Rheological Properties of Alkali Activated Fly Ash Slag Cementitious Materials

-

摘要:

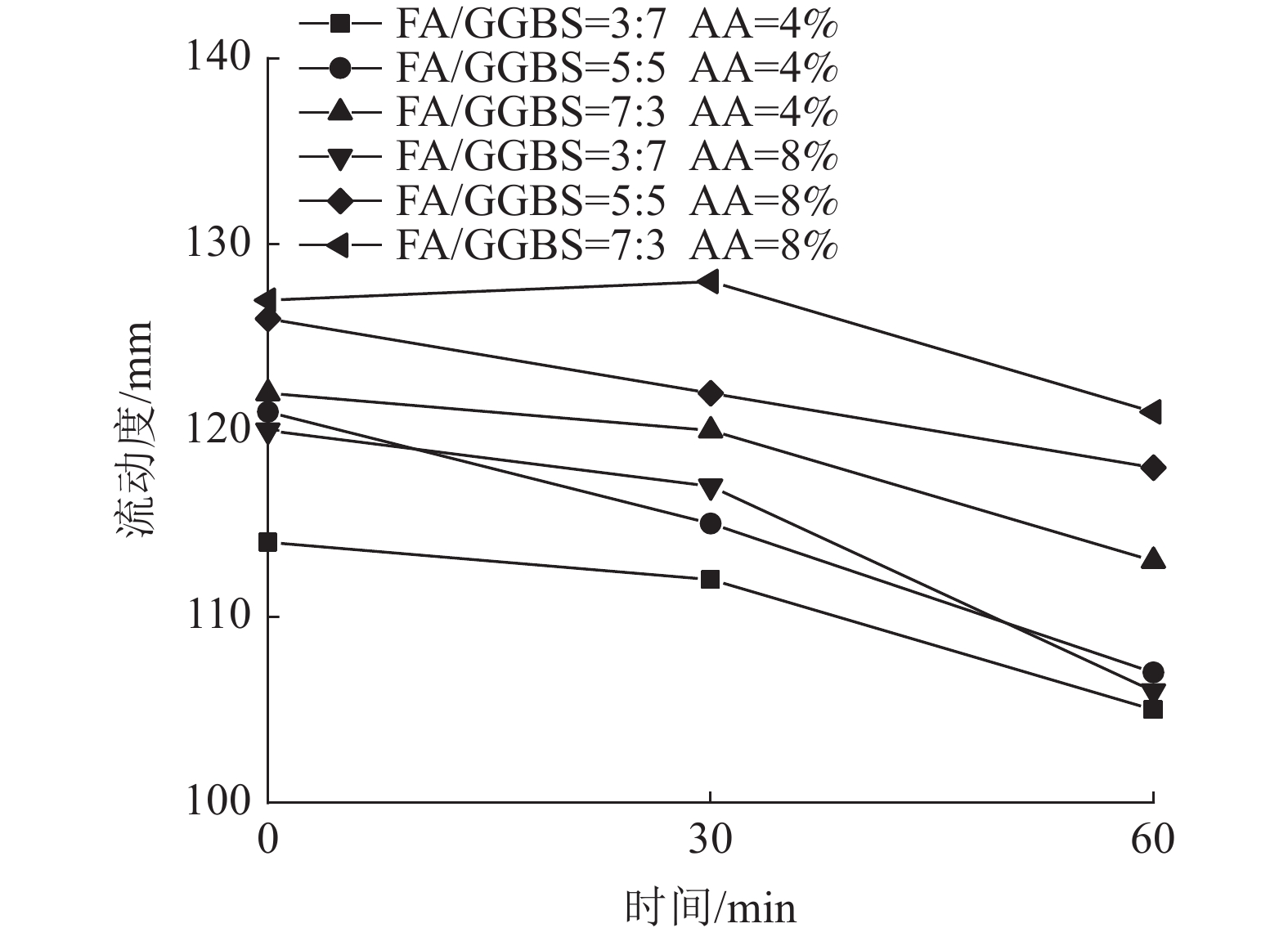

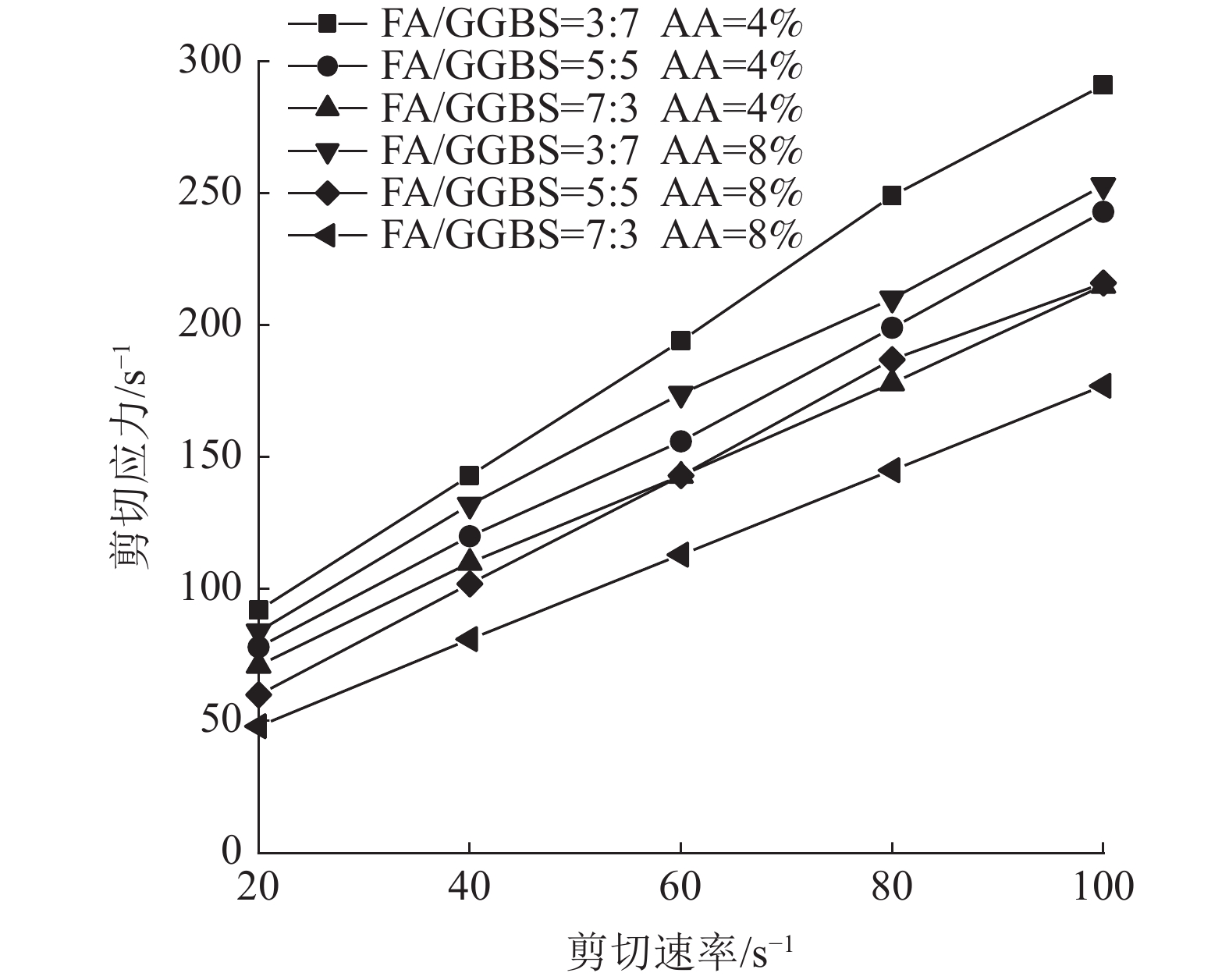

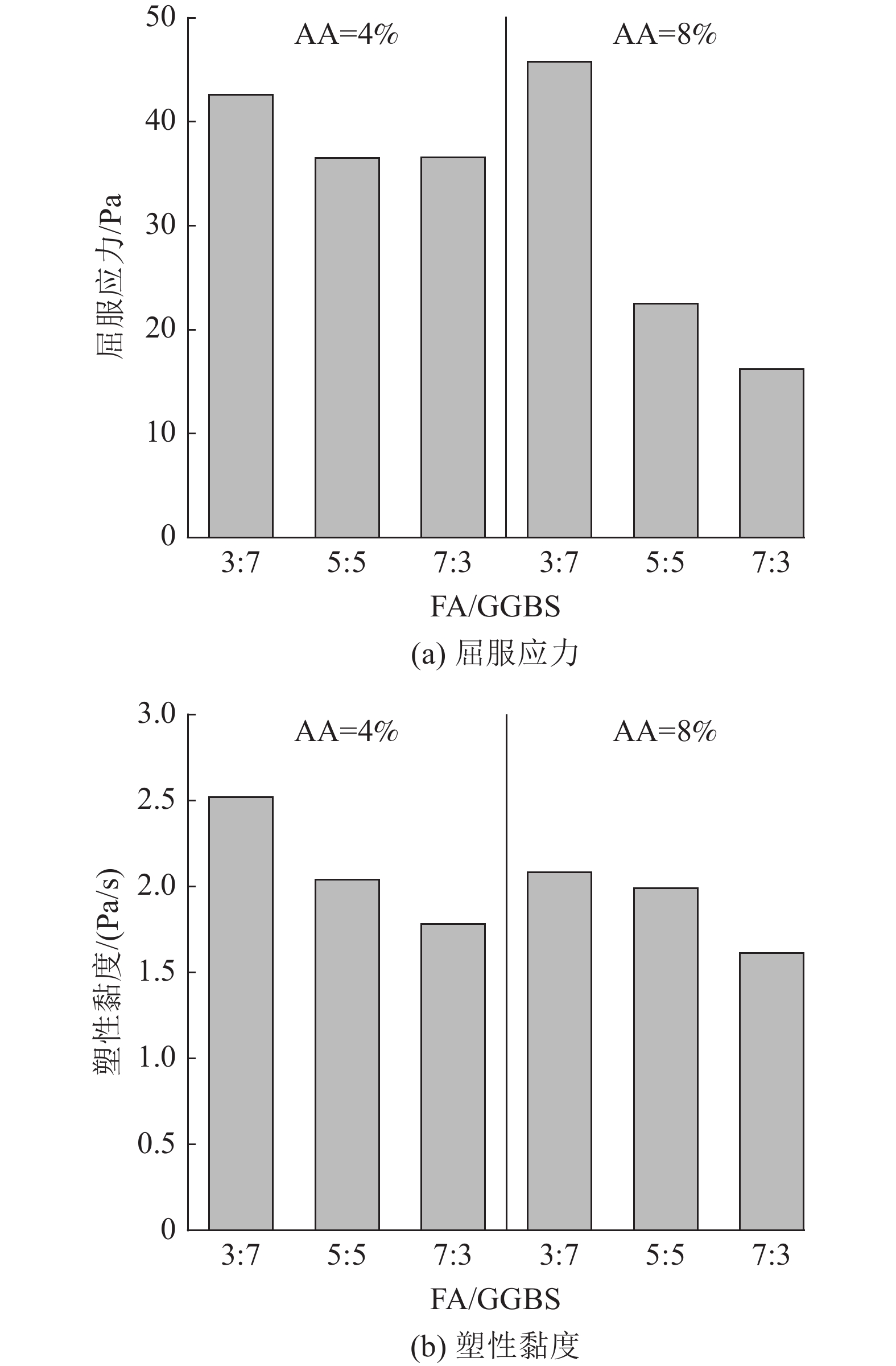

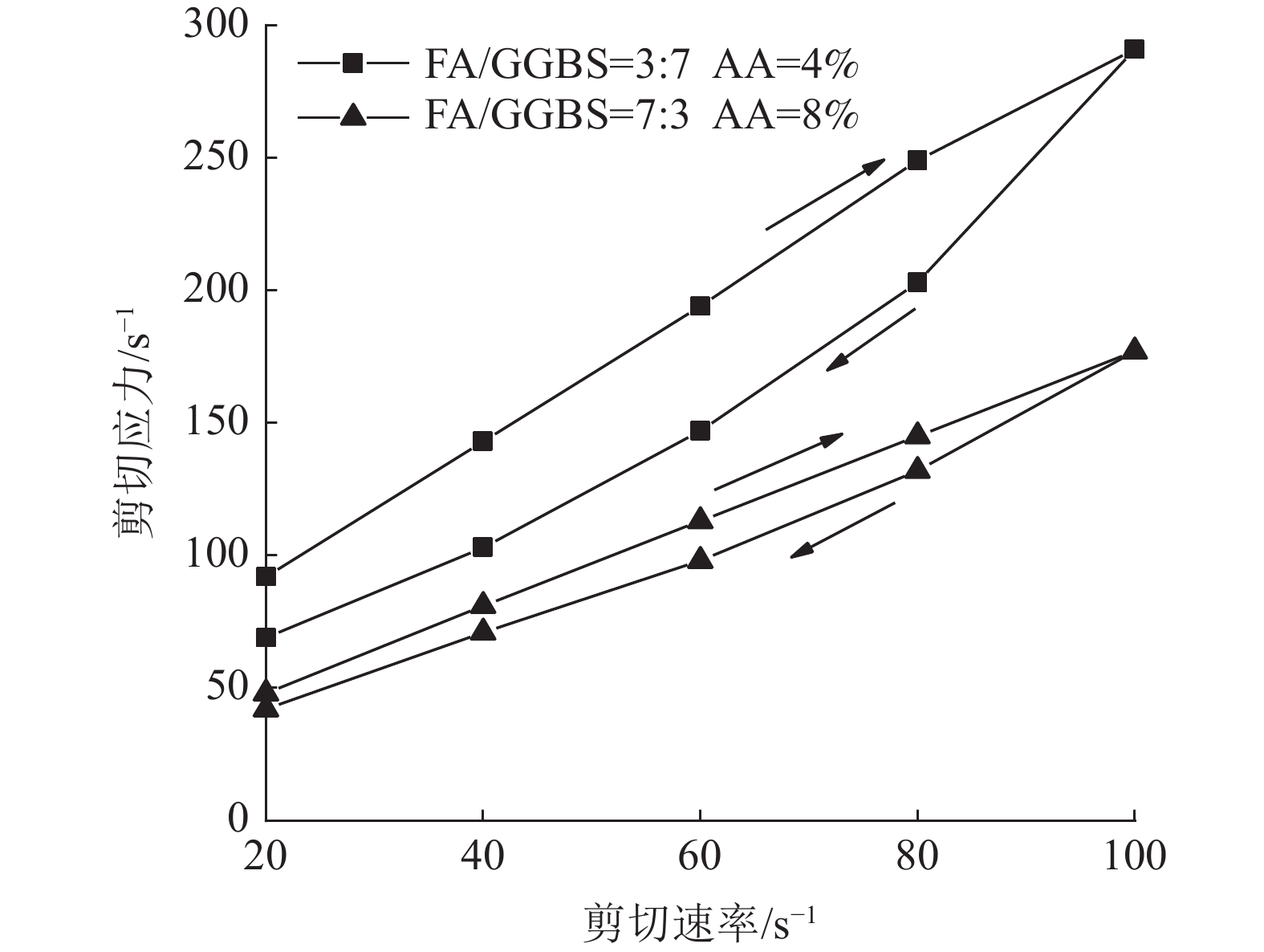

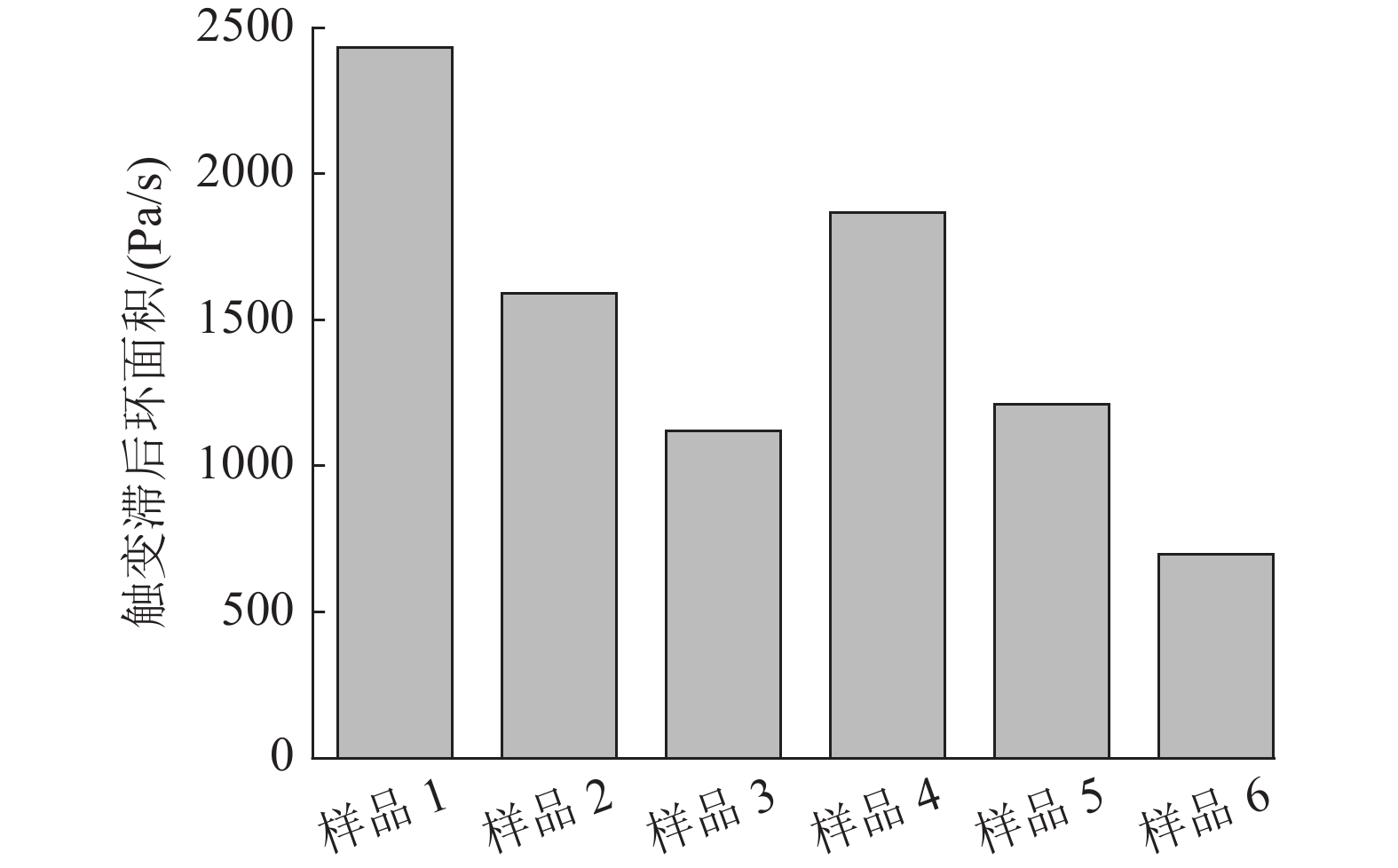

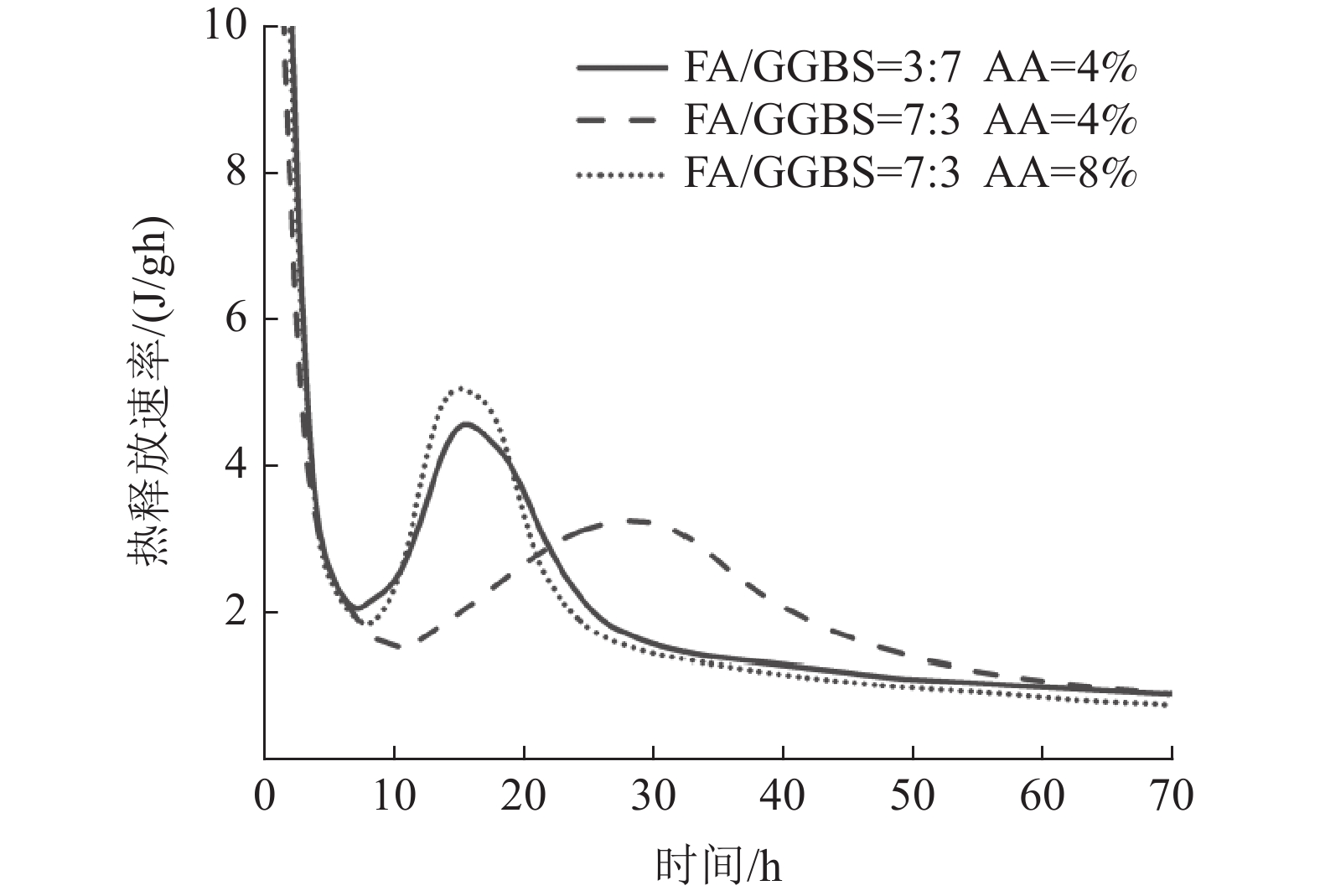

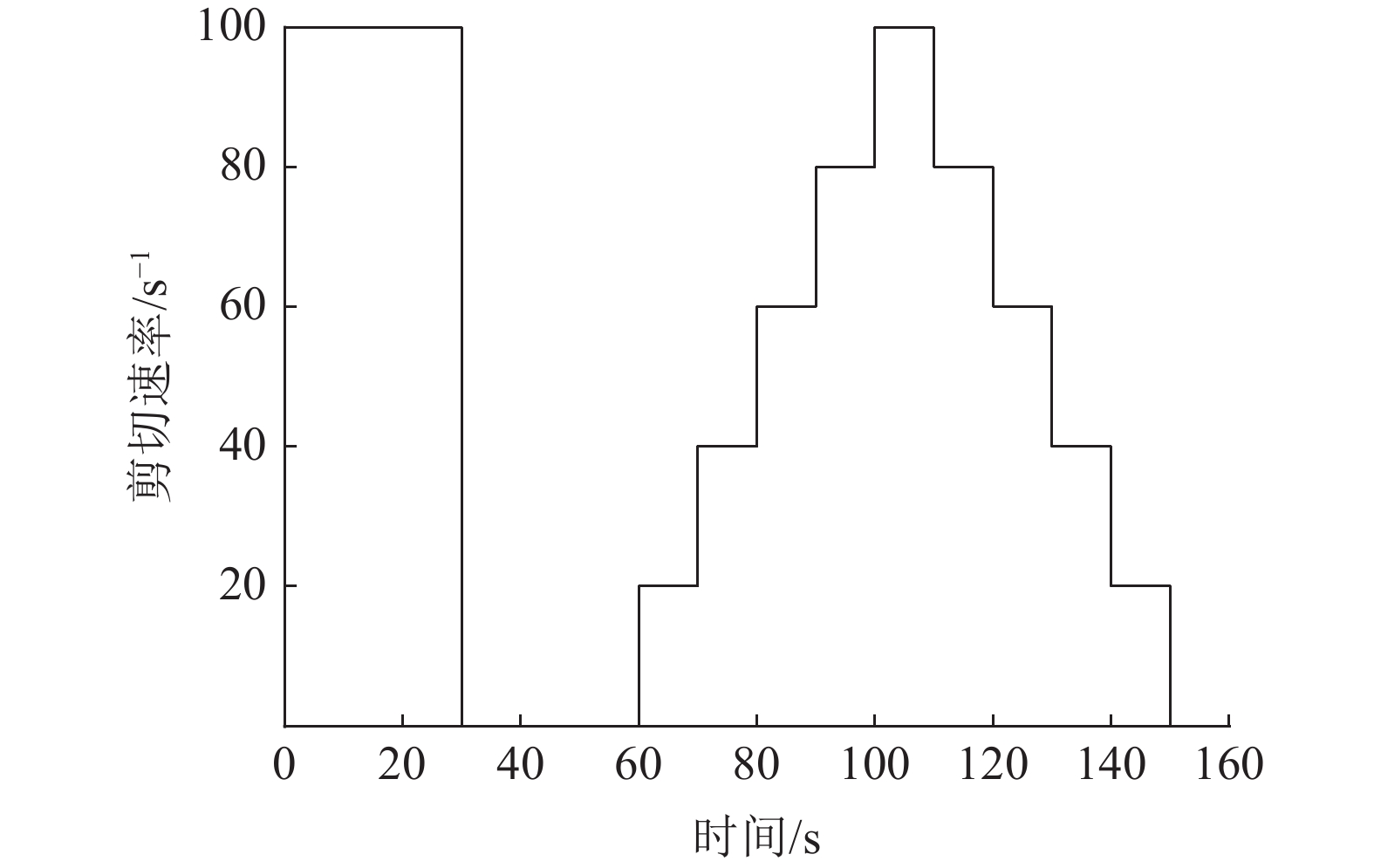

这是一篇陶瓷及复合材料领域的论文。为了研究碱激发粉煤灰矿渣胶凝体系在早期的流变特性,制备了不同粉煤灰和矿粉质量比以及碱激发剂含量的复合浆体,并且分别采用了微型坍落度筒和Brookfield DV3T 流变仪测试其流动性和流变性,最后用等温量热仪测试了各组配比下浆体的水化放热速率。结果表明:当FA/GGBS比为3∶7时,碱激发剂NaOH含量为4%的浆体在所有配合比中流动度为较低。随着粉煤灰质量比和NaOH摩尔质量的升高,碱激发粉煤灰矿渣胶凝体系的流动度均有所上升,且屈服应力和塑性黏度有所下降。粉煤灰掺量的升高使得早期水化速率有所下降,而碱激发剂含量的增加则提高了水化放热峰值速率。

Abstract:This is an article in the field of ceramics and composites. In order to study the early rheological properties of alkali-activated fly ash-slag cementitious system, the composite pastes with different mass ratios of fly ash (FA) to slag (GGBS) and alkaline activator content were prepared. The fluidity and rheological properties of the pastes were tested by mini-cone slump cone, Brookfield DV3T rheometer,respectively. Finally, the hydration exothermic rate of composite pastes with each ratio was tested by isothermal calorimeter. Results show that when FA/GGBS ratio is 3∶7, the fluidity of paste with 4% NaOH content is the lowest. With the increase of FA mass ratio and NaOH molar mass, the fluidity of alkali-activated FA-GGBS cementitious system increased, and the yield stress and plastic viscosity decreased. The growth of FA content decreases the early hydration rate significantly, while the increase of alkali activator content remarkably increases the peak rate of hydration heat release.

-

-

表 1 粉煤灰和矿粉的化学组成/%

Table 1. Chemical compositions of fly ash and slag

SiO2 Al2O3 CaO Fe2O3 MgO SO3 Na2O 粉煤灰 51.65 30.94 5.13 5.64 0.59 0.61 0.52 矿渣 31.54 14.68 41.16 1.19 5.91 2.16 0.43 表 2 碱激发材料的配合比

Table 2. Mixture proportions of alkali-activated materials

序号 FA

含量/%GGBS

含量/%Water to

FA-GGBS

碱激发剂

含量 /%碱激

发剂

浓度/

(mol/L)1 30 70 0.5 4 2 2 50 50 0.5 4 2 3 70 30 0.5 4 2 4 30 70 0.5 8 4 5 50 50 0.5 8 4 6 70 30 0.5 8 4 -

[1] 熊文良, 黄阳, 张丽军, 等. 稀土尾矿配料煅烧硅酸盐水泥熟料的实验研究[J]. 矿产综合利用, 2021(5):76-80.XIONG W L, HUANG Y, ZHANG L J, et al. Experimental study on calcination of Portland cement clinker with rare earth tailings[J]. Multipurpose Utilization of Mineral Resources, 2021(5):76-80.

XIONG W L, HUANG Y, ZHANG L J, et al. Experimental study on calcination of Portland cement clinker with rare earth tailings[J]. Multipurpose Utilization of Mineral Resources, 2021(5):76-80.

[2] 冯卡, 王馨语. 硫铁矿尾矿矿渣改良混凝土力学性质与耐久性[J]. 矿产综合利用, 2022(3):6-11.FENG K, WANG X Y. Research on mechanical properties and durability of concrete improved by pyrite tailings and slag[J]. Multipurpose Utilization of Mineral Resources, 2022(3):6-11.

FENG K, WANG X Y. Research on mechanical properties and durability of concrete improved by pyrite tailings and slag[J]. Multipurpose Utilization of Mineral Resources, 2022(3):6-11.

[3] 邓晓阳, 裴新意, 刘自妥, 等. 粉煤灰中铵离子含量对混凝土减水剂掺量及吸附特性影响[J]. 矿产综合利用, 2022(3):64-69.DENG X Y, PEI X Y, LIU Z T, et al. Effect of ammonium ion content on superplasticizer dosage and adsorption property[J]. Multipurpose Utilization of Mineral Resources, 2022(3):64-69.

DENG X Y, PEI X Y, LIU Z T, et al. Effect of ammonium ion content on superplasticizer dosage and adsorption property[J]. Multipurpose Utilization of Mineral Resources, 2022(3):64-69.

[4] 阎培渝. 粉煤灰在复合胶凝材料水化过程中的作用机理[J]. 硅酸盐学报, 2007(S1):167-171.YAN P Y. Mechanism of fly ash’s effects during hydration process of composite binder[J]. Journal of the Chinese Ceramic Society, 2007(S1):167-171.

YAN P Y. Mechanism of fly ash’s effects during hydration process of composite binder[J]. Journal of the Chinese Ceramic Society, 2007(S1):167-171.

[5] 杨晓炳, 王永定, 高谦, 等. 利用脱硫灰渣和粉煤灰开发充填胶凝材料[J]. 矿产综合利用, 2019(4):130-134.YANG X B, WANG Y D, GAO Q, et al. Research on a new cementitious materials with desulphurization ash and fly ash[J]. Multipurpose Utilization of Mineral Resources, 2019(4):130-134.

YANG X B, WANG Y D, GAO Q, et al. Research on a new cementitious materials with desulphurization ash and fly ash[J]. Multipurpose Utilization of Mineral Resources, 2019(4):130-134.

[6] 聂轶苗, 夏淼, 刘攀攀, 等. 粉煤灰基矿物聚合材料研究进展[J]. 矿产综合利用, 2022(4):123-128.NIE Y M, XIA M, LIU P P, et al. Research progress on fly ash based geopolymer[J]. Multipurpose Utilization of Mineral Resources, 2022(4):123-128.

NIE Y M, XIA M, LIU P P, et al. Research progress on fly ash based geopolymer[J]. Multipurpose Utilization of Mineral Resources, 2022(4):123-128.

[7] HOJATI M, RADLIŃSKA A. Shrinkage and strength development of alkali-activated fly ash-slag binary cements[J]. Construction and Building Materials, 2017, 150:808-816. doi: 10.1016/j.conbuildmat.2017.06.040

[8] FERNÁNDEZ-JIMÉNEZ A, PALOMO A. Composition and microstructure of alkali activated fly ash binder: Effect of the activator[J]. Cement and Concrete Research, 2005, 35(10):1984-1992. doi: 10.1016/j.cemconres.2005.03.003

[9] SINGH B, ISHWARYA G, GUPTA M, et al. Geopolymer concrete: a review of some recent developments[J]. Construction and Building Materials, 2015, 85:78-90. doi: 10.1016/j.conbuildmat.2015.03.036

[10] PANDA B, UNLUER C, TAN M J. Investigation of the rheology and strength of geopolymer mixtures for extrusion-based 3D printing[J]. Cement and Concrete Composites, 2018, 94:307-314. doi: 10.1016/j.cemconcomp.2018.10.002

[11] PUERTAS F, VARGA C, ALONSO M M. Rheology of alkali-activated slag pastes. Effect of the nature and concentration of the activating solution[J]. Cement and Concrete Composites, 2014, 53:279-288. doi: 10.1016/j.cemconcomp.2014.07.012

[12] ALBAR A, CHOUGAN M, AL-KHEETAN M J, et al. Effective extrusion-based 3D printing system design for cementitious-based materials[J]. Results in Engineering, 2020, 6:100135. doi: 10.1016/j.rineng.2020.100135

[13] LI L, LU J X, ZHANG B, et al. Rheology behavior of one-part alkali activated slag/glass powder (AASG) pastes[J]. Construction and Building Materials, 2020, 258:120381. doi: 10.1016/j.conbuildmat.2020.120381

[14] THIEDEITZ M, DRESSLER I, KRÄNKEL T, et al. Effect of pre-shear on agglomeration and rheological parameters of cement paste[J]. Materials, 2020, 13(9):2173. doi: 10.3390/ma13092173

[15] 马昆林, 冯金, 龙广成, 等. 水泥-粉煤灰浆体流变特性及其机理研究[J]. 铁道科学与工程学报, 2017, 14(3):465-472.MA K L, FENG J, LONG G C, et al. Rheological characteristic and its mechanism of cement-fly ash paste[J]. Journal of Railway Science and Engineering, 2017, 14(3):465-472.

MA K L, FENG J, LONG G C, et al. Rheological characteristic and its mechanism of cement-fly ash paste[J]. Journal of Railway Science and Engineering, 2017, 14(3):465-472.

[16] 阎培渝, 郑峰. 水泥基材料的水化动力学模型[J]. 硅酸盐学报, 2006(5):555-559.YAN P Y, ZHENG F. Kinetics model for the hydration mechanism of cementitious materials[J]. Journal of the Chinese Ceramic Society, 2006(5):555-559.

YAN P Y, ZHENG F. Kinetics model for the hydration mechanism of cementitious materials[J]. Journal of the Chinese Ceramic Society, 2006(5):555-559.

[17] PACHECO-TORGAL F, CASTRO-GOMES J, JALALI S. Alkali-activated binders: A review: Part 1. Historical background, terminology, reaction mechanisms and hydration products[J]. Construction and Building Materials, 2008, 22(7):1305-1314. doi: 10.1016/j.conbuildmat.2007.10.015

-

下载:

下载: