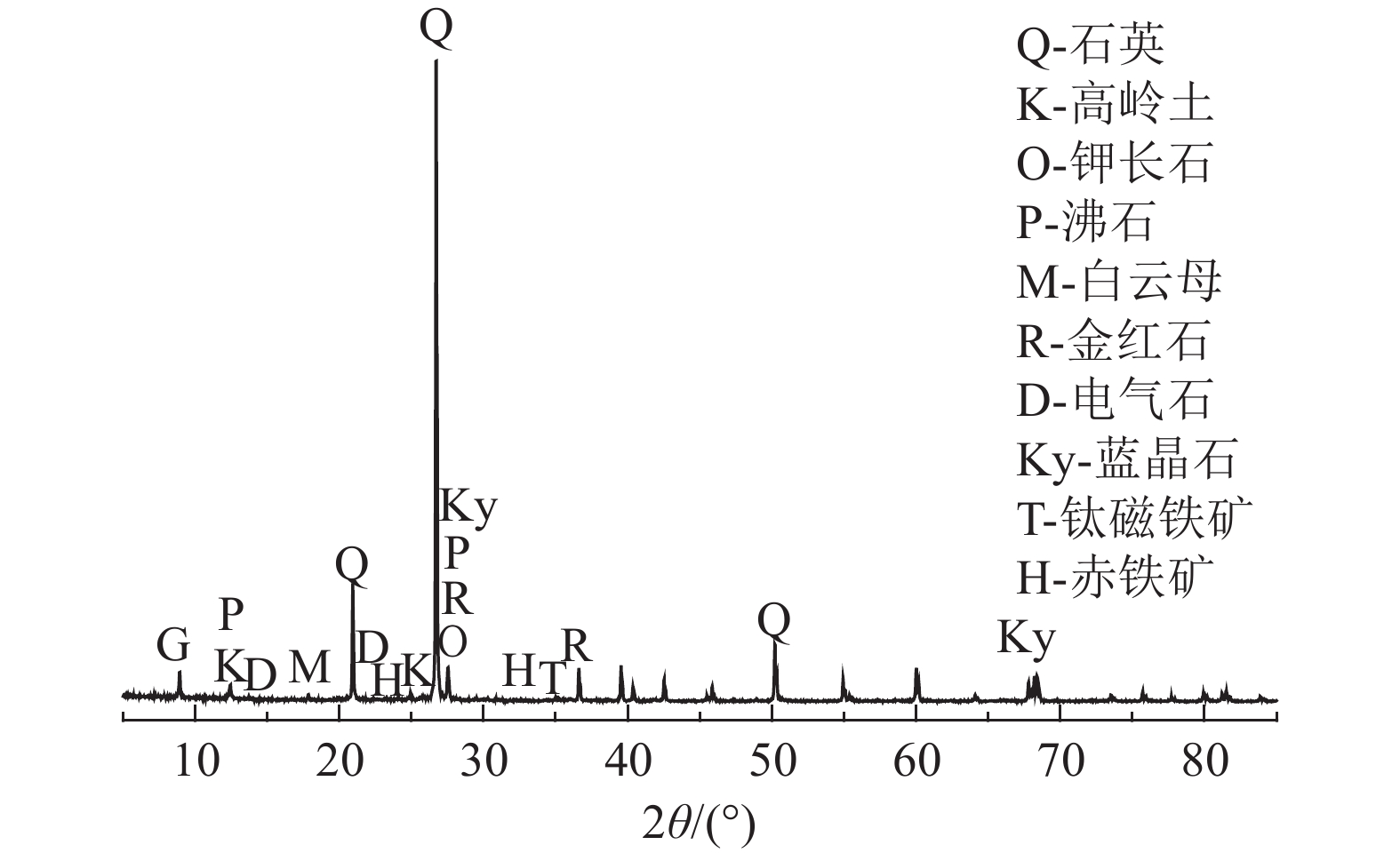

Preparation of Quartz Sand for Solar Photovoltaic Glass from Quartz Associated Kaolin by Size Fraction Distribution

-

摘要:

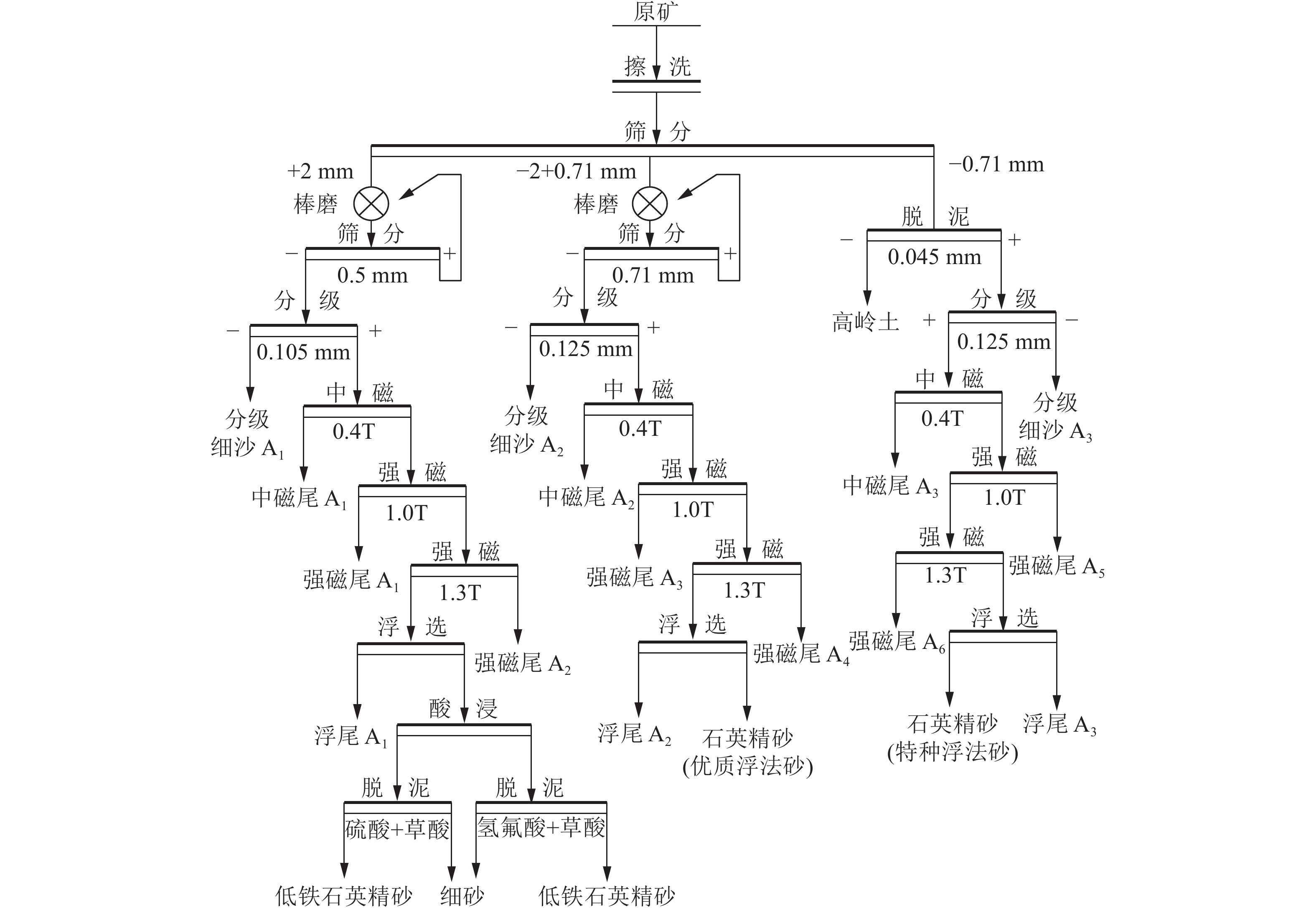

这是一篇陶瓷及复合材料领域的论文。为助力碳中和、碳达峰目标,我国光伏玻璃需求量近年来快速增长,从而使光伏玻璃用低铁石英砂(

$ {{ \omega }}_{{\text{Fe}}_{\text{2}}{\text{O}}_{\text{3}}} $ Abstract:This is an essay in the field of ceramics and composites.To achieve carbon neutrality and peaking carbon dioxide emissions, the low-iron quartz sand(

${{ \omega }}_{{\text{Fe}}_{\text{2}}{\text{O}}_{\text{3}}}$ -

Key words:

- Ceramics and composites /

- Kaolin /

- Quartz /

- Size fraction /

- Purification

-

-

表 1 试样的主要化学成份与含量

Table 1. Main chemical composition and content of quartz associated kaolin sample

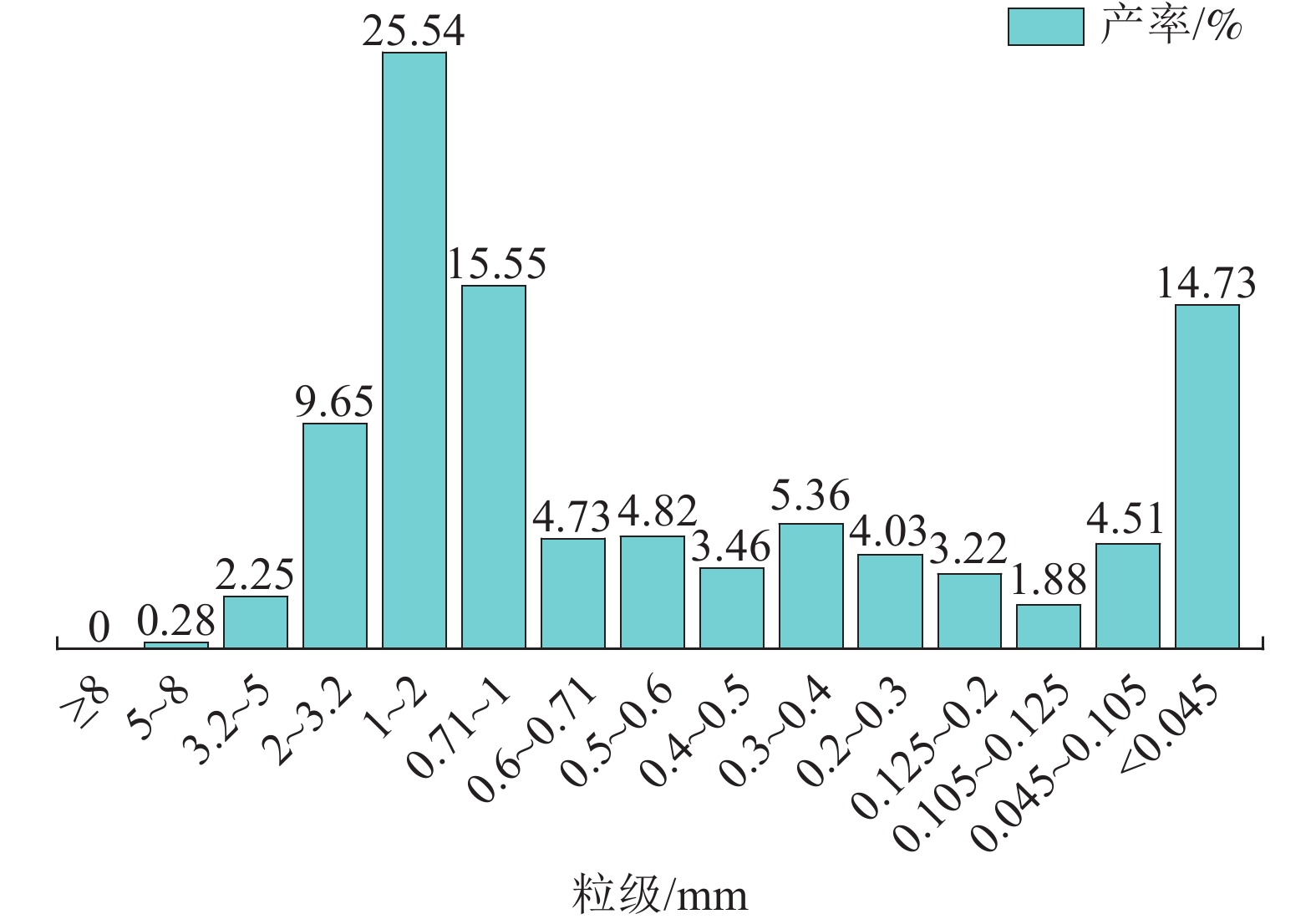

化学成分 SiO2 Al2O3 Fe2O3 TiO2 K2O Na2O CaO MgO LOI 含量/% 试样 88.46 6.01 0.61 0.066 1.92 0.056 0.029 0.078 1.47 +0.045 mm 93.44 2.96 0.30 0.028 1.58 0.059 0.020 0.024 0.49 表 2 不同粒级试样的化学成分与含量

Table 2. Size fraction distribution chemical composition and content of quartz associated kaolin sample

粒级/mm SiO2/% Al2O3/% Fe2O3/% +3.2 95.98 1.65 0.16 -3.2+2 96.02 1.86 0.17 -2+1 95.31 2.10 0.24 -1+0.71 95.50 2.03 0.21 -0.71+0.125 88.78 5.33 0.45 -0.125+0.04 --- 11.07 1.09 -0.045 --- 23.09 2.34 表 3 不同粒级试样强磁精砂主要化学成分

Table 3. High intensity magnetic concentrate chemical composition of different size samples

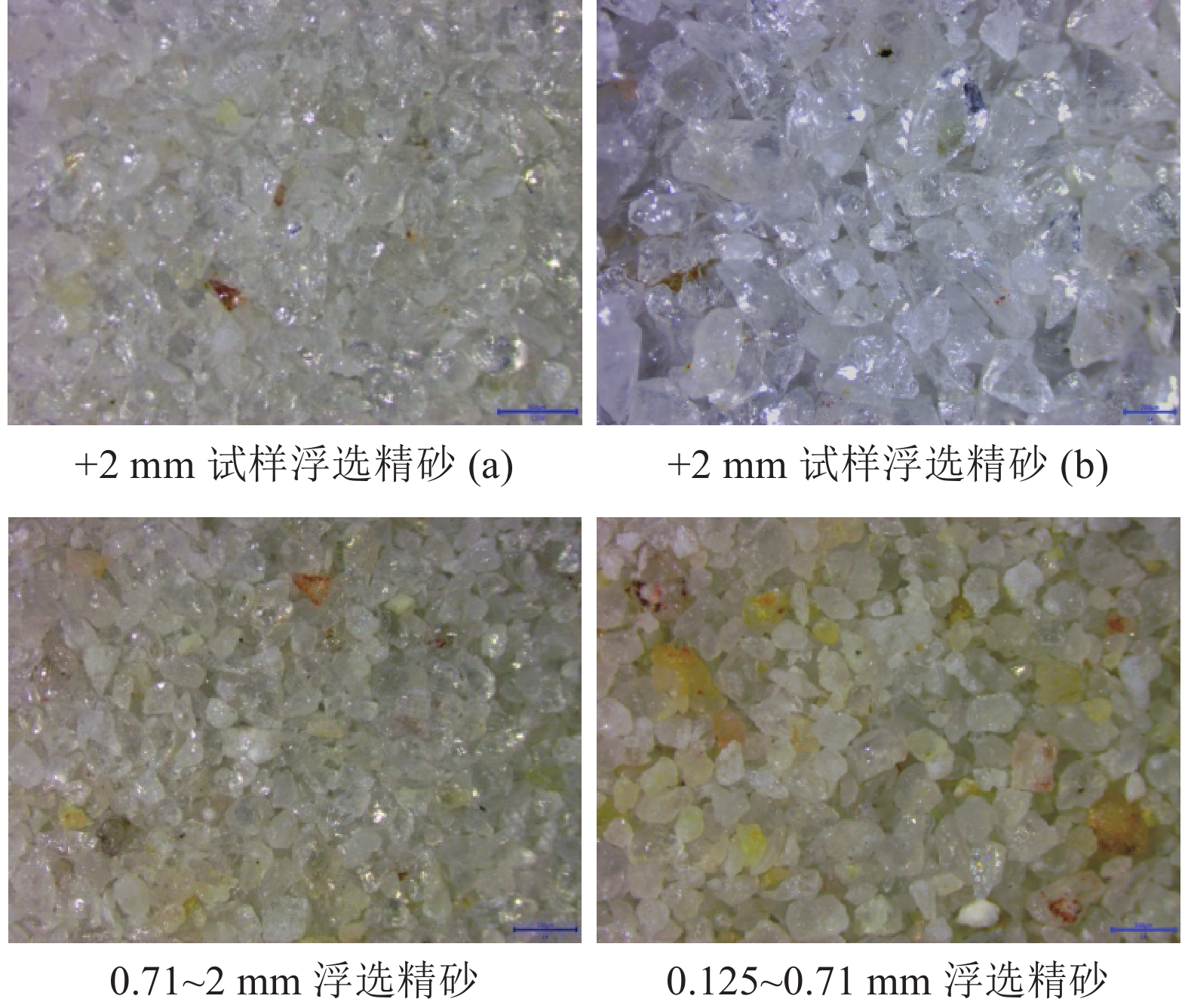

粒级/mm 化学成分/% SiO2 Al2O3 Fe2O3 TiO2 +2 98.27 0.71 0.035 0.014 -2+0.71 97.24 1.22 0.048 0.012 -0.71+0.125 92.54 2.98 0.077 0.016 表 4 +2 mm试样强磁精砂浮选实验结果

Table 4. Flotation test results of high intensity magnetic concentrate from +2 mm sample

药剂量/(kg/t) 精砂指标/% TSPS NPD γ作业 SiO2 Al2O3 Fe2O3 0.72 0.24 90.89 99.31 0.28 0.024 0.96 0.32 85.73 99.42 0.14 0.020 1.20 0.40 83.83 99.48 0.21 0.023 1.44 0.48 80.71 99.60 0.17 0.019 1.68 0.56 78.19 99.55 0.16 0.016 1.92 0.64 76.63 99.47 0.16 0.016 表 5 -2+0.71 mm强磁精砂浮选实验结果

Table 5. Flotation test results of high intensity magnetic concentrate from -2+0.71 mm sample

药剂量/(kg/t) 精砂指标/% TSPS NPD γ作业 SiO2 Al2O3 Fe2O3 0.48 0.16 94.30 97.95 0.79 0.041 0.72 0.24 91.72 98.68 0.58 0.037 0.96 0.32 86.78 99.07 0.31 0.033 表 6 -0.71 mm强磁精砂浮选实验结果

Table 6. Flotation test results of high intensity magnetic concentrate from -0.71 mm sample

药剂量/(kg/t) 精砂指标/% TSPS NPD γ作业 SiO2 Al2O3 Fe2O3 0.72 0.24 92.34 94.19 2.34 0.068 0.96 0.32 89.36 95.31 1.98 0.071 1.20 0.40 88.91 96.14 1.5 0.073 1.80 0.60 80.13 97.40 1.11 0.065 2.40 0.80 72.86 98.28 0.76 0.055 表 7 酸浸介质与用量实验结果

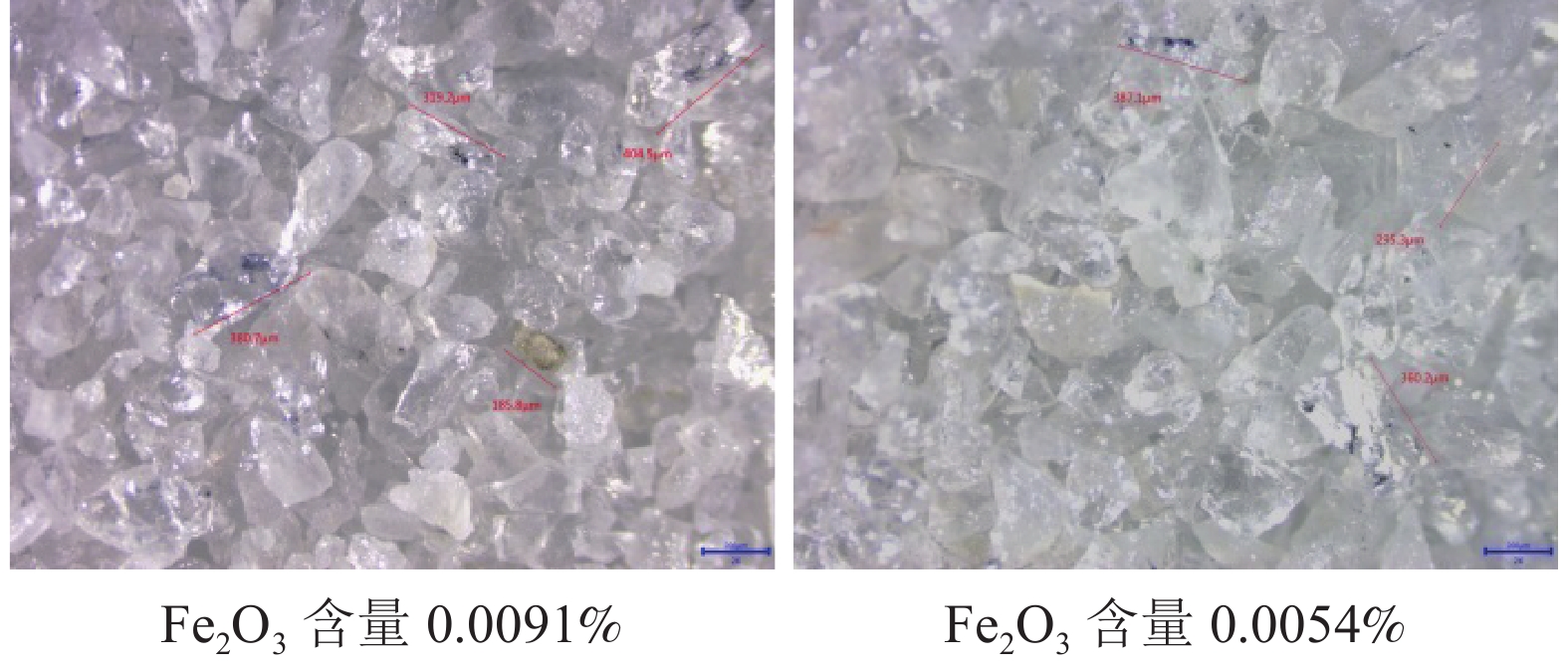

Table 7. Results of acid leaching medium and dosage

酸用量/(kg/t) 精砂指标/% 硫酸 氢氟酸 草酸 γ作业 SiO2 Al2O3 Fe2O3 230.00 --- --- 98.10 99.58 0.12 0.0094 --- 100.00 --- 97.61 99.68 0.097 0.0069 --- --- 62.50 98.57 99.50 0.14 0.011 92.00 --- 31.25 98.14 99.57 0.13 0.0091 46.00 --- 31.25 98.22 99.61 0.13 0.011 --- 75.00 50.00 97.38 99.78 0.067 0.0054 --- 50.00 31.25 97.47 99.80 0.081 0.0057 表 8 酸浸时间、温度实验结果

Table 8. Results of acid leaching time and temperature

实验条件 精砂指标/% 酸用量/(kg/t) 温度/℃ 时间/h γ作业 Fe2O3 硫酸,92.00

草酸,31.25100 2.0 98.30 0.010 100 1.0 98.22 0.010 100 0.5 98.39 0.011 90 1.5 98.54 0.011 80 1.5 98.40 0.011 氢氟酸,75.00

草酸,50.00100 2.0 97.41 0.0059 100 1.0 97.50 0.0067 100 0.5 97.77 0.011 90 1.5 98.38 0.0058 80 1.5 98.00 0.0070 -

[1] 马超. 砂质高岭土尾矿制备高纯石英的基础研究[D]. 北京: 中国地质科学院, 2020.

MA C. Basic study on preparation of high purity quartz from sandy kaolinite tailings [D]. Beijing: Chinese Academy of Geological Sciences, 2020.

[2] 汪灵. 石英的矿床工业类型与应用特点[J]. 矿产保护与利用, 2019, 39(6):39-47. WANG L. Industrial types and application characteristics of quartz ore deposits[J]. Conservation and Utilization of Mineral Resources, 2019, 39(6):39-47. doi: 10.13779/j.cnki.issn1001-0076.2019.06.007

WANG L. Industrial types and application characteristics of quartz ore deposits[J]. Conservation and Utilization of Mineral Resources, 2019, 39(6): 39-47. doi: 10.13779/j.cnki.issn1001-0076.2019.06.007

[3] 吴飞达, 高惠民, 任子杰, 等. 合浦某高岭土尾砂的提纯与利用[J]. 非金属矿, 2019, 42(5):62-66. WU F D, GAO H M, REN Z J, et al. Purification and utilization of kaolin tailings in Hepu[J]. Non-Metallic Mines, 2019, 42(5):62-66. doi: 10.3969/j.issn.1000-8098.2019.05.018

WU F D, GAO H M, REN Z J, et al. Purification and utilization of kaolin tailings in Hepu[J]. Non-Metallic Mines, 2019, 42(5): 62-66. doi: 10.3969/j.issn.1000-8098.2019.05.018

[4] 顾真安, 同继锋, 崔源声, 等. 建材非金属矿产资源强国战略研究[J]. 中国工程科学, 2019, 21(1):104-112. GU Z A, TONG J F, CUI Y S, et al. Strategic research on nonmetallic mineral resources for building materials in China[J]. Strategic Study of CAE, 2019, 21(1):104-112. doi: 10.15302/J-SSCAE-2019.01.015

GU Z A, TONG J F, CUI Y S, et al. Strategic research on nonmetallic mineral resources for building materials in China[J]. Strategic Study of CAE, 2019, 21(1): 104-112. doi: 10.15302/J-SSCAE-2019.01.015

[5] 孙小朋, 何帅杰, 轩云辉. 分级-分选技术在高岭土提纯中的应用分析[J]. 矿冶, 2018, 27(4):10-15+21. SUN X P, HE S J, XUAN Y H. Application of grading-sorting technique in kaolin purification[J]. Mining & Metallurgy, 2018, 27(4):10-15+21. doi: 10.3969/j.issn.1005-7854.2018.04.003

SUN X P, HE S J, XUAN Y H. Application of grading-sorting technique in kaolin purification [J]. Mining & Metallurgy, 2018, 27(4): 10-15+21. doi: 10.3969/j.issn.1005-7854.2018.04.003

[6] 刘泽伟, 邹玄, 赵阳, 等. 某石英砂矿制取高纯石英工艺的研究[J]. 矿产综合利用, 2020(4):111-115. LIU Z W, ZOU X, ZHAO Y, et al. Study on the process of producing high-purity quartz from a quartz sand mine[J]. Multipurpose Utilization of Mineral Resources, 2020(4):111-115. doi: 10.3969/j.issn.1000-6532.2020.04.018

LIU Z W, ZOU X, ZHAO Y, et al. Study on the process of producing high-purity quartz from a quartz sand mine[J]. Multipurpose Utilization of Mineral Resources, 2020(4): 111-115. doi: 10.3969/j.issn.1000-6532.2020.04.018

-

下载:

下载: