Using Fragment-assembly to Research High Efficiency Copper-molybdenum Separation Inhibitor

-

摘要:

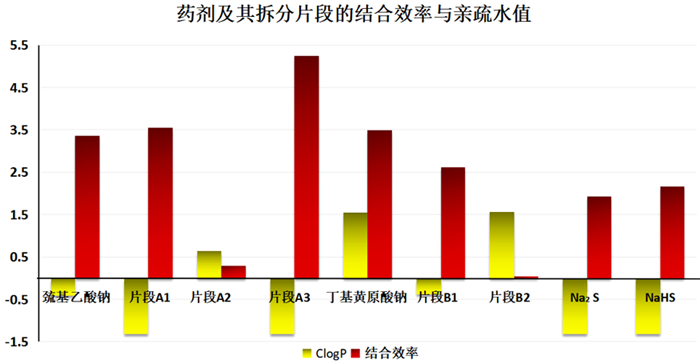

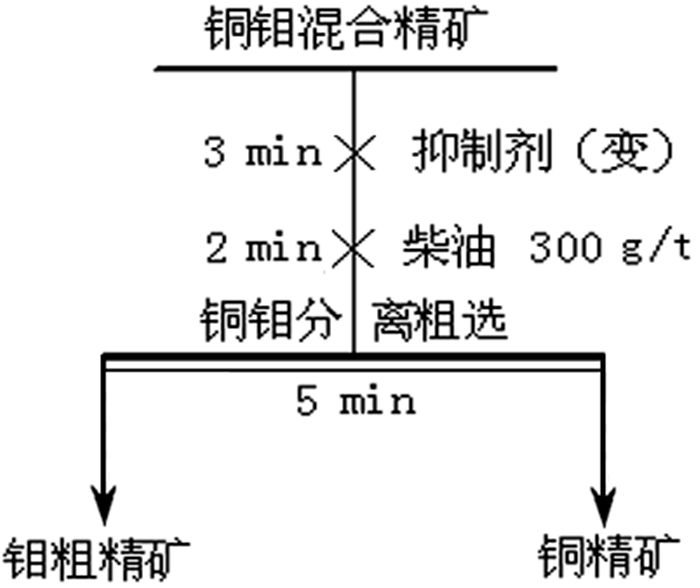

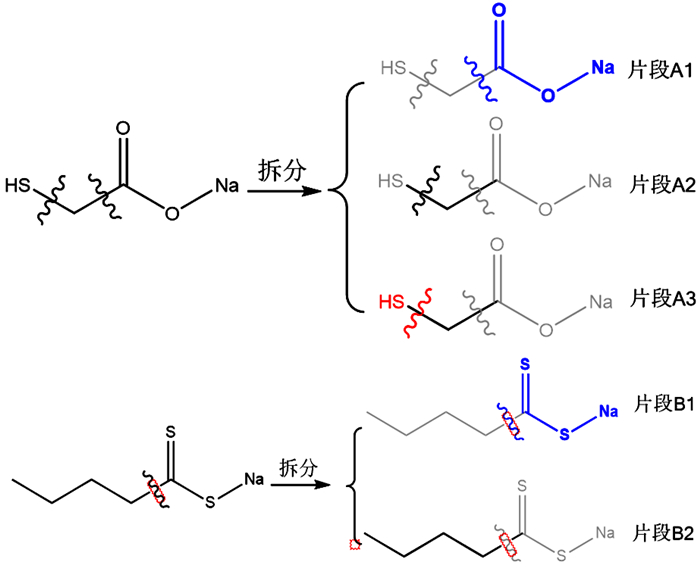

铜钼分离药剂是实现铜钼分离的核心,常用的铜钼分离抑制剂主要有硫化钠、硫氢化钠、诺克斯试剂、巯基乙酸钠及氰化物等,存在用量大、成本高、环境污染严重、适用性差等问题。针对这一问题,利用基于片段的分子组装技术,采用筛选确定先导化合物、先导化合物片段拆分再组装调控的方法,结合计算机辅助分子技术研发高效抑制剂BK511。MS软件计算该药剂与黄铜矿的相互作用能显著大于硫化钠、巯基乙酸钠等,且与辉钼矿的相互作用能大于零,实现选择性高效抑铜浮钼。铜钼矿山工业应用表明,BK511对铜抑制能力强,用量少,可以替代硫氢化钠(硫化钠),药剂用量为硫氢化钠用量的10%~20%,可大幅降低药剂成本,并显著改善车间操作环境,工业应用中可以大幅度降低选矿厂尾水中的硫化物含量。

Abstract:Reagents are the core to achieve the separation of copper and molybdenum. NaHS(Na2S), Knox reagent, sodium thioglycolate and cyanide are commonly used copper molybdenum inhibitors, with the problems of the high dosage, high cost, severe environmental pollution, low industrial applicability and etc. To solve these problems, based on fragment assembly used in study, the method "screening to identify lead compounds, splicing and reassembling the lead compound, with the combination of computer aided molecular design techniques" was conducted to efficient inhibitor BK511. Material Studios (MS) software was used to calculate the interaction between BK511 and chalcopyrite. The results illustrated that the interaction between BK511 and chalcopyrite is significantly greater than that of NaHS and etc, to achieve selective inhibition of chalcopyrite. The industrial application of Cu-Mo separation showed that BK511 displayed outstanding inhibition performance with only 10%~20% dosage of NaHS, which is a solid candidate to substitute NaHS with much lower reagent cost and better environment footprint. The sulfide content is dramatically reduced in the tailings of the processing plant in the industry.

-

Key words:

- fragment assembly /

- copper-molybdenum separation /

- inhibitor

-

-

表 1 药剂拆分片段分类

Table 1. Reagent fragments classification

药剂名称 相互作用能/(kJ·mol-1) 片段分类 巯基乙酸钠 -383.01 / 片段A1 -237.883 功能性片段 片段A2 -4.034 结构性片段 片段A3 -173.527 功能性片段 丁基黄原酸钠 -496.891 / 片段B1 -259.422 功能性片段 片段B2 -1.843 结构性片段 Na2S -150.413 / NaHS -121.482 / 表 2 抑制性能对比试验结果

Table 2. The results of flotation test with different depressants

NaHS+BK511用量/(kg·t-1) 产品名称 产率

/%品位/% 回收率/% Mo Cu Mo Cu 2.25+0 钼粗精矿 31.5 24 9.67 97.53 17.41 铜精矿 68.5 0.28 21.1 2.47 82.59 铜钼混合精矿 100.00 7.75 17.50 100.00 100.00 1.125+0.125 钼粗精矿 33.1 21.5 9.78 97.70 18.03 铜精矿 66.9 0.25 22 2.30 81.97 铜钼混合精矿 100.00 7.28 17.96 100.00 100.00 0.45+0.18 钼粗精矿 34.5 20.7 10.08 96.85 19.76 铜精矿 64.5 0.36 21.9 3.15 80.24 铜钼混合精矿 99.00 7.45 17.78 100.00 100.00 0+0.7 钼粗精矿 26.7 27.3 10.42 94.13 15.56 铜精矿 73.3 0.62 20.6 5.87 84.44 铜钼混合精矿 100.00 7.74 17.88 100.00 100.00 -

[1] 邱丽娜, 戴惠新.钼矿的浮选工艺及药剂现状[J].现代矿业, 2009(7):22-23, 38. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=xdky200907006

[2] 陶坤, 魏明安.巯基乙酸选择性抑制机理的分子模拟研究[J].矿冶, 2011, 20(2):15-19. http://www.cqvip.com/QK/97765A/201102/38472582.html

[3] 林春元.钼矿选矿与深加工[M].北京:冶金工业出版社, 1996.

[4] 黄瑞强, 阮英华, 雷主生, 等.丰山铜矿铜钼分离抑制剂D8应用小型试验研究[J].矿冶, 2014, 23(6):22-26. http://www.cnki.com.cn/Article/CJFDTotal-YNYJ198505027.htm

[5] 杨世亮, 石玉君, 王越, 等.高效合成铜抑制剂在铜钼分离中的应用[J].有色金属(选矿部分), 2017(1):82-85. http://www.wanfangdata.com.cn/details/detail.do?_type=degree&id=Y1678308

[6] 欧乐明, 冯其明, 陈建华, 等.铜钼混合精矿体系中黄铜矿新型抑制剂的研究[J].矿冶工程, 1998, 18(1):34. http://www.cqvip.com/QK/93291X/199801/2995705.html

[7] G.E. Agar. Sulfide depression with thioglycollate of trithiocarbonate[J]. CIM Bull, 1984, 77:43. http://www.cim.org/en/Publications-and-Technical-Resources/Publications/Technical_Papers/1984/12/BULL-1984-12-08.aspx

[8] Erlanson DA, McDowell RS, O'Brien T. Fragment-based drug discovery[J]. J Med Chem, 2004, 47(14):3463-3482. doi: 10.1021/jm040031v

[9] Orita M, Ohno K, Niimi T. Two 'golden ratio' indices in fragment-based drug discovery[J]. Drug Discov Today, 2009, 14(5-6):321-328. doi: 10.1016/j.drudis.2008.10.006

[10] Diane Joseph Mc Carthy, Arthur J. Campbell, Gunther Kern, et al. Fragment-based lead discovery and design[J]. J. Chem. Inf. Model., 2014, 54(3):693. doi: 10.1021/ci400731w

[11] Pradip, B. Rai, T.K. Rao, et al. Molecular modeling of interactions of alkyl hydroxamates with calcium minerals[J]. J. Colloid Interface Sci., 2002, 256(1):106-113. doi: 10.1006/jcis.2001.7994

[12] Guiye Wu, Longli Liu, Mingan Wei, et al. Computer-based study on QSAR of small molecule depressors for chalcopyrite[C]. Santlago: International Mineral Processing Congress, 2014.

-

下载:

下载: