Oxidation Roasting, Gas-based Reduction Followed by Magnetic Separation of a High Phosphorus Iron Ore in Africa

-

摘要:

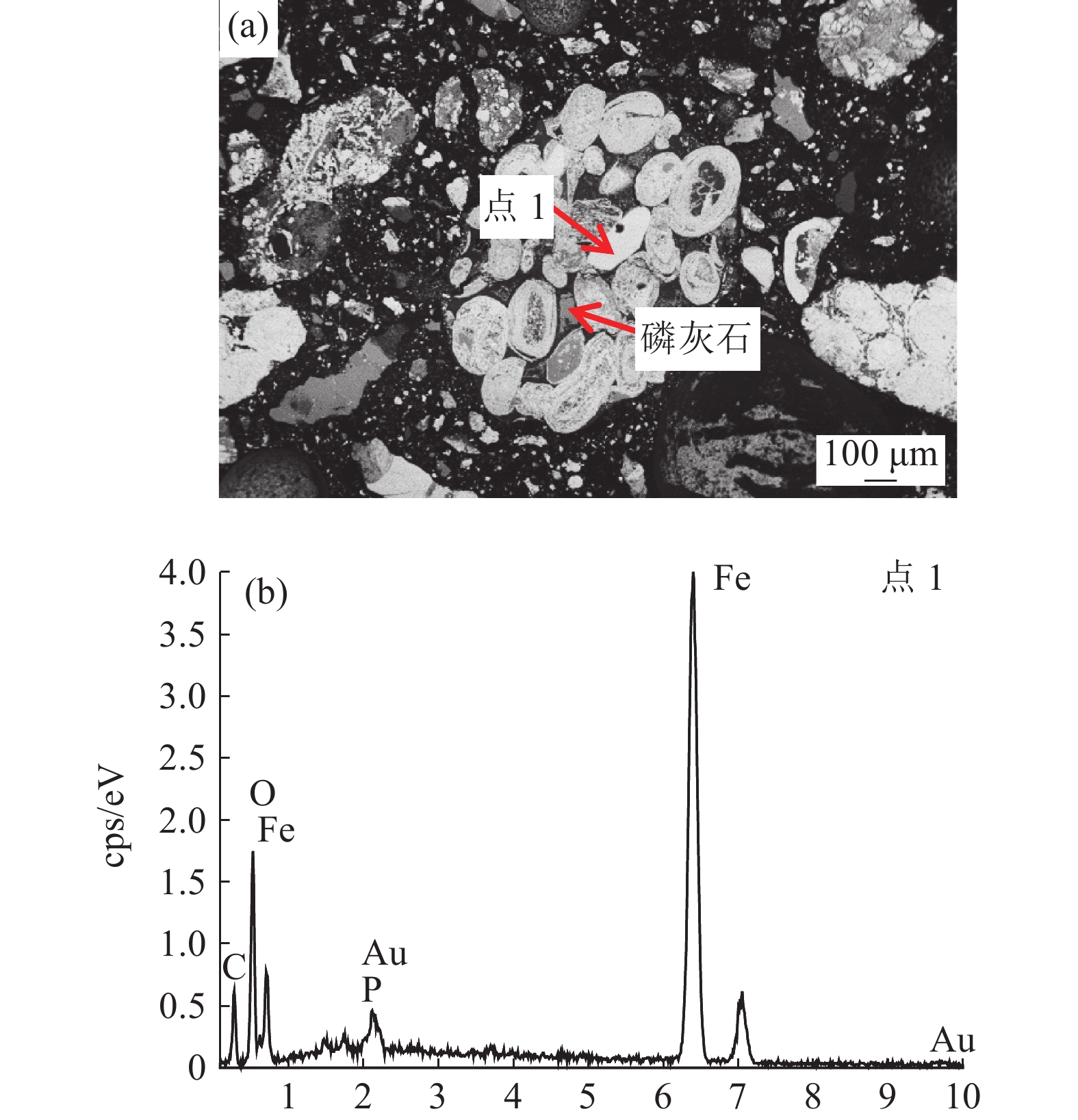

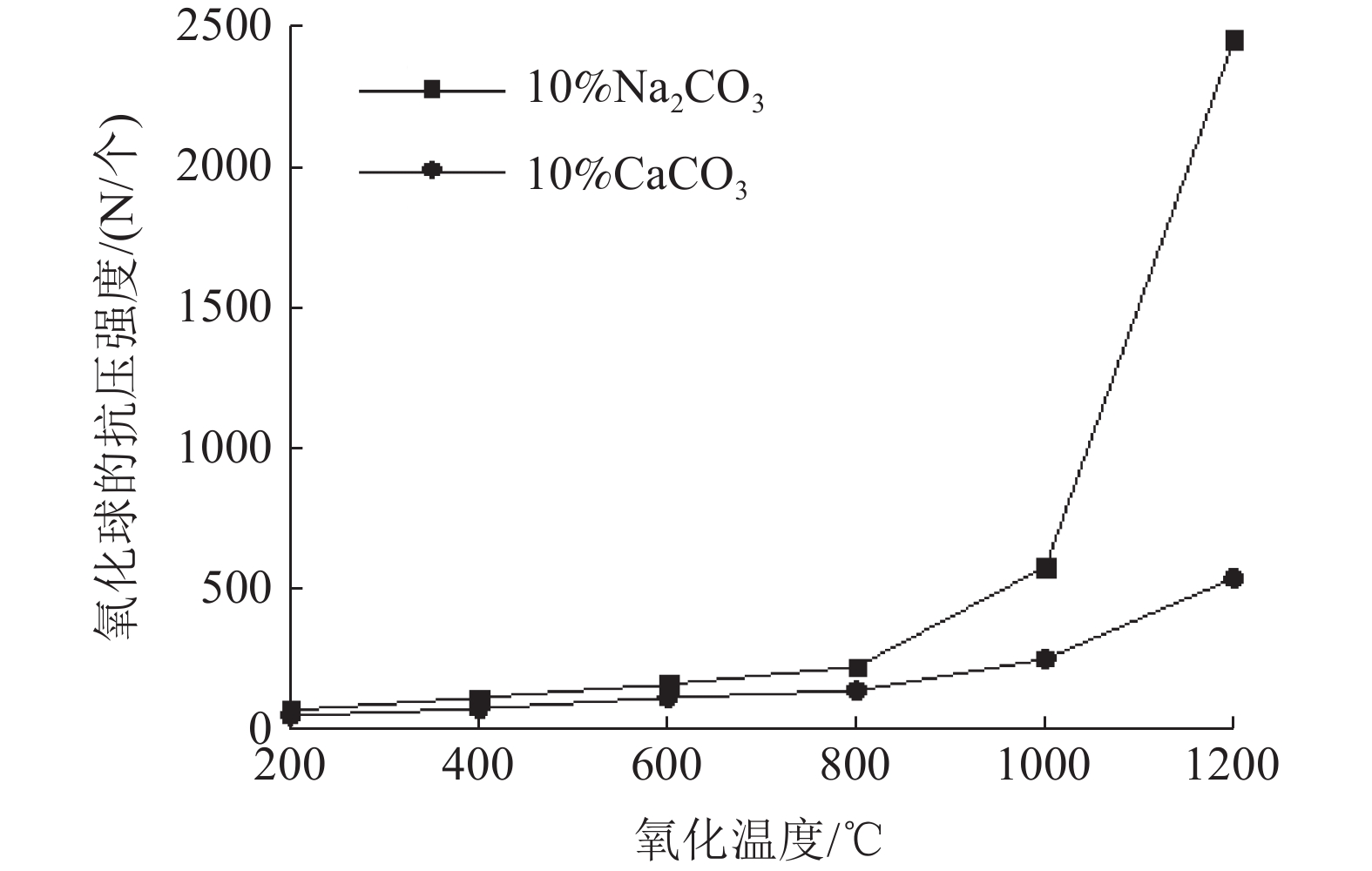

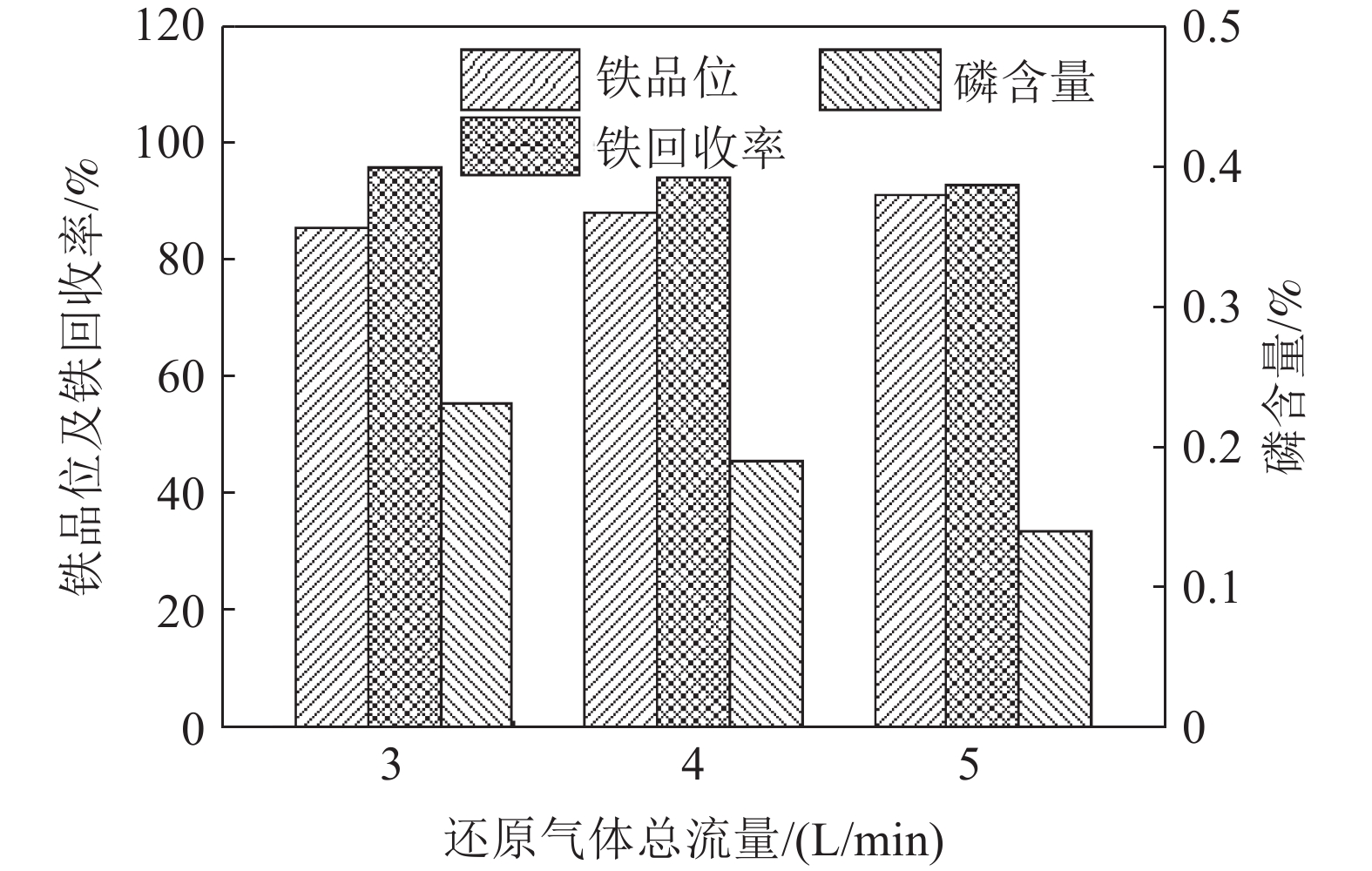

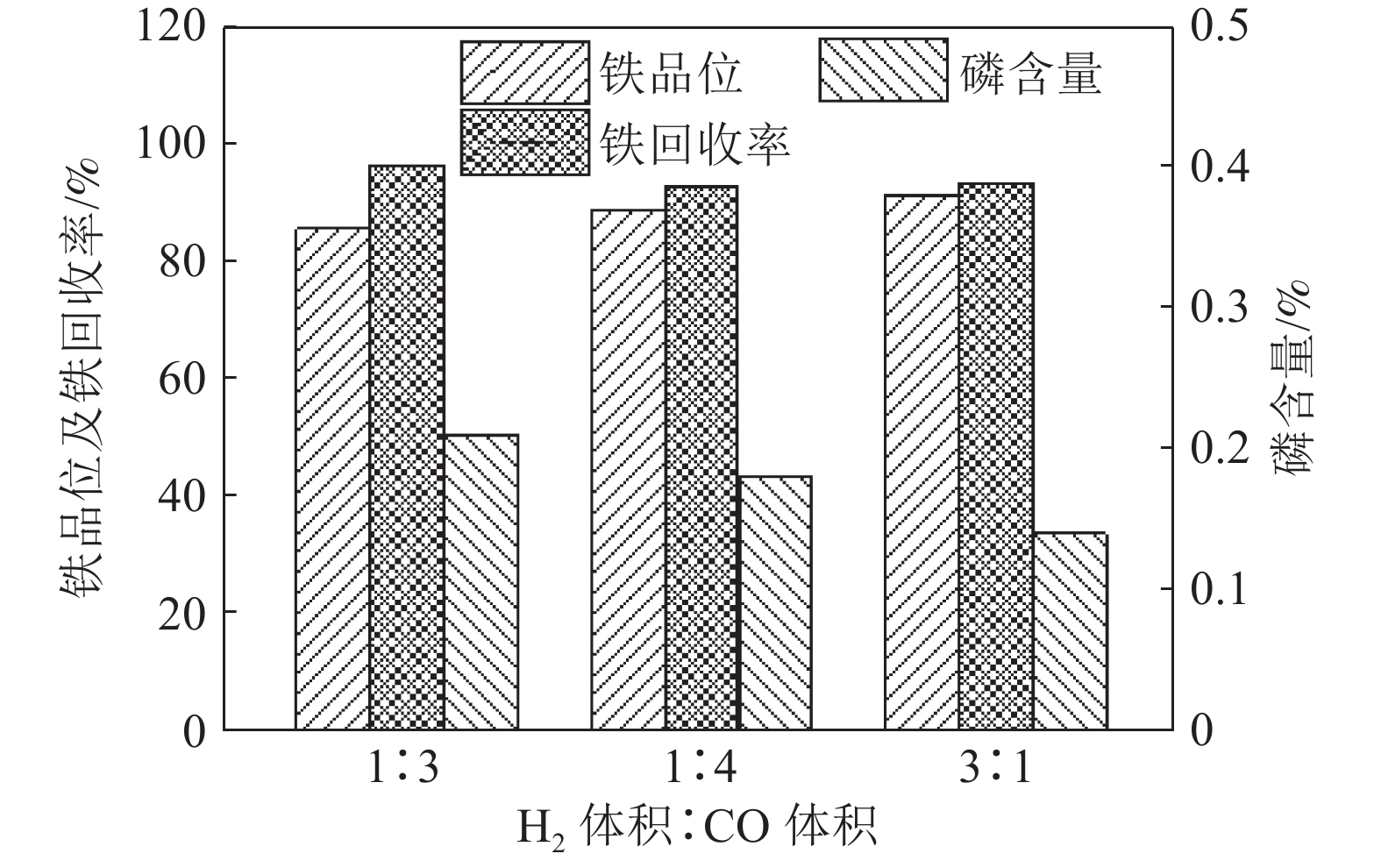

这是一篇冶金工程领域的论文。针对高磷铁矿石气基还原存在球强度低以及还原温度高的问题,提出了氧化焙烧-气基还原-磁选新工艺。考查了氧化温度以及脱磷剂种类对氧化球抗压强度的影响,并找出了符合竖炉强度要求的氧化焙烧条件,在此基础上,研究了还原温度、还原气体总流量、还原气体组成以及还原时间对提铁降磷的影响。结果表明,在Na2CO3用量10%,氧化温度1200 ℃,氧化时间60 min,还原温度950 ℃,H2与CO的流量分别为3.75 L/min以及1.25 L/min,还原时间180 min的条件下,可获得铁品位91.15%、铁回收率93.07%和磷含量0.14%的粉末还原铁。扫描电镜结果表明,粉末还原铁中的磷以机械夹杂的形式存在,磷是通过磨矿-磁选除去。

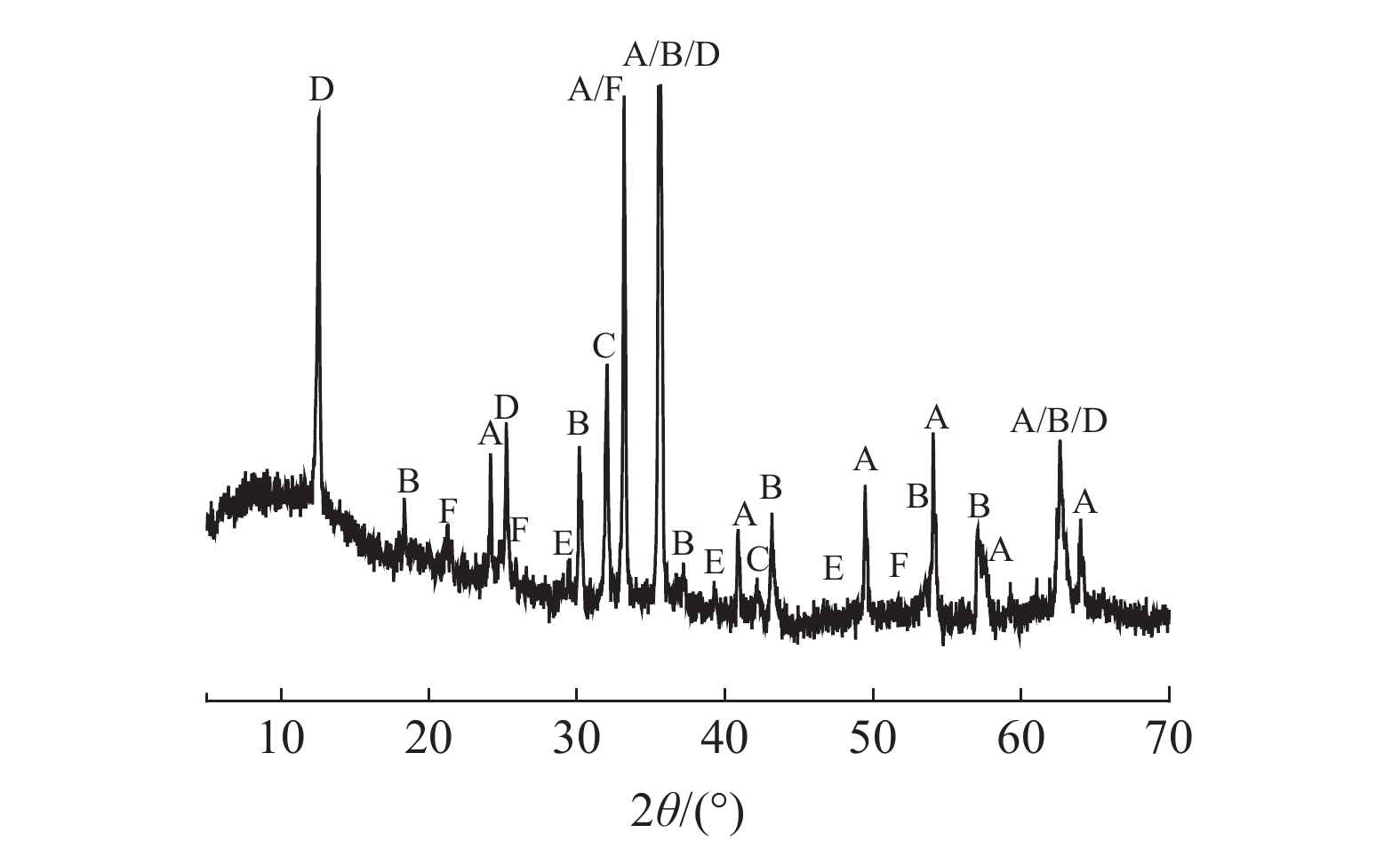

Abstract:This is an article in the field of metallurgical engineering. In view of the problems of low compressive strength and high reduction temperature in the gas-base reduction of a high-phosphorus iron ore, a new process of oxidation roasting, gas-based reduction followed by magnetic separation was proposed. The effect of oxidation temperature and the types and dosages of dephosphorization on the compressive strength of the oxidized pellets were investigated, and the conditions of oxidation roasting that met the strength requirements of the shaft furnace were found. On this basis, the effects of reducing temperature, total reducing gas flow rate, reducing gas composition and reducing time on iron recovery and dephosphorization were studied. The results showed that under the conditions of 10% Na2CO3 dosage, oxidation temperature 1200 ℃, oxidation time 60 min, reduction temperature 950 ℃, flow rates of H2 and CO were 3.75 L/min and 1.25 L/min, respectively, and reduction time 180 min, Iron grade, iron recovery and phosphorus content were 91.15%, 93.07% and 0.14%, respectively. The SEM results show that the phosphorus in the powdered reduced iron exists in the form of mechanical inclusions, and the phosphorus is removed by grinding-magnetic separation.

-

-

表 1 矿石的化学多元素分析结果/%

Table 1. Results of chemical multi-element analysis of ore

TFe P CaO SiO2 Al2O3 MgO MnO S 55.81 0.72 2.24 5.49 4.95 0.55 0.35 0.023 -

[1] 杨敏. 惠民高磷褐铁矿焙烧-酸浸除磷机理研究[D]. 北京: 中国科学院研究生院(过程工程研究所), 2015.YANG M. Dephosphorization mechanism of the raw and as-roasted Huiming high phosphorus limonlite through sulfuric acid leaching[D]. Beijing: Institute of process engineering, Chinese Academy of Sciences, 2015.

YANG M. Dephosphorization mechanism of the raw and as-roasted Huiming high phosphorus limonlite through sulfuric acid leaching[D]. Beijing: Institute of process engineering, Chinese Academy of Sciences, 2015. [2] Fisher-White M J, Lovel R R, Sparrow G J. Phosphorus removal from goethitic iron ore with a low temperature heat treatment and a caustic leach[J]. Isij International. 2012, 52(5): 797–803.

[3] 郝先耀, 戴惠新, 赵志强. 高磷铁矿石降磷的现状与存在问题探讨[J]. 金属矿山, 2007(1):7-10.HAO X Y, DAI H X, ZHAO Z Q. State quo of phosphorous reduction of high phosphorus iron ore and discussion on Its problems[J]. Metal Mine, 2007(1):7-10. doi: 10.3321/j.issn:1001-1250.2007.01.002

HAO X Y, DAI H X, ZHAO Z Q . State quo of phosphorous reduction of high phosphorus iron ore and discussion on Its problems[J]. Metal Mine,2007 (1 ):7 -10 .[4] 肖敏, 邱小英, 蓝桥发. 高磷鲕状赤铁矿金属化还原焙烧-磁选-熔分新工艺研究[J]. 矿产综合利用, 2020(5):101-114.XIAO M, QIU X Y, LAN Q F. Study on the new technology of reduction roasting, magnetic separation and melting of high phosphorus oolitic hematite[J]. Multipurpose Utilization of Mineral Resources, 2020(5):101-114.

XIAO M, QIU X Y, LAN Q F . Study on the new technology of reduction roasting, magnetic separation and melting of high phosphorus oolitic hematite[J]. Multipurpose Utilization of Mineral Resources,2020 (5 ):101 -114 .[5] 李国峰, 韩跃新, 高鹏, 等. 高磷鲕状赤铁矿深度还原过程中磷在金属相富集热力学研究[J]. 矿产综合利用, 2019(2):152-156.LI G F, HAN Y X, GAO P, et al. Thermodynamic study of phosphorus in metallic phase during coal-based reduction of high phosphorus oolitic hematite ore[J]. Multipurpose Utilization of Mineral Resources, 2019(2):152-156. doi: 10.3969/j.issn.1000-6532.2019.02.032

LI G F, HAN Y X, GAO P, et al . Thermodynamic study of phosphorus in metallic phase during coal-based reduction of high phosphorus oolitic hematite ore[J]. Multipurpose Utilization of Mineral Resources,2019 (2 ):152 -156 .[6] 韩跃新, 孙永升, 高鹏, 等. 高磷鲕状赤铁矿开发利用现状及发展趋势[J]. 金属矿山, 2012(3):1-5.HAN Y X, SUN Y S, GAO P, et al. Exploitation situation and development trend of high phosphorus oolitic hematite[J]. Metal Mine, 2012(3):1-5.

HAN Y X, SUN Y S, GAO P, et al . Exploitation situation and development trend of high phosphorus oolitic hematite[J]. Metal Mine,2012 (3 ):1 -5 .[7] 韩继康, 梁冰, 李国峰, 等. 某含磷铁矿的可选性试验研究[J]. 矿产综合利用, 2020(2):49-54.HAN J K, LIANG B, LI G F, et al. Preparability test of a phosphorus-bearing iron ore[J]. Multipurpose Utilization of Mineral Resources, 2020(2):49-54.

HAN J K, LIANG B, LI G F, et al . Preparability test of a phosphorus-bearing iron ore[J]. Multipurpose Utilization of Mineral Resources,2020 (2 ):49 -54 .[8] 吴世超, 孙体昌, 李正要, 等. 高磷铁矿石直接还原-磁选研究进展[J]. 金属矿山, 2021(2):58-64.WU S C, SUN T C, LI Z Y, et al. Research progress of direct reduction-magnetic separation of high phosphorus iron ore[J]. Metal Mine, 2021(2):58-64.

WU S C, SUN T C, LI Z Y, et al . Research progress of direct reduction-magnetic separation of high phosphorus iron ore[J]. Metal Mine,2021 (2 ):58 -64 .[9] 张奔, 赵志龙, 郭豪, 等. 气基竖炉直接还原炼铁技术的发展[J]. 钢铁研究, 2016, 44(5):59-62.ZHANG B, ZHAO Z L, GUO H, et al. Development of direct-reduction iron making technology in gas-based shaft furnace[J]. Research on Iron and Steel, 2016, 44(5):59-62.

ZHANG B, ZHAO Z L, GUO H, et al . Development of direct-reduction iron making technology in gas-based shaft furnace[J]. Research on Iron and Steel,2016 ,44 (5 ):59 -62 .[10] 延黎, 黄武胜, 吴世超, 等. 某高磷鲕状铁矿石气基直接还原-磁选提铁降磷研究[J]. 矿冶工程, 2021, 41(1):72-75.YAN L, HUANG W S, WU S C, et al. High-phosphorus oolitic iron ore processed with gas-based direct reduction and magnetic separation for iron increasing and phosphorus reduction[J]. Mining and Metallurgical Engineering, 2021, 41(1):72-75.

YAN L, HUANG W S, WU S C, et al . High-phosphorus oolitic iron ore processed with gas-based direct reduction and magnetic separation for iron increasing and phosphorus reduction[J]. Mining and Metallurgical Engineering,2021 ,41 (1 ):72 -75 .[11] 黄武胜, 延黎, 吴世超, 等. 国外某高磷鲕状铁矿石工艺矿物学研究[J]. 金属矿山, 2020(9):137-141.HUANG W S, YAN L, WU S C, et al. Study on the process mineralogy of a high phosphorus oolitic iron ore in abroad[J]. Metal Mine, 2020(9):137-141. doi: 10.19614/j.cnki.jsks.202009019

HUANG W S, YAN L, WU S C, et al . Study on the process mineralogy of a high phosphorus oolitic iron ore in abroad[J]. Metal Mine,2020 (9 ):137 -141 .[12] 唐珏. 高铬型钒钛磁铁矿气基竖炉直接还原-熔分新工艺基础研究[D]. 沈阳: 东北大学, 2017.TANG J. Fundamental study on innovative process of gas-based shaft furnace direct reduction-melting separation for high chromium vanadium-bearing titanomagnetite[D]. Shenyang: Northeastern University, 2017.

TANG J. Fundamental study on innovative process of gas-based shaft furnace direct reduction-melting separation for high chromium vanadium-bearing titanomagnetite[D]. Shenyang: Northeastern University, 2017. -

下载:

下载: