Cooperative Preparation of Glass-ceramics by Blast Furnace Slag and Low-carbon Chromium Iron Alloy Slag

-

摘要:

这是一篇矿物材料领域的论文。为对大宗工业固废进行高值化利用和无害化处理,以包钢高炉渣、低碳铬铁合金渣和石英砂为原料熔融法制备CaO-MgO-Al2O3-SiO2-Cr2O3体系微晶玻璃。并通过差热分析(DSC)、X射线衍射(XRD)、扫描电子显微镜(SEM)等分析手段探究较优原料配比。结果表明:当高炉渣、低碳铬铁合金渣、石英砂质量比例为60∶40∶31时,制得微晶玻璃的晶相为透辉石和绿辉石,此时微晶玻璃性能较优,抗折强度达到126.25 MPa,晶化度达到89.19%,显微结构较理想。较优原料配比条件下制备的微晶玻璃满足国家A类装饰装修材料IRa≤1.0和Iγ≤1.3的要求,且微晶玻璃中重金属铬的浸出浓度符合国家标准,表明采用高炉渣和低碳铬铁合金渣制备微晶玻璃具有可行性。

Abstract:This is an article in the field of mineral materials. In order to make high-value utilization and harmless treatment of bulk industrial solid waste, CaO-MgO-Al2O3-SiO2-Cr2O3 system glass-ceramics were prepared by melting method with Baotou Steel blast furnace slag, low-carbon chromium iron alloy slag and quartz sand as the raw materials. The optimum ratio of raw materials was explored by means of differential thermal analysis (DSC), X-ray diffraction (XRD) and scanning electron microscopy (SEM). The results showed that when the mass ratio of blast furnace slag, low-carbon chromium iron alloy slag and quartz sand was 60∶40∶31, the crystalline phases of glass-ceramics were diopside and omphacite. At this time, the performance of glass-ceramics was the best, the flexural strength reached 126.25 MPa, the crystallinity reached 89.19%, and the microstructure was ideal. The glass-ceramics prepared under the optimal raw material ratio met the requirements for national class A decoration materials, i.e. IRa≤1.0 and Iγ≤1.3, and the leaching concentration of heavy metal chromium in the glass-ceramics met the national standard, indicating that it is feasible to prepare glass-ceramics with blast furnace slag and low-carbon chromium iron alloy slag.

-

-

表 1 各原料化学组成(质量分数)/%

Table 1. Chemical composition of raw materials (mass fraction)

成分 CaO Fe2O3 FeO SiO2 K2O Na2O Al2O3 MgO Cr2O3 CaF2 TiO2 CaS MnO 其他 高炉渣 34.43 - 0.69 34.21 0.48 0.54 13.84 9.15 - 0.78 0.89 3.2 0.52 1.27 低碳铬铁合金渣 48.64 0.58 0.5 29.46 - - 7.36 7.23 3.48 - - - - 2.75 石英砂 0.029 0.037 - 98.200 - 0.018 0.120 0.005 - - - - - 1.591 表 2 基础玻璃原料质量比例(质量分数)/%

Table 2. Quality of ratio base glass raw materials

组别低碳铬铁合金渣:高炉渣:

石英砂:纯化学试剂Al2O3原料中固废占比 1# 40∶60 ∶ 26.23∶ 0 79 2# 50∶50 ∶ 28.78∶ 0 78 3# 60∶40 ∶31.33∶ 0 76 4# 70∶30 ∶ 33.88∶ 0 75 5# 80∶20 ∶ 36.44∶0.23 73 6# 90∶10 ∶38.99∶1.16 72 表 3 1 500 ℃时粘度实测值/(Pa·s)

Table 3. Measured viscosity at 1 500 ℃

温度/℃ 1# 2# 3# 4# 5# 6# 1 500 0.613 0.579 0.561 0.493 0.492 0.435 表 4 3#基础玻璃在不同晶化温度下的热处理制度

Table 4. 3# Base glass heat treatment system at different crystallization temperatures

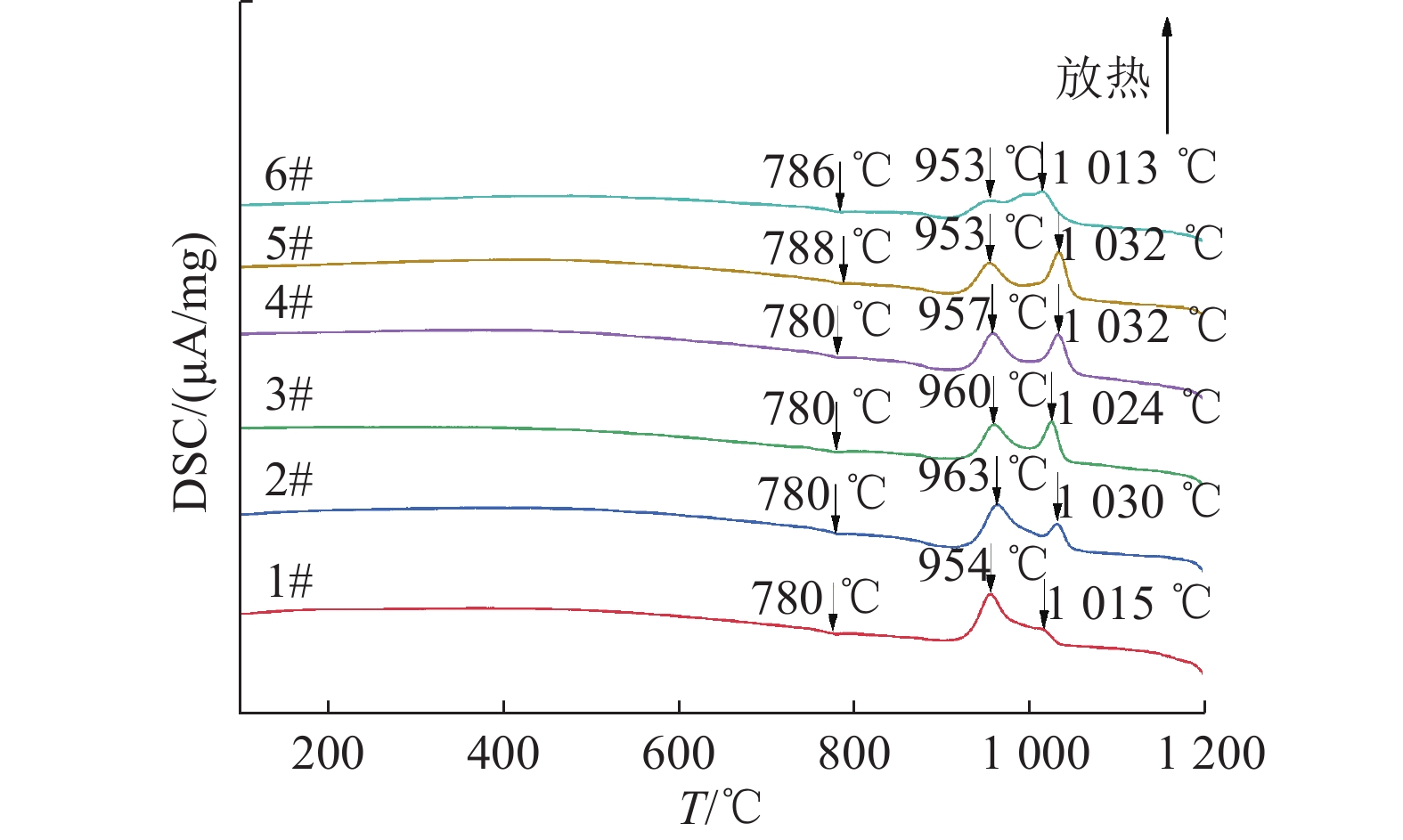

样品 核化温度/℃ 核化时间/min 晶化温度/℃ 晶化时间/min A 830 90 960 90 B 830 90 1 024 90 表 5 热处理核化温度和晶化温度

Table 5. Nucleation temperature and crystallization temperature of heat treatment

组别 核化温度/℃ 晶化温度/℃ 1# 828 954 2# 830 963 3# 830 960 4# 830 957 5# 838 953 6# 836 953 表 6 微晶玻璃样品晶化度计算值

Table 6. Calculated crystallinity of glass-ceramics samples

组别 1# 2# 3# 4# 5# 6# Cr2O3含量

(质量分数)/%1.11 1.36 1.60 1.83 2.05 2.25 晶化度/% 69.53 81.91 89.19 72.97 78.95 64.92 表 7 微晶玻璃样品与大理石、花岗岩理化性能对比

Table 7. Comparison of physical and chemical properties of glass ceramics samples with marble and granite

组别 抗折强度/MPa 莫氏硬度 密度/(g/cm3) 耐酸性/% 耐碱性/% 吸水率/% 1# 86.09 6~7 2.70 0.60 0.12 0.20 2# 107.24 6~7 2.93 0.38 0.06 0.12 3# 126.25 6~7 3.81 0.37 0.06 0.06 4# 94.74 6~7 3.10 0.44 0.07 0.04 5# 87.79 6~7 2.70 0.59 0.04 0.04 6# 35.80 6~7 2.68 0.52 0.07 0.18 大理石 13~15 2.5~5 2.6~2.7 10.3~12.3 0.3 ≤0.3 花岗岩 15~38 6~7 2.5~2.7 0.91 0.08 0.5~0.8 表 8 3#和4#微晶玻璃样品放射性核素检测结果

Table 8. Radionuclide detection results of 3# and 4# glass-ceramics samples

组别 内照射指数IRa 外照射指数Iγ 3# 0.30 0.88 4# 0.19 0.70 -

[1] 郝百川, 李子越, 贾东方, 等. 含钛高炉渣的综合利用[J]. 矿产综合利用, 2020(6):1-6.HAO B C, LI Z Y, JIA D F, et al. Comprehensive utilization of titanium bearing blast furnace slag[J]. Multipurpose Utilization of Mineral Resources, 2020(6):1-6. doi: 10.3969/j.issn.1000-6532.2020.06.001

HAO B C, LI Z Y, JIA D F, et al. Comprehensive utilization of titanium bearing blast furnace slag[J]. Multipurpose Utilization of Mineral Resources, 2020(6):1-6. doi: 10.3969/j.issn.1000-6532.2020.06.001

[2] 苗希望, 白智韬, 卢光华, 等. 典型铁合金渣的资源化综合利用研究现状与发展趋势[J]. 工程科学学报, 2020, 42(6):663-679.MIAO X W, BAI Z T, LU G H, et al. Research status and development trend of resource comprehensive utilization of typicalferroalloy slag[J]. Chinese Journal of Engineering, 2020, 42(6):663-679.

MIAO X W, BAI Z T, LU G H, et al. Research status and development trend of resource comprehensive utilization of typicalferroalloy slag[J]. Chinese Journal of Engineering, 2020, 42(6):663-679.

[3] Yekta B E, Alizadeh P. The effect of CaF2 and Cr2O3 on the crystallisation and mechanical properties of SiO2-CaO- Fe2O3-(Al2O3) glasses[J]. Glass Technology, 2005, 46(5):347-348.

[4] 杨焕银, 郭红力. 工业固体废物制备微晶玻璃研究进展[J]. 科技资讯, 2020, 18(33):53-55.YANG H Y, GUO H L. Research progress in preparation of glass ceramics from industrial solid waste[J]. Science & Technology Information, 2020, 18(33):53-55.

YANG H Y, GUO H L. Research progress in preparation of glass ceramics from industrial solid waste[J]. Science & Technology Information, 2020, 18(33):53-55.

[5] 孙强强, 亢小红. 钙长石系尾矿微晶玻璃的制备及发光性能[J]. 矿产综合利用, 2020(4):152-155+151.SUN Q Q, KANG X H. Preparation and luminescent properties of anorthite tailings glass ceramics[J]. Multipurpose Utilization of Mineral Resources, 2020(4):152-155+151. doi: 10.3969/j.issn.1000-6532.2020.04.026

SUN Q Q, KANG X H. Preparation and luminescent properties of anorthite tailings glass ceramics[J]. Multipurpose Utilization of Mineral Resources, 2020(4):152-155+151. doi: 10.3969/j.issn.1000-6532.2020.04.026

[6] 王亚文, 贵永亮, 宋春燕, 等. 高炉渣制备微晶玻璃的研究进展[J]. 矿产综合利用, 2018(2):1-6.WANG Y W, GUI Y L, SONG C Y, et al. Research progress in preparation of glass ceramics from blast furnace slag[J]. Multipurpose Utilization of Mineral Resources, 2018(2):1-6. doi: 10.3969/j.issn.1000-6532.2018.02.001

WANG Y W, GUI Y L, SONG C Y, et al. Research progress in preparation of glass ceramics from blast furnace slag[J]. Multipurpose Utilization of Mineral Resources, 2018(2):1-6. doi: 10.3969/j.issn.1000-6532.2018.02.001

[7] 文璐, 国宏伟, 李鹏, 等. 中钛型含钛高炉渣与铬铁合金渣制备微晶玻璃[J]. 金属世界, 2020(2):68-72.WEN L, GUO H W, LI P, et al. Preparation of glass ceramics from medium titanium type blast furnace slag containing titanium and ferrochromium alloy slag[J]. Metal World, 2020(2):68-72. doi: 10.3969/j.issn.1000-6826.2020.02.018

WEN L, GUO H W, LI P, et al. Preparation of glass ceramics from medium titanium type blast furnace slag containing titanium and ferrochromium alloy slag[J]. Metal World, 2020(2):68-72. doi: 10.3969/j.issn.1000-6826.2020.02.018

[8] 王亚文, 贵永亮, 宋春燕, 等. CaO/SiO2质量比对CaO-MgO-SiO2-Al2O3系微晶玻璃析晶行为的影响[J]. 矿产综合利用, 2018(1):137-141.WANG Y W, GUI Y L, SONG C Y, et al. Effect of CaO/SiO2 mass ratio on crystallization behavior of CaO-MgO-SiO2- Al2O3 glass ceramics[J]. Multipurpose Utilization of Mineral Resources, 2018(1):137-141. doi: 10.3969/j.issn.1000-6532.2018.01.030

WANG Y W, GUI Y L, SONG C Y, et al. Effect of CaO/SiO2 mass ratio on crystallization behavior of CaO-MgO-SiO2- Al2O3 glass ceramics[J]. Multipurpose Utilization of Mineral Resources, 2018(1):137-141. doi: 10.3969/j.issn.1000-6532.2018.01.030

[9] Deng L B, Lu W W, Zhang Z. Crystallization behavior and structure of CaO-MgO-Al2O3-SiO2 glass-ceramics prepared from Cr-bearing slag[J]. Materials chemistry and physics, 2021, 261:124249. doi: 10.1016/j.matchemphys.2021.124249

[10] Li BW, Deng L B, Zhang X F. Structure and performance of glass-ceramics obtained by Bayan Obo tailing and fly ash[J]. Journal of Non-Crystalline Solids, 2013, 380:103-108. doi: 10.1016/j.jnoncrysol.2013.09.012

[11] Rao M V S, Rajyasree C, Narendrudu T. Physical and spectroscopic properties of multi-component Na2O-PbO-Bi2O3-SiO2 glass-ceramics with Cr2O3 as nucleating agent[J]. Optical materials, 2015, 47:315-322. doi: 10.1016/j.optmat.2015.05.048

[12] 王瑞鑫, 王艺慈, 曹鹏飞, 等. 高炉渣和粉煤灰制备微晶玻璃晶核剂的优化[J]. 中国陶瓷, 2020, 56(11):44-49.WANG R X, WANG Y C, CAO P F, et al. Optimization of nucleating agent for glass ceramics prepared from blast furnace slag and fly ash[J]. China Ceramics, 2020, 56(11):44-49.

WANG R X, WANG Y C, CAO P F, et al. Optimization of nucleating agent for glass ceramics prepared from blast furnace slag and fly ash[J]. China Ceramics, 2020, 56(11):44-49.

[13] 陈莹, 陆雷, 王永志. 云母/β-锂辉石系可加工微晶玻璃热处理工艺的优化研究[J]. 中国陶瓷, 2011, 47(9):27-30.CHEN Y, LU L, WANG Y Z. Mica/ β-Optimization of heat treatment process of spodumene machinable glass ceramics[J]. China Ceramics, 2011, 47(9):27-30.

CHEN Y, LU L, WANG Y Z. Mica/ β-Optimization of heat treatment process of spodumene machinable glass ceramics[J]. China Ceramics, 2011, 47(9):27-30.

[14] 刘晓光. Cr2O3对万通钢铁公司高炉渣冶金性能的影响[D]. 唐山: 华北理工大学, 2016.LIU X G. Effect of Cr2O3 on metallurgical properties of blast furnace slag in Wantong iron and Steel Company[D]. Tangshan: North China University of Science and Technology, 2016.

LIU X G. Effect of Cr2O3 on metallurgical properties of blast furnace slag in Wantong iron and Steel Company[D]. Tangshan: North China University of Science and Technology, 2016.

[15] Zhang S, Zhang Y L, Wu T. Effect of Cr2O3 on the crystallization behavior of synthetic diopside and characterization of Cr-doped diopside glass-ceramics[J]. Ceramics International, 2018, 44(9):10119-10129. doi: 10.1016/j.ceramint.2018.02.231

[16] Li H R, Liu S Y, Xu W C, et al. The mechanism of the crystalline characteristics of spinel-induced epitaxial growth of diopside in CMAS glass-ceramics[J]. Journal of the European Ceramic Society, 2021, 41(2):1603-1612. doi: 10.1016/j.jeurceramsoc.2020.09.037

[17] 雷岩, 汪琦, 刘焕春, 等. 铁尾矿、菱镁石尾矿制备微晶玻璃的研究[J]. 矿产综合利用, 2011(2):41-44.LEI Y, WANG Q, LIU H C, et al. Study on preparation of glass ceramics from iron tailings and magnesite tailings[J]. Multipurpose Utilization of Mineral Resources, 2011(2):41-44. doi: 10.3969/j.issn.1000-6532.2011.02.012

LEI Y, WANG Q, LIU H C, et al. Study on preparation of glass ceramics from iron tailings and magnesite tailings[J]. Multipurpose Utilization of Mineral Resources, 2011(2):41-44. doi: 10.3969/j.issn.1000-6532.2011.02.012

[18] 刘靖靖, 肖汉宁. 晶核剂对高炉渣微晶玻璃晶化行为的影响[J]. 硅酸盐学报, 2016, 44(6):878-883.LIU J J, XIAO H N. Effect of nucleating agent on crystallization behavior of blast furnace slag glass ceramics[J]. Journal of the Chinese Ceramic Society, 2016, 44(6):878-883.

LIU J J, XIAO H N. Effect of nucleating agent on crystallization behavior of blast furnace slag glass ceramics[J]. Journal of the Chinese Ceramic Society, 2016, 44(6):878-883.

[19] 陈国华, 刘心宇. 矿渣微晶玻璃的制备及展望[J]. 陶瓷, 2002(4):16-20.CHEN G H, LIU X Y. Preparation and prospect of slag glass ceramics[J]. Ceramics, 2002(4):16-20. doi: 10.3969/j.issn.1002-2872.2002.04.003

CHEN G H, LIU X Y. Preparation and prospect of slag glass ceramics[J]. Ceramics, 2002(4):16-20. doi: 10.3969/j.issn.1002-2872.2002.04.003

[20] 贾志恒. 含铬微晶玻璃制备过程中铬的赋存状态及分布行为研究[D]. 赣州: 江西理工大学, 2020.JIA Z H. Study on the existing state and distribution behavior of chromium in the preparation of chromium containing glass ceramics[D]. Ganzhou: Jiangxi University of Science and Technology, 2020.

JIA Z H. Study on the existing state and distribution behavior of chromium in the preparation of chromium containing glass ceramics[D]. Ganzhou: Jiangxi University of Science and Technology, 2020.

[21] 杨健. 含铬钢渣制备微晶玻璃及一步热处理研究[D]. 北京: 北京科技大学, 2016.YANG J. Preparation of glass ceramics from chromium containing steel slag and one-step heat treatment[D]. Beijing: University of Science and Technology Beijing, 2016.

YANG J. Preparation of glass ceramics from chromium containing steel slag and one-step heat treatment[D]. Beijing: University of Science and Technology Beijing, 2016.

[22] 袁少伟, 戴新荣, 贺传友, 等. 浅谈建筑装饰装修材料中放射性危害及检测方法[J]. 建材与装饰, 2017(48):42-43.YUAN S W, DAI X R, HE C Y, et al. Discussion on radioactive hazards and detection methods in building decoration materials[J]. Construction Materials & Decoration, 2017(48):42-43. doi: 10.3969/j.issn.1673-0038.2017.48.035

YUAN S W, DAI X R, HE C Y, et al. Discussion on radioactive hazards and detection methods in building decoration materials[J]. Construction Materials & Decoration, 2017(48):42-43. doi: 10.3969/j.issn.1673-0038.2017.48.035

[23] 裘慧广, 沈强, 王传彬, 等. 微晶玻璃的种类、制备及其应用[J]. 中国建材科技, 2005(1):15-19.QIU H G, SHEN Q, WANG C B, et al. Types, preparation and application of glass ceramics[J]. China Building Materials Science and Technology, 2005(1):15-19. doi: 10.3969/j.issn.1003-8965.2005.01.005

QIU H G, SHEN Q, WANG C B, et al. Types, preparation and application of glass ceramics[J]. China Building Materials Science and Technology, 2005(1):15-19. doi: 10.3969/j.issn.1003-8965.2005.01.005

[24] 李保庆, 郭艳平, 党海峰. MgO对飞灰屏玻璃协同制备微晶玻璃析晶及性能的影响[J]. 矿产综合利用, 2020(1):135-139+134.LI B Q, GUO Y P, DANG H F. Effect of MgO on crystallization and properties of glass ceramics prepared by fly ash screen glass[J]. Multipurpose Utilization of Mineral Resources, 2020(1):135-139+134. doi: 10.3969/j.issn.1000-6532.2020.01.028

LI B Q, GUO Y P, DANG H F. Effect of MgO on crystallization and properties of glass ceramics prepared by fly ash screen glass[J]. Multipurpose Utilization of Mineral Resources, 2020(1):135-139+134. doi: 10.3969/j.issn.1000-6532.2020.01.028

-

下载:

下载: