Influence of Two Kinds of Red Mud on the Melting Temperature of Coal Ash in Ningxia

-

摘要:

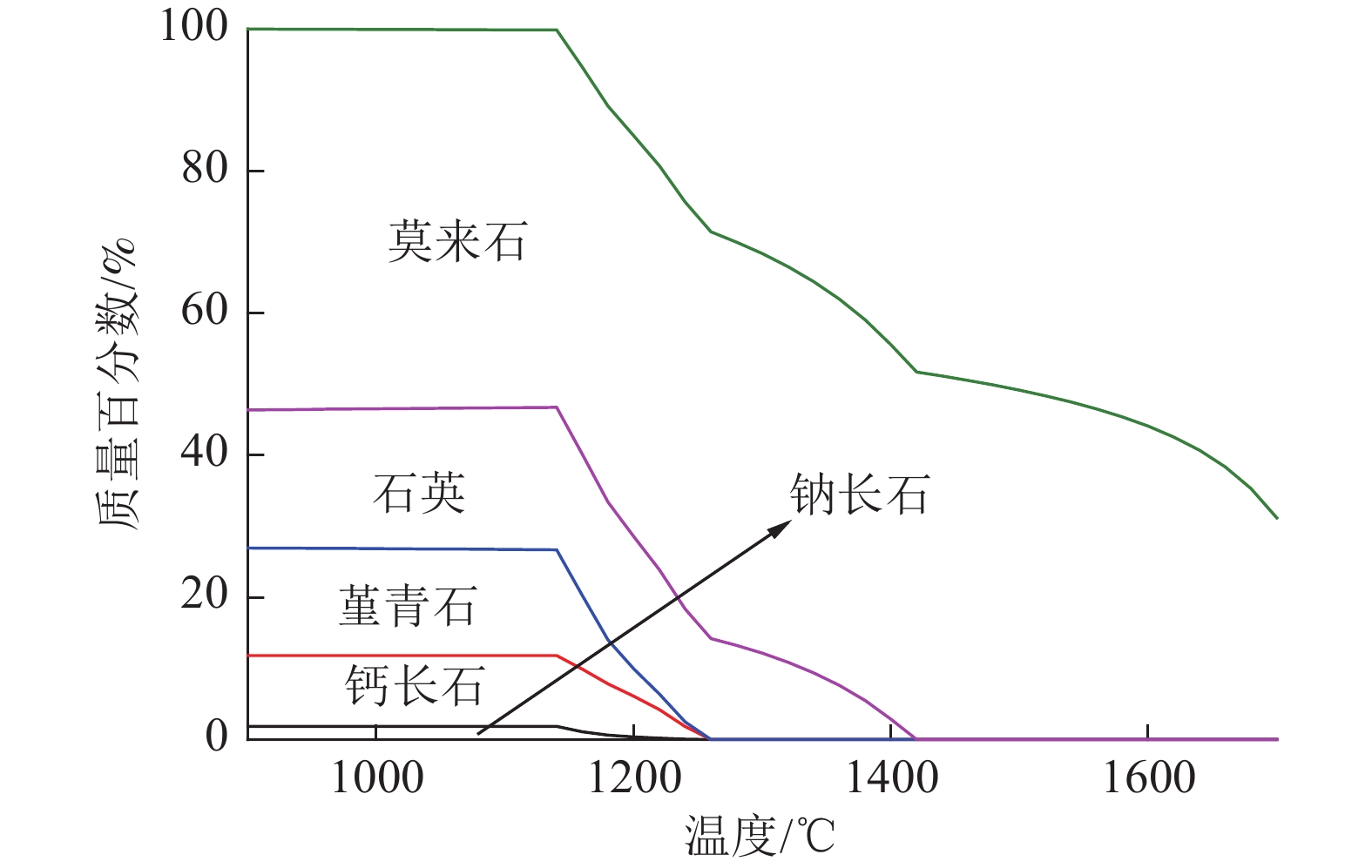

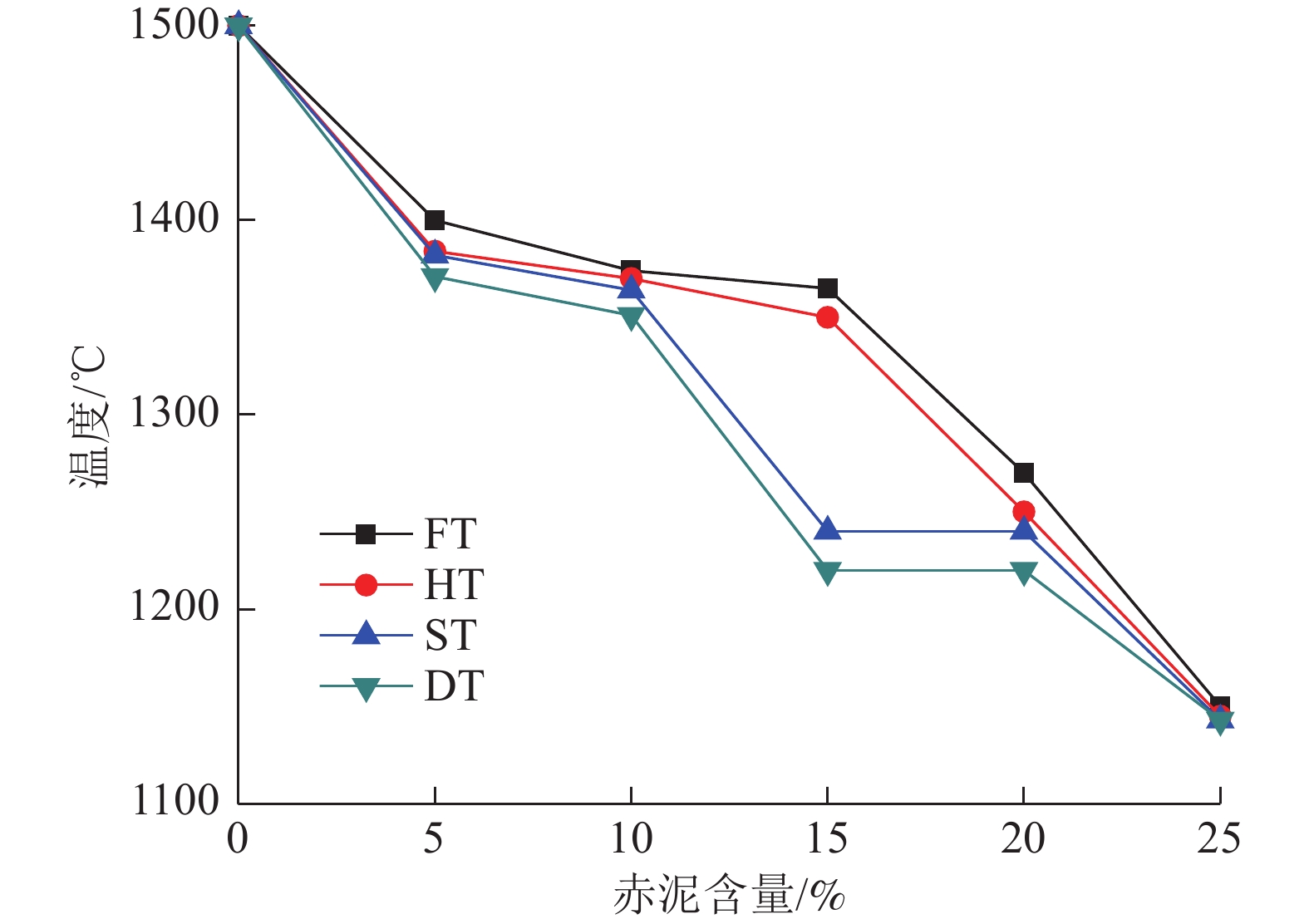

这是一篇冶金工程领域的论文。在宁夏煤中按照一定比例分别添加拜耳赤泥和烧结赤泥,研究这两种不同的赤泥对宁夏煤灰熔融温度的影响,采用Factsage软件研究了灰熔融温度改变机理。实验结果表明,宁夏煤灰矿物质中含有大量的莫来石,导致其煤灰的灰熔点较高,向其中加入赤泥能够有效地降低煤灰熔点。随着拜耳赤泥添加量的增加,煤灰中的莫来石的成分逐步减少,而钙长石与钠长石逐步增多,降低了煤灰的熔融温度。随烧结赤泥添加量的增加煤灰中莫来石的含量逐渐减少,长石的含量逐渐增多。赤泥使宁夏煤灰熔融温度降低的主要原因是由于赤泥中的碱性氧化物与煤灰中的酸性氧化物发生反应生成了低熔点的矿物质以及这些矿物质之间相互作用生成了低温共熔物。

Abstract:This is an essay in the field of metallurgical engineering. Bayer red mud and sintered red mud were added to Ningxia coal in a certain proportion to study the influence of the two different red mud on the ash melting temperature of Ningxia coal. Factsage software was used to study the ash melting temperature change mechanism. The experimental results show that Ningxia coal ash contains a large amount of mullite, which causes the ash melting point of coal ash to be higher, and adding red mud to it can effectively reduce the melting point of coal ash. With the increase in the amount of Bayer red mud added, the composition of mullite in coal ash gradually decreases, while anorthite and albite gradually increase, reducing the melting temperature of coal ash. With the increase of sintered red mud addition, the content of mullite in coal ash gradually decreases, and the content of feldspar gradually increases. The main reason that red mud reduces the melting temperature of coal ash in Ningxia is that the alkaline oxides in the red mud react with the acidic oxides in the coal ash to form low-melting minerals and the interaction between these minerals generates low temperature. Communion.

-

Key words:

- Metallurgical engineering /

- Red mud /

- Ash melting temperature /

- Ningxia /

- Coal ash /

- Low-temperature eutectic

-

-

表 1 宁夏煤灰及赤泥成分分析/%

Table 1. Compositional analysis of coal ash and red mud in Ningxia

成分 SiO2 Al2O3 Fe2O3 CaO MgO K2O Na2O SO2 TiO2 P2O5 宁夏煤灰 47.43 37.69 3.19 2.74 0.28 0.27 0.30 0.79 1.17 0.14 拜耳赤泥 33.29 27.74 8.89 15.40 0.64 0.17 7.01 0.97 5.49 0.40 烧结赤泥 36.11 5.79 6.78 41.09 1.78 0.27 2.83 0.87 4.10 0.38 -

[1] 南相莉, 张廷安, 刘燕, 等. 我国赤泥综合利用分析[J]. 过程工程学报, 2010, 10(Z1):264-270. NAN X L, ZHANG T A, LIU Y, et al. Analysis of comprehensive utilisation of red mud in China[J]. Journal of Process Engineering, 2010, 10(Z1):264-270.

NAN X L, ZHANG T A, LIU Y, et al. Analysis of comprehensive utilisation of red mud in China[J]. Journal of Process Engineering, 2010, 10(Z1): 264-270.

[2] 陈玉爽, 张忠孝, 乌晓江, 等. 配煤对煤灰熔融特性影响的实验与量化研究[J]. 燃料化学学报, 2009, 37(5):521-526. CHEN Y S, ZHANG Z X, WU X J, et al. Experimental and quantitative study of the effect of coal blending on the melting characteristics of coal ash[J]. Journal of Fuel Chemistry, 2009, 37(5):521-526.

CHEN Y S, ZHANG Z X, WU X J, et al. Experimental and quantitative study of the effect of coal blending on the melting characteristics of coal ash[J]. Journal of Fuel Chemistry, 2009, 37(5): 521- 526.

[3] 乌晓江, 张忠孝, 徐雪元, 等. 宁夏煤气化特性及灰渣熔融特性的研究[J]. 动力工程学报, 2011, 31(7):558-562. WU X J, ZHANG Z X, XU X Y, et al. Study on the characteristics of coal gasification and the melting characteristics of ash in Ningxia[J]. Journal of Power Engineering, 2011, 31(7):558-562.

WU X J, ZHANG Z X, XU X Y, et al. Study on the characteristics of coal gasification and the melting characteristics of ash in Ningxia[J]. Journal of Power Engineering, 2011, 31(7): 558-562.

[4] Brown R, Liu Q, Norton G. Catalytic effects observed during the co-gasification of coal and switchgrass[J]. Biomass and Bioenergy, 2017, 18(6):499-506.

[5] 谢良才, 李风海, 薛兆民, 等. 配煤对高熔点煤灰熔融特性影响的研究[J]. 燃料化学学报, 2016, 44(12):1430-1439. XIE L C, LI F H, XUE Z M, et al. Study on the effect of coal blending on the melting characteristics of high melting point coal ash[J]. Journal of Fuel Chemistry, 2016, 44(12):1430-1439.

XIE L C, LI F H, XUE Z M, et al. Study on the effect of coal blending on the melting characteristics of high melting point coal ash[J]. Journal of Fuel Chemistry, 2016, 44(12): 1430- 1439.

[6] 沈铭科, 邱坤赞, 黄振宇, 等. 准东煤掺烧高岭土对固钠率及灰熔融特性影响研究[J]. 燃料化学学报, 2015, 43(9):1044-1051. SHEN M K, QIU K Z, HUANG Z Y, et al. Study on the effect of kaolin blended with Jundong coal on sodium fixation rate and ash melting characteristics[J]. Journal of Fuel Chemistry, 2015, 43(9):1044-1051.

SHEN M K, QIU K Z, HUANG Z Y, et al. Study on the effect of kaolin blended with Jundong coal on sodium fixation rate and ash melting characteristics[J]. Journal of Fuel Chemistry, 2015, 43(9): 1044- 1051.

[7] 蒋武锋, 马腾飞, 郝素菊, 等. 利用钢渣余热还原含锌粉尘可行性的探讨[J]. 矿产综合利用, 2019(6):140-144. JIANG W F, MA T F, HAO S J, et al. Discussion on feasibility of reducing zinc-containing dust by residual heat of steel slag[J]. Multipurpose Utilization of Mineral Resources, 2019(6):140-144. doi: 10.3969/j.issn.1000-6532.2019.06.030

JIANG W F, MA T F, HAO S J, et al. Discussion on feasibility of reducing zinc-containing dust by residual heat of steel slag[J]. Multipurpose Utilization of Mineral Resources, 2019(6): 140-144. doi: 10.3969/j.issn.1000-6532.2019.06.030

[8] Fenghai Li, Quanrun Liu, Meng Li, et al. Understanding fly-ash formation during fluidized-bed gasification of high-silicon-aluminum coal based on its characteristics[J]. Energy, 2018, 150:110-115.

[9] 王志, 韩敏芳, 张以河, 等. 拜耳法赤泥的湿法碳化脱碱工艺研究[J]. 硅酸盐通报, 2013, 32(9):1851-1855. WANG Z, HAN M F, ZHANG Y H, et al. Research on wet carbonisation and dealkalisation process of Bayer red mud[J]. Silicate Bulletin, 2013, 32(9):1851-1855. doi: 10.16552/j.cnki.issn1001-1625.2013.09.043

WANG Z, HAN M F, ZHANG Y H, et al. Research on wet carbonisation and dealkalisation process of Bayer red mud[J]. Silicate Bulletin, 2013, 32(9): 1851-1855. doi: 10.16552/j.cnki.issn1001-1625.2013.09.043

[10] 乌晓江, 张忠孝, 朴桂林, 等. 配煤对降低高灰熔融性煤的三元相图分析[J]. 洁净煤技术, 2007(3):64-67. WU X J, ZHANG Z X, PU G L, et al. Ternary phase diagram analysis of coal blending for reducing high ash fusibility coals[J]. Clean Coal Technology, 2007(3):64-67. doi: 10.3969/j.issn.1006-6772.2007.03.016

WU X J, ZHANG Z X, PU G L, et al. Ternary phase diagram analysis of coal blending for reducing high ash fusibility coals[J]. Clean Coal Technology, 2007(3): 64-67. doi: 10.3969/j.issn.1006-6772.2007.03.016

-

下载:

下载: