究[J]. 天津造纸, 2013(4):7-12. doi: 10.3969/j.issn.1674-5469.2013.04.002

LIU J H, ZHANG M Y, LU Z Q, et al. Study on application of new silicate fillers extracted from fly ash in paper making[J]. Tianjin Paper Making, 2013(4):7-12. doi: 10.3969/j.issn.1674-5469.2013.04.002

[32] 池君洲. 改性粉煤灰提铝残渣填充橡胶复合材料的性能研究[J]. 露天采矿技术, 2017, 32(5):77-80. doi: 10.13235/j.cnki.ltcm.2017.05.022

CHI J Z. Study on properties of modified ash residue after extracting aluminum filling rubber composites[J]. Opencast Mining Technology, 2017, 32(5):77-80. doi: 10.13235/j.cnki.ltcm.2017.05.022

[33] 吴盼, 张美云, 王建, 等. 不同助留体系在新型硅酸钙加填纸中的应用[J]. 纸和造纸, 2013, 32(8):17-20. doi: 10.13472/j.ppm.2013.08.017

WU P, ZHANG M Y, WANG J, et al. Application of different retention systems on paper filled with a novel fly ash based calcium silicate[J]. Paper and Paper Making, 2013, 32(8):17-20. doi: 10.13472/j.ppm.2013.08.017

-

下载:

下载: