Current Status of Rare Earth Resources in China and Progress of Extracting Technology

-

摘要:

综述了我国稀土资源概况及利用现状,针对不同类型的稀土矿资源,介绍了我国稀土冶炼技术的变革及绿色冶炼研究进展。结果表明,我国的稀土资源储量丰富、种类齐全并且出口量大,中国在世界稀土市场的地位举足轻重。随着轻、中重稀土新材料在不同领域应用情况变化,进一步加剧不同稀土元素需求不平衡的同时,推动了不同稀土矿冶炼技术绿色高效的发展,目前的冶炼技术实现了稀土资源高效利用,但仍需进一步研究绿色冶炼工艺。结合我国稀土资源日渐贫化的形势、稀土材料产业大而不强的现状及冶炼面临的环保问题,提出了未来稀土行业的发展趋势。一方面,通过稀土冶炼技术的革新,高效提取稀土资源的同时实现无氨生产及氟资源化,从源头上减少氨氮和氟的排放。另一方面通过高端稀土材料应用领域自主知识产权的建立,提升我国稀土产业核心竞争力,实现稀土产业的蓬勃发展。

Abstract:The general situation of rare earth resources and utilization status of rare earth in China are summarized. According to different types of rare earth mineral resources, the reform of rare earth smelting technology and the progress of green smelting are introduced. The results show that China not only is rich in rare earth resources but also has a large export volume, China plays an important role in the rare earth market of the world.?The changeable demand of new light and medium-heavy rare earth materials in different fields further aggravates the imbalance of demand for different rare earth elements.This situation promotes the development of green and efficient rare earth ore smelting technology. The current smelting technology can efficiently utilize the rare earth resources, however the green smelting process needs to be further studied. Chinese rare earth resources are continuously consumed and rare earth material industry in China is big but not strong enough. Smelting pollution is becoming increasingly serious. With the situation of Chinese rare earth material industry, the development trend of Chinese rare earth industry is put forward.On the one hand, developing ammonia-free smelting technology and realizing fluorine resource utilization are the directions of rare earth smelting technological innovation.On the other hand, with the establishment of independent intellectual property rights in the field of high-end rare earth material, we can enhance competitiveness of China's rare earth industry to realize the development of Chinese rare earth industry.

-

Key words:

- rare earth resources /

- utilization status /

- green metallurgy /

- developing trends

-

-

表 1 2015—2019年稀土矿年产量概况

Table 1. Annual output of rare earth from 2015 to 2019

年份 我国稀土矿年产量/万t 世界稀土矿年产量/万t 产量占比/% 2015 10.5 13 80.8 2016 10.5 12.9 81.4 2017 10.5 13 80.8 2018 12 19 63.2 2019 13.2 21 62.9 表 2 我国2016—2020年稀土矿开采指标

Table 2. 2016—2020 mining index of rare earth mines in China (t REO)

年份 2016 2017 2018 2019 2020 轻稀土 87 100 87 100 100 850 112 850 120 850 中重稀土 179 000 17 900 19 150 19 150 19 150 总计 105 000 105 000 120 000 132 000 140 000 表 3 我国2016—2020年10月稀土氧化物平均价格

Table 3. Chinese Average price of rare earth oxides in October 2016—2020(万元/t REO)

年份 2016 2017 2018 2019 2020 氧化钕 25.3 41.5 31.3 30.75 34.65 氧化镨 31.25 53 40.4 37.25 32.25 氧化铈 0.98 1.7 1.35 1.225 1.025 氧化镧 1.15 1.65 1.4 1.225 1.025 氧化钇 2.05 2.25 2.1 2.1 2.025 氧化镝 122 117 114.8 169 163.5 氧化钆 13.3 17.1 16.9 17.5 氧化铽 275 352.5 290.5 370 483.5 -

[1] BALARAM V. Rare earth elements: A review of applications, occurrence, exploration, analysis, recycling, and environmental impact[J]. Geoscience Frontiers, 2019, 10(4): 1285-1303. doi: 10.1016/j.gsf.2018.12.005

[2] 陈子瞻. "2.0时代"的汽车产业发展以及关键矿产需求展望[C]. 赣州, 2020.

[3] 张丹琳. 当前稀土资源现状与供需形势分析[J]. 国土资源情报, 2020(5): 37-41. https://www.cnki.com.cn/Article/CJFDTOTAL-GTZQ202005006.htm

[4] USGS. Mineral commodity summaries 2020[EB/OL]. (2020-01-31)[2021-01-04. ]. http://minerals.usgs.gov/.

[5] 程建忠, 侯运炳, 车丽萍. 白云鄂博矿床稀土资源的合理开发及综合利用[J]. 稀土, 2007(1): 70-74. doi: 10.3969/j.issn.1004-0277.2007.01.019

[6] 郑强. 综合回收白云鄂博弱磁尾矿中铁、稀土、氟和磷的研究[D]. 沈阳: 东北大学, 2017.

[7] 马莹, 李娜, 王其伟, 等. 白云鄂博矿稀土资源的特点及研究开发现状[J]. 中国稀土学报, 2016, 34(6): 641-649. https://www.cnki.com.cn/Article/CJFDTOTAL-XTXB201606001.htm

[8] 张臻悦, 何正艳, 徐志高, 等. 中国稀土矿稀土配分特征[J]. 稀土, 2016, 37(1): 121-127. https://www.cnki.com.cn/Article/CJFDTOTAL-XTZZ201601022.htm

[9] 原显顺. 山东微山稀土矿床的稀土矿物学研究[J]. 矿产勘查, 2019, 10(9): 2229-2242. doi: 10.3969/j.issn.1674-7801.2019.09.014

[10] 兰孝忠, 何真毅. 四川凉山地区稀土开发利用前景与可供性研究[J]. 四川地质学报, 2013, 33(2): 166-168. doi: 10.3969/j.issn.1006-0995.2013.02.010

[11] 肖燕飞, 黄小卫, 冯宗玉, 等. 离子吸附型稀土矿绿色提取技术研究进展[J]. 稀土, 2015, 36(3): 109-115. https://www.cnki.com.cn/Article/CJFDTOTAL-XTZZ201503026.htm

[12] 池汝安, 刘雪梅. 风化壳淋积型稀土矿开发的现状及展望[J]. 中国稀土学报, 2019, 37(2): 129-140. https://www.cnki.com.cn/Article/CJFDTOTAL-XTXB201902001.htm

[13] 吉力强, 陈明昕, 顾虎, 等. 轻稀土资源现状及在新能源汽车领域的应用[J]. 中国稀土学报, 2020, 38(2): 129-138. https://www.cnki.com.cn/Article/CJFDTOTAL-XTXB202002001.htm

[14] 张福良, 李雨潼, 李晓宇. 国内外稀土资源开发利用现状及新时期我国稀土管理建议[J]. 现代矿业, 2018, 34(12): 11-14+20. doi: 10.3969/j.issn.1674-6082.2018.12.003

[15] 王行, 王锡树, 王雨芹, 等. 稀土功能材料的应用与展望[J]. 上海师范大学学报(自然科学版), 2017, 46(6): 789-794. doi: 10.3969/J.ISSN.1000-5137.2017.06.003

[16] 都有为. 磁性材料新近进展[J]. 物理, 2006(9): 730-739. doi: 10.3321/j.issn:0379-4148.2006.09.006

[17] 张帆, 谌凯. 钕铁硼永磁材料专利技术发展态势分析[J]. 有色金属科学与工程, 2020, 11(3): 115-120. https://www.cnki.com.cn/Article/CJFDTOTAL-JXYS202003016.htm

[18] COEY J M D. Perspective and Prospects for Rare Earth Permanent Magnets[J]. Engineering, 2020, 6(2): 119-131. doi: 10.1016/j.eng.2018.11.034

[19] 薛秉国, 吕清洋, 王婷婷, 等. 钆铝石榴石(GdAG)基发光材料研究进展[J]. 发光学报, 2020, 41(12): 1538-1553. doi: 10.37188/CJL.20200237

[20] LIU G, WANG F G, GUAN X N, et al. Geometric and optical properties of Bi/Er co-doped silica optical fiber[J]. Optical Materials, 2020(107): 110030. http://www.sciencedirect.com/science/article/pii/S0925346720303748

[21] ZHOU Z G, LI J H, BAO X Q, et al. Improvement of bending strength via introduced (Dy, Tb)Cu phase at grain boundary on giant magnetostrictive Tb-Dy-Fe alloy by diffusing Dy-Cu alloys[J]. Journal of Alloys and Compounds, 2020(826): 153959. http://www.researchgate.net/publication/338755669_Improvement_of_bending_strength_via_introduced_DyTbCu_phase_at_grain_boundary_on_giant_magnetostrictive_Tb-Dy-Fe_alloy_by_diffusing_Dy-Cu_alloys

[22] 张学亮, 倪明, 孟洲, 等. 基于铽镝铁换能器的全保偏光纤磁场传感系统[J]. 国防科技大学学报, 2005(3): 30-33. doi: 10.3969/j.issn.1001-2486.2005.03.007

[23] YANG J B, HAN J Z, TIAN H D, et al. Structural and Magnetic Properties of Nanocomposite Nd-Fe-B Prepared by Rapid Thermal Processing[J]. Engineering, 2020, 6(2): 132-140. doi: 10.1016/j.eng.2019.12.008

[24] 戚尧, 李全安, 陈晓亚, 等. Ho在镁合金中的应用及其研究进展[J]. 稀土, 2020, 41(6): 89-96. https://www.cnki.com.cn/Article/CJFDTOTAL-CGGL201711010.htm

[25] LABIB F, FUJITA N, OHHASHI S, et al. Icosahedral quasicrystals and their cubic approximants in the Cd-Mg-RE (RE?=Y, Sm, Gd, Tb, Dy, Ho, Er, Tm) systems[J]. Journal of Alloys and Compounds, 2020(822): 153541. http://arxiv.org/abs/2005.10471v1

[26] LIU J A, YANG M L, ZHANG X R, et al. Effects of Ho content on microstructures and mechanical properties of Mg-Ho-Zn alloys[J]. Materials Characterization, 2019(149): 198-205. http://www.sciencedirect.com/science/article/pii/S1044580318324823

[27] ZHU Z J, PELTON A D. Thermodynamic modeling of the Y-Mg-Zn, Gd-Mg-Zn, Tb-Mg-Zn, Dy-Mg-Zn, Ho-Mg-Zn, Er-Mg-Zn, Tm-Mg-Zn and Lu-Mg-Zn systems[J]. Journal of Alloys and Compounds, 2015(652): 426-443. http://www.sciencedirect.com/science/article/pii/S0925838815309105

[28] 霍知节. "揭秘"稀土超导材料[J]. 新材料产业, 2019(12): 65-71. https://www.cnki.com.cn/Article/CJFDTOTAL-XCLY201912016.htm

[29] 蒋朱敏, 王晨琳, 李载鹏, 等. VVER-1000反应堆控制棒延寿中子物理学论证分析[J]. 科技创新导报, 2019, 16(4): 105-108. https://www.cnki.com.cn/Article/CJFDTOTAL-ZXDB201904060.htm

[30] 张博, 宁阳坤, 曹飞, 等. 世界稀土资源现状[J]. 矿产综合利用, 2018(4): 7-12. doi: 10.3969/j.issn.1000-6532.2018.04.002

[31] 2019年中国稀土行业协会工作报告[J]. 稀土信息, 2020(10): 10-18.

[32] 陈昆峰, 胡家乐, 张一波, 等. 稀土晶体材料研发现状与未来展望[J]. 无机盐工业, 2020, 52(3): 11-16. https://www.cnki.com.cn/Article/CJFDTOTAL-WJYG202003003.htm

[33] 帅庚洪. 氟碳铈矿氧化焙烧-盐酸浸出过程反应机理研究[D]. 北京有色金属研究总院, 2017.

[34] CEN P, WU W Y, BIAN X. Thermodynamic Mechanism Analysis of Calcification Roasting Process of Bastnaesite Concentrates[J]. Met allurgical and Materials Transactions B-Process Met allurgy and Materials Processing Science, 2017, 48(3): 1539-1546. doi: 10.1007/s11663-017-0951-7

[35] WANG L S, WANG C M, YU Y, et al. Recovery of fluorine from bastnasite as synthetic cryolite by-product[J]. Journal of Hazardous Materials, 2012(209-210): 77-83. http://europepmc.org/abstract/MED/22281026

[36] ZUO Y, LIU Y, CHEN J, et al. Extraction and recovery of cerium(Ⅳ) along with fluorine(Ⅰ) from bastnasite leaching liquor by DEHEHP in C(8)mim PF6[J]. Journal of Chemical Technology and Biotechnology, 2009, 84(7): 949-956. doi: 10.1002/jctb.2116

[37] 黄小卫, 李红卫, 龙志奇, 等. 一种富铁独居石稀土矿的冶炼方法: CN101363079[P]. 2009-02-11.

[38] 肖勇, 陈月华. 独居石与独居石渣利用研究进展[J]. 稀土, 2016, 37(4): 129-135. https://www.cnki.com.cn/Article/CJFDTOTAL-XTZZ201604024.htm

[39] 车丽萍, 余永富. 我国稀土矿选矿生产现状及选矿技术发展[J]. 稀土, 2006(1): 95-102. https://www.cnki.com.cn/Article/CJFDTOTAL-XTZZ200601027.htm

[40] 朱智慧, 杨占峰, 王其伟, 等. 白云鄂博稀土精矿工艺矿物学研究[J]. 有色金属(选矿部分), 2019(6): 1-4+22. https://www.cnki.com.cn/Article/CJFDTOTAL-YSXK201906001.htm

[41] 胡轶文, 王丽明, 曹钊, 等. 我国稀土资源冶炼分离技术研究进展[J]. 矿产保护与利用, 2020, 40(2): 151-161. http://kcbh.cbpt.cnki.net/WKD/WebPublication/paperDigest.aspx?paperID=62d9e2fc-37b2-426d-ae58-a32aa05143ad

[42] 杜长顺, 李梅, 柳召刚, 等. 包头稀土精矿处理现状及建议[J]. 湿法冶金, 2010, 29(1): 1-4+28. https://www.cnki.com.cn/Article/CJFDTOTAL-SFYJ201001002.htm

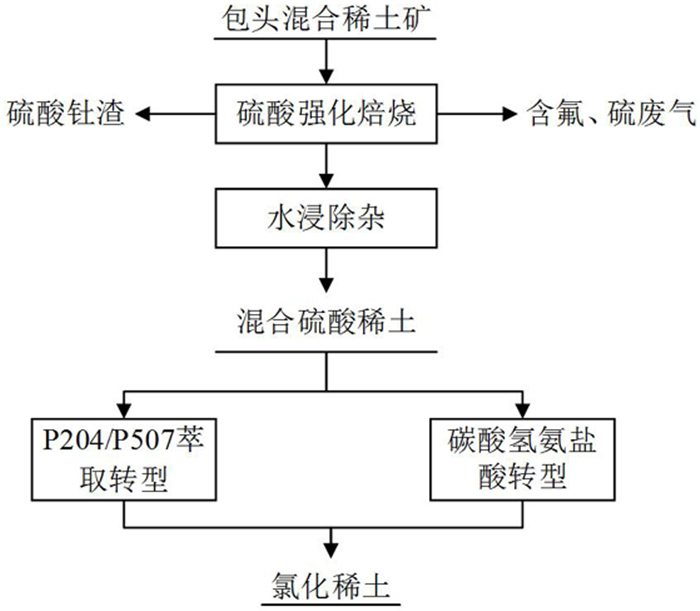

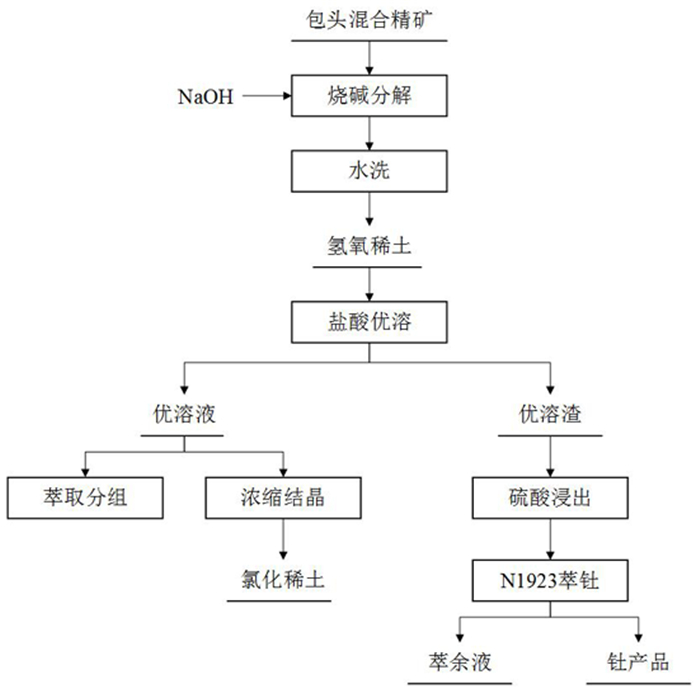

[43] 王猛, 黄小卫, 冯宗玉, 等. 包头混合型稀土矿冶炼分离过程的绿色工艺进展及趋势[J]. 稀有金属, 2019, 43(11): 1131-1141. https://www.cnki.com.cn/Article/CJFDTOTAL-ZXJS201911002.htm

[44] 黄小卫, 李红卫, 龙志奇, 等. 一种非皂化有机相萃取稀土全分离工艺: CN1824814[P]. 2006-08-30.

[45] 黄小卫, 李红卫, 龙志奇, 等. 一种有机萃取剂的预萃取方法、产品及其应用: CN101319276[P]. 2008-12-10.

[46] FENG Z Y, HUANG X W, LIU H J, et al. Study on preparation and application of novel saponification agent for organic phase of rare earths extraction[J]. Journal of Rare Earths, 2012, 30(9): 903-908. http://www.sciencedirect.com/science/article/pii/S1002072112601525

[47] YU Z H, WANG M, WANG L S, et al. Preparation of crystalline mixed rare earth carbonates by Mg(HCO3)2 precipitation method[J]. Journal of Rare Earths, 2020, 38(3): 292-298. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=zgxtxb-e202003010

[48] 黄小卫, 冯宗玉, 徐旸, 等. 稀土矿的冶炼分离方法: CN106282553A[P]. 2017-01-04.

[49] 马莹, 许延辉, 常叔, 等. 包头稀土精矿浓硫酸低温焙烧工艺技术研究[J]. 稀土, 2010, 31(2): 20-23. https://www.cnki.com.cn/Article/CJFDTOTAL-XTZZ201002008.htm

[50] 许延辉. 白云鄂博稀土矿清洁冶金现状及研究进展[J]. 稀土信息, 2015(11): 10-13. https://www.cnki.com.cn/Article/CJFDTOTAL-XTXX201511013.htm

[51] 韩学印, 李良才, 常叔, 等. 浓NaOH溶液分解稀土矿物的研究[J]. 稀土, 1985(3): 39-44. https://www.cnki.com.cn/Article/CJFDTOTAL-XTZZ198503009.htm

[52] 虞宝煜. 工频电场下烧碱法分解稀土精矿机理的研究[J]. 中国稀土学报, 1993(3): 218-221. https://www.cnki.com.cn/Article/CJFDTOTAL-XTXB199303005.htm

[53] MOLDOVEANU G A, PAPANGELAKIS V G. Recovery of rare earth elements adsorbed on clay minerals: I. Desorption mechanism[J]. Hydrometallurgy, 2012(117): 71-78. http://www.sciencedirect.com/science/article/pii/S0304386X12000345

[54] TIAN J, YIN J Q, CHI R A, et al. Kinetics on leaching rare earth from the weathered crust elution-deposited rare earth ores with ammonium sulfate solution[J]. Hydrometallurgy, 2010, 101(3-4): 166-170. http://www.sciencedirect.com/science/article/pii/S0304386X10000046

[55] 许秋华. 离子吸附型稀土分异及高效浸取的基础研究[D]. 南昌大学, 2018.

[56] 刘凯, 邓祥义, 左小华. 风化壳淋积型稀土矿浸取工艺及其发展趋势[J]. 湖北理工学院学报, 2013, 29(2): 32-36. https://www.cnki.com.cn/Article/CJFDTOTAL-HSGD201302010.htm

[57] XIAO Y F, FENG Z Y, HU G H, et al. Reduction leaching of rare earth from ion-adsorption type rare earths ore with ferrous sulfate[J]. Journal of Rare Earths, 2016, 34(9): 917-923.

[58] LAI F G, GAO G H, HUANG L, et al. Compound leaching of rare earth from the ion-adsorption type rare earth ore with magnesium sulfate and ascorbic acid[J]. Hydrometallurgy, 2018(179): 25-35. http://www.sciencedirect.com/science/article/pii/S0304386X17308770

[59] 吕广文, 顾庆和, 胡海兵, 等. 离子型稀土矿原地浸取工艺: CN1048564[P]. 1991-01-16.

[60] 史晓燕, 陈宏文. 废弃池浸堆浸离子型稀土矿污染途径及其修复研究[J]. 中国稀土学报, 2019, 37(4): 409-417. https://www.cnki.com.cn/Article/CJFDTOTAL-XTXB201904003.htm

[61] XIAO Y F, FENG Z Y, HUANG X W, et al. Recovery of rare earths from weathered crust elution-deposited rare earth ore without ammonia-nitrogen pollution: I. leaching with magnesium sulfate[J]. Hydrometallurgy, 2015(153): 58-65. http://www.sciencedirect.com/science/article/pii/S0304386X15000377

[62] XIAO Y F, CHEN Y Y, FENG Z Y, et al. Leaching characteristics of ion-adsorption type rare earths ore with magnesium sulfate[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(11): 3784-3790. http://www.sciencedirect.com/science/article/pii/s1003632615640225

[63] 黄小卫, 于瀛, 冯宗玉, 等. 一种从离子型稀土原矿回收稀土的方法: CN102190325A[P]. 2011-09-21.

[64] XIAO Y F, GAO G H, HUANG L, et al. A discussion on the leaching process of the ion-adsorption type rare earth ore with the electrical double layer model[J]. Minerals Engineering, 2018(120): 35-43. http://www.sciencedirect.com/science/article/pii/S0892687518300876

[65] 冯宗玉, 黄小卫, 王猛, 等. 典型稀土资源提取分离过程的绿色化学进展及趋势[J]. 稀有金属, 2017, 41(5): 604-612. https://www.cnki.com.cn/Article/CJFDTOTAL-ZXJS201705012.htm

[66] 胡智, 张臻悦, 池汝安, 等. 复合镁盐浸取风化壳淋积型稀土矿过程强化研究[J]. 金属矿山, 2020(3): 95-101. https://www.cnki.com.cn/Article/CJFDTOTAL-JSKS202003015.htm

[67] 陈茂生, 华建荣, 焦芸芬, 等. 离子型稀土矿的稀土原地浸出及富集工艺: CN106636683A[P]. 2017-05-10.

[68] 肖燕飞, 黄莉, 赖安邦, 等. 一种从离子吸附型稀土矿中高效清洁提取稀土的方法: CN109097565B[P]. 2019-11-01.

[69] LAI A B, LAI F G, HUANG L, et al. Non-ammonia enrichment of rare earth elements from rare earth leaching liquor in a magnesium salt system Ⅰ: Precipitation by calcium oxide[J]. Hydrometallurgy, 2020(193): 105318. http://www.sciencedirect.com/science/article/pii/S0304386X19309636

-

下载:

下载: