Effect of Roasting Treatment on Leaching Properties of Different Element in Mica

-

摘要:

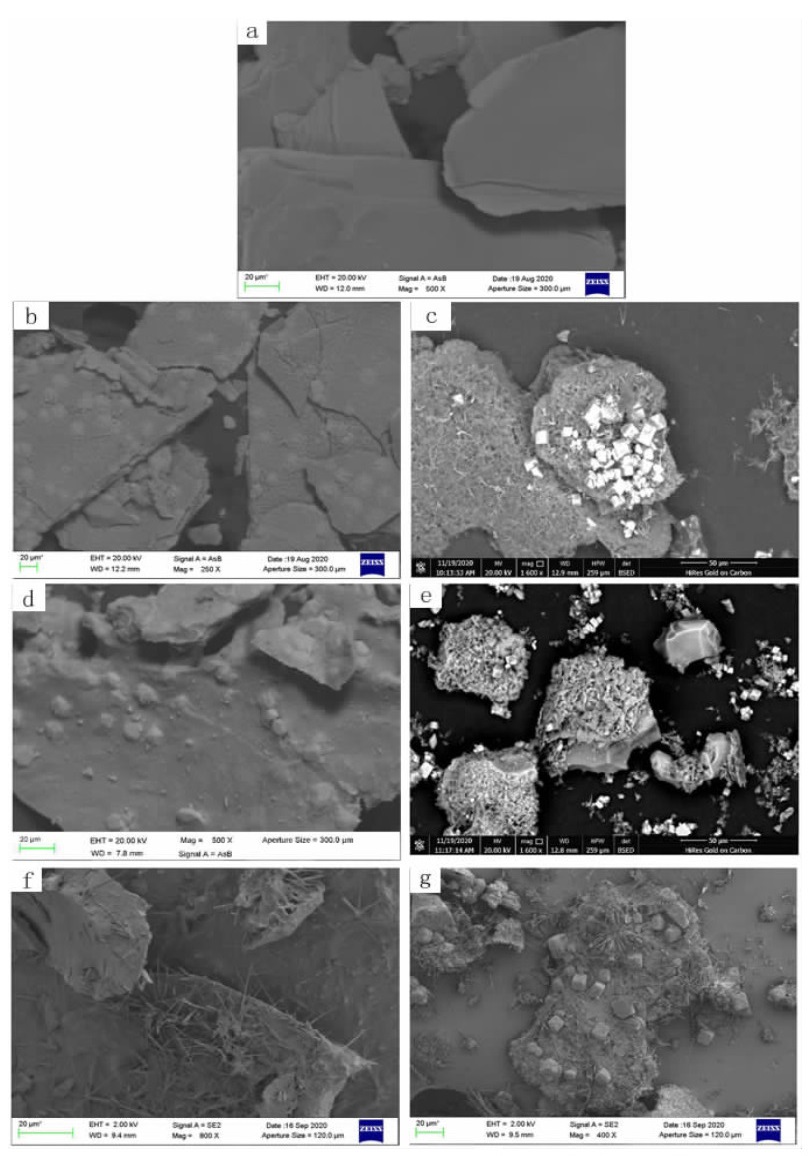

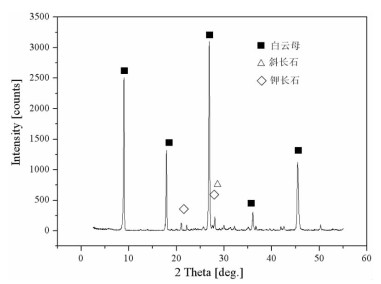

以石英提纯过程中主要杂质矿物云母为研究对象,进行了焙烧、水淬和浸出试验,并对焙砂、浸出渣进行了XRD、SEM表征,对比研究了不同焙烧条件下,云母矿物的物相转化和多元素浸出规律。试验结果表明,控制一定焙烧温度条件,云母经焙烧—水淬或者氯化焙烧处理,钾、钠、铝、铁、钛、镁等元素的脱除率可以得到有效提高,而钙元素的浸出率则有所降低;高温或者氯化焙烧后,云母大部分转换为其它矿物;浸出过程中形成的方氟硅钾石是影响钾元素有效脱除的重要因素;氯化焙烧焙砂中难以浸出的刚玉和莫来石,影响了铝元素的脱除。

Abstract:In this article the mica, which was the major impurity mineral in purification process of high purity quartz, was selected as research object. The roasting, water quenching and leaching experiments were conducted. The roasted product and leaching residue were characterized by XRD and SEM. Under different roasting conditions the contrast research onmineral transformation and multi-element leaching characteristics were conducted. Results showed that under specified roasting temperature, the removal rate of K, Na, Al, Fe, Ti and Mg vastly improved after roasting- water quenching treatment or chloridizing roasting treatment, the only difference was that the removal rate of Ca decreased slightly. After high temperature roasting or chloridizing roasting treatment, the mica transformed to other minerals mostly. The hieratite, formed in leaching process, was resistance factor restraining the effective removal of K, and the refractory corundum and mullite in chloridizing roasting product restrained the effective removal of Al.

-

Key words:

- mica /

- high purity quartz /

- roasting /

- water quenching treatment /

- chloridizing roasting

-

-

表 1 试验原料主要化学组成

Table 1. Main chemical composition of the raw material

/% 元素 K Na Ca Si Al Fe Mg Ti 含量 7.54 0.64 0.087 24.13 14.7 0.77 0.068 0.038 表 2 不同云母样品浸出渣失重率对比

Table 2. The weight loss ratio of the raw material after roasting and leaching process

样品编号 焙烧条件 初始质量/g 浸出渣质量/g 失重率/% 1 未焙烧 20 11.67 41.65 2 700 ℃,缓冷 10.85 45.75 3 950 ℃,水淬 9.61 51.95 4 1 200 ℃,水淬 7.35 63.25 5 950 ℃,氯化焙烧 6.97 65.15 表 3 浸出渣化学组成

Table 3. Main chemical composition of leaching residue

/% 样品号 K Na Ca Si Al Fe Mg Ti 1 10.14 0.24 0.004 23.06 14.46 0.74 0.034 0.035 2 12.04 0.24 0.031 23.12 12.33 0.64 0.048 0.031 3 13.86 0.11 0.029 19.71 13.59 1.39 0.100 0.037 4 14.65 0.23 0.072 17.98 13.56 0.73 0.036 0.021 5 8.75 0.10 0.036 17.46 21.50 1.07 0.110 0.023 表 4 云母焙烧浸出处理后各元素脱除率

Table 4. The removal rate of the main elements in mica after roasting and leaching process

/% 样品号 K Na Ca Si Al Fe Mg Ti 1 21.53 78.12 97.32 44.24 42.60 43.92 70.83 46.26 2 13.37 79.66 80.67 48.02 54.50 54.91 61.71 55.74 3 11.67 91.74 83.98 60.75 55.58 13.26 29.34 53.21 4 28.60 86.79 69.59 72.62 66.10 65.16 80.54 79.69 5 52.50 92.74 88.59 76.83 50.44 20.66 47.49 69.17 表 5 不同条件云母焙砂物相组成对比

Table 5. Main mineral composition of mica after different roasting conditions

/% 编号 云母 钾长石 斜长石 石英 莫来石 刚玉 白榴石 非晶质 1 90~93 2 5~7 - - - - - 2 92 2 3 2 - - - - 3 - 35~40 - 10~15 - - 45~50 - 4 - - - 13 - 7 40 40 5 - 10~15 - 8~10 10~15 3~5 - 60~65 表 6 不同条件云母焙砂浸渣物相组成

Table 6. Main mineral composition of leaching residue

/% 编号 云母 钾长石 斜长石 石英 莫来石 刚玉 方氟硅钾石 1 37.1 - - 28.5 - - 33.3 2 41.7 - - 37.1 - - 20.8 3 - - 0.7 21.0 40.0 28.0 4 - - - 13.4 - 27.3 58.5 5 - 10-15 - 30-35 30-35 5-7 15-20 -

[1] 申士富. 高纯石英砂研究与生产现状[J]. 中国非金属矿工业导刊, 2006(5): 13-16. https://www.cnki.com.cn/Article/CJFDTOTAL-LGFK200605003.htm

[2] 汪灵, 党陈萍, 李彩侠, 等. 中国高纯石英技术现状与发展前景[J]. 地学前缘, 2014, 21(5): 267-273. https://www.cnki.com.cn/Article/CJFDTOTAL-DXQY201405026.htm

[3] 颜玲亚, 刘艳飞, 于海军, 等. 中国高纯石英资源开发利用现状及供需形势[J]. 国土资源情报, 2020(10): 98-103. https://www.cnki.com.cn/Article/CJFDTOTAL-GTZQ202010017.htm

[4] 郝文俊, 冯书文, 詹建华, 等. 全球高纯石英资源现状、生产、消费及贸易格局[J]. 中国非金属矿工业导刊, 2020(5): 15-19. https://www.cnki.com.cn/Article/CJFDTOTAL-LGFK202005008.htm

[5] 李光惠, 王超峰, 詹建华, 等. 高纯石英原料作为战略性矿产的分析及建议[J]. 中国非金属矿工业导刊, 2020(5): 20-24. https://www.cnki.com.cn/Article/CJFDTOTAL-LGFK202005010.htm

[6] 郭文达, 韩跃新, 朱一民, 等. 高纯石英砂资源及加工技术分析[J]. 金属矿山, 2019(2): 22-28. https://www.cnki.com.cn/Article/CJFDTOTAL-JSKS201902006.htm

[7] 雷绍民, 林敏, 裴振宇, 等. 石英中杂质矿物赋存状态及纯化研究[J]. 中国矿业, 2016, 25(6): 79-83. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGKA201606019.htm

[8] 石钰, 张磊, 周东站, 等. 高纯石英砂的制备及应用研究进展[J]. 中国建材科技, 2019, 28(4): 73-75. https://www.cnki.com.cn/Article/CJFDTOTAL-JCKJ201904036.htm

[9] IRANNAJAD M, MEHDILO A, NURI OS. Influence of microwave irradiation on ilmenite flotation behavior in the presence of different gangue minerals[J]. Separation & Purification Technology, 2014, 132(6): 401-412. http://www.sciencedirect.com/science/article/pii/S1383586614003414

[10] SAYILGAN A, AROL AI. Effect of carbonate alkalinity on flotation behavior of quartz[J]. International Journal of Mineral Processing, 2004, 74(1-4): 233-238. http://www.sciencedirect.com/science/article/pii/S0301751604000043

[11] 于福顺. 石英长石无氟浮选分离工艺研究现状[J]. 矿产保护与利用, 2005(3): 41-43. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=9499aed8-27f6-4e61-9a8c-8da15928bbcc

[12] 马超, 冯安生, 刘长淼, 等. 高纯石英原料矿物学特征与加工技术进展[J]. 矿产保护与利用, 2019, 39(6): 48-57. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=d4384618-7806-437b-9c61-95c8fd002e53

[13] 苏英, 周永恒, 黄武, 等. 石英玻璃与HF酸反应动力学的研究[J]. 硅酸盐学报, 2004, 32(3): 287-293. https://www.cnki.com.cn/Article/CJFDTOTAL-GXYB200403015.htm

[14] 银锐明, 李静, 侯清麟, 等. 微波和酸蚀作用下石英砂中气液包裹体的去除机理[J]. 中南大学学报(自然科学版), 2014, 45(2): 389-394. https://www.cnki.com.cn/Article/CJFDTOTAL-ZNGD201402008.htm

[15] ZHANG Z, LI J, LI X, et al. High efficiency iron removal from quartz sand using phosphoric acid[J]. International Journal of Mineral Processing, 2012, 114-117(12): 30-34. http://www.sciencedirect.com/science/article/pii/S030175161200110X

[16] 吴逍. 高纯石英原料选择评价及提纯工艺研究[D]. 绵阳: 西南科技大学, 2016.

[17] 林敏. 脉石英中白云母、晶格杂质分离及机理[D]. 武汉: 武汉理工大学, 2018.

-

下载:

下载: