Study on the Application of X - ray Separation Technology in Phosphate Mine Dressing

-

摘要:

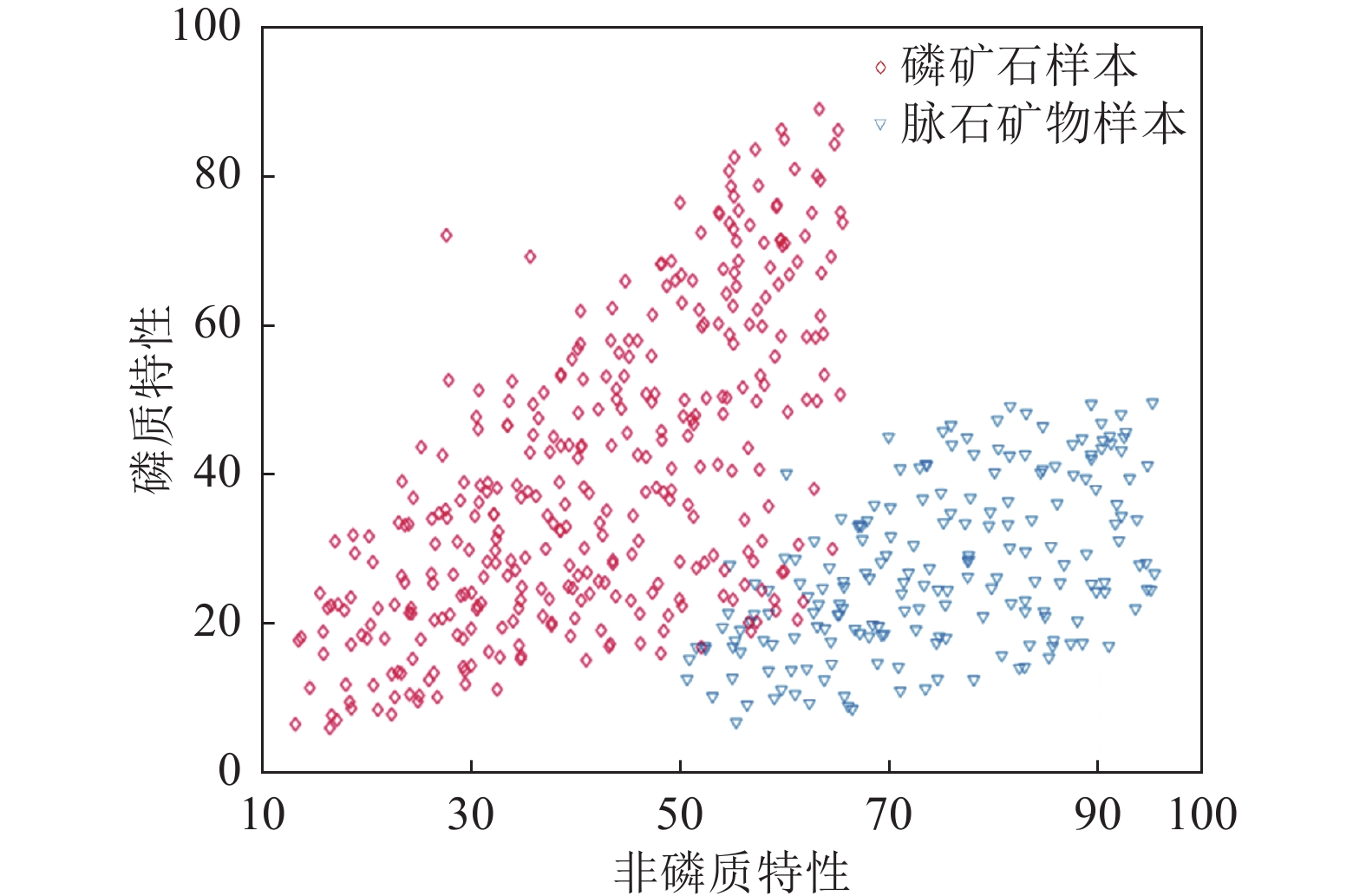

本文介绍了磷矿选矿现状和问题,介绍了X射线分选技术的原理及应用现状,对其在磷矿中的应用进行了详细的介绍和数据分析。X射线分选技术是无水分选,工艺流程简单,可解决因磷矿石品位低选矿比高,重介质选矿介质消耗大,造成传统选矿方法成本高,同时对环境产生不良影响等问题。提出了提高磷矿X射线分选技术精准化的方法,并对该技术在磷矿领域的应用前景进行了展望。

Abstract:This paper introduces the present situation and problems of phosphate mine dressing, introduces the principle and application status of X-ray separation technology, and gives a detailed introduction and data analysis of the application in phosphate mine dressing. X-ray separation technology is non-water separation and simple process, it can solve the problems such as high flotation ratio of low grade phosphate ore, high consumption of heavy medium, high cost and bad influence on environment. Proposes some methods to improve the precision of X-ray separation technology of phosphate rock, and prospects the application prospect of this technology of phosphate.

-

Key words:

- Phosphorus rock /

- X-ray separation /

- Phosphorus mine dressing /

- Precision separation

-

-

表 1 X射线智能分选机分选金属矿石实例

Table 1. X-ray intelligent separator separation of metal ore examples

矿石类型 粒级/mm 产品名称 产率/% 品位/% 回收率/% 湖南锡矿山锑矿(Sb) 15~100 粗精矿 30.10 4.70 95.29 尾矿 69.90 0.10 4.71 原矿 100.00 1.49 100.00 江西章源钨矿(WO3) 15~50 粗精矿 20.34 5.10 97.02 尾矿 79.66 0.04 2.98 原矿 100.00 1.06 100.00 云南某锡矿(Sn) 15~90 粗精矿 29.84 0.60 96.23 尾矿 70.16 0.01 3.77 原矿 100.00 0.19 100.00 湖南某金矿(Au,g/t) 15~60 粗精矿 33.12 7.54 88.40 尾矿 66.88 0.49 11.60 原矿 100.00 2.80 100.00 青海某铜矿(Cu) 8~75 粗精矿 61.78 1.93 98.27 尾矿 38.22 0.05 1.73 原矿 100.00 1.19 100.00 辽宁某铅锌矿 +8-75mm Pb Zn Pb Zn 粗精矿 47.81 3.08 5.33 96.44 96.82 尾矿 52.19 0.10 0.16 3.56 3.18 原矿 100.00 1.53 2.63 100.00 100.00 表 2 X射线智能分选技术分选萤石实例

Table 2. X-ray intelligent sorting technology of fluorite examples

矿石类型 分选粒级/mm 原矿 精矿指标/% 尾矿指标/% 品位/% 产率 品位 回收率 产率 品位 回收率 江西某萤石矿 +10-75 51.24 67.00 71.92 93.77 33.00 9.62 6.23 承德萤石废石 +10-50 17.40 46.00 30.07 80.21 54.00 6.70 19.79 表 3 对比实验结果

Table 3. Comparison test results

实验流程 精矿指标/% 尾矿指标/% 产率 品位 回收率 产率 品位 回收率 正-反浮选 51.62 30.56 80.61 48.38 7.84 19.39 X射线-反浮选 45.57 34.58 80.52 54.43 7.00 19.48 表 4 宜昌磷矿原矿化学多项分析/%

Table 4. Chemical analysis of Yichang Phosphate

P2O5 MgO SiO2 CaO CO2 Fe2O3 Al2O3 F K2O Na2O 22.07 6.09 16.51 37.57 8.31 1.13 2.95 2.13 1.76 0.41 表 5 宜昌磷矿X射线分选实验结果

Table 5. X-ray separation test results of Yichang Phosphate

序号 粒级/mm 原矿品位/% 精矿指标 尾矿指标 产率/% P2O5品位/% MgO含量/% SiO2含量/% 回收率/% 产率/% P2O5品位/% 回收率/% 1 +8-50 19.95 58.20 27.85 2.79 10.19 81.23 41.80 8.96 18.77 2 +8-50 20.47 47.90 31.09 1.91 9.76 72.76 52.10 10.70 27.24 3 +8-25 21.89 58.37 29.71 2.43 10.17 79.22 41.63 10.93 27.06 4 +25-50 16.72 31.47 28.49 2.73 12.07 53.61 68.53 11.32 46.39 表 6 杉树垭磷矿X射线分选实验结果

Table 6. Results of X-ray separation test of Shanshuya phosphate

分选粒级/mm 原矿 精矿指标 尾矿指标 品位/% 产率/% 品位/% 回收率/% 产率/% 品位/% 回收率/% -50+15 16.85 42.71 27.22 68.99 57.29 9.12 31.01 -25+15 17.78 52.28 25.64 75.39 47.72 9.17 24.61 -40+10 19.48 55.73 27.47 78.59 44.27 9.42 21.41 -50+10 20.54 55.22 28.60 76.89 44.78 10.60 23.11 -50+10 20.32 63.49 26.15 81.71 36.51 10.18 18.29 -50+10 21.89 58.36 29.71 79.21 41.64 10.93 20.79 表 7 杉树垭磷矿 精矿、尾矿筛分分析结果

Table 7. Screening analysis results of Shanshuya phosphate concentrate and tailings

筛分粒级/mm 精矿筛析 尾矿筛析 产率/% 品位/% 回收率/% 产率/% 品位/% 回收率/% -10 7.51 20.99 5.55 4.23 14.79 5.99 +10-20 18.26 29.35 18.87 14.99 9.74 13.98 +20-30 42.66 29.26 43.95 31.16 8.92 26.60 +30-40 19.17 27.90 18.83 24.73 13.48 31.91 +40-50 12.39 29.32 12.79 24.89 9.03 21.51 合计 100.00 28.40 100.00 100.00 10.45 100.00 表 8 杉树垭磷矿精矿、尾矿手选分析结果

Table 8. Results of manual separation analysis of Shanshuya phosphate concentrate and tailings

含磷矿物比例/% 精矿 尾矿 产率/% 品位/% 回收率/% 产率/% 品位/% 回收率/% 90 50.60 32.84 58.51 -- -- -- 70 18.87 27.54 18.30 12.65 25.09 30.37 50 15.89 25.13 14.06 19.53 16.17 30.23 10 7.12 14.26 3.58 63.59 5.49 33.41 -10 7.51 20.99 5.55 4.23 14.79 5.99 合计 100.00 28.40 100.00 100.00 10.45 100.00 -

[1] 韩豫川, 夏学惠, 肖荣阁, 等. 中国磷矿床[M]. 北京: 地质出版社, 2012.

HAN Y C, XIA X H, XIAO R G, et al. China phosphorus deposit[M]. Beijing: Geological Publishing House, 2012.

[2] 彭儒, 罗廉明. 磷矿选矿[M]. 武汉: 武汉测绘科技大学出版社, 1992.

PENG R, LUO L M. Phosphate mine dressing[M]. Wuhan: Wuhan University of Surveying and Mapping Technology Publishing House, 1992.

[3] 王涛, 付磊, 李宁. 某硅钙质胶磷矿正反浮选实验研究[J]. 矿产综合利用, 2020(2):91-95. WANG T, FU L, LI N. Study on direct-reverse flotation of a silica calcinate phosphate ore[J]. Multipurpose Utilization of Mineral Resources, 2020(2):91-95. doi: 10.3969/j.issn.1000-6532.2020.02.016

[4] 汤优优, 喻连香, 陈雄. 重介质选矿技术在处理有色金属矿和非金属矿的研究现状及展望[J]. 矿产综合利用, 2021(4):118-124. TANG Y Y, YU L X, CHEN X. Research status and prospects of heavy medium beneficiation technology in treating non-ferrous and non-metallic ores[J]. Multipurpose Utilization of Mineral Resources, 2021(4):118-124. doi: 10.3969/j.issn.1000-6532.2021.04.018

[5] 朱一民. 2020 年浮选药剂的进展[J]. 矿产综合利用, 2021(2):102-118. ZHU Y M. Development of flotation reagent in 2020[J]. Multipurpose Utilization of Mineral Resources, 2021(2):102-118. doi: 10.3969/j.issn.1000-6532.2021.02.019

[6] 孙照焱, 蒋康生, 尹华功, 等. XNDT-104智能分选系统在闪星锑业的应用[J]. 有色金属设计, 2019, 46(3):128-131. SUN Z Y, JIANG K S, YIN H G, et al. Application of XNDT-104 intelligent sorting system in Shanxing Antimony Industry Co., Ltd.[J]. Nonferrous Metal Design, 2019, 46(3):128-131. doi: 10.3969/j.issn.1004-2660.2019.03.039

[7] 韩跃新, 王泽红, 陈晓龙, 等. X射线辐射分选技术及设备的发展与应用[J]. 矿产综合利用, 2013(6):11-14. HAN Y X, WANG Z H, CHEN X L, et al. Development and application of X-ray radiation separation technology and equipment[J]. Multipurpose Utilization of Mineral Resources, 2013(6):11-14. doi: 10.3969/j.issn.1000-6532.2013.06.004

[8] 印万忠, 吴尧, 等. X射线辐射分选原理及应用[J]. 中国矿业, 2011, 20(12):88-90. YIN W Z, WU Y, et al. The theory and application of X-ray separation technology[J]. China Mining Magazine, 2011, 20(12):88-90. doi: 10.3969/j.issn.1004-4051.2011.12.023

[9] 李宇新, 童晓蕾, 李艳, 等. 重介质选矿、X 射线分选在宜昌磷矿各矿层选矿的工业应用对比[J]. 化工矿产地质, 2020, 42(1):77-82. LI Y X, TONG X L, LI Y, et al. Comparison of the industrial application of heavy medium beneficiation and X-ray separation of mineral dressing in mineral layers of Yichang phosphate mine[J]. Geology of Chemical Minerals, 2020, 42(1):77-82. doi: 10.3969/j.issn.1006-5296.2020.01.013

[10] 余新文, 杨敏, 毛素荣, 等. X射线分选技术在磷矿石选矿中的应用[J]. 化工矿物与加工, 2020, 网络首发: 2020, network launch: 1-8.

YU X W, YANG M, MAO S R, et al. Research on application of X-ray separation technology in beneficiation of phosphate rock[J]. Industrial Minerals & Processing, 2020, network launch: 1-8.

[11] 李宁, 张树洪, 彭桦, 等. 光电选矿在某磷矿中的应用实践及评价[J]. 非金属矿, 2018, 41(2):73-75. LI N, ZHANG S H, PENG H, et al. Application practice and evaluation of photoelectric separation in a phosphate mining industry[J]. Non-Metallic Mines, 2018, 41(2):73-75. doi: 10.3969/j.issn.1000-8098.2018.02.024

-

下载:

下载: