Study on Preparation and Properties of Steel Slag-Shale Slag Foamed Ceramics Material

-

摘要:

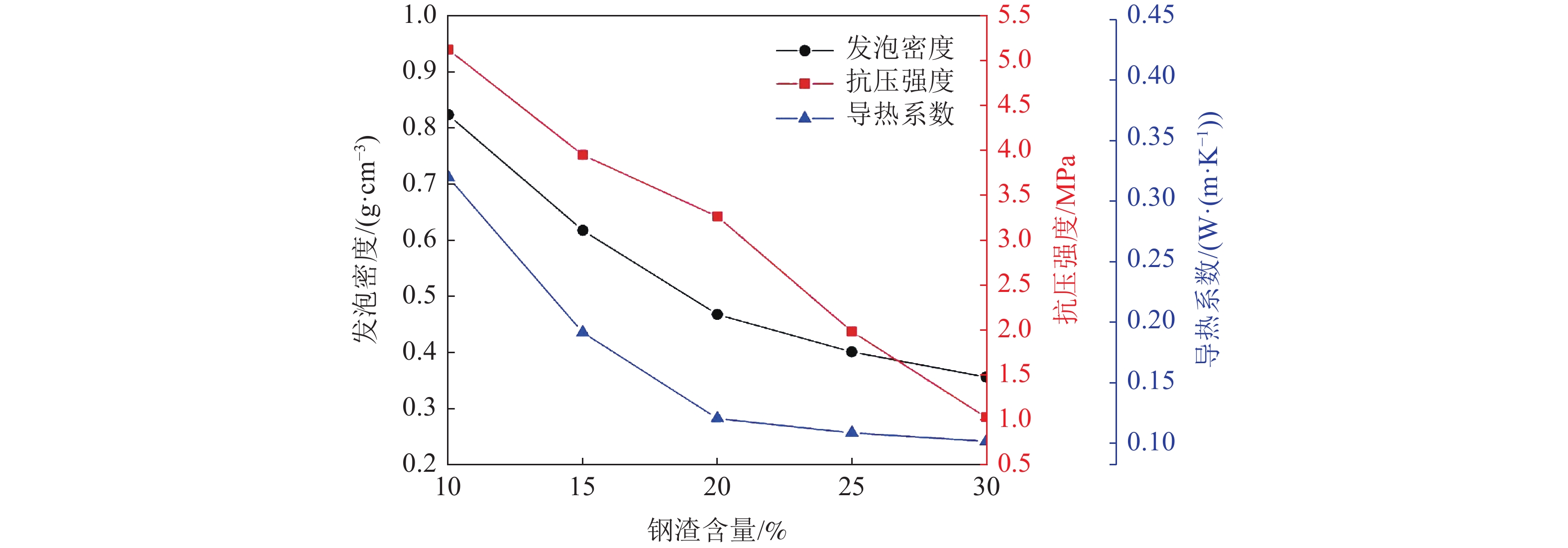

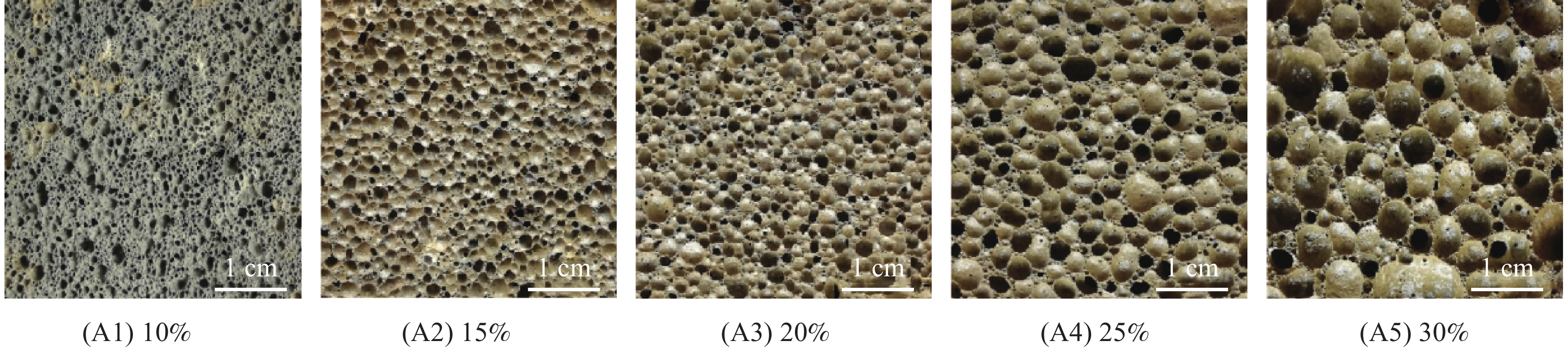

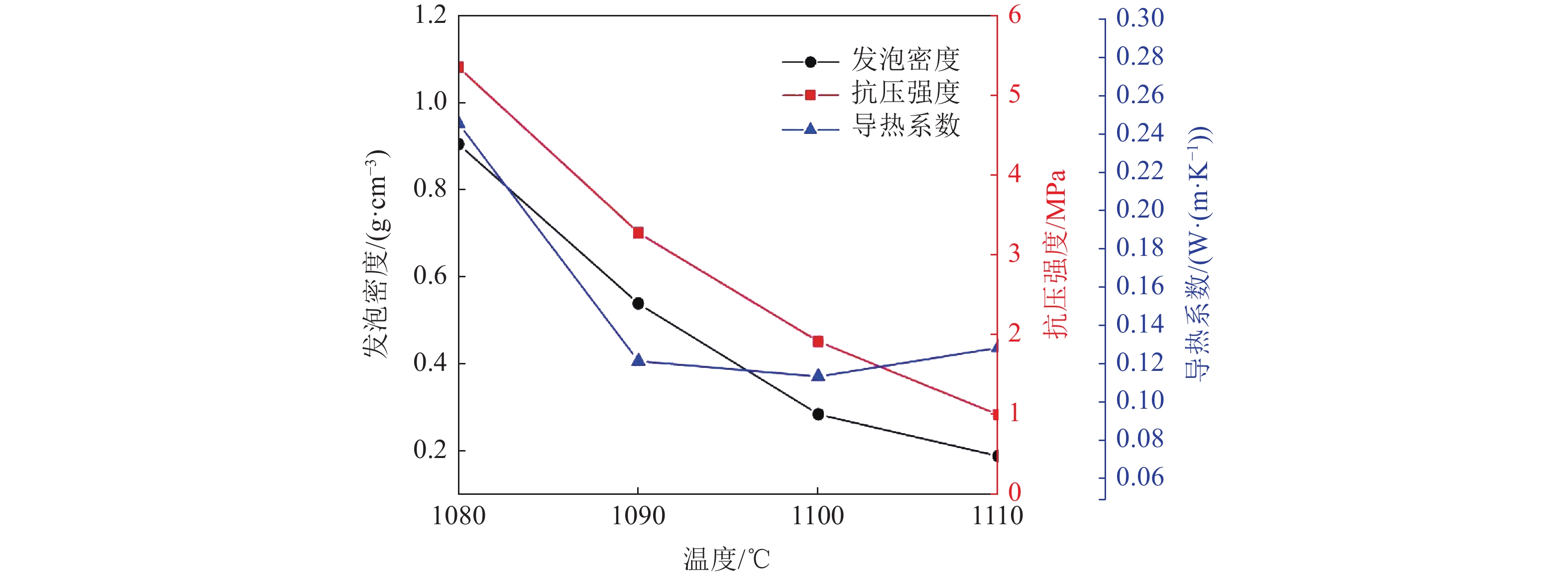

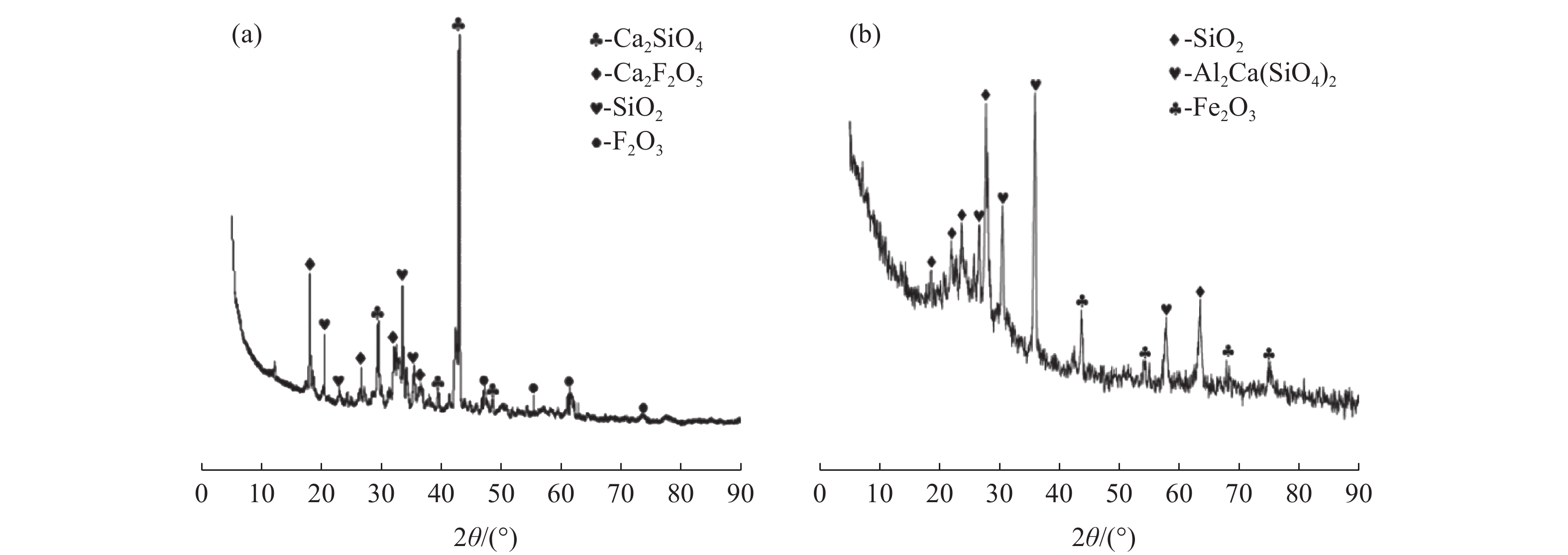

这是一篇陶瓷及复合材料领域的论文。利用钢渣和页岩渣为主要原料,添加碳化硅、硼砂作为发泡剂和助熔剂,采用高温发泡法成功制备出发泡陶瓷材料。本文重点研究了钢渣含量、SiC添加量、硼砂添加量及发泡温度对发泡陶瓷的气孔结构和性能的影响。实验结果表明,当钢渣含量为20%,页岩渣为80%,额外添加0.5%的SiC,4%的硼砂,在发泡温度1090 ℃,保温时间40 min的条件下得到的发泡陶瓷材料性能较优。该条件下发泡陶瓷的体积密度为0.468 g/cm3,抗压强度为3.265 MPa,导热系数为0.121 W/(m·K),其性能符合建筑保温材料的要求,主晶相为辉石相、石英相和透辉石相。

Abstract:This is a paper in the field of ceramics and composites. High-temperature foaming method has been successfully applied to prepare foamed ceramics material by using steel slag and shale slag as the main raw materials. Silicon carbide and borax were used as the foaming agent and fluxing agent, respectively. This paper focused on the influence of steel slag content, SiC addition, borax addition and foaming temperature on the pore structure and properties of foamed ceramics. The experimental results showed that when the steel slag content is 20%, the shale slag is 80%, SiC of 0.5% and borax of 4% are additionally added, the foaming temperature is 1090 ℃ and the holding time is 40 min, the foamed ceramics material has the best properties. Under optimal conditions, the bulk density, compressive strength and thermal conductivity of the foamed ceramics are 0.468 g/cm3, 3.265 MPa and 0.121 W/(m·K), which meets the property requirements of building insulation materials. The main crystal phases are augite phase, quartz phase and diopside phase.

-

Key words:

- Steel slag /

- Shale slag /

- Foamed ceramics /

- Pore structure /

- Comprehensive properties

-

-

表 1 钢渣和页岩渣的化学组成/%

Table 1. Chemical composition of steel slag and shale slag

名称 SiO2 Al2O3 Fe2O3 TiO2 CaO MgO K2O Na2O IL 钢渣 15.02 6.14 22.58 0.51 42.18 8.94 0.14 0.12 4.37 页岩渣 63.17 18.21 6.14 0.76 5.09 1.95 2.84 0.21 1.63 表 2 实验配方/ %

Table 2. Experimental formula

配方编号 钢渣 页岩渣 碳化硅 硼砂 A1 10 90 0.5 4 A2 15 85 0.5 4 A3 20 80 0.5 4 A4 25 75 0.5 4 A5 30 70 0.5 4 B1 20 80 0.1 4 B2 20 80 0.3 4 B3 20 80 0.5 4 B4 20 80 0.7 4 B5 20 80 0.9 4 C1 20 80 0.5 0 C2 20 80 0.5 2 C3 20 80 0.5 4 C4 20 80 0.5 6 C5 20 80 0.5 8 -

[1] 邓坚勇, 胡丽芳, 罗淑芬, 等. 发泡剂在发泡陶瓷保温板中发泡原理的研究[J]. 佛山陶瓷, 2017, 27(1):34-36. DENG J Y, HU L F, LUO S F, et al. Research of foaming mechanism of foaming agent in foam ceramic insulation board[J]. Foshan Ceramics, 2017, 27(1):34-36.

DENG J Y, HU L F, LUO S F, et al. Research of foaming mechanism of foaming agent in foam ceramic insulation board[J]. Foshan Ceramics, 2017, 27(1): 34-36.

[2] Huo W L, Zhang X Y, Chen Y G, et al. Novel mullite ceramic foams with high porosity and strength using only fly ash hollow spheres as raw material[J].Journal of the European Ceramic Society, 2017, 38(4): 2035-2042.

[3] 刘欣, 李家科, 程凯. 蛇纹石尾矿资源化制备发泡陶瓷的研究[J]. 陶瓷学报, 2013, 34(4):461-466. LIU X, LI J K, CHEN K. Preparation of the foamed ceramic with serpentine tailings[J]. Journal of Ceramics, 2013, 34(4):461-466. doi: 10.13957/j.cnki.tcxb.2013.04.013

LIU X, LI J K, CHEN K. Preparation of the foamed ceramic with serpentine tailings[J]. Journal of Ceramics, 2013, 34(4): 461-466. doi: 10.13957/j.cnki.tcxb.2013.04.013

[4] Jiang C C, Huang S F, Li G Z, et al. Formation of closed-pore foam ceramic from granite scraps[J]. Ceramics International, 2018, 44(3): 3469-3471, 44(3):3469-3471.

[5] 杨赞中. 抛光砖废渣复合发泡法制备闭孔泡沫陶瓷[J]. 材料导报, 2017, 20(31):122-126. YANG Z Z. Preparation of closed pore foamed ceramics through complex foaming method by using porcelain tile residues[J]. Materials Reports, 2017, 20(31):122-126.

YANG Z Z. Preparation of closed pore foamed ceramics through complex foaming method by using porcelain tile residues[J]. Materials Reports, 2017, 20(31): 122-126.

[6] 庞才良, 杨雪晴, 宋杰光, 等. 钢渣综合利用的研究现状及发展趋势[J]. 砖瓦, 2020, 387(3):79-82. PANG C L, YANG X Q, SONG J G, et al. Research status and development trend of comprehensive utilization of steel slag[J]. Brick-Tile, 2020, 387(3):79-82.

PANG C L, YANG X Q, SONG J G, et al, Research status and development trend of comprehensive utilization of steel slag[J]. Brick-Tile, 2020, 387(3): 79-82.

[7] 丁力. 利用页岩制作发泡陶瓷的研究[J]. 陶瓷, 2015(4):23-27. DING L. Research on making foamed ceramics from shale[J]. Ceramics, 2015(4):23-27. doi: 10.19397/j.cnki.ceramics.2015.04.005

DING L. Research on making foamed ceramics from shale[J]. Ceramics, 2015(4): 23-27. doi: 10.19397/j.cnki.ceramics.2015.04.005

[8] Liu T Y, Li X Y, Guan L M, et al. Low-cost and environment-friendly ceramic foams made from ead-zinc mine tailings and red mud: Foaming mechanism, physical, mechanical and chemical properties[J]. Ceramics International, 2016, 42(1):1733-1739. doi: 10.1016/j.ceramint.2015.09.131

[9] Wang H, Chen Z W, Liu L L, et al. Synthesis of a foam ceramic based on ceramic tile polishing waste using SiC as foaming agent[J]. Ceramics International, 2018, 44(9):10078-10086. doi: 10.1016/j.ceramint.2018.02.211

[10] 张优. 铝灰发泡建筑陶瓷材料的制备及其发泡机理的研究[D]. 景德镇: 景德镇陶瓷大学, 2019.

ZHANG Y. Research on the preparation and foaming mechanism of foamed architectural ceramic materials by aluminum ash[D]. Jingdezhen: Jingdezhen Ceramic Institute, 2019.

[11] 池跃章, 沈光银, 吴子荣, 等. 发泡剂对利用废渣和尾矿制备闭孔发泡陶瓷的影响[J]. 新型建筑材料, 2008(7): 80-82.

CHI Y Z, SHEN G Y, WU Z R, et al. Influence of foaming agent on producing closed porosity ceramics using solid residue and tailings[J]. New Building Materials, 2008(7): 80-82.

-

下载:

下载: