Separation of Alkali-free Iso-flotation Process on Au-Cu-Fe Polymetallic Ore in Peru

-

摘要:

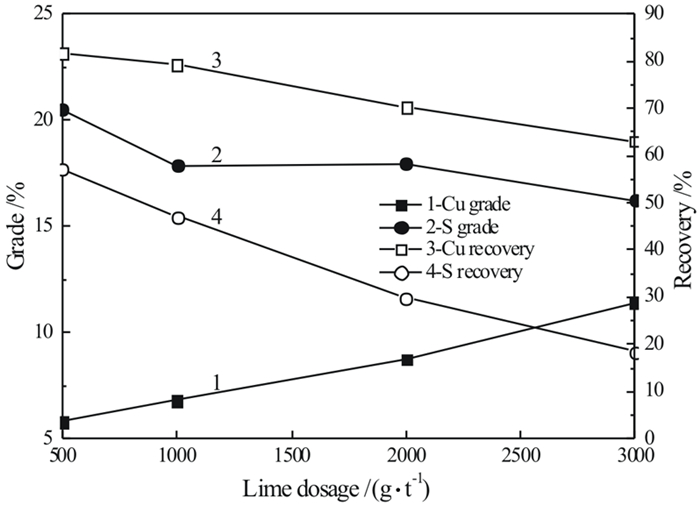

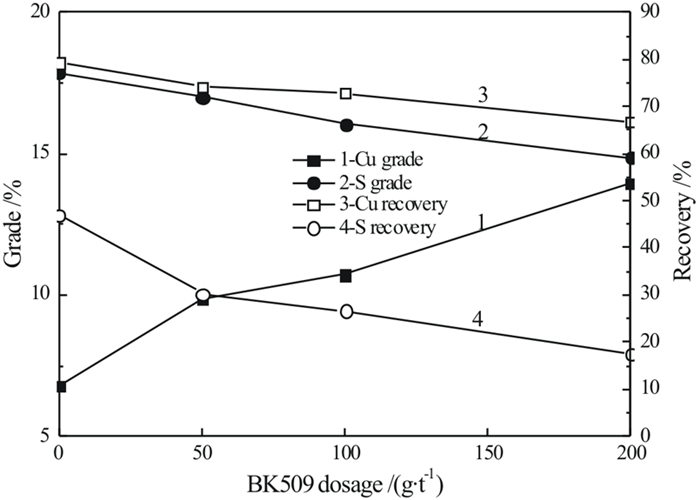

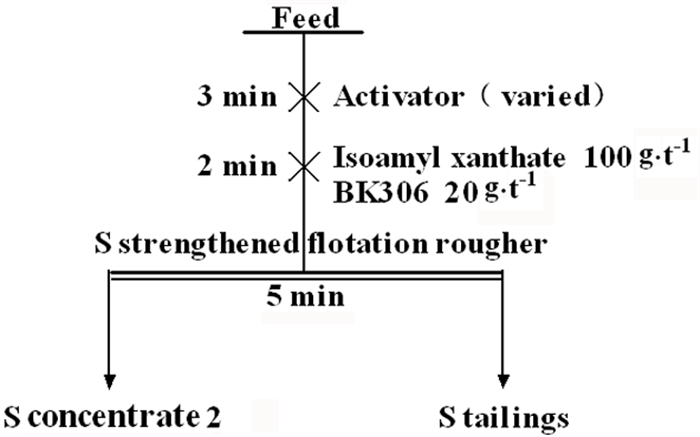

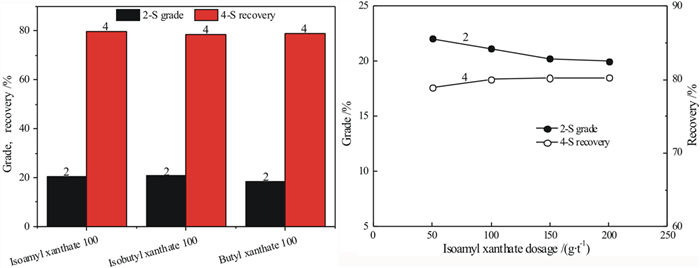

对秘鲁某含Cu 0.12%、Au 0.12 g/t、S 2.60%、Fe 45.52%的金铜铁多金属矿石进行了选矿工艺优化试验研究。该矿石原设计选矿工艺流程为铜硫混选—铜硫分离—混选尾矿磁选回收铁,存在铜硫分离难度大、石灰用量高和分选指标不理想等问题。针对原流程存在的问题,提出采用铜硫等可浮—铜硫分离—难选硫强化浮选—浮选尾矿磁选回收铁的优化工艺流程。铜硫等可浮分选时,在无碱条件下采用选择性的铜捕收剂BK306将铜和部分易浮黄铁矿等硫化矿物浮出,并进行铜硫分离回收铜、金;然后采用活化剂和强力捕收剂强化浮选脱除矿石中的难浮硫化物;最后通过磁选从浮选尾矿中回收铁。该优化工艺既可实现矿石中铜、金等有价金属的高效回收和硫的脱除,又能显著降低铜硫分离所需的石灰用量,并保证后续磁选作业直接获得含硫低、铁品质较好的铁精矿。闭路试验获得铜品位20.10%、金品位15.29 g/t、铜回收率68.42%、金回收率49.07%的铜精矿,硫品位30.78%、总硫回收率84.05%的硫精矿以及铁品位68.88%、含硫0.18%、铁回收率90.57%的铁精矿。与原工艺相比,优化工艺的铜精矿铜品位和铜回收率分别提高2.49和10.25个百分点,铜精矿中金品位和金回收率分别提高5.27 g/t和17.05个百分点,硫回收率提高1.78个百分点。实现了矿石中铜、金、硫、铁的高效综合回收。

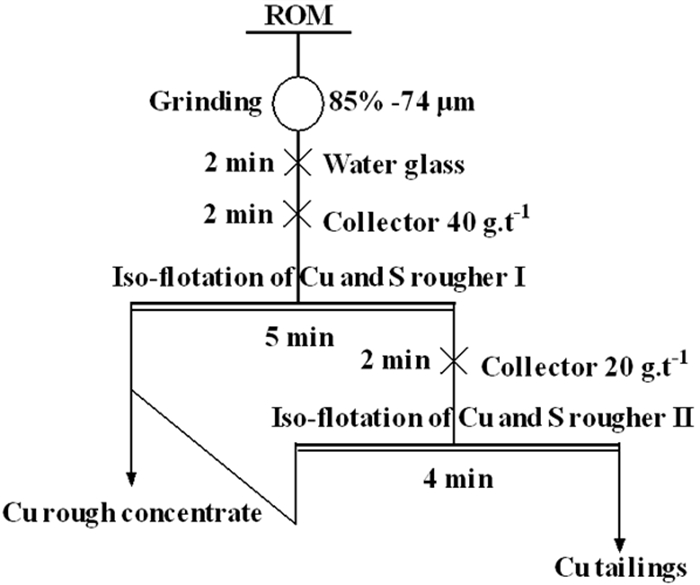

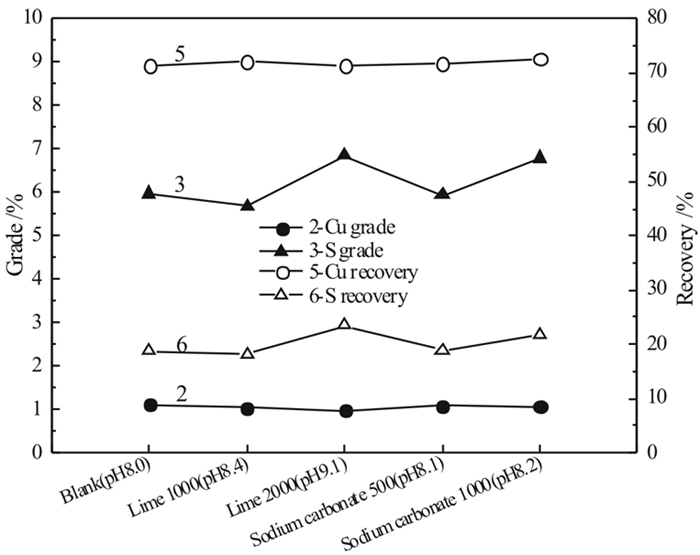

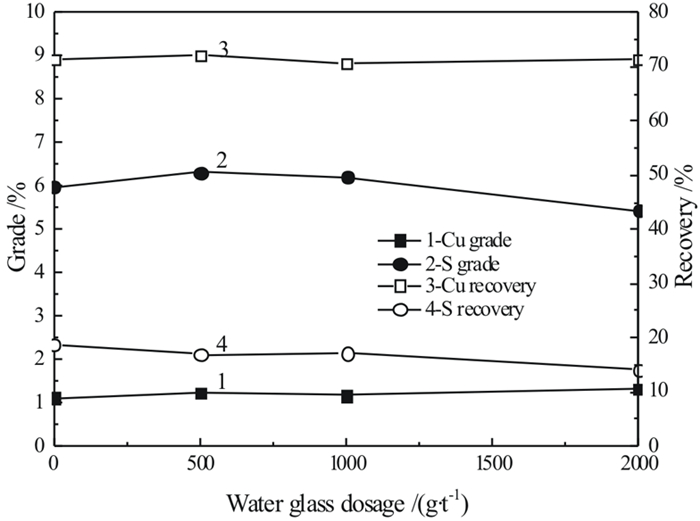

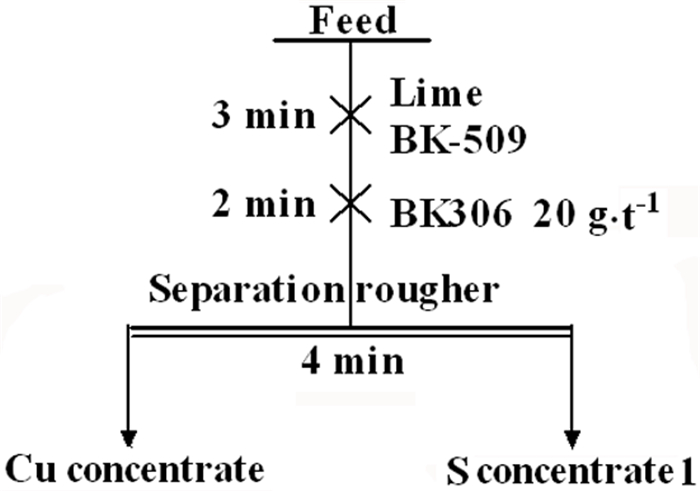

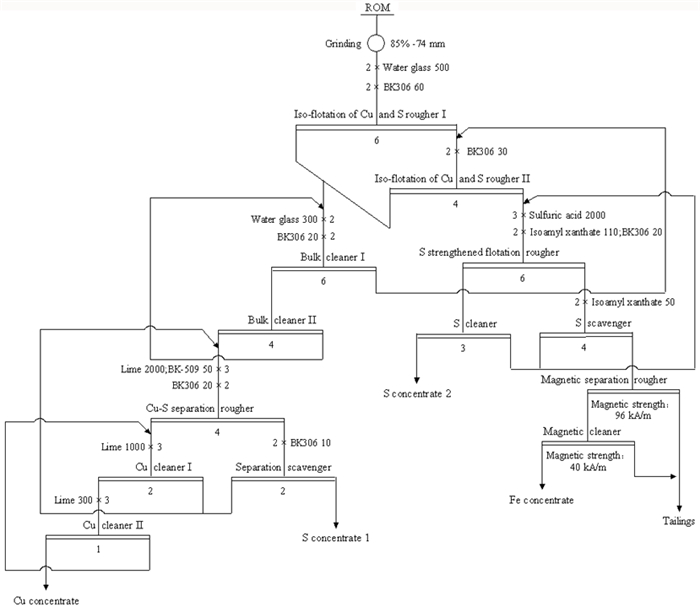

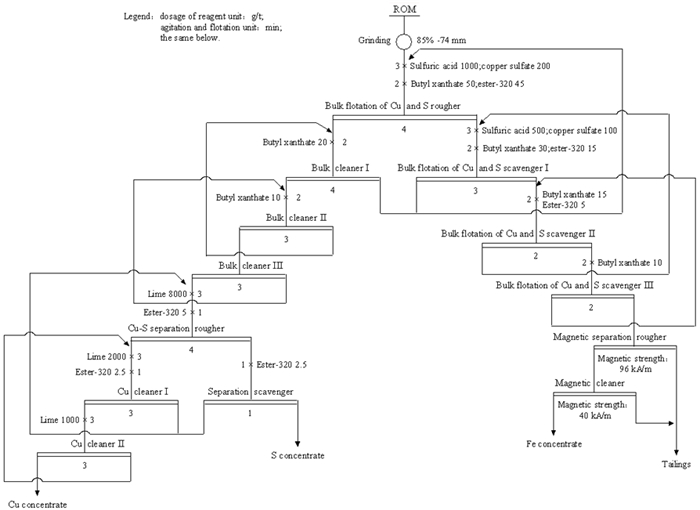

Abstract:The optimization test for the mineral processing process on Au-Cu-Fe polymetallic ore with Cu of 0.12%, Au of 0.12 g/t, S of 2.60% and Fe of 45.52% was studied. There are some problems such as difficulty in copper-sulfur separation, high lime consumption and unsatisfactory separation indexes that exist in the originally designed process of "copper and sulfur bulk flotation-copper and sulfur flotation separation-magnetic separation from the flotation tailings to recover iron". Therefore, the optimization process of "iso-flotation of copper and sulfur-copper and sulfur flotation separation-strengthened flotation of sulfur- magnetic separation from the flotation tailings to recover iron" was proposed based on the problems existing in the original process. Firstly, the selective collector BK306 was adopted to collect copper sulfides and part of easy-floating pyrite from the alkali-free pulp with the iso-flotation process, and then separated them to recover copper and gold. Secondly, the refractory sulfides in the ore were removed by strengthened flotation using activator and strong collector. Finally, the iron was recovered by magnetic separation from the flotation tailings. This optimized process can not only realize the efficient recovery of copper, gold and other valuable metals in the ore and the removal of sulfur, but also significantly reduce the amount of lime required for copper-sulfur separation, and can directly obtain iron concentrate with low content sulfur and better quality in the followed magnetic separation operation. The results of the closed circuit test showed that a copper concentrate could be obtained with Cu grade of 20.10%, Au grade of 15.29 g/t, Cu recovery rate of 68.42% and Au recovery rate of 49.07%; a sulfur concentrate with S content of 30.78% and total sulfur recovery rate of 84.05%; and a iron concentrate with Fe grade of 68.88%, S content of 0.18% and Fe recovery rate of 90.57%. Compared with the originally designed process, the optimized process could increase the copper grade and copper recovery in copper concentrate by 2.49 and 10.25 percentage points, the gold grade and gold recovery in copper concentrate by 5.27 g/t and 17.05 percentage points, and the sulfur recovery rate by 1.78 percentage points, respectively. It realizes efficient and comprehensive recovery of copper, gold, sulfur and iron.

-

-

表 1 试样的主要化学成分分析结果

/% Table 1. Analysis results of run-of-mine ore

TFe Cu Co S Au* Ag* Pb Zn FeO Ni TiO2 SiO2 Al2O3 K2O Na2O MgO CaO P As C 45.52 0.115 0.013 2.60 0.12 2.91 0.010 0.019 19.26 0.005 0.083 13.38 1.89 0.42 0.090 11.51 2.66 0.050 < 0.005 0.35 *:Ag、Au单位为g·t-1。 表 2 矿石中铜的化学物相分析结果

/% Table 2. Analysis results of copper phase of run-of-mine ore

Phase Cu in primary copper sulfide Cu in secondary copper sulfide Cu in free copper oxide Total Cu Cu content 0.090 0.021 0.006 0.117 Cu occupation rate 76.92 17.95 5.13 100.00 表 3 矿石中硫的化学物相分析结果

/% Table 3. Analysis results of sulfur phase of run-of-mine ore

Phase S in sulfides Other S Total S S content 2.57 0.024 2.594 S occupation rate 99.07 0.93 100.00 表 4 验证工艺闭路试验结果

Table 4. Results of locked-circuit test of verification process

Product Yield /% Grade Recovery Cu /% Fe /% S /% Au /(g·t-1) Cu /% Fe /% S /% Au /(g·t-1) Cu concentrate 0.37 17.61 28.35 29.03 10.02 58.17 0.23 4.22 32.02 S concentrate 6.53 0.19 36.58 32.10 0.35 11.07 5.24 82.27 19.74 Fe concentrate 60.11 0.009 68.68 0.22 0.04 4.70 90.54 5.22 22.60 Tailings 32.99 0.088 5.52 0.64 0.09 26.06 3.99 8.29 25.64 ROM 100.00 0.112 45.60 2.55 0.116 100.00 100.00 100.00 100.00 表 5 磨矿细度对铜、硫等可浮选指标影响的结果

Table 5. Results of effect of grinding fineness on iso-flotation of Cu and S indexes

Grinding fineness,-74 μm /% Product Yield/% Grade /% Recovery /% Cu S Cu S 80 Cu rough concentrate 9.37 0.99 7.39 76.76 27.44 Cu tailings 90.63 0.031 2.02 23.24 72.56 ROM 100.00 0.121 2.52 100.00 100.00 85 Cu rough concentrate 10.09 0.92 7.05 79.27 27.60 Cu tailings 89.91 0.027 2.08 20.73 72.40 ROM 100.00 0.117 2.58 100.00 100.00 表 6 全流程闭路试验结果

Table 6. Results of closed-circuit test

Product Yield /% Grade Recovery Cu /% Fe /% S /% Au /(g·t-1) Cu /% Fe /% S /% Au /(g·t-1) Cu concentrate 0.38 20.10 24.56 23.78 15.29 68.42 0.21 3.56 49.07 S concentrate 1 2.46 0.35 26.34 24.39 0.29 7.71 1.42 23.61 6.02 S concentrate 2 4.48 0.14 39.01 34.29 0.36 5.62 3.83 60.44 13.61 Fe concentrate 59.94 0.006 68.88 0.18 0.02 3.21 90.57 4.24 9.19 Tailings 32.74 0.051 5.53 0.63 0.08 15.04 3.97 8.15 22.11 ROM 100.00 0.112 45.59 2.54 0.118 100.00 100.00 100.00 100.00 -

[1] 刘正适, 付文章.复合铁矿石的综合利用[J].矿产综合利用, 1986(4):39-45. http://www.cnki.com.cn/Article/CJFDTotal-KCZL198604011.htm

[2] 唐平宇, 葛敏, 庞雪敏, 等.河北某难选锌铁矿石选矿试验[J].金属矿山, 2014(10):56-60. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=jsks201410013

[3] 涂光富, 王海亮.河北某含钴硫磁铁矿石选矿工艺研究[J].现代矿业, 2015(7):70-72. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=xdky201507028

[4] 杜保清.首钢秘鲁铁矿资源综合利用研究[C]//2011'中国矿业科技大会.2011.

[5] 谭欣, 王中明, 刘书杰, 等.提高某高硫铜矿石伴生金银指标的试验研究[J].有色金属(选矿部分), 2018(2):20-26. http://www.cnki.com.cn/Article/CJFDTotal-YSXK201802005.htm

[6] 刘磊, 王双玉, 孙晓华, 等.青海某铁铜矿铜、硫综合回收试验研究[J].矿产保护与利用, 2017(6):52-56. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=89813dd1-9804-4248-a1e7-b58c55b0a76d

[7] 常永强, 付毅.越南某铜矿石选矿试验研究[J].矿产保护与利用, 2013(4):16-19. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=6ce3d08f-a584-47e3-bf48-8e7d5cd14f06

-

下载:

下载: