Corrosion performance of steel in geothermal water environment in Xining area and suggestions for anti-corrosion measures

-

摘要:

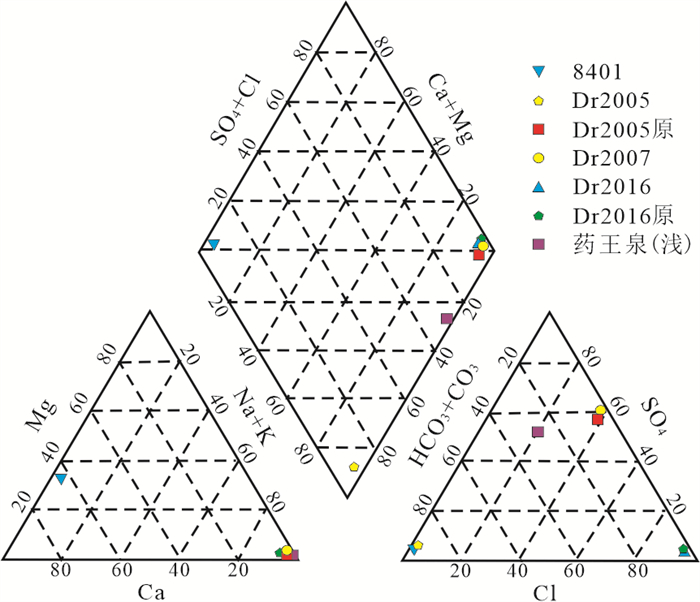

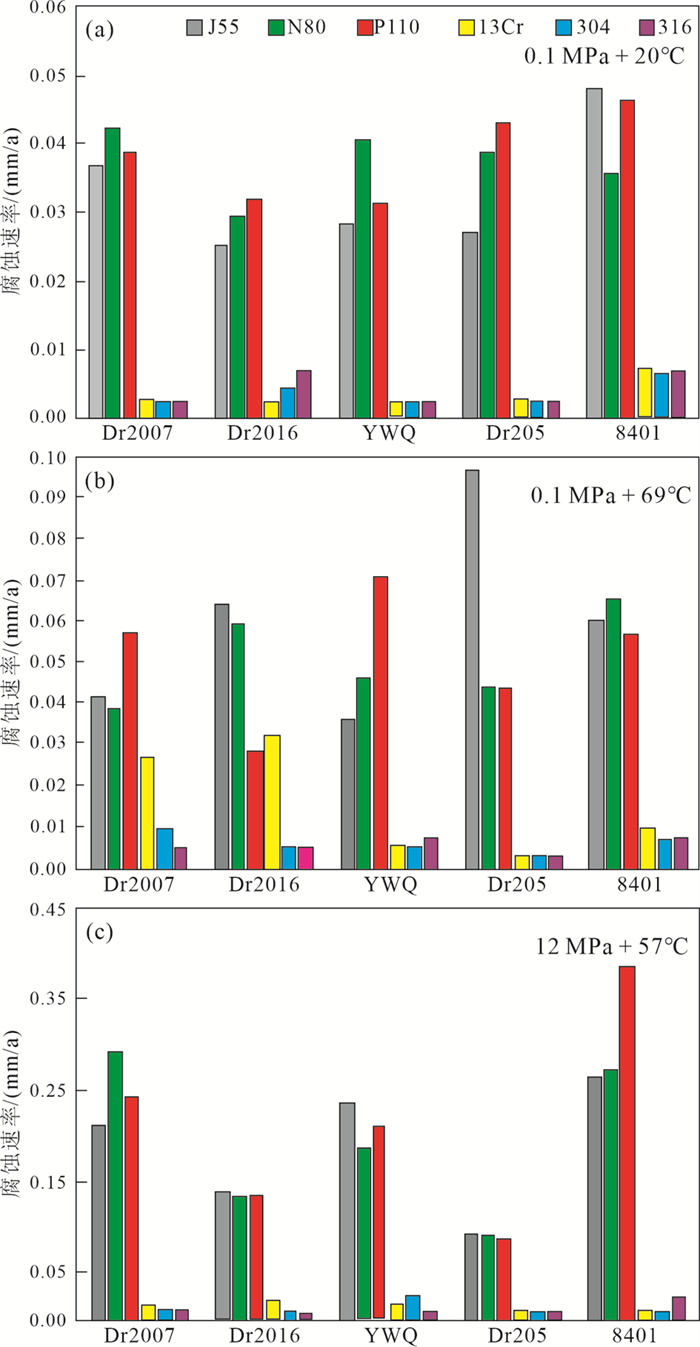

研究目的 西宁地区中低温地热资源丰富,但地热水矿化度高、腐蚀性强,限制了地热能的高效开发,提出安全经济有效的综合井筒防腐措施,是有效利用高矿化度地热资源的基础和关键。

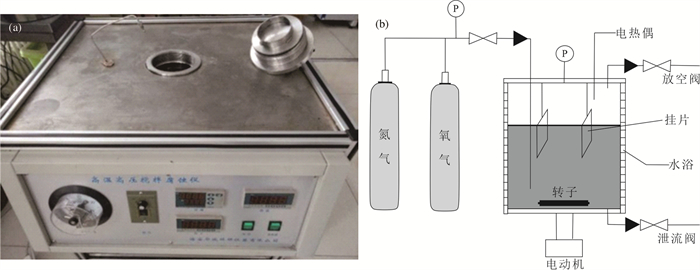

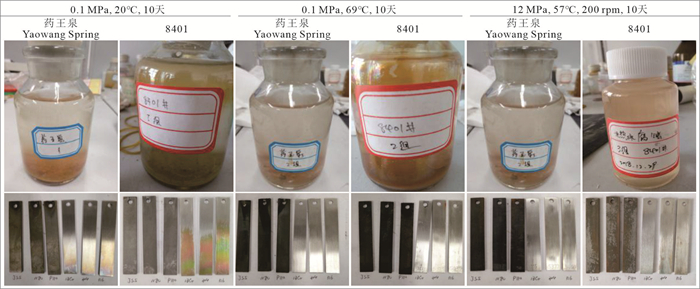

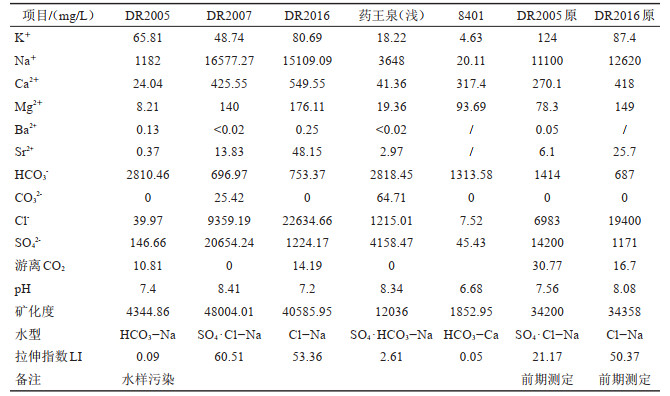

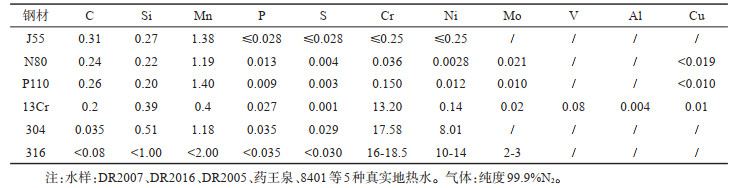

研究方法 本文针对西宁地区典型地热水样进行采集化验,采用高温高压反应釜,开展了金属挂片腐蚀实验,评价了在开放环境中回灌井筒条件下的钢材腐蚀风险,判断了腐蚀类型,分析了腐蚀规律及其影响因素,最后提出地热水回灌防腐建议。

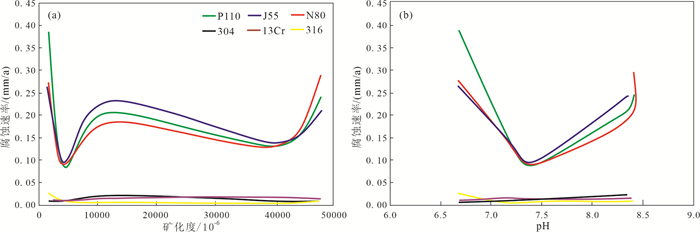

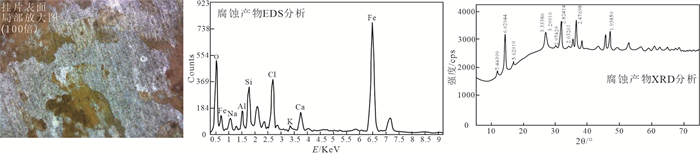

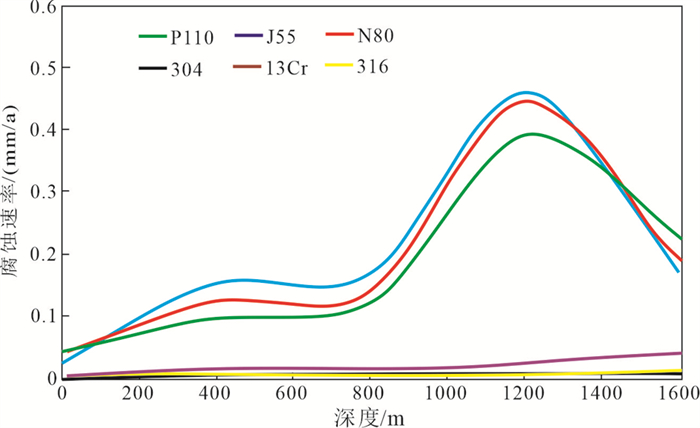

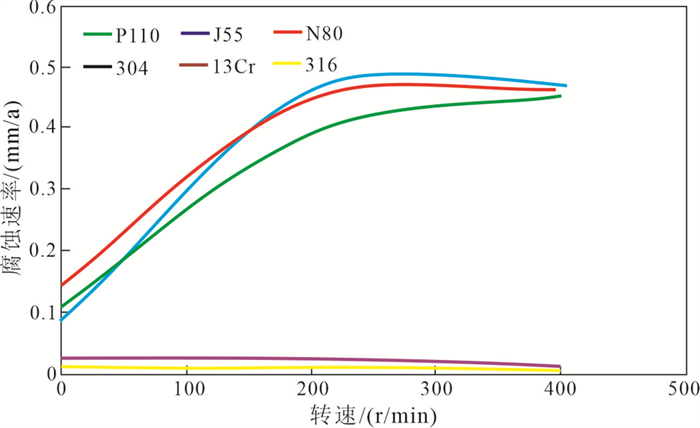

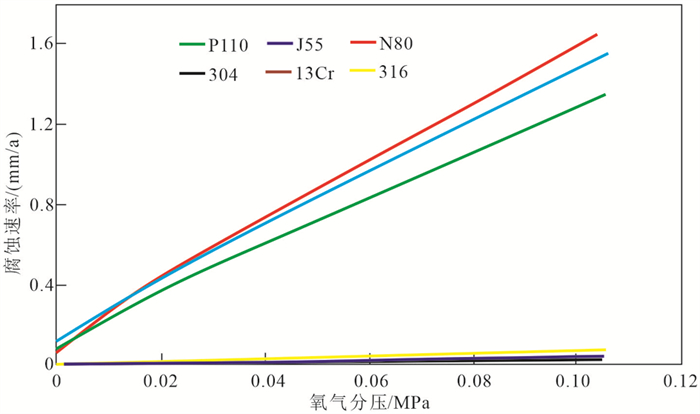

研究结果 西宁盆地地热水具有较强腐蚀性,主要腐蚀成分为溶解氧、Cl-、SO42-、H+等,可对碳钢造成均匀腐蚀、台状腐蚀及少量点蚀,主要腐蚀产物为FeO(OH)及Fe3O4;沿回灌井筒向下碳钢腐蚀速率先增大后减小,腐蚀规律与地热水性质、温压场、水流速及混入井筒的溶解氧等都有关系。

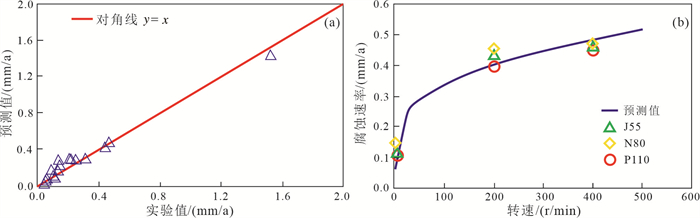

结论 通过拟合碳钢腐蚀实验数据,建立经验方程,利用该经验方程得到的预测值与实验值一致性较好。可从防腐管材选择、回灌水预处理、回灌工艺参数优化等角度,采取安全经济有效的综合井筒防腐措施。

Abstract:This paper is the result of geothermal survey engineering.

Objective Xining area is rich in medium and low temperature geothermal resources, but the high salinity and strong corrosion of geothermal water limit the efficient development of geothermal energy. The proposed safe, economic and effective comprehensive well bucket anticorrosion measures are the basis and key to the effective utilization of high salinity geothermal resources.

Methods In this study, the typical geothermal water in Xining area was collected, and the ionic composition and content of corrosive bacteria were tested. The high-temperature and high-pressure reactor was used to carry out metal plate corrosion tests to evaluate the corrosion performance of geothermal water on different steels under typical wellbore conditions. The corrosion type and the relationship between the corrosion rate and the influencing factors was analyzed. Finally, the anti-corrosion measures for geothermal water reinjection were proposed.

Results The main corrosion components in geothermal water are Cl-, SO42-, H+ and dissolved oxygen, which cause uniform corrosion, platform corrosion and a small amount of pitting corrosion. The main corrosion products are FeO(OH) and Fe3O4; the corrosion rate along the wellbore gradually increases, and the corrosion risk at bottom hole is the greatest. In addition, the corrosion rate has a greater correlation with the geothermal water properties, P-T condition, flow speed and dissolved oxygen mixed into wellbore.

Conclusions By fitting carbon steel corrosion experiment data, an empirical equation is established. The predicted value obtained by using the empirical equation is in good agreement with the experimental value. Safe, cost-effective and comprehensive wellbore anti-corrosion measures can be taken from the perspective of anti-corrosion pipes, reinjection geothermal water pretreatment, reinjection process parameters.

-

-

表 1 西宁地区典型地热水样水质分析结果

Table 1. Water quality analysis results of typical geothermal water samples in Xining area

表 2 金属挂片元素组成(%)

Table 2. Chemical composition of metal coupons (%)

表 3 井筒地热水腐蚀性能评价实验方案

Table 3. Experimental scheme for evaluating corrosion performance of geothermal water in wellbore

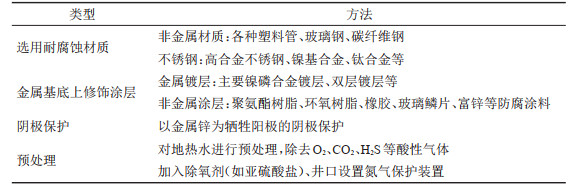

表 4 地热井防腐措施

Table 4. Anti-corrosion measures for geothermal wells

-

Gao Xiangdong, Cheng Guiping, Wang Zhaoyu. 2001. A.T.O cermet coating used in geothermal water pipeline internal protection[J]. Corrosion and Protection, 22(2): 64-65, 86 (in Chinese with English abstract).

Kaya E, Zarrouk S J, O'Sullivan M J. 2011. Reinjection in geothermal fields: A review of worldwide experience[J]. Renewable and Sustainable Energy Reviews, 15(1): 47-68. doi: 10.1016/j.rser.2010.07.032

Knipe E C, Rafferty K D. 1985. Corrosion in low-temperature geothermal applications[J]. American Society of Heating, Refrigerating and Air-Conditioning Engineers, 91(2B-1): 81-91.

Larson T E, Sollo F R. 1967. Loss in water main carrying capacity[J]. Journal-American Water Works Association, 59(12): 1565-1572. doi: 10.1002/j.1551-8833.1967.tb03486.x

Li Xiaoyuan, Wen Jiuba, Li Quanan. 2003. Anticorrosion technology of downhole tubing in oil and gas fields[J]. Corrosion Science and Protection Technology, 15(5): 272-276 (in Chinese with English abstract).

Liu Jie, Song Meiyu, Tian Guanghui. 2012. Current status of the development and utilization of geothermal resources in Tianjin and suggestions for sustainable development and utilization[J]. Geological Survey and Research, 35(1): 67-73 (in Chinese with English abstract).

Liu Jiurong. 2003. Development status of geothermal recharge[J]. Hydrogeology and Engineering Geology, 30(3): 100-104 (in Chinese with English abstract). doi: 10.3969/j.issn.1000-3665.2003.03.025

Liu Mingyan, Zhu Jialing. 2011. Research progress on anti-corrosion and anti-scaling in the utilization of geothermal energy[J]. Progress in Chemical Industry, 30(5): 1120-1123 (in Chinese with English abstract).

Ma Bing, Jia Lingxiao, Yu Yang, Wang Huan. 2021. The development and utilization of geothermal energy in the world[J]. Geology in China, 48(6): 1734-1747 (in Chinese with English abstract).

Ma Jianjun, He Ting, Zhang Chuang. 2019. Anticorrosion technology of high temperature geothermal well pipeline[J]. Oil and Gas Field Surface Engineering, 38(S1): 131-134 (in Chinese with English abstract).

Shao Kun. 2009. Pipeline corrosion and its control in the development and utilization of geothermal water[J]. Pipeline Technology and Equipment, (2): 52-53, 59 (in Chinese with English abstract).

Wang Tinghao. 2019. Evaluation of geothermal resources and target selection in Shandong Province[J]. Petrochemical Technology, 26(7): 114-115 (in Chinese with English abstract).

Wei Zhenshu. 2001. Environmental Water Chemistry[M]. Beijing: Textbook Publishing Center of Chemical Industry Press (in Chinese).

Woollam R C, Hernandez S. 2006. Assessment and comparison of CO2 corrosion prediction models[C]//SPE 100673-MS, SPE International Oilfield Corrosion Symposium, Aberdeen, UK.

Wu Ye. 2014. Research on Geological Environmental Problems and Key Technologies of Shallow Geothermal Energy Development[D]. Wuhan: China University of Geosciences (Wuhan) (in Chinese with English abstract).

Xing Yifei, Wang Huiqun, Li Jie, Teng Yanguo, Zhang Baojian, Li Yanyan, Wang Guiling. 2022. Chemical field of geothermal water in Xiong'an New Area and analysis of influencing factors[J]. Geology in China, 49(6): 1711-1722 (in Chinese with English abstract).

Zhang Fengxiong, Yang Jiakai, Liu Shuying, Yan Weide. 2006. Discussion on the distribution of geothermal resources in Xining area[J]. Science and Technology Information, 21(6): 138-139 (in Chinese with English abstract).

Zhang Senqi, Xu Weilin, Yan Weide, Wang Jianrong, Li Qijiang, Shi Weidong. 2013. Geothermal Geology of Xining Basin[M]. Beijing: Geological Publishing House (in Chinese).

Zhang Wei, Wang Guiling, Liu Feng, Xing Linxiao, Li Man. 2019. Characteristics of geothermal resources of sedimentary basins in China[J]. Geology in China, 46(2): 255-268 (in Chinese with English abstract).

Zhao Jinping, Wang Xinyi, Han Pengfei, Jiao Shuqiang. 2004. Research on the evaluation and protection technology of scaling and corrosion of geothermal water in the eastern plain of Henan Province[J]. Journal of Fuzhou University (Natural Science Edition), 32(1): 118-122 (in Chinese with English abstract).

Zhao Zhen, Yu Piaoluo, Chen Huijuan, Luo Yinfei, Zhao Dongyang, Bian Jiang. 2015. Genesis analysis and resource evaluation of Xining geothermal field in Qinghai Province[J]. Geology in China, 42(3): 803-810 (in Chinese with English abstract).

Zhao Zhen, Qin Guangxiong, Luo Yinfei, Chao Jiahao, Geng Songhe, Zhang Liang. 2021. Characteristics of geothermal water and risk of recharge scaling in the Xining Basin[J]. Hydrogeology and Engineering Geology, 48(5): 193-204 (in Chinese with English abstract).

Zhu Liqun, Wu Kunhu, Li Weiping, Liu Huicong. 2010. Simulating the corrosion and scaling of 304 stainless steel pipes and galvanized steel pipes in geothermal water[J]. Acta Physico-Chimica Sinica, 26(1): 39-46 (in Chinese with English abstract). doi: 10.3866/PKU.WHXB20100142

高向东, 成桂萍, 王昭宇. 2001. A.T.O金属陶瓷涂料用于地热水管道内防护[J]. 腐蚀与防护, 22(2): 64-65, 86.

李晓源, 文九巴, 李全安. 2003. 油气田井下油管的防腐技术[J]. 腐蚀科学与防护技术, 15(5): 272-276.

刘杰, 宋美钰, 田光辉. 2012. 天津地热资源开发利用现状及可持续开发利用建议[J]. 地质调查与研究, 35(1): 67-73.

刘久荣. 2003. 地热回灌的发展现状[J]. 水文地质工程地质, 30(3): 100-104.

刘明言, 朱家玲. 2001. 地热能利用中的防腐防垢研究进展[J]. 化工进展, 30(05): 1120-1123.

马冰, 贾凌霄, 于洋, 王欢. 2021. 世界地热能开发利用现状与展望[J]. 中国地质, 48(6): 1734-1747. http://geochina.cgs.gov.cn/cn/article/doi/10.12029/gc20210606

马建军, 何亭, 张闯. 2019. 耐高温地热井管线防腐技术[J]. 油气田地面工程, 38(S1): 131-134.

邵昆. 2009. 地热水开发利用中的管道腐蚀及其控制[J]. 管道技术与设备, (2): 52-53, 59.

王婷灏. 2019. 山东省地热资源评价及靶区优选[J]. 石化技术, 26(7): 114-115. doi: 10.3969/j.issn.1006-0235.2019.07.062

魏振枢. 2001. 环境水化学[M]. 北京: 化学工业出版社教材出版中心.

吴烨. 2014. 浅层地热能开发的地质环境问题及关键技术研究[D]. 武汉: 中国地质大学(武汉).

邢一飞, 王慧群, 李捷, 滕彦国, 张保健, 李燕燕, 王贵玲. 2022. 雄安新区地热水的化学场特征及影响因素分析[J]. 中国地质, 49(6): 1711-1722. http://geochina.cgs.gov.cn/cn/article/doi/10.12029/gc20220601

张丰雄, 杨家凯, 刘淑英, 严维德. 2006. 西宁地区地热资源分布规律探讨[J]. 科技资讯, 21(6): 138-139.

张森琦, 许伟林, 严维德, 王建荣, 李其江, 石维栋. 2013. 西宁盆地地热地质[M]. 北京: 地质出版社.

张薇, 王贵玲, 刘峰, 邢林啸, 李曼. 2019. 中国沉积盆地型地热资源特征[J]. 中国地质, 46(2): 255-268. http://geochina.cgs.gov.cn/cn/article/doi/10.12029/gc20190204

赵金平, 王心义, 韩鹏飞, 焦述强. 2004. 河南省东部平原地热水结垢与腐蚀评价及防护技术的研究[J]. 福州大学学报(自然科学版), 32(1): 118-122. doi: 10.3969/j.issn.1000-2243.2004.01.028

赵振, 于漂罗, 陈惠娟, 罗银飞, 赵东阳, 边疆. 2015. 青海省西宁地热田成因分析及资源评价[J]. 中国地质, 42(3): 803-810. doi: 10.3969/j.issn.1000-3657.2015.03.029

赵振, 秦光雄, 罗银飞, 晁嘉豪, 耿松鹤, 张亮. 2021. 西宁盆地地热水特征及回灌结垢风险[J]. 水文地质工程地质, 48(5): 193-204.

朱立群, 吴坤湖, 李卫平, 刘慧丛. 2010. 模拟地热水中304不锈钢管和镀锌钢管的腐蚀与结垢[J]. 物理化学学报, 26(1): 39-46. doi: 10.3866/PKU.WHXB20100142

-

下载:

下载: