Investigation of New Floating Box Paste Backfill Roof contact Technology in Underground Mines

-

摘要:

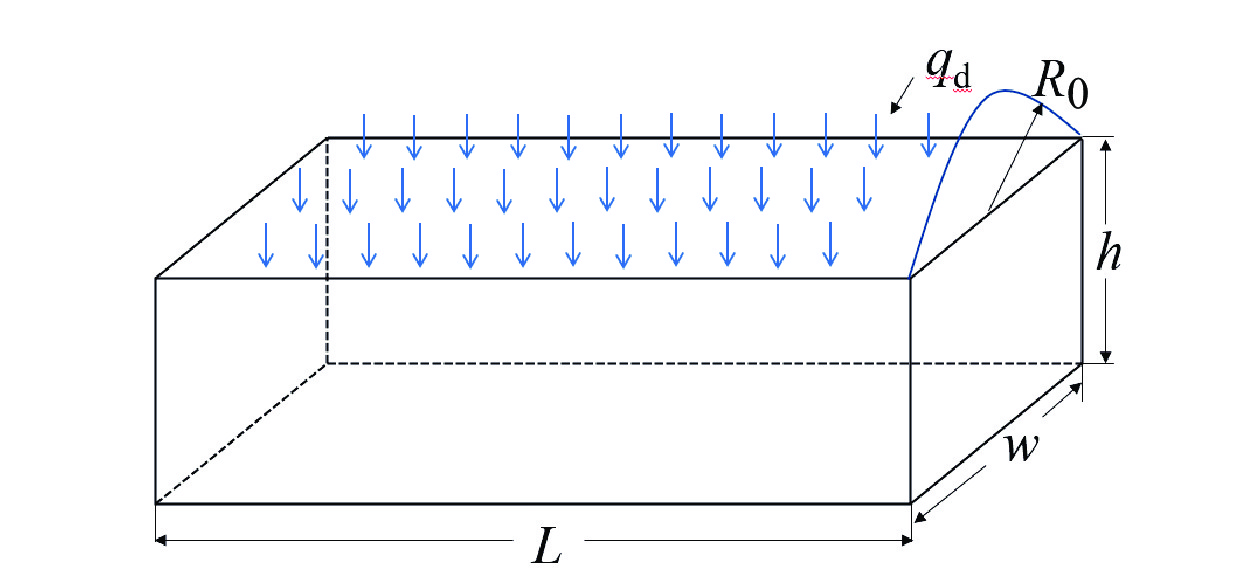

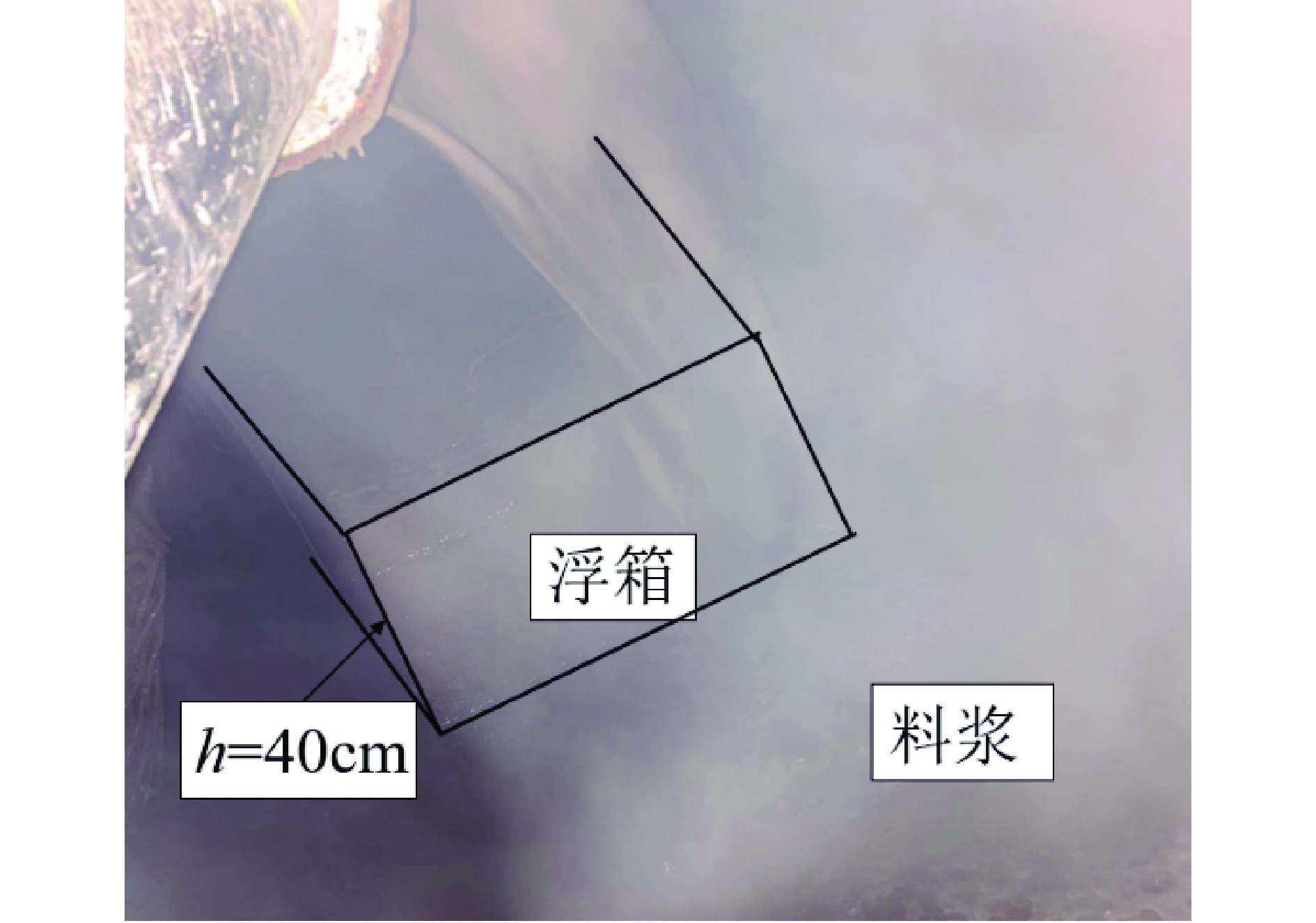

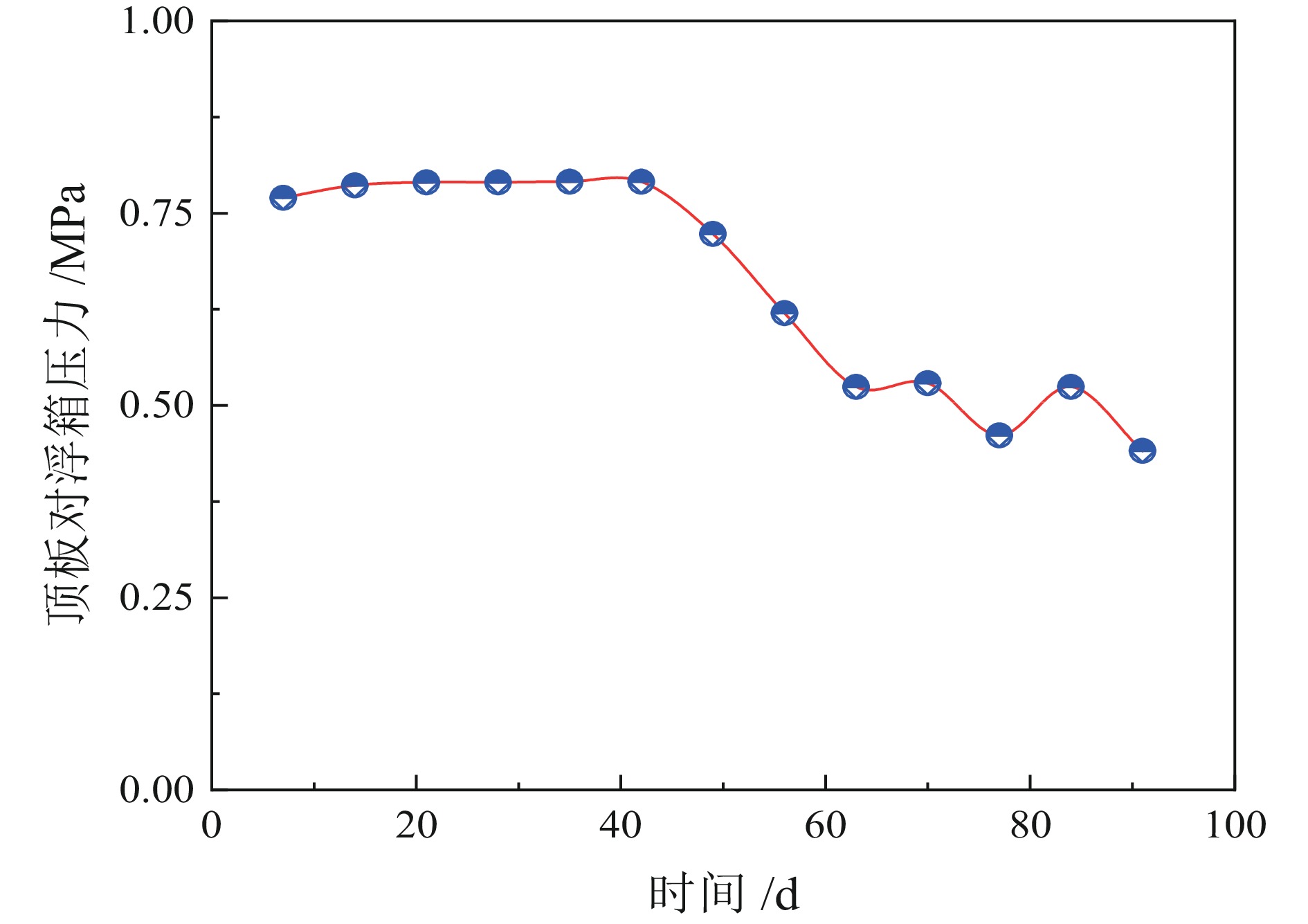

膏体充填后充填体存在一定下沉量和自流坡度角,导致充填接顶效果不佳的问题。为了提升窄长形下向进路式采场的充填接顶效果,避免顶板暴露面积过大而失稳,提出浮箱式点柱接顶技术。分析了浮箱式点柱的承载机理,量化了浮箱尺寸、强度和排间距计算方法。开展现场实验,探究浮箱在高黏度料浆中能否浮起问题。结合该技术在云南某铅锌矿的应用实例,验证了本文提出的设计方法和接顶技术的有效性。结果表明:浮箱可在高黏度料浆中浮起,且部分凸出充填体,对顶板形成有效支撑。采用该技术的实验采场顶板对充填体浮箱的压力约为0.65 MPa。采用浮箱式点柱接顶技术可以形成充填体−浮箱式点柱共同支护体系,提升顶板稳定性,具有显著的安全效益。

Abstract:The issue of the filling body exhibiting a certain degree of subsidence and self−flow slope angle following paste filling, which results in a suboptimal filling effect, must be addressed. In order to enhance the filling and roof−contacting efficacy of narrow and long downward drift stope and circumvent the instability associated with an excessively large exposed area of roof, a floating box−type point pillar roof−contacting technology was proposed. The bearing mechanism of floating box−type point columns was analyzed, and the calculation methods of floating box size, strength, and spacing were quantified. A series of field experiments were conducted to ascertain whether the floating box could float in a high viscosity slurry. The efficacy of the proposed design method and roof connection technology was validated through a case study of their application in a lead−zinc mine in Yunnan. The results demonstrated that the floating box can float in the high viscosity slurry and partially protrudes the filling body, thereby providing an effective support for the roof. The pressure exerted by the roof of the test stope on the floating box of the filling body was approximately 0.6 MPa. The utilization of floating box−type point−column roof−contacting technology enabled the formation of a joint support system comprising the filling body and floating box−type point−column. This configuration enhanced the stability of the roof, offering substantial safety benefits.

-

Key words:

- drift fill stoping method /

- roof−contacted filling /

- buoyant box /

- industrial test

-

-

表 1 实验采场顶板充填体力学参数

Table 1. Mechanical parameters of roof filling body in test stope

项目 平均

密度

/(g·cm−³)原位抗

压强度

/MPa抗压

强度

/MPa抗拉

强度

/MPa弹性

模量

/GPa泊松比 数值 1.66 7.70 5.5 0.43 1.51 0.14 -

[1] 吴爱祥, 杨莹, 程海勇, 等. 中国膏体技术发展现状与趋势[J]. 工程科学学报, 2018, 40(5): 517−525.

WU A X, YANG Y, CHEN H Y, et al. Status and prospects of paste technology in China[J]. Chinese Journal of Engineering, 2018, 40(5): 517−525.

[2] 尹升华, 吴爱祥. 缓倾斜中厚矿体采矿方法现状及发展趋势[J]. 金属矿山, 2007(12): 10−13. doi: 10.3321/j.issn:1001-1250.2007.12.002

YIN S H, WU A X. Status quo of mining methods for gently inclined medium−thick orebodies and their development trend[J]. Metal Mine, 2007(12): 10−13. doi: 10.3321/j.issn:1001-1250.2007.12.002

[3] 邵亚建. 采场内膏体料浆流动特性及充填接顶技术研究[D]. 北京: 北京科技大学, 2021.

SHAO Y J. Study on flow characteristics of paste slurry and filling roof technology in stope[D]. Beijing: Beijing University of Science and Technology, 2021.

[4] 刘福春, 白龙剑, 严庆文, 等. 充填采场内膏体流动规律及接顶率预测模型[J]. 有色金属(矿山部分), 2023, 75(3): 124−130+136.

LIU F C, BAI L J, YAN Q W, et al. Flow law of paste in filling stope and prediction model of roof rate[J]. Non−ferrous Metals, 2023, 75(3): 124−130+136.

[5] 吴爱祥, 王勇, 王洪江. 膏体充填技术现状及趋势[J]. 金属矿山, 2016(7): 1−9.

WU A X, WANG Y, WANG H J. Present situation and trend of paste filling technology[J]. Metal Mine, 2016(7): 1−9.

[6] 张爱卿, 吴爱祥, 王贻明, 等. 分段胶结充填法非胶结充填体顶水高度的力学模型[J]. 中国有色金属学报, 2021, 31(6): 1686−1693.

ZHANG A Q, WU A X, WANG Y M, et al. Mechanical model of top water height of non−cemented filling body in segmented cemented filling method[J]. Transactions of Nonferrous Metals Society of China, 2021, 31(6): 1686−1693.

[7] 朱磊, 宋天奇, 古文哲, 等. 矸石浆体输送阻力特性及采空区流动规律试验研究[J]. 煤炭学报, 2022, 47(S1): 39−48.

ZHU L, SONG T Q, GU W Z, et al. Experimental study on transportation resistance characteristics of gangue slurry and flow law of goaf[J]. Journal of China Coal Society, 2022, 47(S1): 39−48.

[8] LIM D K, CHOI M S. Shrinkage and crack characteristics of filling materials under restrain stress in prefabricated structure connection[J]. Construction and Building Materials, 2021, 309(11): 125188.

[9] 肖军. Mathews稳定图法在确定矿山采场暴露面积中的应用[J]. 新疆有色金属, 2013, 36(2): 19−20.

XIAO J. The application of mathews stability diagram method in determining the exposed area of mine stope[J]. Xinjiang Non−ferrous Metals, 2013, 36(2): 19−20.

[10] 马志浩. 膨胀性全尾砂充填材料性能试验研究[J]. 矿业工程, 2022, 20(2): 22−26.

MA Z H. Experimental study on the performance of expansive full tailings filling material[J]. Mineral Engineering, 2022, 20(2): 22−26.

[11] 白龙剑, 严国超, 杨涛. 氟石膏改性高水粉煤灰复合充填材料性能研究[J]. 矿业安全与环保, 2020, 47(6): 32−36.

BAI L J, YAN G C, YANG T. Study on properties of fluorine gypsum modified high water fly ash composite filling material[J]. Mining Safety and Environmental Protection, 2020, 47(6): 32−36.

[12] 程文文. 等量分流技术在上向进路充填接顶中的应用[J]. 黄金, 2018, 39(3): 40−43.

CHENG W W. The application of equivalent diversion technology in the upward drift filling roof[J]. Gold, 2018, 39(3): 40−43.

[13] 王梓安. 进路式充填采矿法充填接顶技术要点及有效应用[J]. 内蒙古煤炭经济, 2021(15): 122−123. doi: 10.3969/j.issn.1008-0155.2021.15.060

WANG Z A. Key points and effective application of filling and roofing technology of drift filling mining method[J]. Coal Economy in Inner Mongolia, 2021(15): 122−123. doi: 10.3969/j.issn.1008-0155.2021.15.060

[14] 姜立春, 陈鹏, 吴爱祥. 基于不同充填接顶率的采空区顶板拱架自稳效应[J]. 中国有色金属学报, 2019, 29(1): 187−193.

JIANG L C, CHEN P, WU A X. Self−stabilization effect of goaf roof arch based on different filling rate[J]. Chinese Journal of Nonferrous Metals, 2019, 29(1): 187−193.

[15] 赵国彦, 周礼, 李金跃, 等. 房柱法矿柱合理尺寸设计及矿块结构参数优选[J]. 中南大学学报(自然科学版), 2014, 45(11): 3943−3948.

ZHAO G Y, ZHOU L, LI J Y, et al. Reasonable size design of room−and−pillar pillar and optimization of structural parameters of ore block[J]. Journal of Central South University (Natural Science Edition), 2014, 45(11): 3943−3948.

[16] 黄敏, KULATILAKE P H, 罗嗣海, 等. 传统矿柱安全系数计算公式优化研究[J]. 矿冶工程, 2020, 40(4): 32−37.

HUANG M, KULATILAKE P H, LUO S H, et al. Study on optimization of calculation formula of traditional pillar safety factor[J]. Mining and Metallurgy Engineering, 2020, 40(4): 32−37.

[17] 汪波, 喻勇. 关于圆形隧道卡斯特纳公式的讨论[J]. 地下空间与工程学报, 2021, 17(5): 1408−1413.

WANG B, YU Y. Discussion on Castner 's formula for circular tunnels[J]. Journal of Underground Space and Engineering, 2021, 17(5): 1408−1413.

[18] 韩森, 王卫军, 董恩远, 等. 基于支护干涉的巷道围岩蝶形塑性区控制方法研究[J]. 采矿与安全工程学报, 2023, 40(4): 743−753.

HAN S, WANG W J, DONG E Y, et al. Study on control method of butterfly plastic zone in roadway surrounding rock based on support interference[J]. Journal of Mining and Safety Engineering, 2023, 40(4): 743−753.

[19] ZHAO J S, JIANG Q, LU J F, et al. Rock fracturing observation based on microseismic monitoring and borehole imaging: In situ investigation in a large underground cavern under high geostress[J]. Tunnelling and Underground Space Technology, 2022, 126(8): 104549.

[20] PRASSETYO H S, IRNAWAN A M, SIMANGUNSONG M G, et al. New coal pillar strength formulae considering the effect of interface friction[J]. International Journal of Rock Mechanics and Mining Sciences, 2019, 123(C).

-

下载:

下载: