Study on Improvement of Phosphorus Release Characteristics of a Phosphate Rock Powder by Wet Grinding

-

摘要:

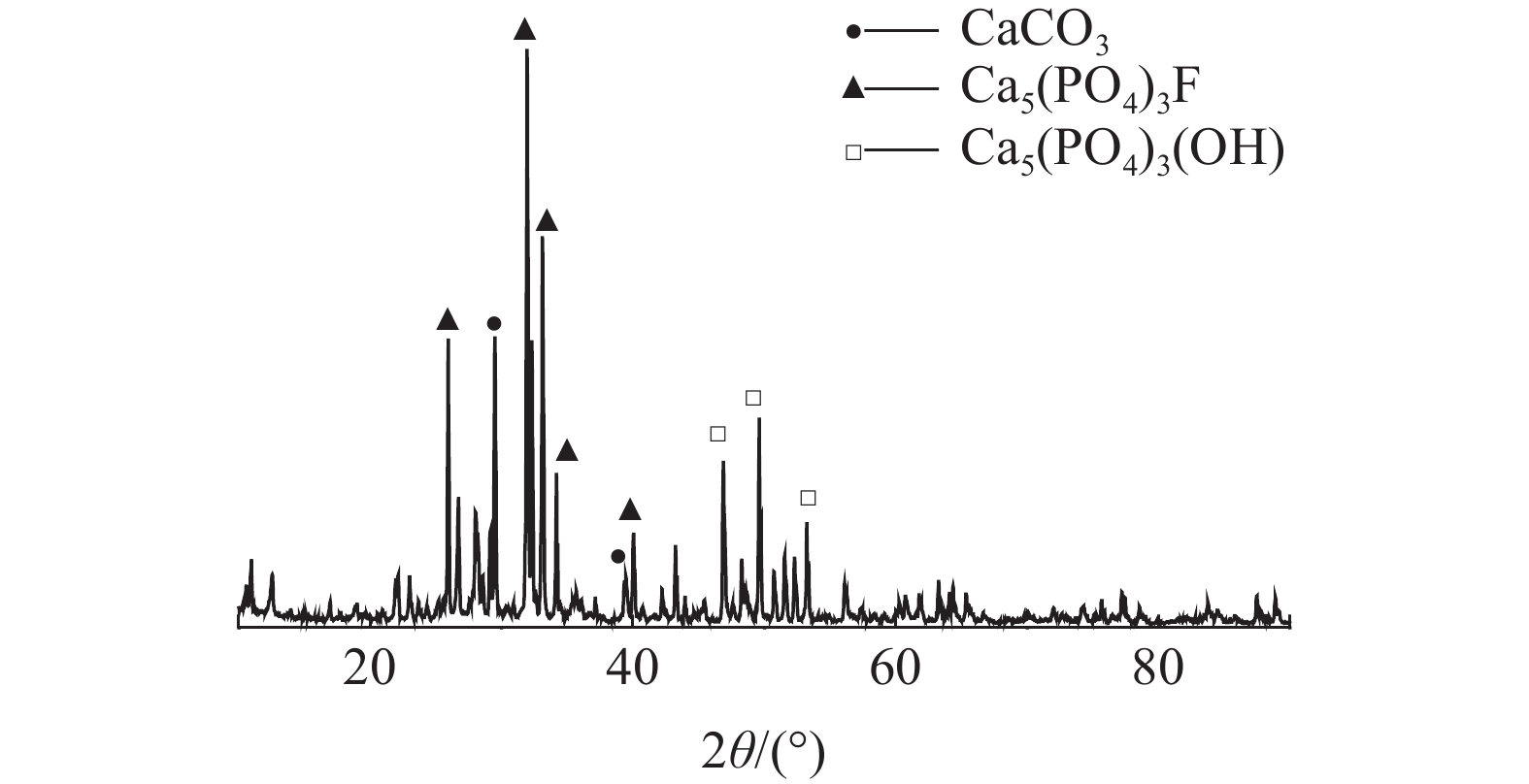

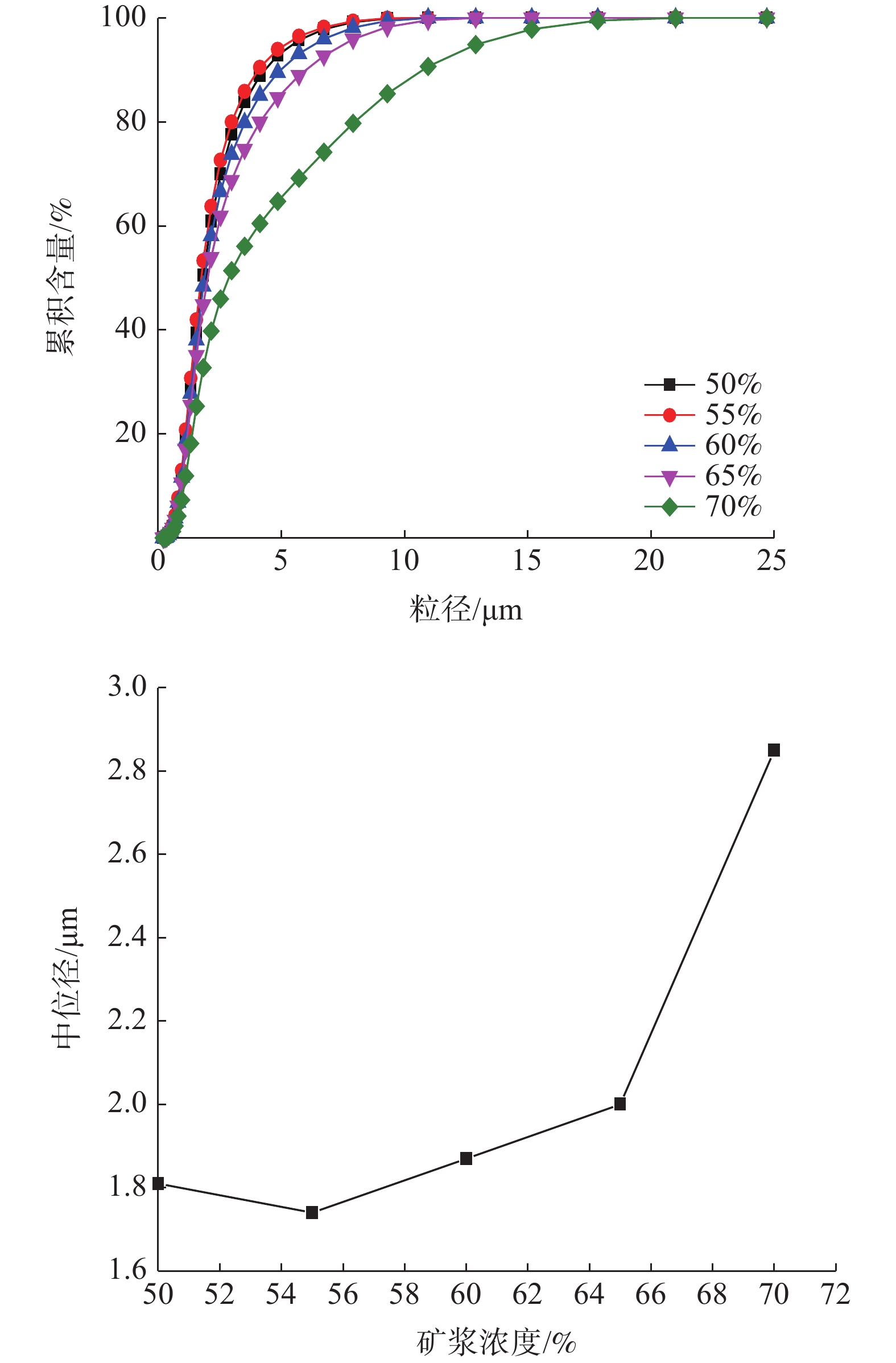

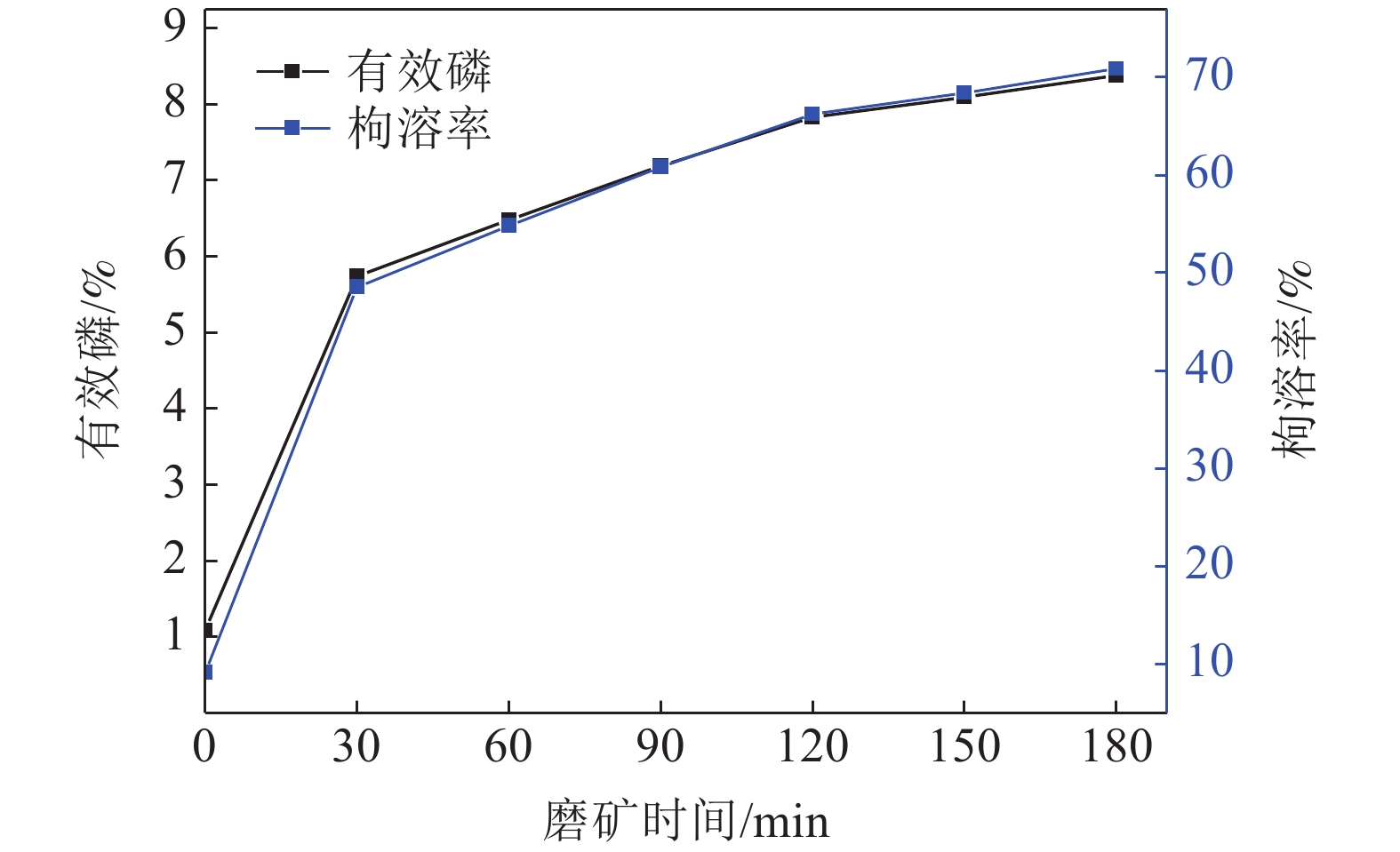

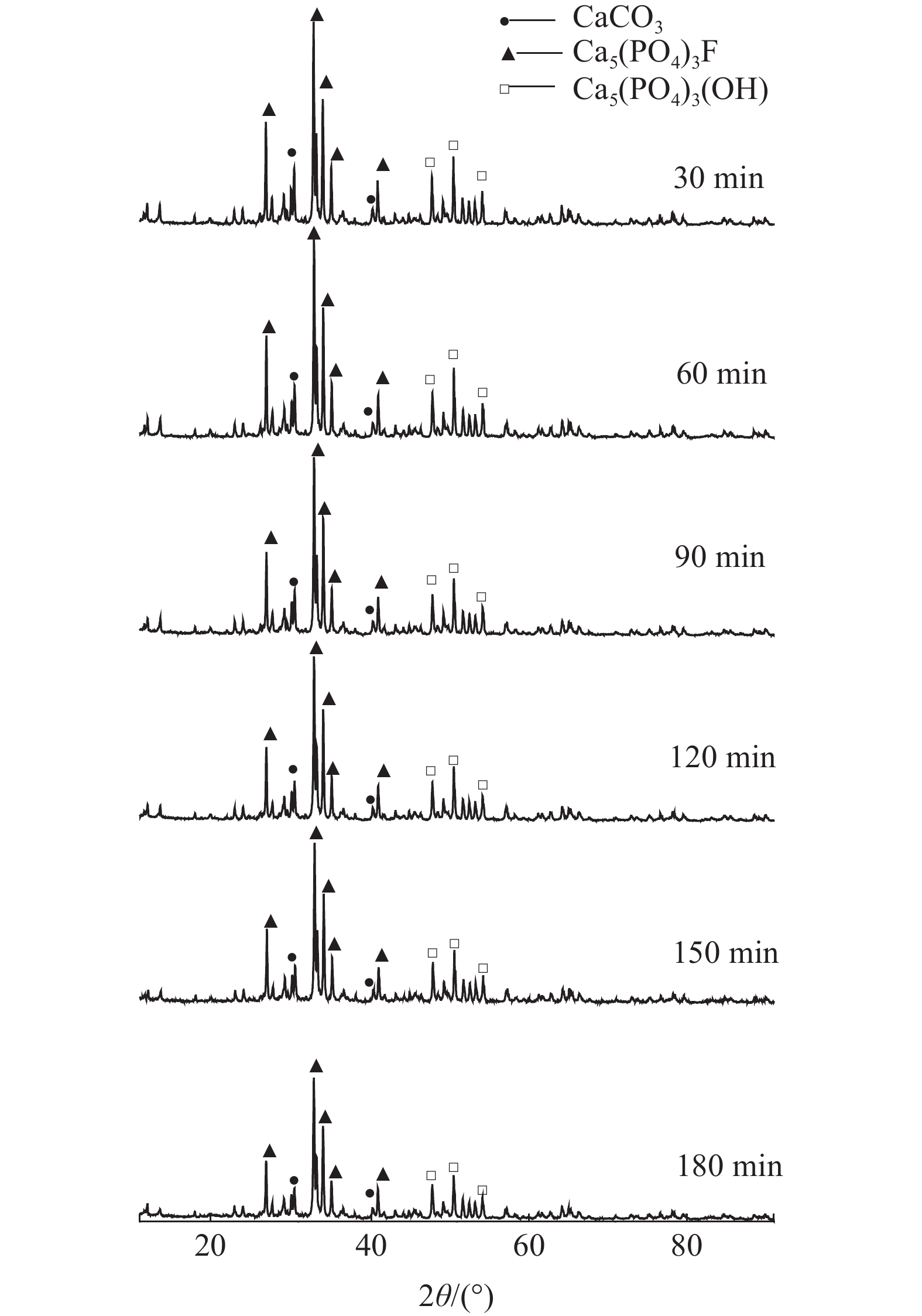

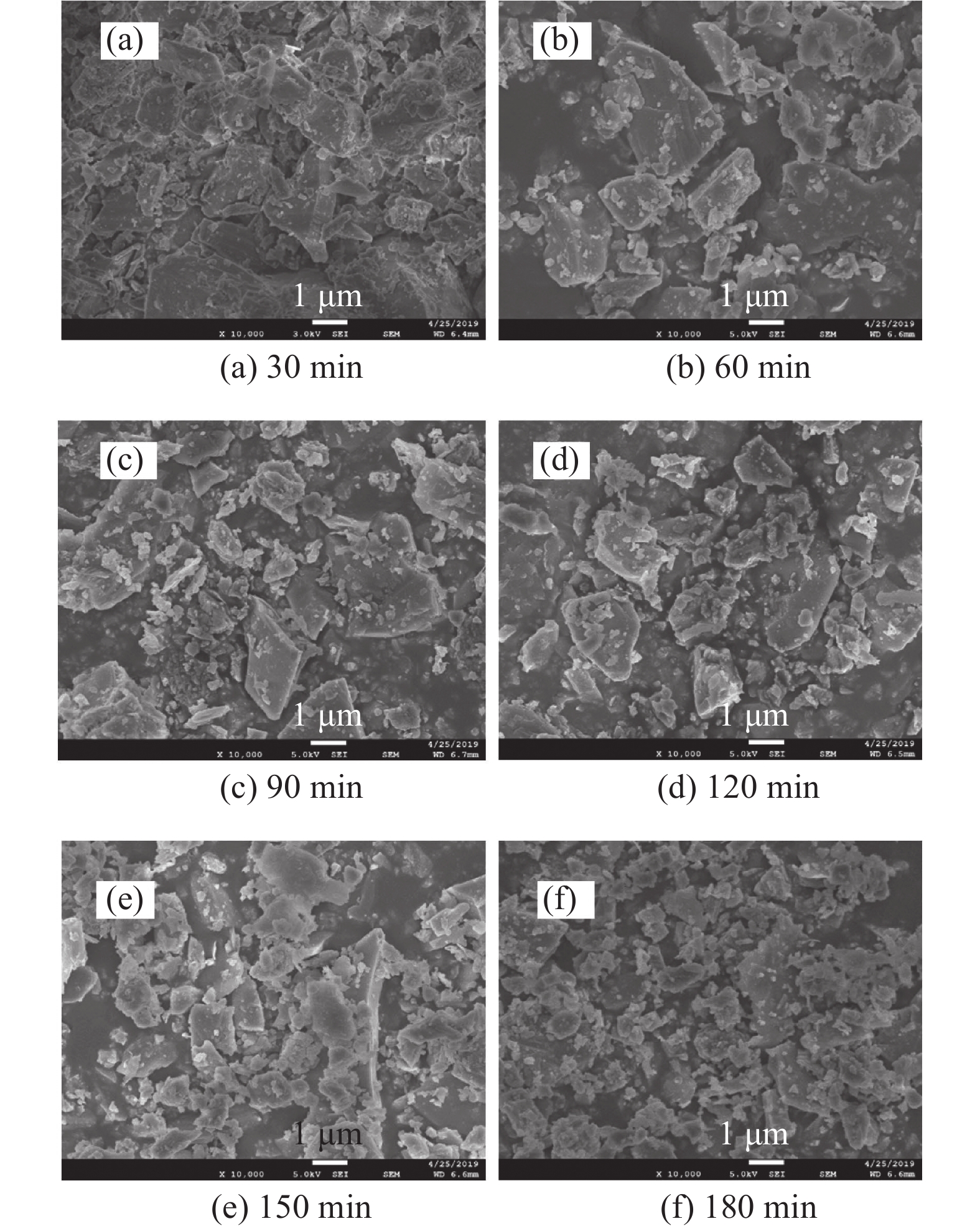

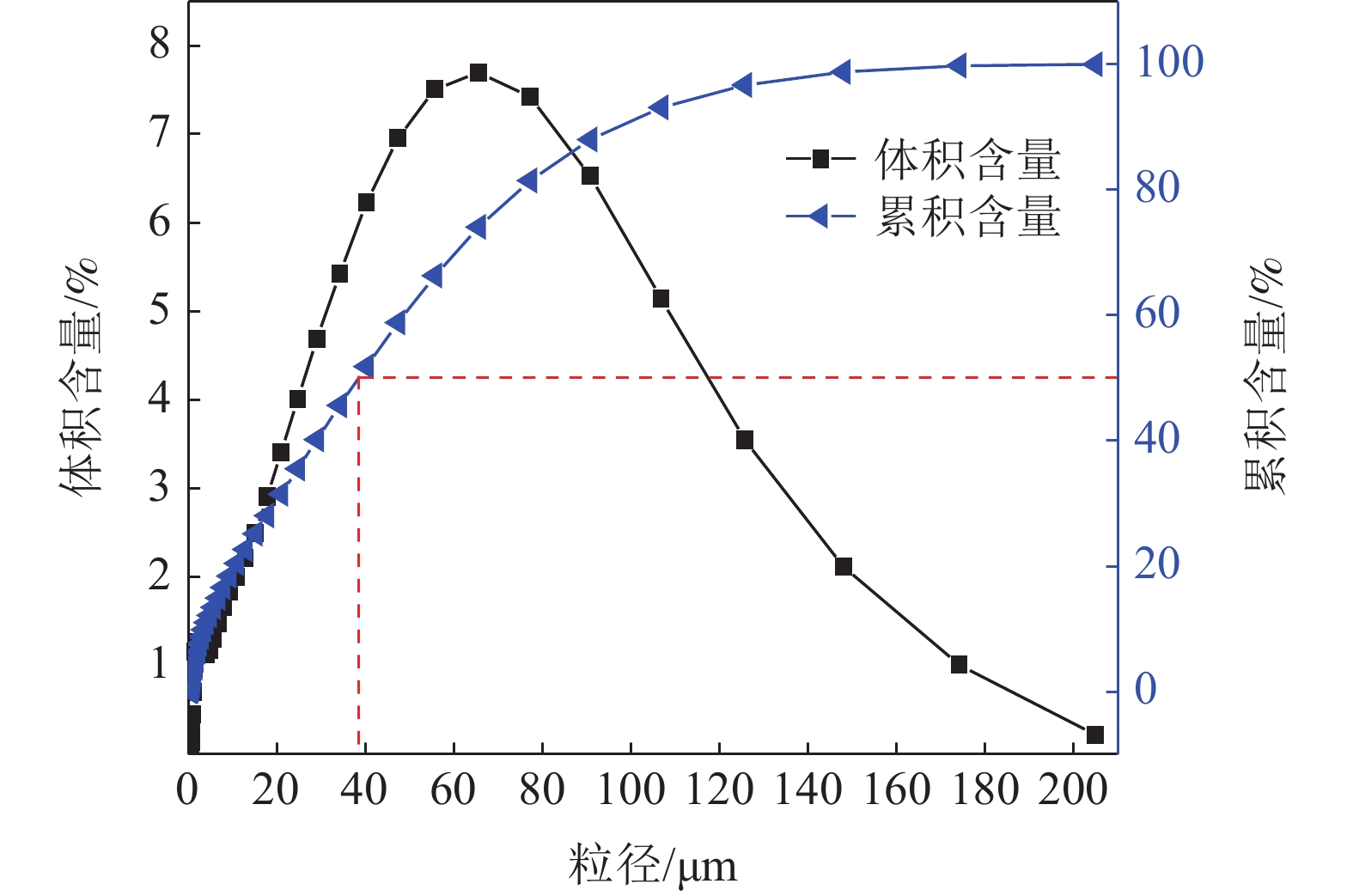

采用行星式球磨机对P2O5含量为27.07%的磷矿粉进行超细粉磨,在已确定的适宜干式粉磨工艺参数下,考查了矿浆浓度、磨矿时间对粉磨产品粒度和枸溶率的影响。借助X射线衍射分析、扫描电镜分析、接触角测量仪等测试手段,分别考查了不同磨矿时间条件下粉磨产品的结晶程度、微观形貌和表面自由能的变化规律。结果表明:在矿浆浓度为55%,磨矿时间为150 min条件下,粉磨产品中位径为1.74 μm、枸溶率达到66.24%。随着磨矿时间的延长,磷矿粉中磷矿物结晶程度显著降低,粉磨产品中基本不存在大颗粒,产品接触角逐渐减少,相应的表面自由能呈增加趋势,提高了磷矿粉的释磷特性。

Abstract:Planetary ball mill was used for ultra-fine grinding of phosphate rock powder with P2O5 content of 27.07%. The influences of pulp concentration and grinding time on particle size and solubility of powder products were investigated under the determined optimum dry grinding process parameters. By means of X-ray diffraction analysis, scanning electron microscope analysis and contact Angle measuring instrument, the variation law of crystallization degree, microstructure and surface free energy of pulverized products under different grinding time were investigated. The results showed that under the condition of 55% pulp concentration and 150 min grinding time, the median diameter and solubility of powder products were 1.74 μm and 66.24%, respectively. With the extension of grinding time, the crystallization degree of phosphate ore in the phosphate ore powder decreases significantly, there is basically no large particle in the powder product, the product contact angle gradually decreases, the corresponding surface free energy shows an increasing trend, and the phosphorus release characteristics of the phosphate ore powder are improved.

-

Key words:

- Phosphate rock powder /

- Ultrafine grinding /

- Grinding time

-

-

表 1 磷矿粉化学多元素分析结果/%

Table 1. Results of chemical multi-element analysis of phosphate rock

P2O5 SiO2 CaO Al2O3 MgO TFe F Cl 27.07 12.25 41.92 2.77 1.84 5.50 2.17 0.009 -

[1] 蒋俊. 中低品位磷矿的开发利用途径[J]. 矿产综合利用, 2014(4):16-19. doi: 10.3969/j.issn.1000-6532.2014.04.004

JIANG J. Development and utilization of medium - and low-grade phosphate deposits[J]. Multipurpose Utilization of Mineral Resources, 2014(4):16-19. doi: 10.3969/j.issn.1000-6532.2014.04.004

[2] 薛珂, 张润宇. 中国磷矿资源分布及其成矿特征研究进展[J]. 矿物学报, 2019, 39(1):7-14. doi: 10.16461/j.cnki.1000-4734.2019.39.002

XUE K, ZHANG R Y. Research progress on distribution and metallogenic characteristics of phosphate ore resources in China[J]. Acta Mineralogica Sinica, 2019, 39(1):7-14. doi: 10.16461/j.cnki.1000-4734.2019.39.002

[3] 王涛, 付磊, 李宁. 某硅钙质胶磷矿正反浮选试验研究[J]. 矿产综合利用, 2020(2):91-95. doi: 10.3969/j.issn.1000-6532.2020.02.016

WANG T, FU L, LI N. Study on direct-reverse flotation of a silica calcinate phosphate ore[J]. Multipurpose Utilization of Mineral Resources, 2020(2):91-95. doi: 10.3969/j.issn.1000-6532.2020.02.016

[4] 王晨, 高宏, 刘淑红, 等. 中低品位磷矿粉的机械力化学活化与活性表征[J]. 化工矿物与加工, 2012, 41(7):1-4. doi: 10.3969/j.issn.1008-7524.2012.07.001

WANG C, GAO H, LIU S H, et al. Mechanochemical activation and activity characterization of medium and low grade phosphate rock powder[J]. Chemical Minerals and Processing, 2012, 41(7):1-4. doi: 10.3969/j.issn.1008-7524.2012.07.001

[5] 李成秀, 文书明. 我国磷矿选矿现状及其进展[J]. 矿产综合利用, 2010(2):22-25. doi: 10.3969/j.issn.1000-6532.2010.02.007

LI C X, WEN S M. Status and progress of phosphate ore dressing in China[J]. Multipurpose Utilization of Mineral Resources, 2010(2):22-25. doi: 10.3969/j.issn.1000-6532.2010.02.007

[6] 宋晓岚, 邱冠周, 杨华明. 机械化学及其应用研究进展[J]. 金属矿山, 2004(11):34-38. doi: 10.3321/j.issn:1001-1250.2004.11.010

SONG X L, QIU G Z, YANG H M. Advances in mechanical chemistry and its applications[J]. Metal Mine, 2004(11):34-38. doi: 10.3321/j.issn:1001-1250.2004.11.010

[7] 单志伟, 李凤久, 刘立伟, 等. 超细粉磨活化河北某磷矿粉实验研究[J]. 矿产综合利用, 2020(2):55-59. doi: 10.3969/j.issn.1000-6532.2020.02.009

SHAN Z W, LI F J, LIU L W, et al. Experimental study on activation of phosphate ore powder by ultrafine pulverization in Hebei Province[J]. Multipurpose Utilization of Mineral Resources, 2020(2):55-59. doi: 10.3969/j.issn.1000-6532.2020.02.009

-

下载:

下载: