Pre-concentration Process of Pre-throw—Classification Recovery of Pre-thrown Tailings on Deep Ore in a Au-Cu-Fe Polymetallic Deposit in Peru

-

摘要:

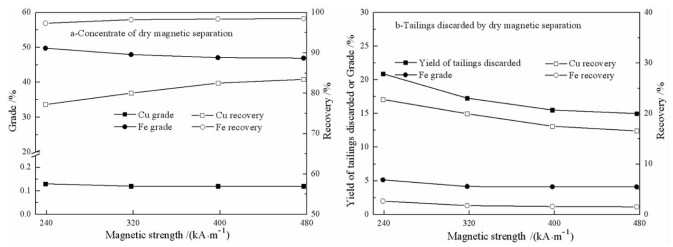

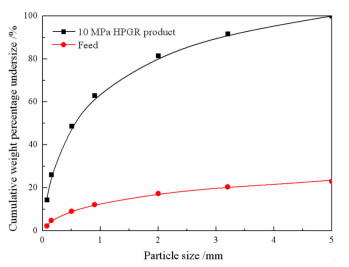

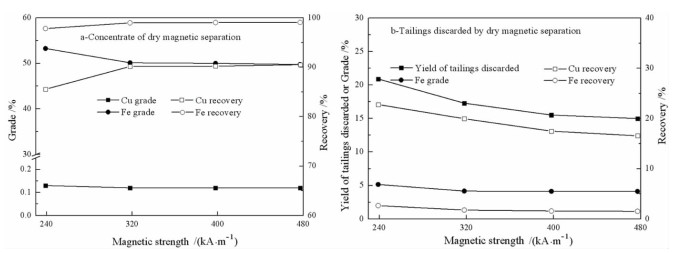

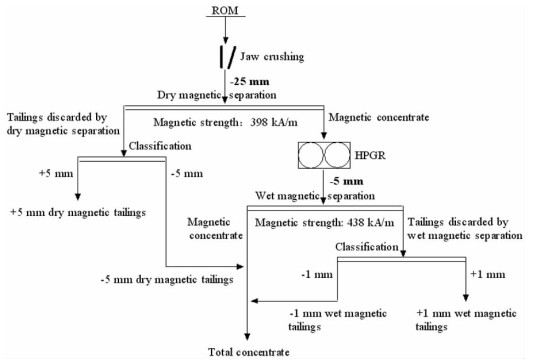

采用浅部矿的预选工艺对秘鲁某金铜铁多金属矿含Cu 0.127%、Au 0.08 g/t、S 2.08%、Fe 40.56%的深部矿石进行了选矿预选富集试验研究,为该矿石的合理预选工艺提供参考。结果表明,浅部矿的预抛—分级预选工艺(原矿-25 mm干抛—干抛精矿高压辊磨细碎—高压辊磨细碎产品湿抛—预抛尾矿分级回收)对深部矿石具有较好的适应性和预选富集效果,最终获得铜品位0.13%、铁品位48.76%、铜回收率87.49%、铁回收率97.93%的总预选精矿,总预选抛尾率为18.84%。项目成果为该矿石的合理预选工艺选择提供了参考,并为提高选厂后续磨浮作业的矿石入选品位,降低入磨矿量和磨选成本,综合回收矿石中铁铜等伴生有价金属创造了良好的前提条件。

Abstract:To provide the reference for reasonable pre-concentration process for the deep ore of Au-Cu-Fe polymetallic deposit in Peru with 0.127% Cu, 0.08 g/t Au, 2.08% S and 40.56% Fe, the mineral processing pre-concentration test on the ore was studied, with a process of pre-throw—classification recovery for the shallow ore. It shows that the pre-concentration process of pre-throw—classification recovery for the shallow ore composing of dry throwing of raw ore -25 mm—fine grinding of rough concentrate by high pressure roller grinding—wet throwing of the fine grinding product by high pressure roller grinding—classification recovery of copper and iron from pre-thrown tailings has a good adaptability and pre-concentration effect for the deep ore, the concentrate with Cu grade 0.13%, Fe grade 48.76%, Cu recovery rate of 87.49% and Fe recovery rate of 97.93% can be obtained, and the tailings discarding yield can reach 18.84%. The research results provide the reference for the selection of the reasonable pre-concentration process for the ore, and have created a good prerequisite for improving the grade of beneficiation in the follow-up grinding and flotation operation, reducing the grinding amount of ore and the cost of mineral processing and comprehensively recovering the associated valuable metals such as iron and copper in the ore.

-

-

表 1 试样的主要化学成分分析结果

Table 1. Analysis results of run-of-mine ore

/% TFe Cu Co S Au* Ag* Pb Zn FeO Ni TiO2 SiO2 Al2O3 K2O Na2O MgO CaO P As C 40.56 0.127 0.010 2.08 0.08 < 1 0.033 0.026 15.81 < 0.005 0.17 12.31 2.04 0.31 0.29 12.33 5.75 0.075 0.013 1.71 注:Ag、Au单位为g·t-1。 表 2 矿石中铁的化学物相分析结果

Table 2. Analysis results of iron phase of run-of-mine ore

/% Phase Magnetic iron oxide Magnetic iron sulfide Non-magnetic iron sulfide Hematite Iron carbonate Iron silicate Total Fe Fe content 36.67 1.33 0.96 0.37 0.13 1.10 40.56 Fe occupation rate 90.41 3.28 2.37 0.91 0.32 2.71 100.00 表 3 不同皮带转速下的干抛试验结果

Table 3. Results of dry magnetic preconcentration under different belt speed

Belt speed

/(m·s-1)Product Yield/% Grade/% Recovery/% Cu Fe Cu Fe 1.5 Concentrate 79.23 0.12 49.72 73.39 97.84 Tailings 20.77 0.17 4.20 26.61 2.16 ROM 100.00 0.13 40.26 100.00 100.00 1.0 Concentrate 82.71 0.12 47.95 80.03 98.22 Tailings 17.29 0.15 4.17 19.97 1.78 ROM 100.00 0.13 40.38 100.00 100.00 0.5 Concentrate 82.99 0.12 47.76 80.79 98.47 Tailings 17.01 0.14 3.62 19.21 1.53 ROM 100.00 0.13 40.25 100.00 100.00 表 4 磁场强度对-5 mm HPGR产品湿抛预选指标的影响

Table 4. Effect of magnetic strength on the index of wet magnetic preconcentrate for -5 mm HPGR product

Magnetic strength

/(kA·m-1)Product Operational yield/% Grade/% Operational recovery

/%Cu Fe Cu Fe 239 Concentrate 72.19 0.086 60.02 51.53 92.05 Tailings 27.81 0.21 13.46 48.47 7.95 Feed 100.00 0.12 47.07 100.00 100.00 358 Concentrate 82.18 0.10 55.60 70.19 97.31 Tailings 17.82 0.19 7.09 29.81 2.69 Feed 100.00 0.12 46.95 100.00 100.00 438 Concentrate 82.23 0.10 55.54 70.89 97.38 Tailings 17.77 0.19 6.90 29.11 2.62 Feed 100.00 0.12 46.90 100.00 100.00 表 5 -5 mm HPGR产品磁选预选抛尾结果对比

Table 5. Comparison of index of magnetic preconcentration mode of -5 mm HPGR product

Preconcentration mode Product Operational yield/% Grade/% Operational yield/% Cu Fe Cu Fe Concentrate 91.97 0.12 50.14 90.16 98.99 Dry magnetic

separationTailings 8.03 0.15 5.85 9.84 1.01 Feed 100.00 0.12 46.58 100.00 100.00 Concentrate 82.23 0.10 55.54 70.89 97.38 Wet magnetic

separationTailings 17.77 0.19 6.90 29.11 2.62 Feed 100.00 0.12 46.90 100.00 100.00 表 6 -25 mm深部矿干抛尾矿筛析结果

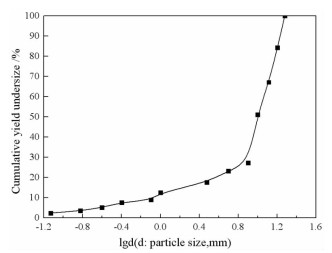

Table 6. Screening results of tailings of dry magnetic preconcentration of -25 mm deep ROM

Particle size/mm Operational yield/% Grade/% Operational recovery

/%Cu Fe Cu Fe +12 59.06 0.12 3.96 47.67 56.64 -12+10 8.01 0.031 3.11 1.67 6.02 -10+8 3.44 0.032 3.26 0.74 2.72 -8+5 6.55 0.11 2.92 4.84 4.63 -5+3 6.34 0.27 3.82 11.51 5.86 -3+1 5.41 0.24 4.77 8.73 6.25 -1 11.19 0.33 6.60 24.84 17.89 Tailings of dry magnetic separation 100.00 0.15 4.13 100.00 100.00 表 7 -5 mm HPGR细碎产品湿抛尾矿筛析结果

Table 7. Screening results of tailings of wet magnetic preconcentration of -5 mm HPGR product

Particle size/mm Operational yield/% Grade/% Operational recovery

/%Cu Fe Cu Fe +3 33.99 0.035 5.18 5.95 24.79 -3+1 11.82 0.10 7.38 6.16 12.29 -1+0.4 13.00 0.22 9.34 14.16 17.10 -0.4+0.25 7.38 0.32 8.11 11.88 8.43 -0.25+0.15 7.78 0.32 7.12 12.53 7.80 -0.15 26.03 0.38 8.07 49.32 29.59 Tailings of wet magnetic separation 100.00 0.20 7.10 100.00 100.00 表 8 选矿预富集工艺全流程试验结果

Table 8. Results of full flowsheet of magnetic preconcentration process

Product Yield/% Grade/% Recovery/% Cu Fe Cu Fe Magnetic concentrate 69.47 0.105 55.75 58.50 95.83 -5 mm dry magnetic tailings 3.56 0.27 5.41 7.88 0.48 -1 mm wet magnetic tailings 8.13 0.32 8.06 21.11 1.62 Total concentrate 81.16 0.13 48.76 87.49 97.93 +1 mm wet magnetic tailings 6.88 0.052 5.62 2.91 0.96 +5 mm Dry magnetic tailings 11.96 0.099 3.76 9.60 1.11 ROM 100.00 0.123 40.41 100.00 100.00 -

-

下载:

下载: