Characteristics and Removal Process of Aluminum Nitride in Secondary Aluminum Dross: A Review

-

摘要:

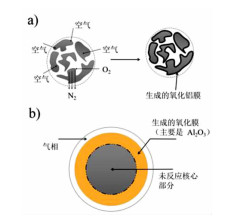

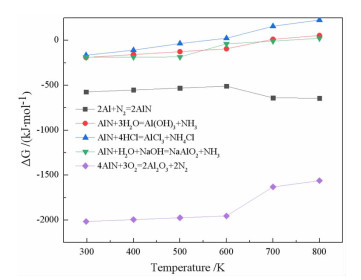

二次铝灰中的氮化铝遇水会释放出氨气是导致铝灰成为危险废弃物的主要原因,因此实现铝灰无害化及资源化对铝资源可持续发展具有重要意义。阐述了铝灰中氮化铝的来源及物理化学性质。重点介绍了氮化铝的两种不同转化行为:水解行为、氧化行为,详细介绍了氮化铝水解、氧化过程中产物的变化及影响因素。并依据氮化铝转化行为对比了目前铝灰湿法、火法除氮工艺的特点及不同,指出未来铝灰除氮工艺的研究方向不仅要着重在工艺方法上,还应关注到相关检测标准、工艺过程中产物的成分及工艺安全性上。

Abstract:The aluminum nitride in the secondary aluminum dross will release ammonia gas when it is contact with water, which is the main reason that the aluminum dross becomes a hazardous waste, therefore, the realization of the harmlessness and resourcezation of aluminum dross is of great significance to the sustainable development of aluminum resources. The source and physical and chemical properties of aluminum nitride in aluminum ash are described. The focus is on two different transformation behaviors of aluminum nitride: hydrolysis behavior and oxidation behavior. The composition of the product and influencing factors during the hydrolysis and oxidation of aluminum nitride are introduced in detail. According to the transformation behavior of aluminum nitride, the characteristics and differences of the current aluminum dross hydrometallurgy and pyrometallurgy nitrogen removal process are introduced, and the research direction of the future aluminum dross nitrogen removal process should not only focus on the process method, but also pay attention to the relevant testing standards, the composition of the product in the process and the safety of the process.

-

Key words:

- secondary aluminum dross /

- aluminum nitride /

- harmless /

- high-temperature roasting

-

-

表 1 不同条件下铝渣灰中AlN水解后的含量

Table 1. The content of AlN in aluminum slag ash after hydrolysis under different conditions

/% 温度 水解时间/h 0.5 4 8 12 16 20 24 室温 67.02 66.06 64.77 63.43 62.04 60.56 59.26 60 ℃ 66.78 63.71 59.45 58.45 53.90 49.40 44.81 80 ℃ 66.44 63.38 59.36 51.32 43.03 35.28 26.85 100 ℃ 64.62 45.43 30.06 15.46 8.38 0.67 0.00 煮沸 65.82 51.41 33.17 15.61 0.00 -

[1] 贾成厂. 金属: 地壳与人体中的金属[J]. 金属世界, 2018(2): 22-26. doi: 10.3969/j.issn.1000-6826.2018.02.06

[2] SARKER R S, ALAM Z, QADIR R, et al. Extraction and characterization of alumina nanopowders from aluminum dross by acid dissolution process[J]. International Journal of Minerals Metallurgy and Materials, 2015, 22(4): 429-436. doi: 10.1007/s12613-015-1090-2

[3] ABDULKADIR A, AJAYI A, HASSAN M I. Evaluating the chemical composition and the molar heat capacities of a white aluminum dross[J]. Energy Procedia, 2015, 75: 2099-2105. doi: 10.1016/j.egypro.2015.07.326

[4] DAS BR, DASH B, TRIPATHY BC, et al. Acid dissolution of alumina from waste aluminium dross[J]. Hydrometallurgy, 2008, 92(1): 48-53. http://www.sciencedirect.com/science/article/pii/S0304386X0800011X

[5] 佚名. 国家危险废物名录[J]. 中华人民共和国国务院公报, 2016(26): 39-40. https://www.cnki.com.cn/Article/CJFDTOTAL-SHJA201604001.htm

[6] MIRIAN CHIEKOSHINZATO, RAPHAEL HYPOLITO. Effect of disposal of aluminum recycling waste in soil and water bodies[J]. Environmental Earth Sciences, 2016, 75(7): 628-638. doi: 10.1007/s12665-016-5438-3

[7] MAHINROOSTA M, ALLAHVERDI ALI. Enhanced alumina recovery from secondary aluminum dross for high purity nanostructured γ-alumina powder production: Kinetic study[J]. Journal of Environmental Management, 2018, 212: 278-291. http://www.sciencedirect.com/science/article/pii/S0301479718301105

[8] BEHESHTI R, MOOSBERG-BUSTNES J, AKHTAR S, et al. Black dross: processing salt removal from black dross by thermal treatment[J], JOM, 2014, 66(11): 2243-2252. doi: 10.1007/s11837-014-1178-6

[9] MESHRAM A, SINGH K K. Recovery of valuable products from hazardous aluminum dross: A review[J]. Resources Conservation & Recycling, 2018, 130: 95-108. http://www.sciencedirect.com/science/article/pii/S0921344917304172

[10] MOSSFA MAHINROOSTAA, ALI ALLAHVERDI. Hazardous aluminum dross characterization and recycling strategies: A critical review[J]. Journal of Environmental Management, 2018, 223: 452-468. http://www.sciencedirect.com/science/article/pii/S0301479718307205

[11] 刘桂华, 黄文强, 熊德芬, 等. 铝灰中活性物相的反应行为[J]. 中国有色金属学报, 2018, 28(11): 2341-2350. https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ201811020.htm

[12] 杨航, 申士富, 刘海营, 等. 二次铝灰工艺矿物学特性研究[J]. 有色金属工程, 2019, 9(10): 117-124. doi: 10.3969/j.issn.2095-1744.2019.10.017

[13] HIRAKI T, NAGASAKA T. An easier upgrading process of aluminum dross residue by screening technique[J]. Journal of Material Cycles and Waste Management, 2015, 17(3): 566-573. doi: 10.1007/s10163-014-0283-5

[14] GIL A, ARRIETA E, VICENTE M A, KORILI S A. Application of industrial wastes from chemically treated aluminum saline slags as adsorbents[J]. ACS omega, 2018, 3(12): 18275-18284. doi: 10.1021/acsomega.8b02397

[15] LI Q, YANG Q, ZHANG G F, et al. Investigations on the hydrolysis behavior of AlN in the leaching process of secondary aluminum dross[J]. Hydrometallurgy, 2018, 182: 121-127. doi: 10.1016/j.hydromet.2018.10.015

[16] Han Lv, Hongliang Zhao, Zhengping Zuo, et al. A thermodynamic and kinetic study of catalyzed hydrolysis of aluminum nitride in secondary aluminum dross. 2020, 9(5): 9735-9745.

[17] 张勇, 郭朝晖, 王硕, 等. 响应曲面法对铝灰中AlN的水解行为[J]. 中国有色金属学报, 2016, 26(4): 919-927. https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ201604025.htm

[18] W M MOBLEY. Processing and characterization of aluminum nitride suspensions[D]. Colloidal Properties, 1996.

[19] A KOCJAN, A DAKSKOBLER, T KOSMAC. Evolution of aluminum hydroxides in diluted aqueous aluminum nitride powder suspensions[J]. Cryst Growth Des, 2012, 12: 1299-1307. doi: 10.1021/cg201349s

[20] A KOCJAN, A DAKSKOBLER, T KOSMAC. The influence of temperature and time on the AlN powder hydrolysis reaction products[J]. Journal of the European Ceramic Society, 2007, 28(5): 1003-1008. http://www.sciencedirect.com/science/article/pii/S0955221907004839

[21] P LI, M GUO, M ZHANG, et al. Leaching process investigation of secondary aluminium dross: investigation of AlN hydrolysis behaviour in NaCl solution[J]. Mineral Processing and Extractive Metallurgy, 2012, 121(3): 140-146. doi: 10.1179/1743285512Y.0000000008

[22] FUKUMOTO S, HOOKABE T H. Hydrolysis behavior of aluminum nitride in various solutions[J]. Journal of Materials Science, 2000, 35(11): 2743-2748. doi: 10.1023/A:1004718329003

[23] SVEDBERG L M, ARNDT K C, CIMA M J. Corrosion of aluminum nitride (AlN) in aqueous cleaning solutions[J]. Journal of the American Ceramic Society, 2000, 83: 41-46. doi: 10.1111/j.1151-2916.2000.tb01145.x

[24] 姜澜, 邱明放, 丁友东等. 铝灰中AlN的水解行为[J]. 中国有色金属学报, 2012, 22(12): 3555-3561. https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ201212037.htm

[25] A KOCJAN, A DAKSKOBLER, K KRNEL, et al. The course of the hydrolysis and the reaction kinetics of AlN powder in diluted aqueous suspensions[J]. Journal of the European Ceramic Society, 2011, 31(5): 815-823. doi: 10.1016/j.jeurceramsoc.2010.12.009

[26] KRNEL K, KOSMAC T. Reactivity of AlN powder in an aqueous environment[J]. Key Engineering Materials, 2004, 264/268(1): 29-32. http://www.scientific.net/KEM.264-268.29

[27] 周长祥, 王卿, 张文娟, 等. 铝渣灰中氨氮的回收[J]. 矿产保护与利用, 2012(3): 38-41. doi: 10.3969/j.issn.1001-0076.2012.03.010 https://kns.cnki.net/kcms/detail/detail.aspx?dbcode=CJFD&dbname=CJFD2012&filename=KCBH201203011&v=R0X7dsF6Ok59JDE619ucDGHRFoPgpv%25mmd2FdS4ohLUAmxy40YrYfbfDlk26WSEp%25mmd2BtgKb

[28] 吕帅帅, 倪威, 倪红军, 等. 基于正交试验及非线性回归分析的铝灰渣水解研究[J]. 有色金属工程, 2019, 9(10): 52-56. doi: 10.3969/j.issn.2095-1744.2019.10.008

[29] HSIEN K, UENG T H, CHEN C. A study of stabilization and recycling for aluminum dross[J]. Applied Mechanics and Materials, 2013, 2212: 2237-2240. http://www.scientific.net/AMM.275-277.2237

[30] M YOLDI, E. G FUENTES-ORDONEZ, S. A KORILI, A GIL. Efficient recovery of aluminum from saline slag wastes[J]. Minerals Engineering, 2019, 140: 105884. doi: 10.1016/j.mineng.2019.105884

[31] ZHANG YONGHENG, BINNER J. Hydrolysis process of a surface treated aluminum nitride powder-A FTIR study[J]. Journal of Materials Science Letters, 2002, 21(10): 803-805. doi: 10.1023/A:1015714212305

[32] HUANG X L, TOLAYMAT T. Does phosphate restrain reactivity of salt cake from secondary aluminum production[C]//Proceedings of 2014 3rd International Conference on Informatics, Environment, Energy and Applications, 2014-06, Shanghai, China: IACSIT Press, Singapore, 2014: 177-182.

[33] 牛锛, 王孙昊, 李保平, 等. AlN陶瓷低温烧结制备与性能研究[J]. 中国陶瓷工业, 2010, 17(2): 1-4. doi: 10.3969/j.issn.1006-2874.2010.02.001

[34] 牛锛, 胡尊彬, 李保平, 等. AlN陶瓷制备过程中氧化行为研究[J]. 山东陶瓷, 2010, 33(6): 11-13. doi: 10.3969/j.issn.1005-0639.2010.06.003

[35] 邴纯. 铝灰在焙烧中的变化及铝灰返电解槽的试验研究[D]. 沈阳: 东北大学, 2012.

[36] 李亚伟, 李楠, 张文辉. 氮化铝抗水化性能及其在浇注料中的应用[J]. 耐火材料, 2000(5): 256-258, 261. doi: 10.3969/j.issn.1001-1935.2000.05.003

[37] 王榕林, 孙加林, 卜景龙, 等. AlN微粉非等温氧化动力学研究[J]. 材料工程, 2011(4): 29-32, 37. https://www.cnki.com.cn/Article/CJFDTOTAL-CLGC201104008.htm

[38] 唐铃虹. 铝灰渣中氮化铝在焙烧与水解过程中转化的研究[D]. 沈阳: 东北大学, 2015.

[39] 陈欣, 杨洁, 黄刚, 等. 氮化铝陶瓷的氧化机理研究[J]. 真空电子技术, 2020(1): 27-31. https://www.cnki.com.cn/Article/CJFDTOTAL-ZKDJ202001003.htm

[40] 文于华, 张梅, 金佳鸿, 等. 氮化铝表面热氧化的分子动力学研究[J]. 科技创新导报, 2018, 15(5): 82-84. https://www.cnki.com.cn/Article/CJFDTOTAL-ZXDB201805050.htm

[41] 姚义俊, 刘斌, 苏静, 等. AlN粉末在氮氧混合气氛下抗水解性能的研究[J]. 南京信息工程大学学报(自然科学版), 2014, 6(1): 69-73. https://www.cnki.com.cn/Article/CJFDTOTAL-NJXZ201401011.htm

[42] BECKMANN M. Recovery of aluminum and salt slag in Nordrhein-Westphalen[J]. Aluminum, 1991, 67(6): 586-589. http://www.researchgate.net/publication/291983992_Recovery_of_Aluminum_and_Salt_Slag_in_Nordrhein-Westphalen

[43] 倪红军, 唐伟佳, 汪兴兴, 等. 铝灰渣除氮方法: CN108671462A[P]. 2018-10-19.

[44] 陈湘清, 陈小松, 唐剑, 等. 一种铝灰脱氨方法: CN109746249A[P]. 2019-05-14.

[45] 付明波, 郭强, 李永利, 等. 一种强化铝灰脱盐脱氮的方法: CN110314923A[P]. 2019-10-11.

[46] LI P, GUO M, ZHANG M, et al. Leaching process investigation of secondary aluminum dross: the effect of CO2 on leaching process of salt cake from aluminum remelting process[J]. Metallurgical and Materials Transactions B, 2012, 43(5): 1220-1230. doi: 10.1007/s11663-012-9678-7

[47] AMER A M. Aluminum extraction from Aluminum industrial wastes[J]. JOM, 2010, 62(5): 60-63. doi: 10.1007/s11837-010-0080-0

[48] 张宁燕. 碱法焙烧脱除二次铝灰中的氟、氯元素及铝的回收[J]. 新疆有色金属, 2019, 42(2): 47-49. https://www.cnki.com.cn/Article/CJFDTOTAL-XJYS201902024.htm

[49] 张勇, 郭朝晖, 王硕等. 二次铝灰烧结制备钙铝黄长石/镁铝尖晶石复相材料[J]. 中国有色金属学报, 2018, 28(2): 334-339. https://www.cnki.com.cn/Article/CJFDTOTAL-ZYXZ201802015.htm

[50] 田林, 赵加平, 杜建伟, 等. 再生铝过程铝灰渣提取冶金级氧化铝研究[J]. 轻金属, 2019(6): 25-29. https://www.cnki.com.cn/Article/CJFDTOTAL-QJSS201906007.htm

[51] A K TRIPATHY, S MAHALIK, C K SARANGI. A pyro-hydrometallurgical process for the recovery of alumina from waste aluminium dross[J]. Minerals Engineering, 2019, 137: 181-186. doi: 10.1016/j.mineng.2019.04.009

-

下载:

下载: