Simulation Study on Separation Effect of Mineral Particles Based on EDEM-FLUENT Coupling

-

摘要:

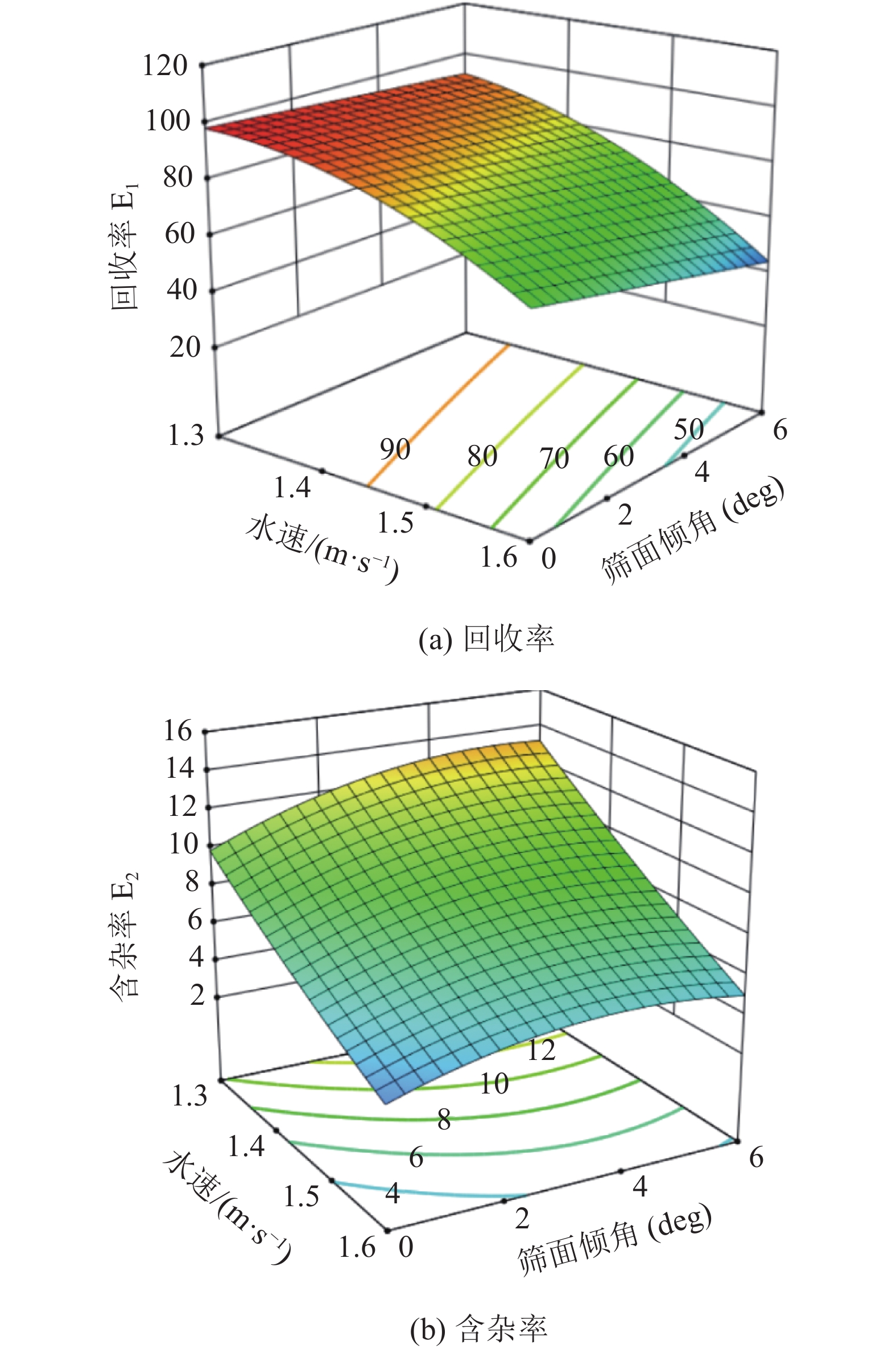

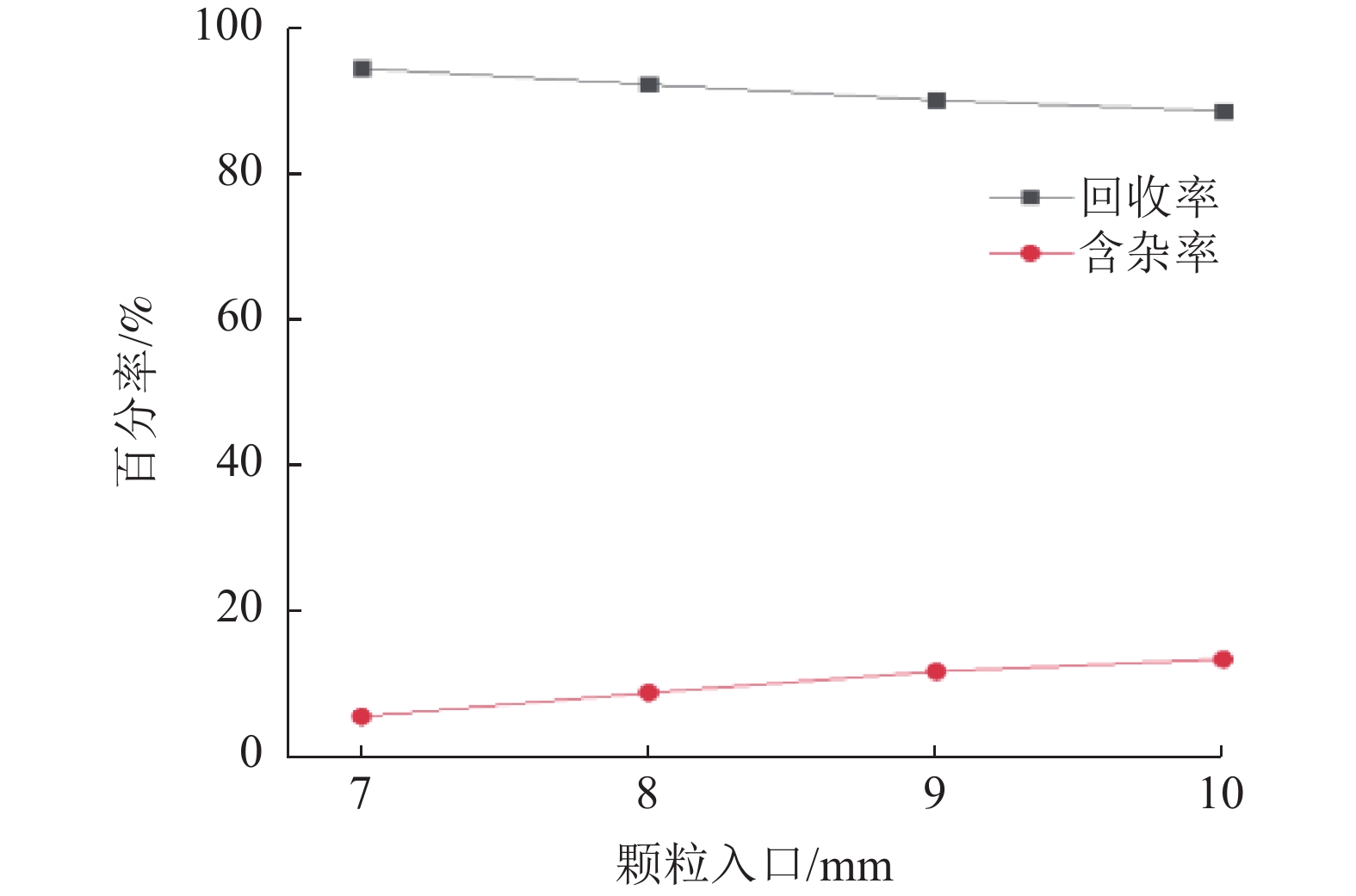

为了能同时依据矿粒的密度和粒度对其分离,尝试选用水平冲击水流和振动作用的联合分离工艺,采用EDEM-FLUENT耦合方法,以矿粒的回收率及分离产品含杂率为评价指标,对矿粒在分选装置中的分离行为进行模拟研究,并探讨不同工艺参数对矿粒分离效果的影响。结果表明:所选用的分离工艺可有效地依据矿粒的密度和粒径进行分离。添加振动筛能大幅度降低分离产品的含杂率。分选装置的较佳参数为:筛面倾角为0°、振动频率为10 Hz、振幅为3 mm、颗粒入口底部宽度为7 mm,此时回收率96.8%,含杂率5.67%。

-

关键词:

- EDEM-FLUENT耦合 /

- 矿粒分离 /

- 回收率 /

- 含杂率 /

- 模拟研究

Abstract:In order to separate different minerals at the same time according to density and grain size of mineral particles, the combined separation process of horizontal water flow and vibration and the coupling method of EDEM-FLUENT were used, mineral recovery and impurity rate used as the evaluation index. The separation behavior of mineral particles in the separation device was simulated, and the influence of different process parameters on the separation effect of mineral particles was discussed. The results show that the selected separation process can effectively separate mineral particles according to the density of mineral particles and size of mineral particles. The addition of vibrating screen can greatly reduce the impurity content of mineral particles in the separated products.The optimal parameters of the sorting device are: screen surface inclination Angle is 0°, vibration frequency is 10 Hz, amplitude is 3 mm, particle inlet bottom width is 7 mm. By this time recovery 96.8% and containing impurity rate 5.67% were obtained.

-

Key words:

- EDEM-FLUENT coupling /

- Separation of mineral particles /

- Recovery /

- Impurity rate /

- Simulation study

-

-

表 1 壳体各部分尺寸 /mm

Table 1. Dimensions of each part of the shell

进料口底部 进水口 出口Ⅰ 出口Ⅱ 出口Ⅲ 出口Ⅳ 长度 60 90 100 100 100 90 宽度 8 10 77 57 95 70 高度 15 10 20 20 20 5 表 2 材料物理参数

Table 2. Material physical parameters

名 称 泊松比 剪切模量/MPa 密度/(kg·m-3) 目标矿粒 0.4 70 6500 脉石矿粒 0.4 21 2650 分选装置 0.3 7.9×104 7800 表 3 材料接触系数

Table 3. Material contact coefficient

名 称 恢复系数 静摩擦系数 动摩擦系数 颗粒-颗粒 0.44 0.27 0.1 颗粒-筛网 0.50 0.15 0.1 表 4 有无振动筛作用下矿粒的回收率及含杂率

Table 4. Recovery rate and impurity content of ore particles with and without vibrating screen

名 称 颗粒总数 目标矿粒

总数/个脉石矿粒

总数/个回收率/% 含杂率/% 无振动筛 1609 988 621 98.8 38.60 有振动筛 1139 962 177 96.2 15.54 表 5 不同颗粒入口底部宽度时目标矿粒回收率及含杂率

Table 5. Recovery rate and impurity content of target ore with different bottom width of particle inlet

颗粒入口宽度/mm 回收率/% 含杂率/% 7 96.8 5.67 8 94.6 8.94 9 90.4 11.87 10 88.9 13.53 -

[1] 张晋, 贺爱平, 李国栋, 等. 钙镁质磷矿选矿尾矿综合利用技术现状及展望[J]. 矿产综合利用, 2021(2):199-203. doi: 10.3969/j.issn.1000-6532.2021.02.034

ZHANG J, HE A P, LI G D, et al. Status and prospect of comprehensive utilization technology of calcium-magnesium phosphate tailings[J]. Multipurpose Utilization of Mineral Resources, 2021(2):199-203. doi: 10.3969/j.issn.1000-6532.2021.02.034

[2] 陈福林, 杨晓军, 杨道广, 等. 甘肃某低品位钒钛磁铁矿工艺矿物学研究[J]. 矿产综合利用, 2020(6):64-68. doi: 10.3969/j.issn.1000-6532.2020.06.011

CHEN F L, YANG X J, YANG D G, et al. Research on process mineralogy for a low grade vanadium titano-magnetite in Gansu province[J]. Multipurpose Utilization of Mineral Resources, 2020(6):64-68. doi: 10.3969/j.issn.1000-6532.2020.06.011

[3] 易欣. 选矿, 当技术遇到设备[J]. 矿业装备, 2016(12):12-20.

YI X. Beneficiation, when technology meets equipment[J]. Mining Equipment, 2016(12):12-20.

[4] 李振宇. 西北某高硫铝土矿浮选脱硫试验研究[J]. 矿产综合利用, 2020(5):77-81. doi: 10.3969/j.issn.1000-6532.2020.05.010

LI Z Y. Study on the flotation desulfurization of high-sulfur bauxite in Northwest[J]. Multipurpose Utilization of Mineral Resources, 2020(5):77-81. doi: 10.3969/j.issn.1000-6532.2020.05.010

[5] 朱志波, 朱书全, 陈慧昀, 等. 浮选动力学模型研究进展及展望[J]. 洁净煤技术, 2017, 23(2):20-24. doi: 10.13226/j.issn.1006-6772.2017.02.004

ZHU Z B, ZHU S Q, CHEN H J, et al. Research progress and prospect of flotation kinetic model[J]. Clean Coal Technology, 2017, 23(2):20-24. doi: 10.13226/j.issn.1006-6772.2017.02.004

[6] 刘立伟, 赵礼兵, 李国峰, 等. 某钒钛磁铁精矿深度还原-磁选试验研究[J]. 矿产综合利用, 2020(6):56-63. doi: 10.3969/j.issn.1000-6532.2020.06.010

LIU L W, ZHAO L B, LI G F, et al. Study on coal-based reduction followed by magnetic separation of a vanadium-titanium magnetite concentrate[J]. Multipurpose Utilization of Mineral Resources, 2020(6):56-63. doi: 10.3969/j.issn.1000-6532.2020.06.010

[7] 李罗生. 强磁选机的技术进展[J]. 冶金矿山设计与建设, 1996(3):52-54.

LI L S. Technical progress of strong magnetic separator[J]. Metallurgy Mine Design and Construction, 1996(3):52-54.

[8] 陈向, 廖德华. 某铬铁矿磁浮联合回收实验研究[J]. 矿产综合利用, 2021(1):61-64. doi: 10.3969/j.issn.1000-6532.2021.01.009

CHEN X, LIAO D H. Experimental study on combined recovery of chromite by magnetic levitation[J]. Multipurpose Utilization of Mineral Resources, 2021(1):61-64. doi: 10.3969/j.issn.1000-6532.2021.01.009

[9] 贾清梅, 李凤久, 尚新月, 等. 磁场强度对磁铁矿反浮选过程的影响[J]. 矿产综合利用, 2020(3):84-88. doi: 10.3969/j.issn.1000-6532.2020.03.013

JIA Q M, LI F J, SHANG X Y, et al. Influence of magnetic field strength on reverse flotation process of magnetite[J]. Multipurpose Utilization of Mineral Resources, 2020(3):84-88. doi: 10.3969/j.issn.1000-6532.2020.03.013

[10] Li H C, Li Y M, Gao F, et al. CFD-DEM simulation of material motion in air-and-screencleaning device[J]. Computers and Electronics in Agriculture, 2012, 88:111-119. doi: 10.1016/j.compag.2012.07.006

[11] 蒋恩臣, 孙占峰, 潘志洋, 等. 基于CFD-DEM的收获机分离室内谷物运动模拟与实验[J]. 农业机械学报, 2014, 45(4):117-122. doi: 10.6041/j.issn.1000-1298.2014.04.018

JIANG E C, SUN Z F, PAN Z Y, et al. CFD-DEM-based simulation and experiment of grain movement in harvester separation chamber[J]. Transactions of the Chinese Society of Agricultural Machinery, 2014, 45(4):117-122. doi: 10.6041/j.issn.1000-1298.2014.04.018

[12] 和建荣, 王进明, 俞霞, 等. 基于 EDEM-FLUENT 耦合的离心选矿机仿真优化分析[J]. 矿产综合利用, 2021(2):174-179. doi: 10.3969/j.issn.1000-6532.2021.02.030

HE J R, WANG J M, YU X, et al. Simulation and optimization analysis of centrifugal concentrator based on EDEM-FLUENT coupling[J]. Multipurpose Utilization of Mineral Resources, 2021(2):174-179. doi: 10.3969/j.issn.1000-6532.2021.02.030

[13] 董辉, 伍开松, 况雨春, 等. 基于DEM-CFD水力旋流器的水合物浆体分离规律研[J].浙江大学学报(工学版), 2018, 52(9): 1811-1820.

DONG H, WU K S, KUANG Y C, et al. Research on the separation of hydrate slurry based on DEM-CFD hydrocyclone[J]. Journal of Zhejiang University (Engineering Science Edition), 2018, 52(9): 1811-1820.

[14] 卢臣, 杨聪仁, 张仕奇, 等. 内蒙古某金矿磨矿分级产物离心重选实验研究[J]. 矿产综合利用, 2021(3):152-157.

LU C, YANG C R, ZHANG S Q, et al. Experimental research on centrifugal gravity separation of grinding classification products in a gold mine in Inner Mongolia[J]. Multipurpose Utilization of Mineral Resources, 2021(3):152-157.

[15] Tsuji Y, Anaka T, Ishida T. Lagrangian numerical imulation of plug flow of cohesionless particles in a horizontal pipe[J]. Powder technology, 1992, 71(3):239-250. doi: 10.1016/0032-5910(92)88030-L

-

下载:

下载: