Experimental Research on Beneficiation of Copper-bearing Tin Polymetallic Ore in Yunnan

-

摘要:

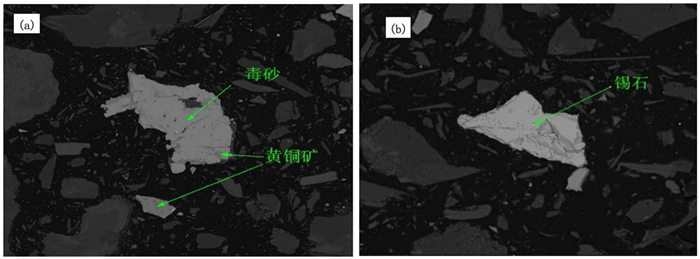

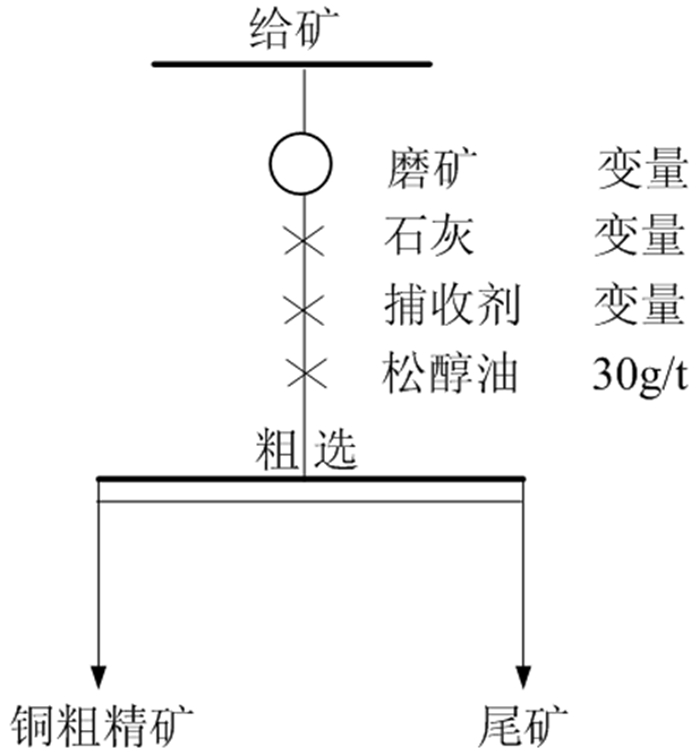

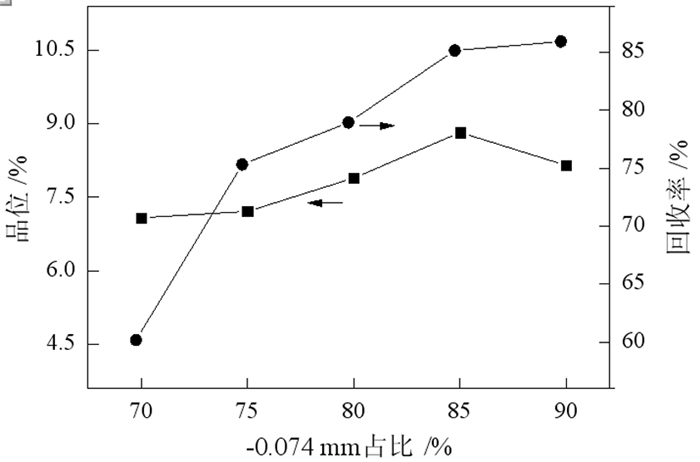

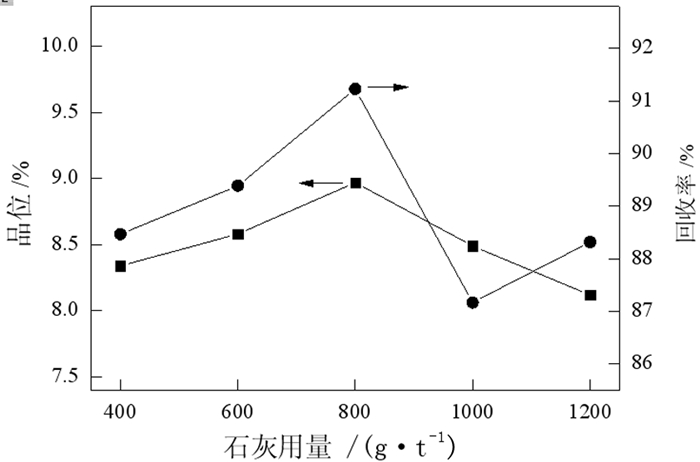

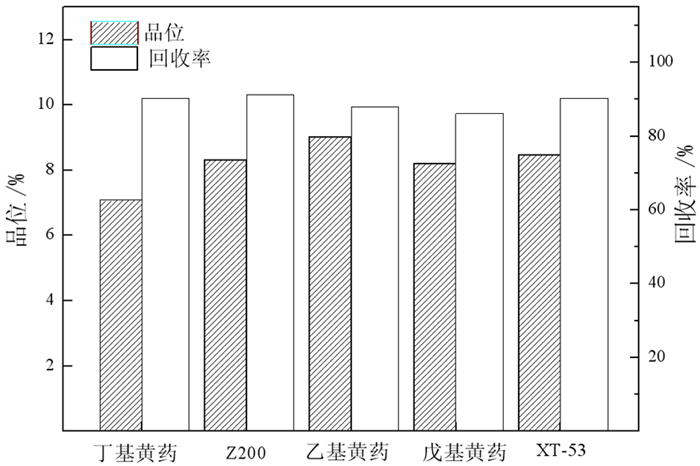

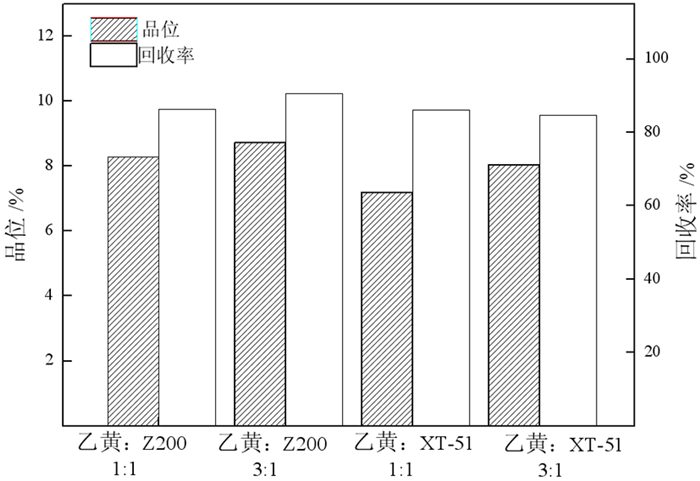

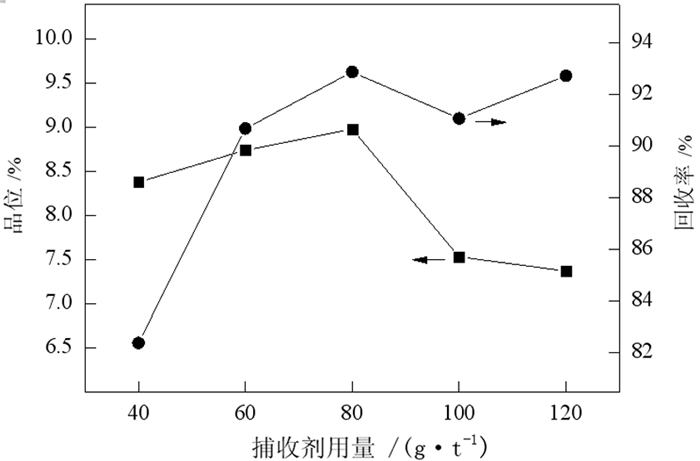

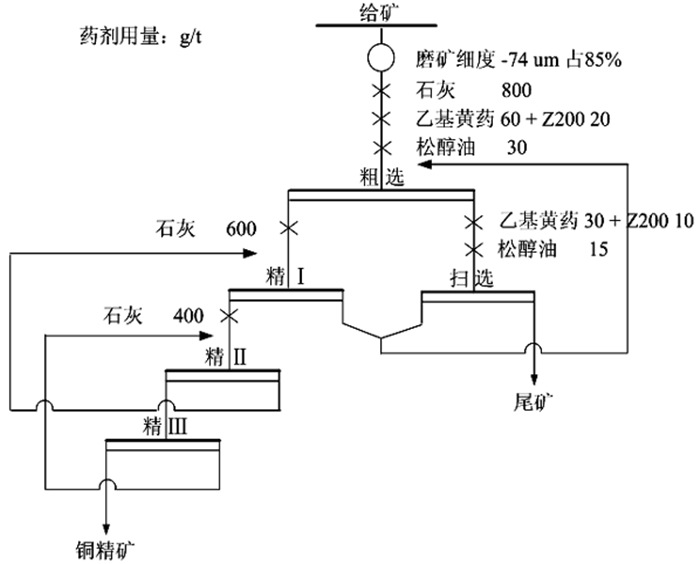

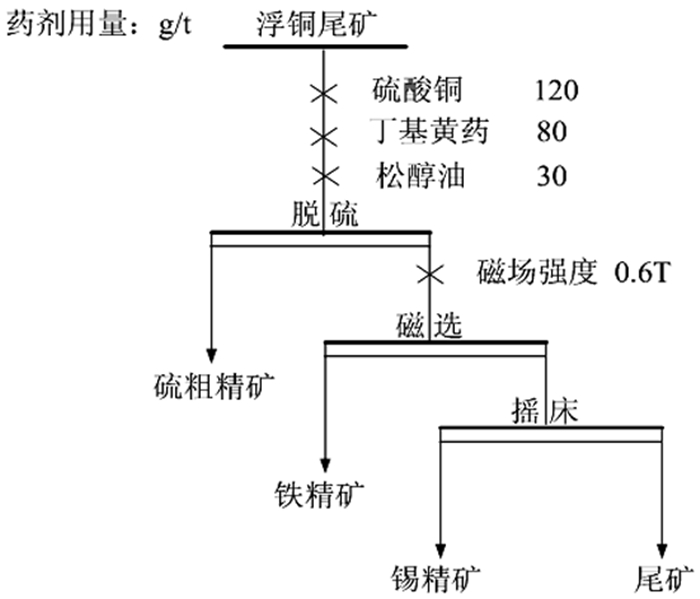

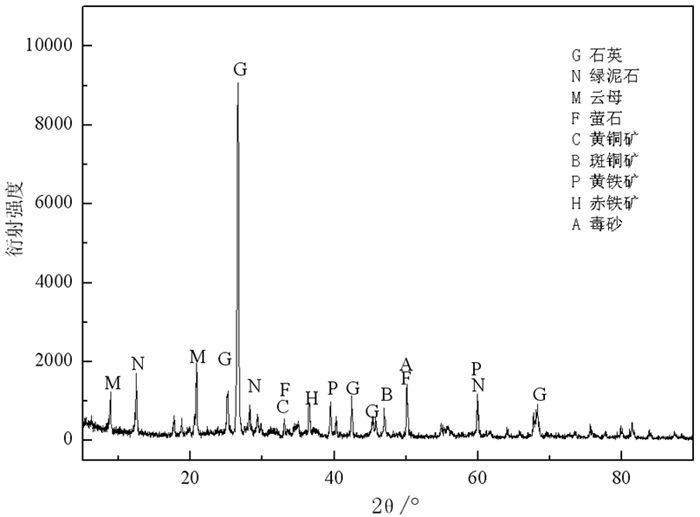

云南某含铜多金属锡矿石中含铜0.79%、银38 g/t、铟43.6 g/t和锡0.56%,其主要矿物有黄铜矿、黄铁矿、斑铜矿和锡石。根据矿样性质,对其进行试验研究,最终确定采用优先浮铜—浮选脱硫—磁选除铁—重选选锡的联合工艺流程。结果表明:浮铜工艺可获得含铜21.98%、银694.5 g/t、铟265.17 g/t,回收率分别为93.14%、65.76%和19.31%的铜精矿。浮锡工艺可获得含锡35.58%、铟465.24 g/t,回收率分别为77.42%和46.52%的锡精矿,实现了铜、银、铟和锡的综合回收利用。

Abstract:A tin-copper-bearing polymetal tin ore in Yunnan contains 0.79% of copper, 38 g/t of silver, 43.6 g/t of indium, and 0.56% of tin. Its main minerals are chalcopyrite, pyrite, bornite and cassiterite. According to the properties of ore samples, the exploration and experimental study were carried out. The combined process of copper floatation-desulfurization flotation-magnetic separation iron removal-gravity tin separation was finally determined. The results show that the copper float process can obtain copper concentrates containing 21.98% copper, 694.5 g/t silver, and 265.17 g/t indium, and recovery rates of 92.92%, 66.2%, and 19.62%, respectively. The gravity separation can obtain tin concentrates containing 35.58% tin and 465.24 g/t indium, and the recovery rates of 77.42% and 46.52%, respectively, which realizes the comprehensive recycling of copper, silver, indium and tin.

-

Key words:

- copper /

- tin /

- indium /

- flotation /

- gravity separation /

- comprehensive utilization

-

-

表 1 矿样多元素分析结果

Table 1. Multi-element analysis results of ore samples

/% 元素 Cu SiO2 Ag* S Zn In* MgO CaO Fe As Sn 含量 0.79 54.2 38.0 2.65 0.318 43.6 2.19 5.80 7.80 1.34 0.55 注:“*”单位为g/t。 表 2 铜矿中的铜物相分析结果

Table 2. Phase analysis results of copper in copper ore

/% 名称 胆矾 游离氧化铜 结合氧化铜 硫化铜 总铜 含量 0.0049 0.0049 0.032 0.74 0.782 分布率 0.63 0.63 4.10 94.64 100 表 3 浮选闭路试验结果

Table 3. Flotation closed circuit test results

产品名称 产率/% 品位/% 回收率/% Cu Ag* In* As S Cu Ag* In* As S 铜精矿 3.27 21.98 694.50 265.11 0.79 28.2 93.14 65.76 19.31 1.93 34.8 尾矿 96.73 0.05 12.21 37.40 1.36 1.79 6.86 34.24 80.69 98.07 65.2 原矿 100 0.77 34.50 44.84 1.34 2.65 100.00 100.00 100.00 100.00 100.00 表 4 浮铜尾矿选锡试验结果

Table 4. Test results of tin beneficiation from floating copper tailings

名称 产率 品位/% 回收率/% Sn S In* Sn S In 硫粗精矿 8.40 0.22 17.80 66.35 2.44 83.53 30.96 铁精矿 7.36 0.25 2.19 20.54 2.46 9.00 8.40 锡精矿 1.80 35.58 1.05 465.24 84.27 1.06 46.52 尾矿 82.44 0.10 0.14 3.08 10.83 6.41 14.11 给矿 100.00 0.76 1.79 18.00 100.00 100.00 100.00 -

[1] 张惠芬, 陈文平, 曾文, 等. 某锡铜矿选矿工艺试验研究[J]. 中国矿业, 2015(7): 108-112. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGKA201507025.htm

[2] 袁帅, 刘杰, 李艳军, 等. 内蒙古某铜锡硫化矿石选矿试验[J]. 金属矿山, 2016(2): 87-90. https://www.cnki.com.cn/Article/CJFDTOTAL-JSKS201602018.htm

[3] 仇云华, 黄勇彬, 张慧, 等. 云南某低品位难选锡铜多金属矿选矿工艺试验研究[J]. 有色金属(选矿部分), 2017(6): 12-17. https://www.cnki.com.cn/Article/CJFDTOTAL-YSXK201706004.htm

[4] 朱月锋. 某低品位斑岩型铜矿选别流程对比试验研究[J]. 矿山机械, 2013(10): 97-103. https://www.cnki.com.cn/Article/CJFDTOTAL-KSJX201310027.htm

[5] 谢海云, 孙瑞, 吴继宗, 等. 铜炉渣的强化浮选试验研究[J]. 有色金属工程, 2020, 10(6): 58-64. https://www.cnki.com.cn/Article/CJFDTOTAL-YOUS202006010.htm

[6] ALTER H. The compositionand environmental hazard of copper slagsinthe context of the Basel convention[J]. Resources Conservation and Recycling, 2005, 43(4): 353-360. http://www.sciencedirect.com/science/article/pii/S0921344904001284

[7] 李杰, 钟宏, 刘广义. 硫化铜矿石浮选捕收剂的研究进展[J]. 铜业工程, 2004(4): 15-18. https://www.cnki.com.cn/Article/CJFDTOTAL-TYGC200404004.htm

-

下载:

下载: