Research Progress and Thinking on the Preparation of Calcium Carbonate Whiskers from Calcium-containing Minerals and Solid Waste

-

摘要:

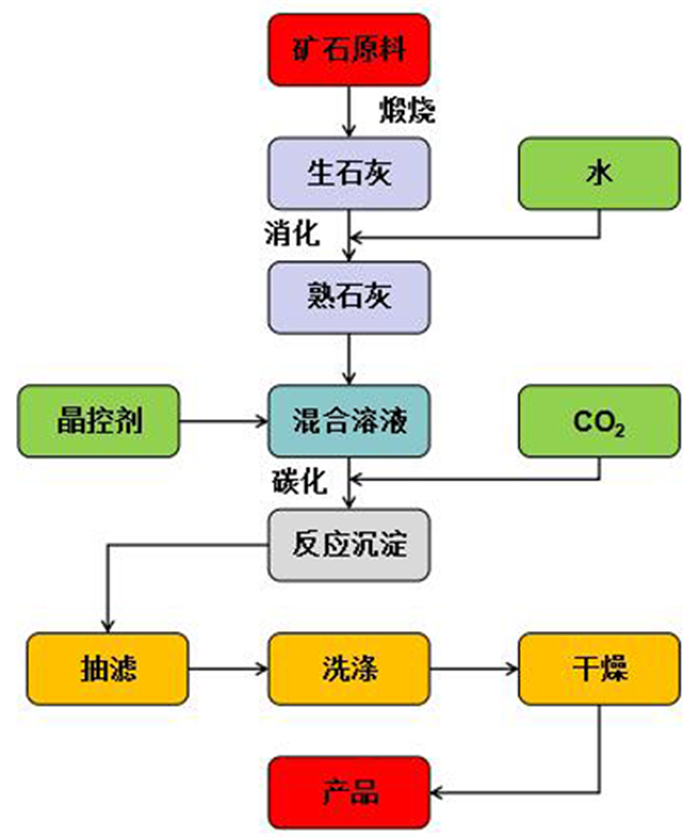

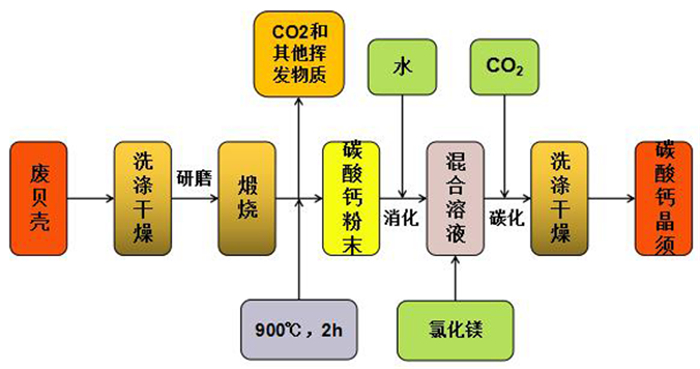

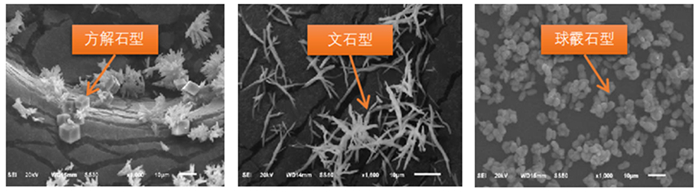

碳酸钙作为最广泛的工业原料之一,被广泛应用在塑料、橡胶、造纸、涂料、食品、医药、电子等行业。而具有特殊纤维状形貌的碳酸钙晶须,成本低廉,来源广泛,产品本身及生产工艺绿色环保,并且具有高强度、高模量、高拉伸率等优良性能,开始逐渐取代其他成本高昂的纤维材料用作复合材料的增强剂、增韧剂及填充剂。本文在研究团队多年从事钙基材料制备及产业化的基础上,从碳酸钙晶须的制备方法和原料两个角度对碳酸钙晶须材料研究进行了详细论述,分析目前各种碳酸钙晶须制备方法的优缺点,并对工业废弃物、生活废弃物等多样性原料制备碳酸钙晶须的方向进行了展望。

Abstract:As one of the most extensive industrial raw materials, calcium carbonate is widely used in plastics, rubber, papermaking, coatings, food, medicine, electronics and other industries. Calcium carbonate whiskers with special fibrous morphology have the advantages of low cost, wide sources, and environmental protection of the product itself and production process. Moreover, it has excellent properties such as high strength, high modulus, and high elongation, and it has gradually replaced other costly fiber materials as a reinforcing agent, toughening agent and filler for composite materials. Based on the preparation and industrialization of calcium-based materials for many years, this article discusses the research of calcium carbonate whisker materials in detail from the perspectives of preparation methods and raw materials of calcium carbonate whiskers. The advantages and disadvantages of various current preparation methods of calcium carbonate whiskers are analyzed, and the direction of preparing calcium carbonate whiskers from diverse raw materials such as industrial waste and domestic waste is prospected.

-

Key words:

- calcium carbonate /

- whisker /

- preparation method /

- solid waste

-

-

表 1 碳酸钙晶须制备方法对比结果

Table 1. Comparison results of preparation methods of calcium carbonate whiskers

方法 晶控剂 优点 缺点 碳化法 需要 工艺简单,适合工业化生产 需要控制剂,容易引入杂质 复分解法 不需要 长径比大,纯度高 产量低,反应周期长 尿素水解法 不需要 表面光洁度高,纯度高 长径比小,能耗大 碳酸氢钙分解法 不需要 晶须较长,纯度较高 均匀性差,晶须直径大 溶胶-凝胶法 需要 过程易于控制,均匀性好 容易引入杂质 超重力法 需要 长径比大,生产周期短 需要特定装置,投资大 表 2 一步碳化法和气-液间歇碳化法制备最佳参数

Table 2. Best parameters of the one-step carbonization method and the gas-liquid intermittent carbonization method

方法 原料摩尔比 反应温度/℃ 通气速率/(mL·min-1) 搅拌速率/(r·min-1) 反应时间/h 一步碳化法 Mg:Ca = 2 110 100 150 1 气-液间歇碳化法 CaO:NH4Cl= 1:2.2 90 100 400 1 -

[1] R. BROOKS, L. M. CLARK, E. F. THURSTON. Calcium carbonate and its hydrates Philosophical Transactions of the Royal Society of London. Series A, Mathematical and Physical Sciences, 1950, 243(86): 145–167.

[2] ZHAO YZ, HABRAKEN W J E M, GALINA M, et al. A hydrated crystalline calcium carbonate phase: Calcium carbonate hemihydrate[J]. Science, 2019, 363(6425): 396-400. doi: 10.1126/science.aav0210

[3] HAMMAD SAYLAT, MINGLI CAO, MUHAMMAD MASOOD, et al. Preparation and applications of calcium carbonate whisker with a special focus on construction materials[J]. Construction and Building Materials, 2020, 236(0950-0618), 10.1016/j.conbuildmat.2019.117613. doi: 10.1016/j.conbuildmat.2019.117613

[4] ANTAO S M, HASSAN I. Temperature dependence of the structural parameters in the transformation of aragonite to calcite, as determined from in situ synchrotron powder X-ray-diffratction data[J]. Canadian Mineralogist, 2011, 48(5): 1225-1236.

[5] JING YW, NAI XY, LI D, et al. Reinforcing polypropylene with calcium carbonate of different morphologies and polymorphs[J]. Science and Engineering of Composite Materials, 2018, 25(4), 10.1515/secm-2015-0307. doi: 10.1515/secm-2015-0307

[6] HAN J S, JUNG S Y, KANG D S, et al. Development of flexible calcium carbonate for papermaking filler[J]. ACS Sustainable Chemistry & Engineering, 2020, 8(24): 8994–9001.

[7] 陈锐, 罗康碧, 李沪萍, 谭艳霞. 晶须在材料中的应用[J]. 化工科技, 2007(6): 58-61. doi: 10.3969/j.issn.1008-0511.2007.06.015

[8] 程优优. 碳酸钙晶须的制备及对天然橡胶补强性能的研究[J]. 中国粉体工业, 2017(4): 10-13.

[9] 操欢, 朱星宇, 袁世炬. 石膏晶须及其在造纸上的应用[J]. 湖北造纸, 2012(Z1): 83-85.

[10] 钱军民, 金志浩. 填料碳酸钙的制备及其形状与晶型控制研究进展[J]. 化工矿物与加工, 2002(4): 1-4, 10. doi: 10.3969/j.issn.1008-7524.2002.04.001

[11] 王会利, 杨娟娟, 刘斌, 陈寿田. 碳酸钙晶须在涂料中的应用[J]. 涂料工业, 2004(4): 52-54. doi: 10.3969/j.issn.0253-4312.2004.04.016

[12] 姚伯龙, 焦钰, 杜郑帅, 倪才华, 宋洪昌. 室温自交联乳液制备及晶须改性涂料性能研究[J]. 光谱实验室, 2008(6): 1070-1072. doi: 10.3969/j.issn.1004-8138.2008.06.013

[13] ZHANG N, CHEN Y. Nanoscale plastic deformation mechanism in single crystal aragonite[J]. Journal of Materials Science, 2013, 48(2): 785-796. doi: 10.1007/s10853-012-6796-1

[14] YOREO J D, GILBERT P U, SOMMERDIJK N A, et al. Crystallization by particle attachment in synthetic, biogenic, and geologic environments[J]. Science, 2015, 349(6247), 10.1126/science.aaa6760. doi: 10.1126/science.aaa6760

[15] BOON, MATTHEW, RICKARD, et al. Stabilization of Aragonite: Role of Mg2+ and Other Impurity Ions[J]. Crystal Growth & Design, 2020, 20(8): 5006-5017.

[16] 陈华雄, 宋永才. 文石型碳酸钙晶须的制备研究[J]. 材料科学与工程学报, 2004(2): 197-200. doi: 10.3969/j.issn.1673-2812.2004.02.011

[17] 李庆蕾. 碳酸钙晶须制备工艺研究及优化[D]. 杭州: 浙江大学, 2020.

[18] WARY J L. Precipitation of Calcite and Aragonite[J]. J. Am. Chem. Soc, 1957, 79(9), 10.1021/ja01566a001. doi: 10.1021/ja01566a001

[19] LEE S W, KIM Y I, AHN J W. The use of iminodiacetic acid for low-temperature synthesis of aragonite crystal microrods: Correlation between aragonite crystal microrods and stereochemical effects[J]. International Journal of Mineral Processing, 2009, 92(3-4): 190-195. doi: 10.1016/j.minpro.2009.04.005

[20] WANG L, SONDI I, MATIJEVI E. Preparation of Uniform Needle-Like Aragonite Particles by Homogeneous Precipitation[J]. Journal of Colloid & Interface Science, 1999, 218(2): 545-553.

[21] J. CHEN, L. XIANG. Controllable synthesis of calcium carbonate polymorphs at different temperatures[J]. Powder Technology, 2008, 189(1): 64-69.

[22] CARLOS ROSSI, RAFAEL P, LOZANO. Hydrochemical controls on aragonite versus calcite precipitation in cave dripwaters[J]. Geochimica et Cosmochimica Acta, 2016, 192(1): 70-96.

[23] 林若枫. 石钟乳与石笋[J]. 炎黄地理, 2020(1): 82-83.

[24] YOSHIYUKI KOJIMA, AKIKO SADOTOMO, TAMOTSU YASUE. Control of crystal shape and modification of calcium carbonate prepared by precipitation from calcium hydrogencarbonate solution[J]. Journal of the Ceramic Society of Japan, 1992, 100(9): 1145-1153.

[25] CHEBOTAREVA R. D, NANIEVA A. V, REMEZ S. V. Features of magnetic treatment of calcium bicarbonate waters[J]. Journal of Water Chemistry and Technology, 2020, 42(5): 490-498.

[26] 胡光辉. 溶胶-凝胶技术研究及其应用[J]. 重庆工业高等专科学校学报, 2005(1): 26-29.

[27] 韩志华, 曹林. CaCO3纳米线的制备及表征[J]. 无机材料学报, 2005(6): 71-74.

[28] 谢元彦, 杨海林, 阮建明, 周忠诚. 溶胶-凝胶法制备碳酸钙晶须[J]. 粉末冶金材料科学与工程, 2009, 14(3): 164-168. doi: 10.3969/j.issn.1673-0224.2009.03.007

[29] 李彬彬, 杨绍利, 赵均辉, 王尊. 超重力技术及其在材料制备中的应用[J]. 广州化工, 2015, 43(23): 53-55. doi: 10.3969/j.issn.1001-9677.2015.23.015

[30] CHEN J F, WANG Y H, GUO F, et al. Synthesis of nanoparticles with novel technology: high-gravity reactive precipitation[J]. Industrial & Engineering Chemistry Research, 2000, 39(4): 948-954.

[31] CHAO Y, JIN L Synthesis of aragonite CaCO3 nanocrystals by reactive crystallization in a high shear mixer[J]. Crystal Research & Technology, 2017, 52(5).

[32] WANG M, ZOU H K, SHAO L, et al. Controlling factors and mechanism of preparing needlelike CaCO3 under high-gravity environment[J]. Powder Technology, 2004, 142(2-3): 166-174. doi: 10.1016/j.powtec.2004.05.003

[33] 裴冰野. 利用方解石制备碳酸钙晶须及其反应机理的研究[D]. 沈阳化工大学, 2018.

[34] 李会杰, 黄娜娜, 仇龙, 等. 白云石制备碳酸钙晶须及其机理的研究[J]. 人工晶体学报, 2020, 49(1): 119-124, 137. doi: 10.3969/j.issn.1000-985X.2020.01.020

[35] 罗东山. 石棉县大理石尾矿资源化综合利用技术研究[D]. 西南科技大学, 2020.

[36] 刘万伟. 探讨化工工业三废处理技术方法及环境保护[J]. 科技风, 2020(10): 141.

[37] SAID A, MATTILA H P, JAERVINEN M, et al. Production of precipitated calcium carbonate (PCC) from steelmaking slag for fixation of CO2[J]. Applied Energy, 2013, 112(dec. ): 765-771.

[38] MATTILA H P, ZEVENHOVEN R. Production of precipitated calcium carbonate from steel converter slag and other calcium-containing industrial wastes and residues[J]. Advances in Inorganic Chemistry, 2014, 66(1): 347-384.

[39] 刘咏, 闫利花, 汤建伟, 等. 磷石膏脱硫残渣制备碳酸钙晶须及改性工艺研究[C]全国磷复肥/磷化工技术创新. 2015: 209-214.

[40] SONG K, KIM W, BANG J H, et al. Polymorphs of pure calcium carbonate prepared by the mineral carbonation of flue gas desulfurization gypsum[J]. Materials and Design, 2015, 83(suppl 3): 308-313.

[41] WANG Y, LI Y, YUAN A, et al. Preparation of calcium sulfate whiskers by carbide slag through hydrothermal method[J]. Crystal Research & Technology, 2015, 49(10): 800-807.

[42] 刘飞, 袁铭鸿, 曹建新. 利用电石渣制备碳酸钙晶须的初步研究[J]. 贵州大学学报(自然科学版), 2010, 27(2): 126-128. doi: 10.3969/j.issn.1000-5269.2010.02.033

[43] LU, FANG, YANFEN, et al. Self-sustaining carbon capture and mineralization via electrolytic carbonation of coal fly ash. [J]. Chemical Engineering Journal, 2016, 306: 330-335. doi: 10.1016/j.cej.2016.07.060

[44] 屠志康. 利用双氰胺工业废渣制取高分子合成制品填充剂[P]. 中国专利, 93117020, 1998-11-18.

[45] 赵海鹏. 双氰胺废渣制备碳酸钙晶须联产氯化铵工艺研究[D]. 宁夏大学, 2016.

[46] ZHANG DK, ZHOU XQ, LIU CL, et al. Crystallization of calcium carbonate from lithium-containing brines[J]. Journal of Crystal Growth, 2021, 556, 10.1016/j.jcrysgro.2020.125989. doi: 10.1016/j.jcrysgro.2020.125989

[47] SEBASTIAN TEIR, TUUKKA KOTIRANTA, JOUKO PAKARINEN, et al. Case study for production of calcium carbonate from carbon dioxide in flue gases and steelmaking slag[J]. Journal of CO2 Utilization, 2016, 14: 37-46. doi: 10.1016/j.jcou.2016.02.004

[48] SATOSHI KODAMA, TAIKI NISHIMOTO, NAOKI YAMAMOTO, et al. Development of a new pH-swing CO2 mineralization process with a recyclable reaction solution[J]. Energy, 2008, 33(5): 776-784. doi: 10.1016/j.energy.2008.01.005

[49] LU SQ, MIAO YM, LIU ZQ. Mineralization of simulated flue gas to prepare CaCO3 whisker using suspended CaSO4[J]. Journal of the Chinese Chemical Society, 2020, 67(8): 1408-1414. doi: 10.1002/jccs.201900493

[50] 李佳乐, 王新宇, 陈天艺, 杨星硕, 赵颖颖, 袁俊生. 连续鼓泡法海水碳化制备碳酸钙文石的研究[J]. 无机盐工业, 2021, 53(2): 42-46.

[51] ARAKI Y, TSUKAMOTO K, OYABU N, et al. Atomic resolution imaging of aragonite (001) surface in water by frequency modulation atomic force microscopy[J]. Japanese Journal of Applied Physics, 2012, 51(8ISSUE4): 08KB09-08KB09-4.

[52] A N Z, B S Y, C L X, et al. Nanoscale toughening mechanism of nacre tablet[J]. Journal of the Mechanical Behavior of Biomedical Materials, 2016, 53: 200-209. doi: 10.1016/j.jmbbm.2015.08.020

[53] VERMA N, KUMAR V, BANSAL M C, et al. Utilization of egg shell waste in cellulase production by neurospora crassa under wheat bran-based solid state fermentation[J]. Polish Journal of Environmental Studies, 2012, 21(2): 491-497.

[54] KHAN M D, AHN J W, NAM G. Environmental benign synthesis, characterization and mechanism studies of green calcium hydroxide nano-plates derived from waste oyster shells[J]. Journal of Environmental Management, 2018, 223(OCT. 1): 947-951.

[55] M. FELIPE-SESé, ELICHE-QUESADA D, CORPAS-IGLESIAS F A. The use of solid residues derived from different industrial activities to obtain calcium silicates for use as insulating construction materials[J]. Ceramics International, 2011, 37(8): 3019-3028.

[56] ALOK MITTAL, MEENU TEOTIA, R.K. SONI, JYOTI MITTAL. Applications of egg shell and egg shell membrane as adsorbents: A review[J]. Journal of Molecular Liquids, 2016, 223: 376-387.

[57] HABTE L, KHAN M D, SHIFERAW N, et al. Synthesis, characterization and mechanism study of green aragonite crystals from waste biomaterials as calcium supplement[J]. Sustainability, 2020, 12(12): 5062, 10.3390/su12125062. doi: 10.3390/su12125062

-

下载:

下载: