Endowment Conditions of Mineral Resources and the Heterogeneity of Development and Utilization: a Study Based on the Accumulation Area of Iron Ore Resources in Hebei Province of China

-

摘要:

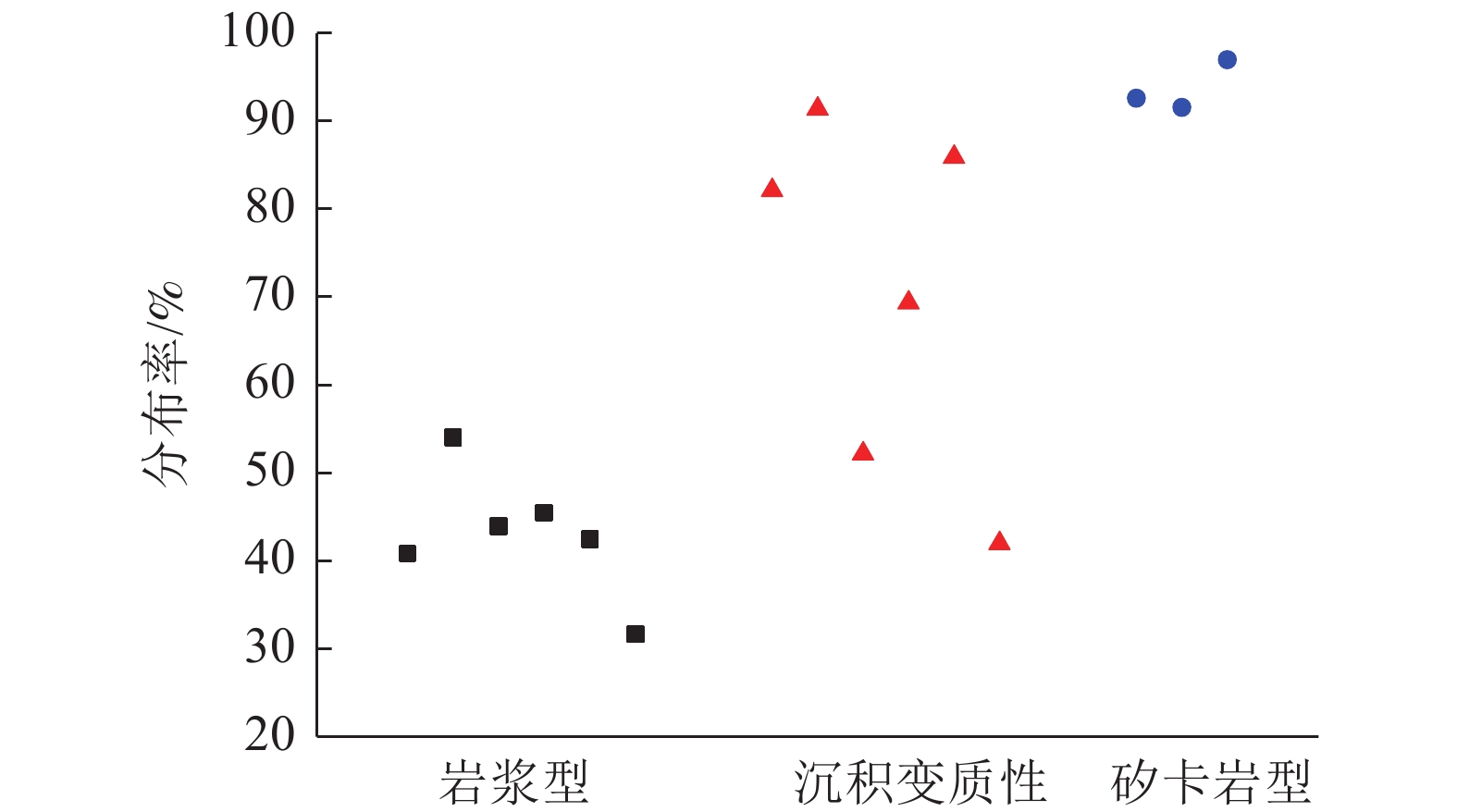

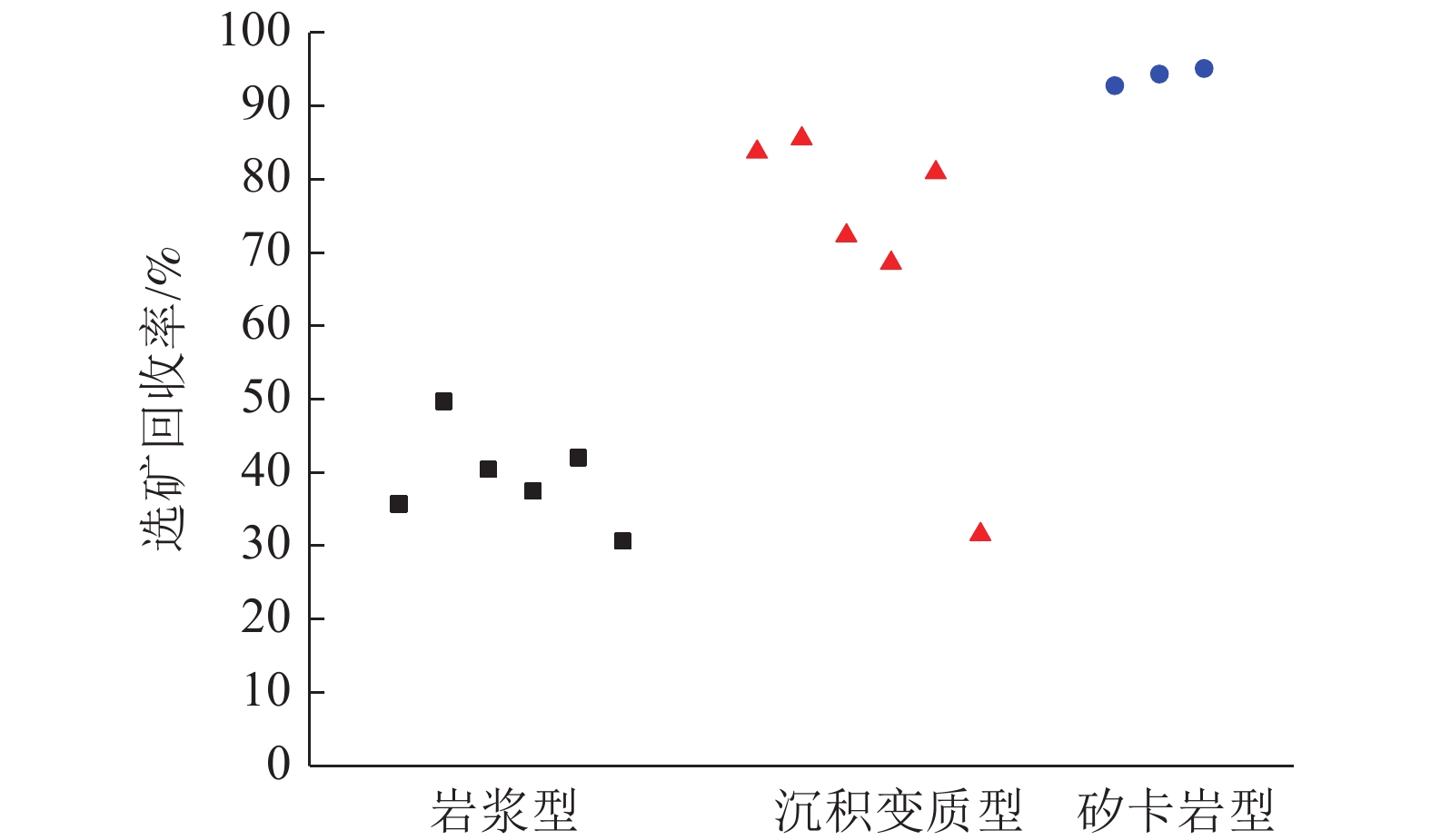

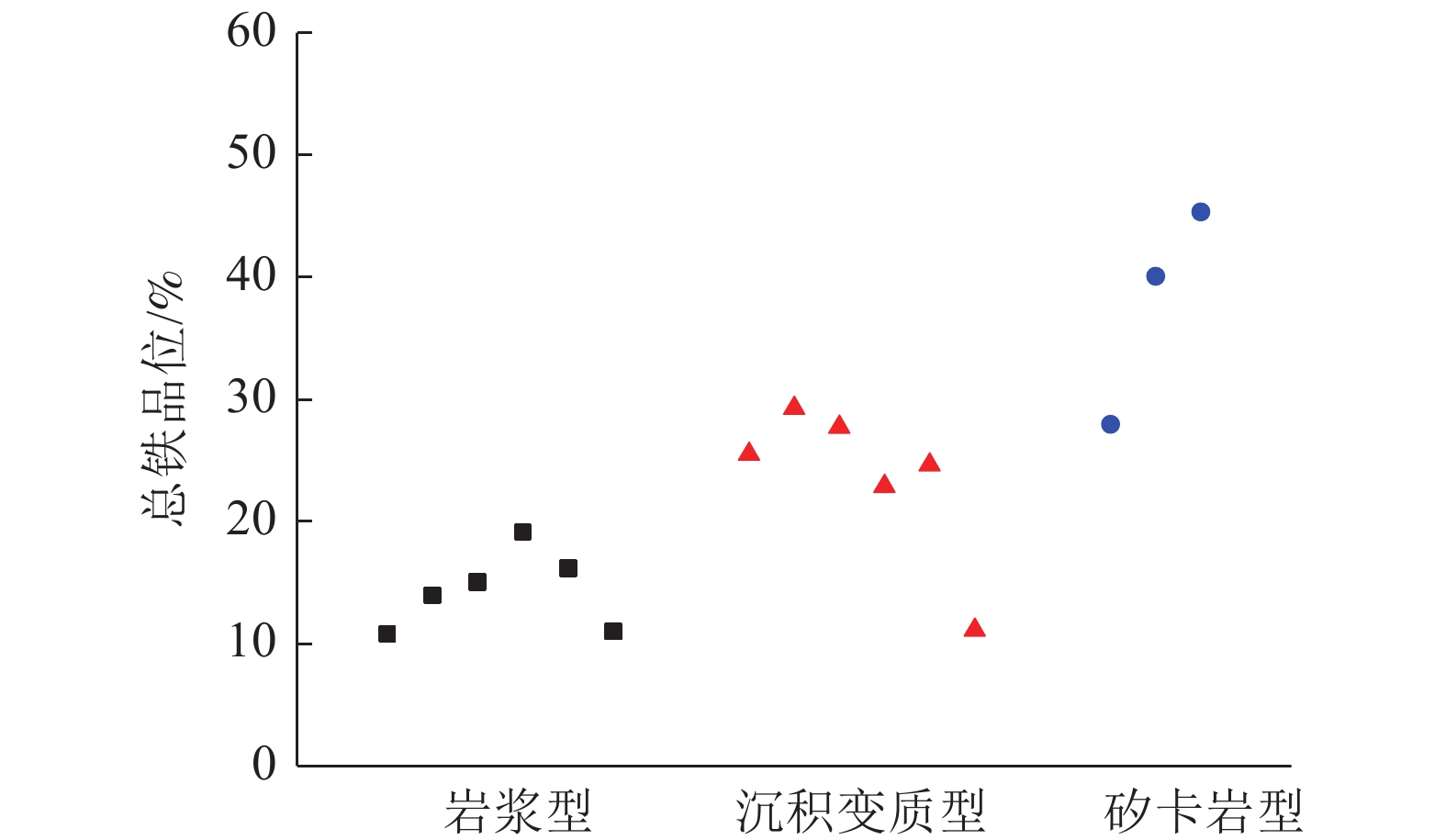

本文调查了河北省15座大中型铁矿山,系统地研究了河北地区铁矿资源的空间集聚特征和开发利用现状,具体分析了典型铁矿聚集区铁矿资源禀赋条件、开采和选矿的相似性和异质性、共伴生元素和尾矿的综合利用潜力,并给出了差异化利用的建议。研究结果表明:河北北部成矿类型是岩浆型铁矿床,河北东部成矿类型是沉积变质型铁矿床,河北中南部成矿类型是矽卡岩型铁矿床;三种类型的铁矿床中铁的品位和磁铁矿的占比呈现出矽卡岩型铁矿床>沉积变质型铁矿床>岩浆型铁矿床的规律,选矿回收率也呈现出同样的规律。岩浆型铁矿中的伴生元素TiO2,P2O5和Sc,具有回收利用的价值,应该加强综合利用的研究。铁矿山产生大量的尾矿,可根据其性质研究尾矿利用的方式,尽量减少尾矿的产生。

Abstract:In this study, 15 large and medium-sized iron deposits in Hebei Province are studied on their spatial agglomeration characteristics, development and utilization status of iron ore resources. We analyse detailedly on the endowment conditions of iron ore resources, the similarity and heterogeneity of mining and mineral processing, the comprehensive utilization potential of associated elements and tailings in typical accumulation areas of iron ore resources. Also, the differential utilization policies of different types of iron ore are given. The research results showed that the metallogenic types in northern Hebei, eastern Hebei, and central and southern Hebei are magmatic iron deposits, sedimentary metamorphic iron deposits, and skarn iron deposits respectively. The grade of iron and the proportion of magnetite in the three types of iron deposits are in the order of magnitude, skarn iron deposits > sedimentary metamorphic iron deposits > magmatic iron deposits. The recovery rate of mineral processing are also in the same order. The associated elements TiO2, P2O5 and Sc in the magmatic iron deposits have recyclable value and therefore, research on the comprehensive utilization of these elements should be strengthened. The iron deposits exploitation leads to the production of a large amount of tailings waste and the use of tailings can be studied according to their properties to minimize their production rate and recyclable benefits.

-

-

表 1 铁矿石原矿物相分析/%

Table 1. Mineral phase analysis of iron ores

矿山编号 所在地区 矿石类型 含量/分布率 磁性铁中的铁 菱铁中的铁 赤铁中的铁 硫铁中的铁 硅酸铁中的铁 总铁品位 1 承德市 岩浆型 含量 4.40 0.36 1.99 0.30 3.74 10.79 分布率 40.78 3.34 18.44 2.78 34.66 100.00 2 岩浆型 含量 7.52 0.36 2.48 0.36 3.21 13.93 分布率 53.98 2.58 17.80 2.58 23.04 100.00 3 岩浆型 含量 6.59 0.36 3.18 0.89 4.01 15.03 分布率 43.85 2.40 21.16 5.92 26.68 100.00 4 岩浆型 含量 8.68 0.86 3.99 0.55 5.04 19.12 分布率 45.40 4.50 20.87 2.88 26.36 100.00 5 岩浆型 含量 6.86 0.43 3.87 0.99 4.01 16.16 分布率 42.45 2.66 23.95 6.13 24.81 100.00 6 岩浆型 含量 3.48 0.56 3.81 0.30 2.85 11.00 分布率 31.64 5.09 34.64 2.73 25.91 100.00 7 秦皇岛市 沉积变质型 含量 20.96 0.43 1.42 0.03 2.68 25.52 分布率 82.13 1.68 5.56 0.12 10.50 100.00 8 唐山市 沉积变质型 含量 26.76 0.86 0.89 0.07 0.70 29.28 分布率 91.39 2.94 3.04 0.24 2.39 100.00 9 沉积变质型 含量 14.47 0.70 9.51 0.23 2.82 27.73 分布率 52.18 2.52 34.29 0.83 10.17 100.00 10 沉积变质型 含量 15.86 2.09 3.81 0.03 1.09 22.88 分布率 69.32 9.13 16.65 0.13 4.76 100.00 11 沉积变质型 含量 21.16 0.70 1.32 0.17 1.29 24.64 分布率 85.88 2.84 5.36 0.69 5.24 100.00 12 保定市 沉积变质型 含量 4.67 1.42 4.04 0.23 0.76 11.12 分布率 42.00 12.77 36.33 2.07 6.83 100.00 13 矽卡岩型 含量 25.88 0.60 1.21 0.07 0.20 27.96 分布率 92.56 2.15 4.33 0.25 0.72 100.00 14 邯郸市 矽卡岩型 含量 36.66 0.13 1.09 1.62 0.56 40.06 分布率 91.51 0.32 2.72 4.04 1.40 100.00 15 邢台市 矽卡岩型 含量 43.95 0.03 0.70 0.10 0.56 45.34 分布率 96.93 0.07 1.54 0.22 1.24 100.00 表 2 开采方式和采矿回采率

Table 2. Mining methods and mining recovery rate

矿山编号 矿床成因类型 开采方式 采矿方法 采矿回采率/% 1 岩浆型 露天开采 组合台阶采矿法 97.00 2 岩浆型 露天开采 组合台阶采矿法 91.50 3 岩浆型 露天开采 组合台阶采矿法 96.00 4 岩浆型 露天开采 组合台阶采矿法 95.00 5 岩浆型 露天开采 组合台阶采矿法 94.00 6 岩浆型 露天开采 组合台阶采矿法 95.00 7 沉积变质型 露天开采 组合台阶采矿法 91.20 8 沉积变质型 地下开采 分段凿岩阶段矿房嗣后充填采矿法 87.67 9 沉积变质型 地下开采 无底柱分段崩落采矿法 92.00 10 沉积变质型 露天开采 组合台阶采矿法 87.50 11 沉积变质型 露天开采 组合台阶采矿法 96.00 12 沉积变质型 露天开采 组合台阶采矿法 93.67 13 矽卡岩型 露天开采 组合台阶采矿法 97.00 14 矽卡岩型 地下开采 无底柱分段崩落采矿法 82.85 15 矽卡岩型 地下开采 上向分层充填采矿法 91.34 表 3 选矿主要指标

Table 3. Main mineral processing performances

矿山编号 矿床成因类型 主要目的矿物 选矿回收率/% 原矿入选品位/% 精矿品位/% 尾矿品位/% 1 岩浆型 主要为磁铁矿,黄铜矿 35.68 10.76 64.91 7.18 2 岩浆型 主要为磁铁矿,其次为赤铁矿 49.66 13.97 63.75 7.56 3 岩浆型 主要为磁铁矿,其次为赤铁矿 40.44 14.76 64.66 9.56 4 岩浆型 主要为磁铁矿,其次为钛铁矿 37.46 19.12 58.37 12.97 5 岩浆型 主要为磁铁矿,其次为钛铁矿 42.04 15.95 64.33 11.15 6 岩浆型 主要为磁铁矿,其次为赤铁矿 30.64 11.15 66.32 8.28 7 沉积变质型 主要为磁铁矿,其次为赤铁矿 83.72 28.32 66.24 7.18 8 沉积变质型 主要为磁铁矿,其次为赤铁矿 85.57 27.01 66.98 5.80 9 沉积变质型 主要为磁铁矿,黄铜矿 72.33 27.84 67.20 11.00 10 沉积变质型 主要为磁铁矿,其次为赤铁矿 68.59 22.96 66.73 9.44 11 沉积变质型 主要为磁铁矿,其次为赤铁矿 80.91 24.67 68.06 6.40 12 沉积变质型 主要为磁铁矿,其次为赤铁矿和菱铁矿 31.60 10.82 65.08 7.61 13 矽卡岩型 主要为磁铁矿,其次为赤铁矿和菱铁矿 92.77 28.15 62.76 3.42 14 矽卡岩型 主要为磁铁矿,其次为赤铁矿和褐铁矿 94.33 39.93 65.65 9.06 15 矽卡岩型 主要为磁铁矿,其次为赤铁矿 95.11 45.43 64.17 5.24 -

[1] 张艳飞, 郑国栋, 陈其慎, 等. 后疫情时期全球铁矿资源格局分析[J]. 地球学报, 2021, 42(2):209-216. doi: 10.3975/cagsb.2020.102605

ZHANG Y F, ZHENG G D, CHEN Q S, et al. Analysis of the global iron ore resource pattern in the post-epidemic period[J]. Chinese Journal of Geosciences, 2021, 42(2):209-216. doi: 10.3975/cagsb.2020.102605

[2] YU S W, DUAN H R, CHENG J H. An evaluation of the supply risk for China's strategic metallic mineral resources[J]. Resources Policy, 2020, 70(6):101891.

[3] 赵一鸣. 中国主要富铁矿床类型及地质特征[J]. 矿床地质, 2013, 32(4):686-705. doi: 10.16111/j.0258-7106.2013.04.004

ZHAO Y M. Types and geological characteristics of major iron-rich deposits in China[J]. Mineral Geology, 2013, 32(4):686-705. doi: 10.16111/j.0258-7106.2013.04.004

[4] 贺喜, 张举钢, 周吉光, 等. 河北省铁矿资源保障能力分析[J]. 地球学报, 2013, 34(6):731-737. doi: 10.3975/cagsb.2013.06.10

HE X, ZHANG J G, ZHOU J G, et al. Analysis on the guarantee ability of iron ore resources in Hebei Province[J]. Chinese Journal of Earth Sciences, 2013, 34(6):731-737. doi: 10.3975/cagsb.2013.06.10

[5] 印万忠, 徐东, 杨耀辉, 等. 承德某钒钛磁铁矿尾矿资源化利用技术研究[J]. 矿产综合利用, 2020(6):37-42. doi: 10.3969/j.issn.1000-6532.2020.06.007

YIN W Z, XU D, YANG Y H, et al. Research on the recycling technology for a vanadium-titanium Magnetite tailings in Chengde[J]. Multipurpose Utilization of Mineral Resources, 2020(6):37-42. doi: 10.3969/j.issn.1000-6532.2020.06.007

[6] 温子龙. 河北省铁矿行业发展现状及未来展望[J]. 冶金经济与管理, 2020, 2:39-41. doi: 10.3969/j.issn.1002-1779.2020.02.010

WEN Z L. The development status and future prospect of iron ore industry in Hebei Province[J]. Metallurgical Economics and Management, 2020, 2:39-41. doi: 10.3969/j.issn.1002-1779.2020.02.010

[7] 工业固废网. 中国大宗工业固体废物综合利用产业发展报告(2020-2021年度)[R], 2021.

Industrial Solid Waste Network. China's industrial development report on comprehensive utilization of bulk industrial solid waste (2020-2021) [R], 2021.

[8] 赵志勇. 冀东铁矿资源价值研究[D]. 唐山: 河北理工学院, 2003.

ZHAO Z Y. Research on the value of iron ore resources in Jidong[D]. Tangshan: Hebei Institute of Technology, 2003.

[9] 沈保丰, 翟安民, 苗培森, 等. 华北陆块铁矿床地质特征和资源潜力展望[J]. 地质调查与研究, 2006(4):244-252. doi: 10.3969/j.issn.1672-4135.2006.04.003

SHEN B F, ZHAI A M, MIAO P S, et al. Geological characteristics and resource potential prospect of iron ore deposits in the North China continental block[J]. Geological Survey and Research, 2006(4):244-252. doi: 10.3969/j.issn.1672-4135.2006.04.003

[10] 张亚明, 王雪峰, 李文超. 铁矿资源综合利用效益评价体系研究[J]. 中国国土资源经济, 2019, 32(4):43-48. doi: 10.19676/j.cnki.1672-6995.0000256

ZHANG Y M, WANG X F, LI W C. Research on the evaluation system of comprehensive utilization of iron ore resources[J]. China Land and Resources Economy, 2019, 32(4):43-48. doi: 10.19676/j.cnki.1672-6995.0000256

[11] 黄雯孝, 卢可可. 攀西钒钛磁铁矿尾矿中钪的提取工艺研究[J]. 矿产综合利用, 2020(2):135-139. doi: 10.3969/j.issn.1000-6532.2020.02.024

HUANG W X, LU K K. Study on scandium extraction technology for Panxi vanadium titanium magnetite tailings[J]. Multipurpose Utilization of Mineral Resources, 2020(2):135-139. doi: 10.3969/j.issn.1000-6532.2020.02.024

[12] 陈超, 张裕书, 李潇雨, 等. 攀西某钒钛磁铁矿尾矿中磷的回收实验研究[J]. 矿产综合利用, 2021(4):165-169. doi: 10.3969/j.issn.1000-6532.2021.04.026

CHEN C, ZHANG Y S, LI X Y, et al. Recovery of phosphorus from a vanadium titanium magnetite tailing in Panxi[J]. Multipurpose Utilization of Mineral Resources, 2021(4):165-169. doi: 10.3969/j.issn.1000-6532.2021.04.026

[13] 刘文宝, 张昊, 刘文刚, 等. 铁矿废石综合利用研究进展[J]. 矿产保护与利用, 2021, 41(3):118-125. doi: 10.13779/j.cnki.issn1001-0076.2021.03.017

LIU W B, ZHANG H, LIU W G, et al. Research progress on comprehensive utilization of iron ore waste rock[J]. Mineral Protection and Utilization, 2021, 41(3):118-125. doi: 10.13779/j.cnki.issn1001-0076.2021.03.017

[14] 李涛, 刘晨, 佘世杰. 铜渣中铁铜回收的试验研究[J]. 矿产综合利用, 2020(2):145-150. doi: 10.3969/j.issn.1000-6532.2020.02.026

LI T, LIU C, SHE S J. Research on recovery of iron and copper in copper slag[J]. Multipurpose Utilization of Mineral Resources, 2020(2):145-150. doi: 10.3969/j.issn.1000-6532.2020.02.026

[15] 刘俊杰, 梁钰, 曾宇, 等. 利用铁尾矿制备免烧砖的研究[J]. 矿产综合利用, 2020(5):136-141. doi: 10.3969/j.issn.1000-6532.2020.05.021

LIU J J, LIANG Y, ZENG Y, et al. Preparation of baking-free bricks by iron tailings[J]. Multipurpose Utilization of Mineral Resources, 2020(5):136-141. doi: 10.3969/j.issn.1000-6532.2020.05.021

[16] LI C, SUN H H, BAI J, et al. Innovative methodology for comprehensive utilization of iron ore tailings: part 1. The recovery of iron from iron ore tailings using magnetic separation after magnetizing roasting[J]. Journal of Hazardous Materials, 2010, 174(1-3):71-77. doi: 10.1016/j.jhazmat.2009.09.018

-

下载:

下载: