Comprehensive Utilizations of the Strategic Mineral Resources from Vanadium Titano-Magnetite Tailings in the Panxi Region, SW China

-

摘要:

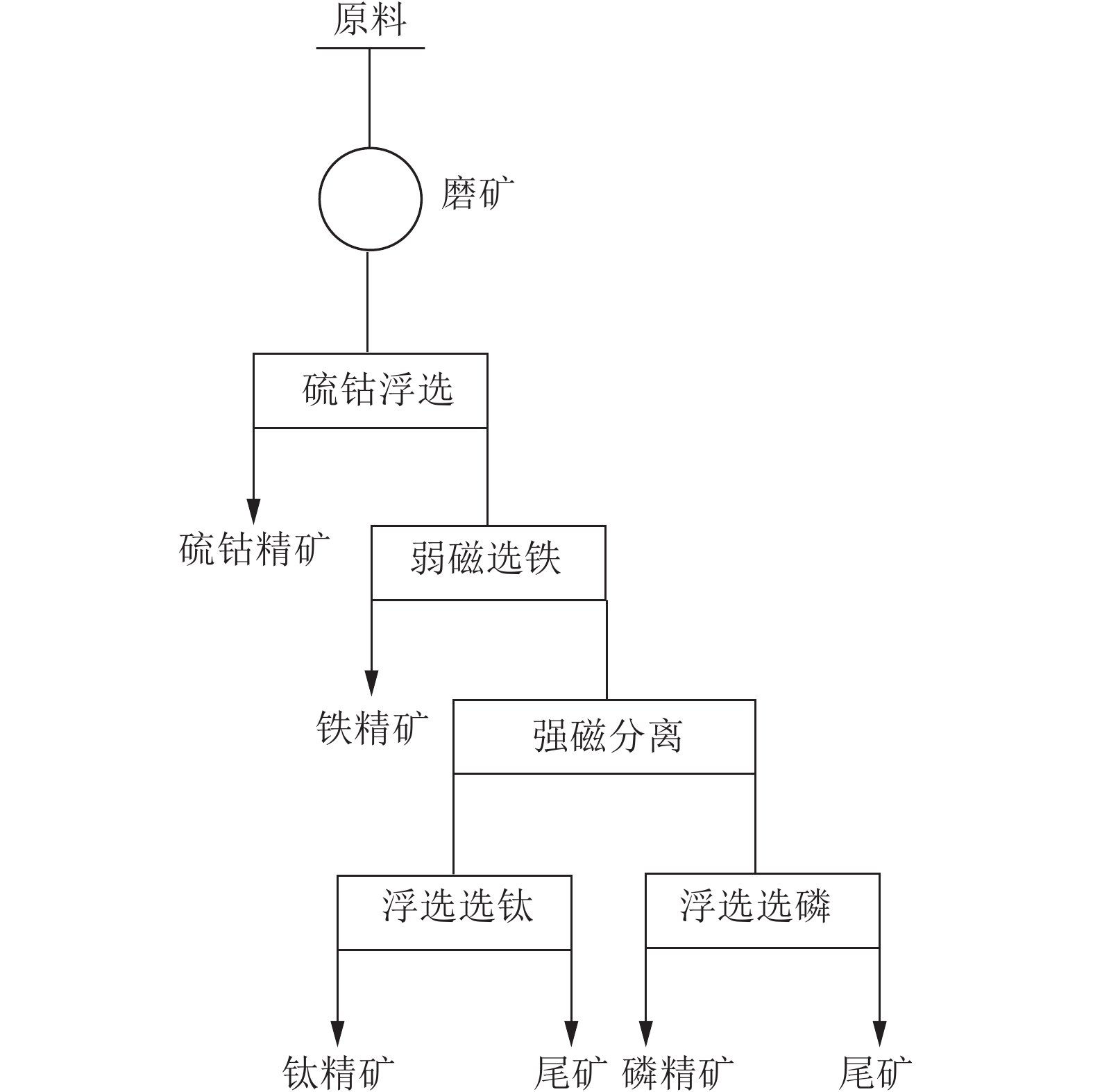

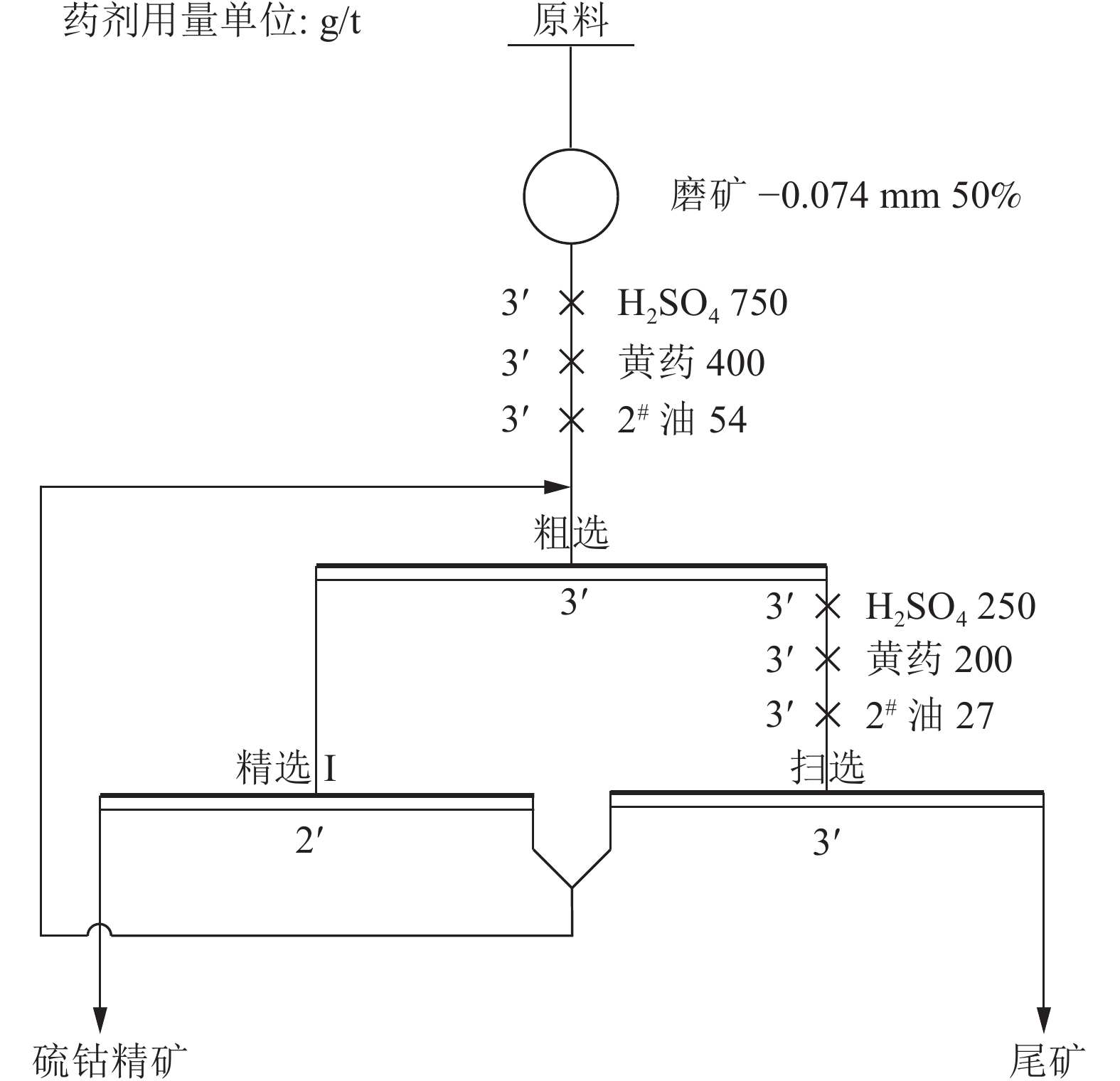

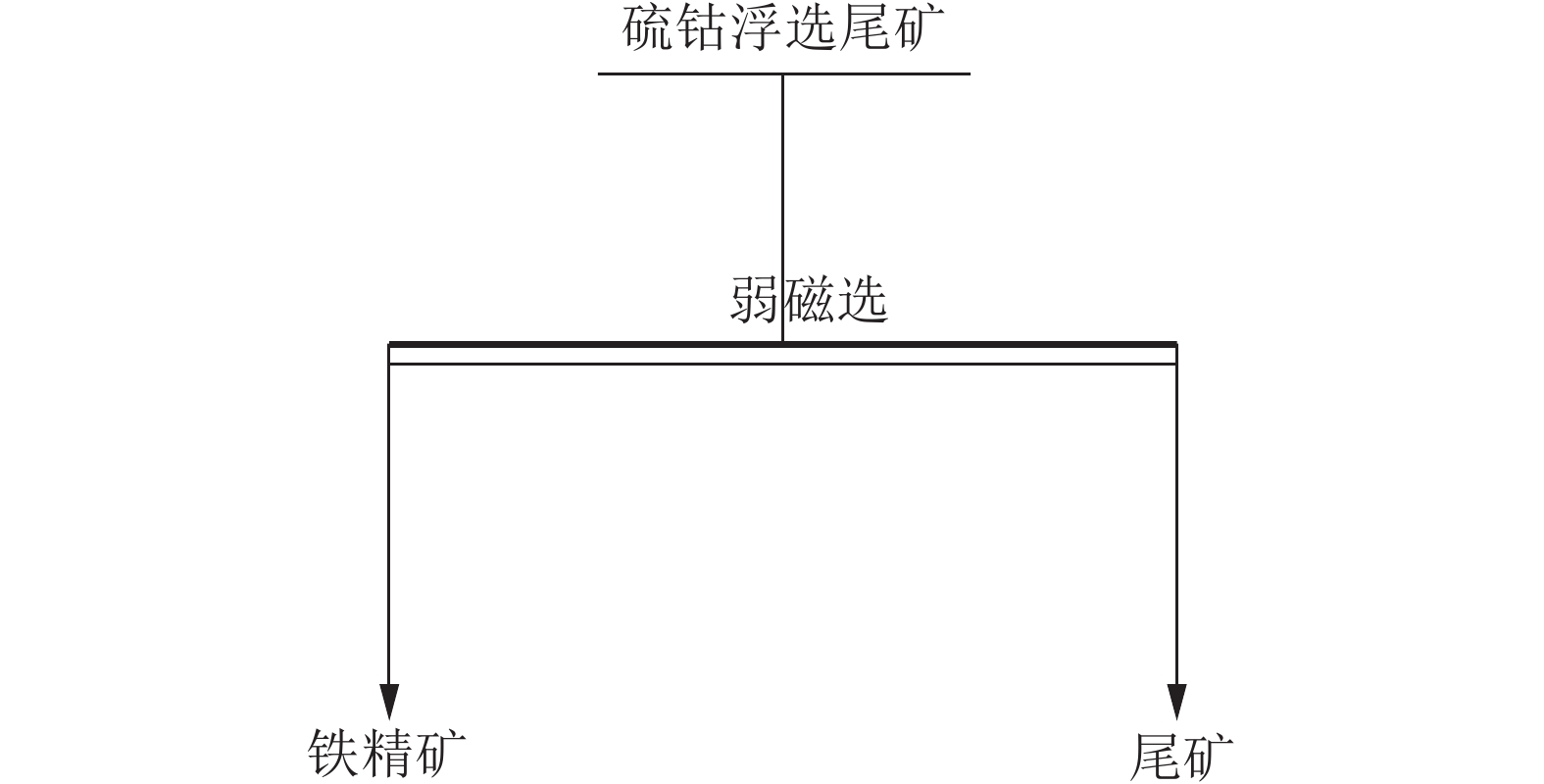

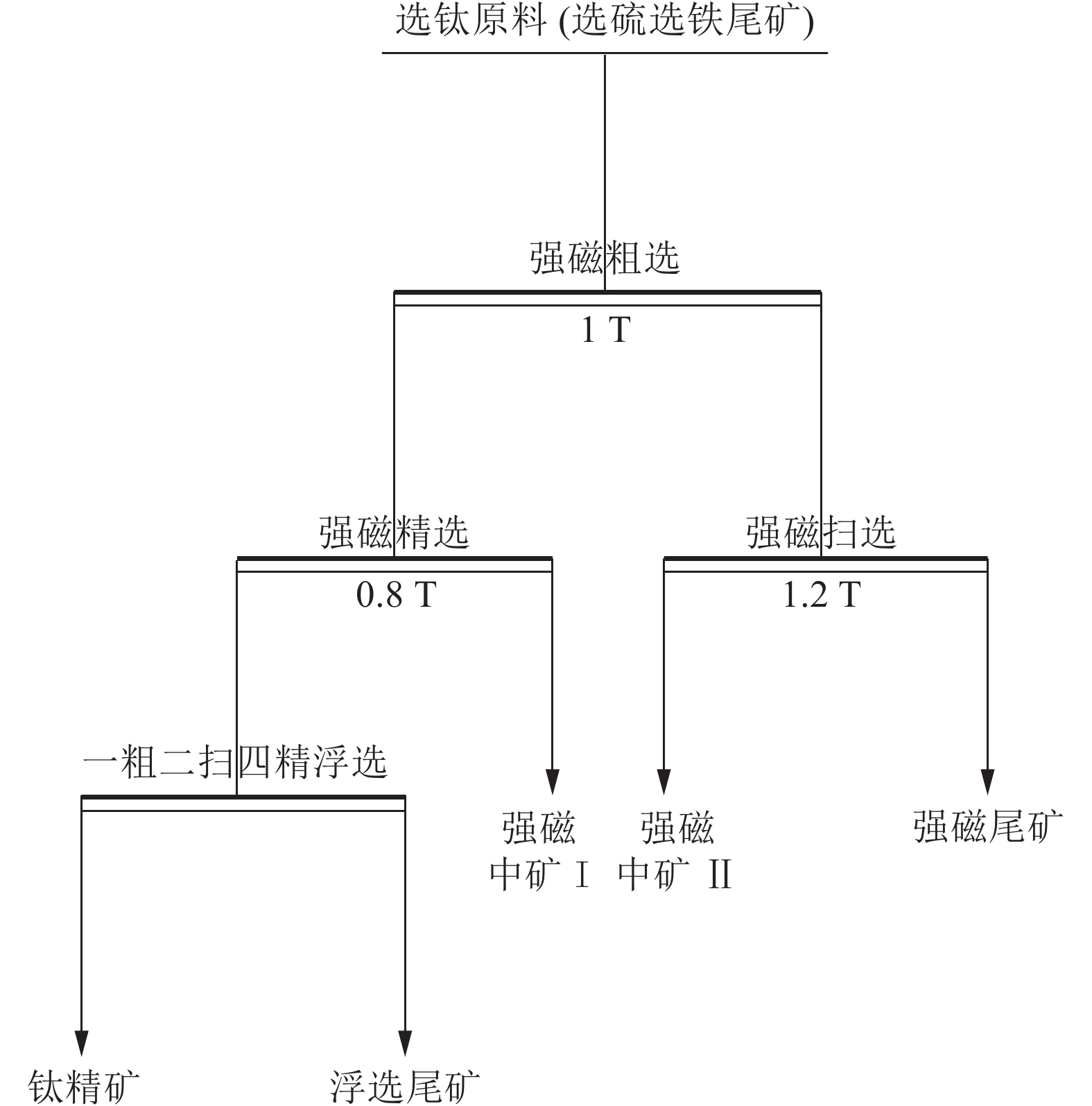

这是一篇矿物加工工程领域的论文。攀西地区是我国最大的钒钛磁铁矿资源基地,伴随着钒钛磁铁矿的开采和选冶,产生了巨量的尾矿。攀西钒钛磁铁矿尾矿中钒、钛、铁、铜、钴、镍、磷、钪等战略性元素的含量较高,具有潜在的回收价值,但尚未开展系统的选矿回收实验。通过对攀西地区红格矿区尾矿工艺矿物学的研究,拟定了尾矿中战略性元素综合利用技术路线,并开展了系统的选矿回收实验。以浮选选硫—弱磁选铁—强磁浮选选钛—强磁尾矿浮选磷为技术路线,获得了钴品位为0.175%的硫钴精矿、TFe品位56.57%的铁精矿、TiO2品位45.97%的钛精矿、P2O5品位31.73%的磷精矿。研究表明,通过系统的选矿回收实验,能够减少尾矿排放量21.3%,并且,回收这些战略性矿产能获得年产值7134.89万元。因此,回收攀西地区钒钛磁铁矿尾矿的战略性矿产,具有良好的经济效益和社会效益。

Abstract:This is an essay in the field of mineral processing engineering. Extraction of the vanadium titano-magnetite ore deposits in the Panxi Region, the biggest vanadium titano-magnetite mineral resource base, results in the production of a significant volume of tailings. The tailings have a high recovery potential of the strategic mineral resources (eg.,Vi, Ti, Fe, Co, Cu, Ni, P, and Sc). Based on the process mineralogy study, we determine the comprehensive utilization technology flowsheet and conduct a systematic recovery test of tailing samples from the Hongge mine in the Panxi Region. By the process of (1) flotation of sulfur, (2) low-intensity magnetic separation of iron, (3) high-intensity magnetic separation and flotation of titanium, (4) flotation of Phosphorous, we obtain the sulfur-cobalt concentrate (Co 0.175%), the iron concentrate (TFe 56.57%), the titanium concentrate (TiO2 45.97%) and phosphorous concentrate (P2O5 31.73%). These results show that the systematic recovery test of tailings can reduce the production of a volume of tailings with significant economic and social benefits.

-

-

表 1 红格北矿一期选厂各元素在选矿流程中的走向/%

Table 1. Direction of each element in the beneficiation process of the first phase of the Hongge North mine processing plant

样品名称 TFe TiO2 V2O5 Cr2O3 S Co* Ni* Cu* Sc* Ga* Cd* TREO* In* 原矿 22.90 9.35 0.20 0.032 0.48 134 193 157 13.8 54.4 16.8 460 115 干式预选尾矿 9.19 3.53 0.06 0.018 0.071 89.6 33.2 89.6 20.1 32.7 12.7 633 51 铁精矿 55.79 13.32 0.61 0.100 0.23 142 174 158 2.4 99.3 21.3 383 231 选钛入料 19.36 19.85 0.09 0.017 0.37 136 150 122 21.5 44.2 12.5 359 39.8 选钛尾矿 10.73 7.15 0.06 0.016 0.42 174 284 215 23 43.6 8.67 335 68.9 钛精矿 33.09 47.06 0.06 0.014 0.46 150 128 113 14 45.6 14.2 479 68.3 *单位为:g/t。 表 2 红格尾矿样品化学多项分析结果

Table 2. Results of multiple chemical analyses of Hongge tailings samples

名称 TFe FeO TiO2 S P2O5 SiO2 Al2O3 CaO MgO K2O Na2O MnO V2O5 Cr2O3* Sc2O3* 烧失 含量/% 15.28 13.10 10.90 0.28 1.01 35.58 8.65 11.98 8.14 0.74 1.62 0.27 0.10 358 40.40 1.14 *单位为:g/t。 表 3 红格尾矿样品粒度筛析及主要元素分布

Table 3. Particle size and some major elements of tailing samples from the Hongge mine

粒级/mm 产率/% 品 位/% 分布率/% TFe TiO2 S TFe TiO2 S +2 1.90 17.55 8.73 0.42 2.15 1.46 2.54 -2+1 7.42 14.52 7.79 0.33 6.96 5.10 7.80 -1+0.5 16.63 11.07 7.27 0.24 11.89 10.66 12.71 -0.5+0.25 27.46 14.53 11.85 0.32 25.76 28.69 27.99 -0.25+0.15 18.28 15.48 14.12 0.31 18.27 22.76 18.05 -0.15+0.1 10.19 18.28 14.83 0.32 12.03 13.32 10.39 -0.1+0.075 6.77 18.04 12.41 0.35 7.89 7.41 7.55 -0.075+0.045 7.36 19.89 10.91 0.32 9.45 7.08 7.50 -0.045 3.99 21.74 10.00 0.43 5.60 3.52 5.47 合计 100.00 15.49 11.34 0.31 100.00 100.00 100.00 表 4 红格尾矿样品铁物相分析

Table 4. Iron mineralogical phase analysis of tailing samples from the Hongge mine

名称 菱铁

矿中Fe赤褐铁

矿中Fe黄铁

矿中Fe硅酸

铁中Fe磁性

铁中Fe合计 含量/% 0.52 4.34 0.38 3.96 6.04 15.24 分布率/% 3.41 28.48 2.49 25.98 39.63 100.00 表 5 红格尾矿样品钛物相分析

Table 5. Titanium mineralogical phase analysis of tailing samples from the Hongge mine

名称 钛铁

矿中钛硅酸

盐中钛金红石

中钛钛磁铁

矿中钛合计 含量/% 8.64 1.44 0.042 0.58 10.702 分布率/% 80.73 13.46 0.39 5.42 100.00 表 6 红格尾矿浮选选硫钴闭路实验结果

Table 6. Results of S-Co closed-circuit flotation test of tailing samples from the Hongge mine

产品名称 产率/% 品位 回收率/% S/% Co/(g/t) S Co 精矿 0.63 37.61 1750.00 73.69 14.48 尾矿 99.37 0.09 65.47 26.31 85.52 合计 100.00 0.32 76.07 100.00 100.00 表 7 红格尾矿弱磁选铁实验结果

Table 7. Results of low intensity magnetic separation of iron from tailing samples from the Hongge mine

磁场强度/T 产品名称 产率/% 品 位/% 回收率/% TFe TiO2 TFe TiO2 0.1 铁精矿 6.03 56.86 12.83 22.12 7.21 尾矿 93.97 12.85 10.59 77.88 92.79 合计 100.00 15.50 10.73 100.00 100.00 0.12 铁精矿 5.79 57.48 12.74 21.90 6.77 尾矿 94.21 12.60 10.78 78.10 93.23 合计 100.00 15.20 10.89 100.00 100.00 0.14 铁精矿 5.93 57.50 13.47 22.19 7.44 尾矿 94.07 12.71 10.56 77.81 92.56 合计 100.00 15.37 10.73 100.00 100.00 0.16 铁精矿 6.08 57.04 13.33 22.12 7.61 尾矿 93.92 13.00 10.48 77.88 92.39 合计 100.00 15.68 10.65 100.00 100.00 表 8 红格尾矿选钛全流程实验结果

Table 8. Results of Ti separation test from tailing samples from the Hongge mine

产品名称 产 率/% TiO2品位/% TiO2回收率/% 钛精矿 14.21 45.97 65.37 浮选尾矿 40.59 5.01 20.35 强磁中矿I 15.81 4.30 6.80 强磁中矿II 9.41 5.12 4.82 强磁尾矿 19.98 1.33 2.66 合计 100.00 9.99 100.00 表 9 红格尾矿浮选选磷探索实验结果

Table 9. Results of phosphorous flotation test of tailing samples from the Hongge mine

产品名称 产率/% P2O5品位/% P2O5回收率/% 磷精矿 4.26 31.73 92.56 尾矿 95.74 0.11 7.44 合计 100.00 1.46 100.00 表 10 红格尾矿中战略性矿产回收实验结果

Table 10. Results of strategic mineral resources recovery test of tailing samples from the Hongge mine

产品名称 产率/% 品 位/% 回收率/% S TFe TiO2 P2O5 S TFe TiO2 P2O5 硫钴精矿 0.64 36.15 82.11 铁精矿 6.27 56.57 13.59 23.22 7.82 钛精矿 13.23 33.41 45.97 28.93 55.79 磷精矿 1.16 31.73 50.51 浮钛尾矿 37.79 强磁选钛尾矿 14.79 浮磷尾矿 26.12 总尾矿 78.70 原料 100.00 0.28 15.28 10.90 0.73 100.00 100.00 100.00 100.00 -

[1] Kossoff D, Dubbin W E, Alfredsson M, et al. Mine tailings dams: characteristics, failure, environmental impacts, and remediation[J]. Applied Geochemistry, 2014, 51:229-245. doi: 10.1016/j.apgeochem.2014.09.010

[2] Lottermoser B. Mine Wastes: Characterization, treatment and environmental impacts[M]. Springer, Berlin, Heidelberg, New York, 2007.

[3] Mason L, Prior T D, Mudd G M, et al. Availability, addiction and alternatives: three criteria for assessing the impact of peak minerals on society[J]. Journal of Cleaner Production, 2010, 19:958-966.

[4] 王海军, 王伊杰, 李文超, 等. 全国矿产资源节约与综合利用报告(2019) [M]. 北京: 地质出版社, 2020.

WANG H J, WANG Y J, LI W C, et al. Report on national conservation and comprehensive utilization of mineral resources (2019)[M]. Beijing: Geological Publishing House, 2020.

[5] 舒敏, 刘昆, 李德军, 等. 铁尾矿资源化利用标准化现状及对策研究[J]. 中国标准化, 2021(6):154-158. SHU M, LIU K, LI D J, et al. Study on standardization status and countermeasures of iron tailings resource utilization[J]. China Standardization, 2021(6):154-158.

SHU M, LIU K, LI D J, et al. Study on standardization status and countermeasures of iron tailings resource utilization[J]. China Standardization, 2021(6): 154-158.

[6] Provornaya I V, Yurkevich N V, Dzuba Y A. Mine Tailings: Environmental damage and resource potential[J]. IOP Conference Series:Earth and Environmental Science, 2020, 459:022084. doi: 10.1088/1755-1315/459/2/022084

[7] 路畅, 陈洪运, 傅梁杰, 等. 铁尾矿制备新型建筑材料的国内外进展[J]. 材料导报, 2021, 35(5):511-526. LU C, CHEN H Y, FU L J, et al. Research progress on the preparation of new building materials using iron tailings[J]. Materials Review, 2021, 35(5):511-526.

LU C, CHEN H Y, FU L J, et al. Research progress on the preparation of new building materials using iron tailings[J]. Materials Review, 2021, 35(5): 511-526.

[8] 李德先, 王锦, 张长青, 等. 冀东司家营铁矿尾矿特征及综合利用建议[J]. 地质学报, 2022, 96(4):1460-1468. LI D X, WANG J, ZHANG C Q, et al. Tailing characteristics and comprehensive utilization suggestions of the Sijiaying iron ore deposit in eastern Hebei Province[J]. Acta Geologica Sinica, 2022, 96(4):1460-1468.

LI D X, WANG J, ZHANG C Q, et al. Tailing characteristics and comprehensive utilization suggestions of the Sijiaying iron ore deposit in eastern Hebei Province[J]. Acta Geologica Sinica, 2022, 96(4): 1460-1468.

[9] Hudson-Edwards K A, Macklin M G, Jamieson H E, et al. The impact of tailings dam spills and clean-up operations on sediment and water quality in river systems: the Rios Agrio-Guadiamar, Aznalcollar, Spain[J]. Applied Geochemistry, 2003, 18:221-239. doi: 10.1016/S0883-2927(02)00122-1

[10] 王茜, 廖阮颖子, 田小林, 等. 四川省攀西地区钒钛磁铁矿[M]. 北京: 科学出版社, 2015.

WANG Q, LIAO R Y Z, TIAN X L, et al. Vanadium Titano-Magnetite deposits in the Panxi region, Sichuan province[M]. Beijing: Science Press, 2015.

[11] 周家云, 毛益林, 邓杰, 等. 攀西地区金属矿山尾矿资源化综合利用[M]. 武汉: 中国地质大学出版社, 2021.

ZHOU J Y, MAO Y L, DENG J, et al. Comprehensive utilization of tailings in the Panxi Region[M]. Wuhan: China University of Geosciences Press, 2021.

[12] 朱志敏, 刘应冬, 陈超, 等. 攀枝花矿业城市矿山地质环境调查成果报告[R]. 成都: 中国地质科学院矿产综合利用研究所, 2021.

ZHU Z M, LIU Y D, CHEN C, et al. Report of mining geo-environment survey of the Panzhihua mining city[R]. Chengdu: Institute of Multipurpose Utilization of Mineral Resources, CAGS, 2021.

[13] 黄霞光, 罗国清, 李亚平. 攀西钒钛磁铁矿中钪的赋存状态研究[J]. 有色金属(选矿部分), 2016(6):1-4. HUANG X G, LUO G Q, LI Y P. Study on the occurrence state of scandium in Panxi vanadium-titanium magnetite[J]. Nonferrous Metals(Mineral Processing Section), 2016(6):1-4.

HUANG X G, LUO G Q, LI Y P. Study on the occurrence state of scandium in Panxi vanadium-titanium magnetite[J]. Nonferrous Metals(Mineral Processing Section), 2016(6): 1-4.

[14] 李潇雨, 朱志敏, 周家云, 等. 钒钛磁铁矿尾矿资源调查取样方法比较——以红格尾矿库为例[J]. 矿产综合利用, 2020(6):96-99. LI X Y, ZHU Z M, ZHOU J Y, et al. Comparison of sampling methods for investigation of vanadium-titanium magnetite tailings resources - taking Hongge tailings pond as an example[J]. Multipurpose Utilization of Mineral Resources, 2020(6):96-99.

LI X Y, ZHU Z M, ZHOU J Y, et al. Comparison of sampling methods for investigation of vanadium-titanium magnetite tailings resources -- taking Hongge tailings pond as an example[J]. Multipurpose Utilization of Mineral Resources, 2020(6): 96-99.

[15] Xiao J H, Chen C, Ding W, et al. Extraction of phosphorous from a phosphorous-containing vanadium titano-magnetite tailings by direct flotation[J]. Processes, 2020, 8:874. doi: 10.3390/pr8070874

[16] 吕子虎, 赵登魁, 程宏伟, 等. 某钒钛磁铁矿尾矿资源化利用[J]. 有色金属(选矿部分), 2020(1):55-58. LV Z H, ZHAO D K, CHENG H W, et al. Resource utilization of titanomagnetite tailings[J]. Nonferrous Metals (Mineral Processing Section), 2020(1):55-58.

LV Z H, ZHAO D K, CHENG H W, et al. Resource utilization of titanomagnetite tailings[J]. Nonferrous Metals (Mineral Processing Section), 2020(1): 55-58.

[17] 印万忠, 徐东, 杨耀辉, 等. 承德某钒钛磁铁矿尾矿资源化利用技术研究[J]. 矿产综合利用, 2020(6):37-42. YIN W Z, XU D, YANG Y H, et al. Research on the recycling technology for a vanadium-titanium magnetite tailings in Chengde[J]. Multipurpose Utilization of Mineral Resources, 2020(6):37-42.

YIN W Z, XU D, YANG Y H, et al. Research on the recycling technology for a vanadium-titanium magnetite tailings in Chengde[J]. Multipurpose Utilization of Mineral Resources, 2020(6): 37-42.

[18] 刘能云, 陈超, 张裕书, 等. 从尾矿中回收钛铁矿的实验研究[J]. 矿冶工程, 2020, 40(1):65-68. LIU N Y, CHEN C, ZHANG Y S, et al. Experimental study on recovery of ilmenite from tailings[J]. Mining and Metallurgical Engineering, 2020, 40(1):65-68.

LIU N Y, CHEN C, ZHANG Y S, et al. Experimental study on recovery of ilmenite from tailings[J]. Mining and Metallurgical Engineering, 2020, 40(1): 65-68.

[19] 邹锋, 殷志刚, 陈思竹. 攀枝花白马选铁尾矿综合回收利用研究[J]. 矿产综合利用, 2020(6):19-25. ZOU F, YIN Z G, CHEN S Z. Research on cmprehensiveutilization of iron tailings from Baima Panzhihua[J]. Multipurpose Utilization of Mineral Resources, 2020(6):19-25. doi: 10.3969/j.issn.1000-6532.2020.06.004

ZOU F, YIN Z G, CHEN S Z. Research on cmprehensiveutilization of iron tailings from Baima Panzhihua[J]. Multipurpose Utilization of Mineral Resources, 2020(6): 19-25. doi: 10.3969/j.issn.1000-6532.2020.06.004

[20] 黄雯孝, 卢可可. 攀西钒钛磁铁矿尾矿中钪的提取工艺研究[J]. 矿产综合利用, 2020(2):135-139. HUANG W X, LU K K. Study on scandium extraction technology for Panxi vanadium titanium magnetite tailings[J]. Multipurpose Utilization of Mineral Resources, 2020(2):135-139.

HUANG W X, LU K K. Study on scandium extraction technology for Panxi vanadium titanium magnetite tailings[J]. Multipurpose Utilization of Mineral Resources, 2020(2): 135-139.

[21] 王浚杰, 肖军辉, 张烨毓, 等. 从攀西地区含钪钒钛磁铁矿尾矿中回收钪研究[J]. 矿冶工程, 2021, 41(6):61-64. WANG J J, XIAO J H, ZHANG Y Y, et al. Recovery of scandium resource from Sc-bearing vanadium-titanium magnetite tailings in Panxi Region[J]. Mining and Metallurgical Engineering, 2021, 41(6):61-64. doi: 10.3969/j.issn.0253-6099.2021.06.015

WANG J J, XIAO J H, ZHANG Y Y, et al. Recovery of scandium resource from Sc-bearing vanadium-titanium magnetite tailings in Pan-Xi Region[J]. Mining and Metallurgical Engineering, 2021, 41(6) : 61-64. doi: 10.3969/j.issn.0253-6099.2021.06.015

[22] 邓杰, 张渊, 刘飞燕, 等. 钒钛磁铁矿选铁尾矿中硫钴资源综合回收研究[J]. 有色金属(选矿部分), 2015(2):30-33+48. DENG J, ZHANG Y, LIU F Y, et al. Recovery of cobalt and sulfur from the iron ore tailing of vanadium-titanium magnetite[J]. Nonferrous Metals(Mineral Processing Section), 2015(2):30-33+48.

DENG J, ZHANG Y, LIU F Y, et al. Recovery of cobalt and sulfur from the iron ore tailing of vanadium-titanium magnetite[J]. Nonferrous Metals(Mineral Processing Section), 2015(2): 30-33+48.

[23] 陈超, 张裕书, 李潇雨, 等. 攀西某钒钛磁铁矿尾矿中磷的回收实验研究. 矿产综合利用, 2021(4): 165-169.

CHEN C, ZHANG Y S, LI X Y, et al. Recovery of phosphorus from a vanadium titanium magnetite tailing in Panxi [J]. Multipurpose Utilization of Mineral Resources, 2021(4): 165-169.

[24] 陈超, 张裕书, 李潇雨, 等. 钛磁铁矿选矿技术研究进展[J]. 矿产综合利用, 2021(3):99-105. CHEN C, ZHANG YS, LI X Y, et al. Research progress in titanium-magnetite beneficiation technology[J]. Multipurpose Utilization of Mineral Resources, 2021(3):99-105.

CHEN C, ZHANG YS, LI X Y, et al. Research progress in titanium-magnetite beneficiation technology [J]. Multipurpose Utilization of Mineral Resources, 2021(3): 99-105.

[25] 肖仪武. 钒钛磁铁矿矿石基因特性及其对选铁的影响[J]. 矿产综合利用, 2021(5):198-201. XIAO Y W. Ore genetic characteristics of vanadium-titanium magnetite and its influence for mineral processing[J]. Multipurpose Utilization of Mineral Resources, 2021(5):198-201. doi: 10.3969/j.issn.1000-6532.2021.05.033

XIAO Y W. Ore genetic characteristics of vanadium-titanium magnetite and its influence for mineral processing[J]. Multipurpose Utilization of Mineral Resources, 2021(5): 198-201. doi: 10.3969/j.issn.1000-6532.2021.05.033

-

下载:

下载: