Optimization of Mining Method for Gently Inclined Broken Thin Vein Based on Bayes Algorithm and Numerical Simulation

-

摘要:

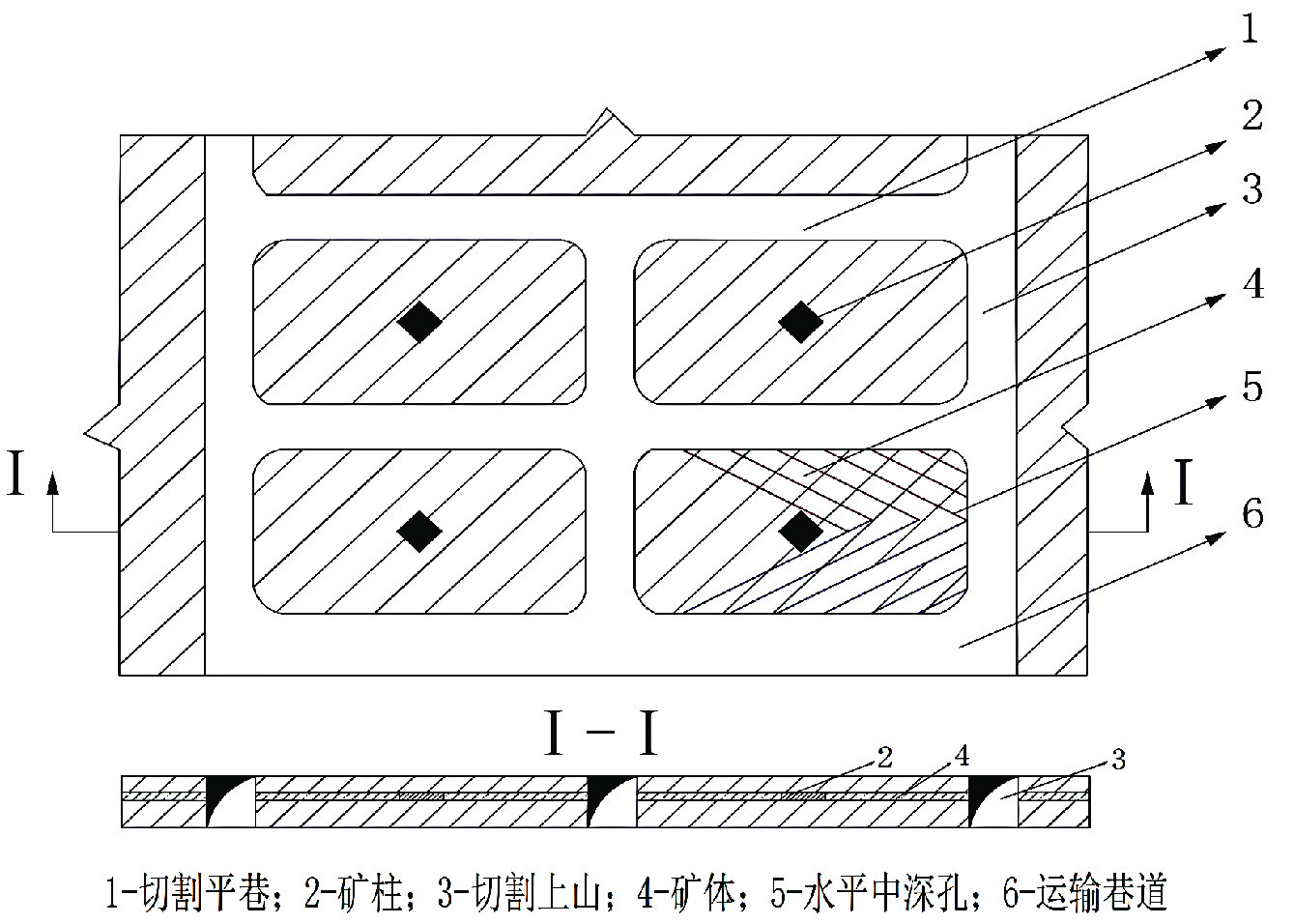

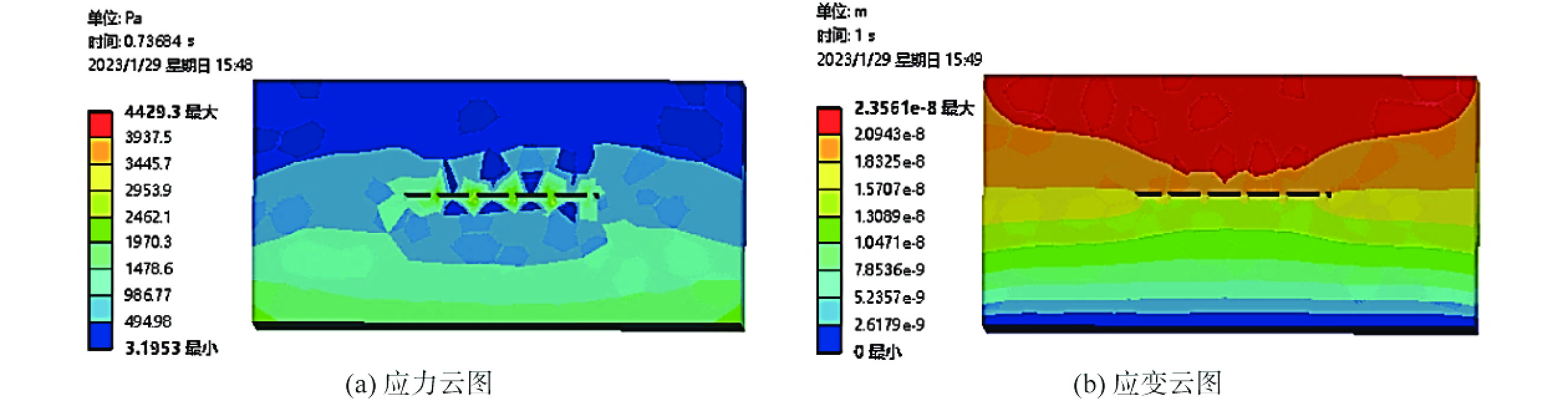

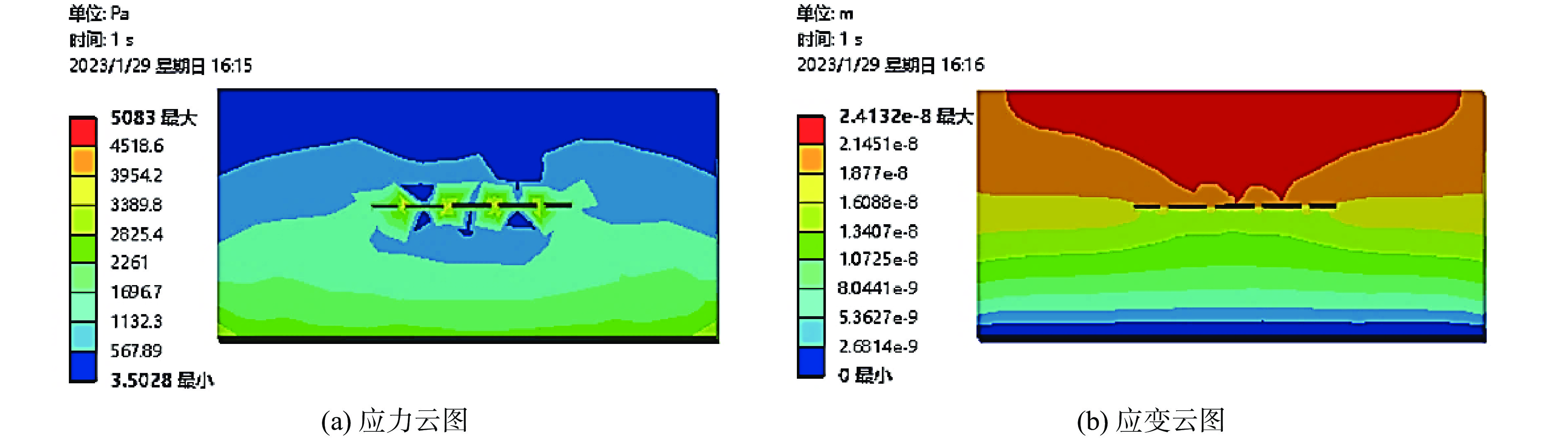

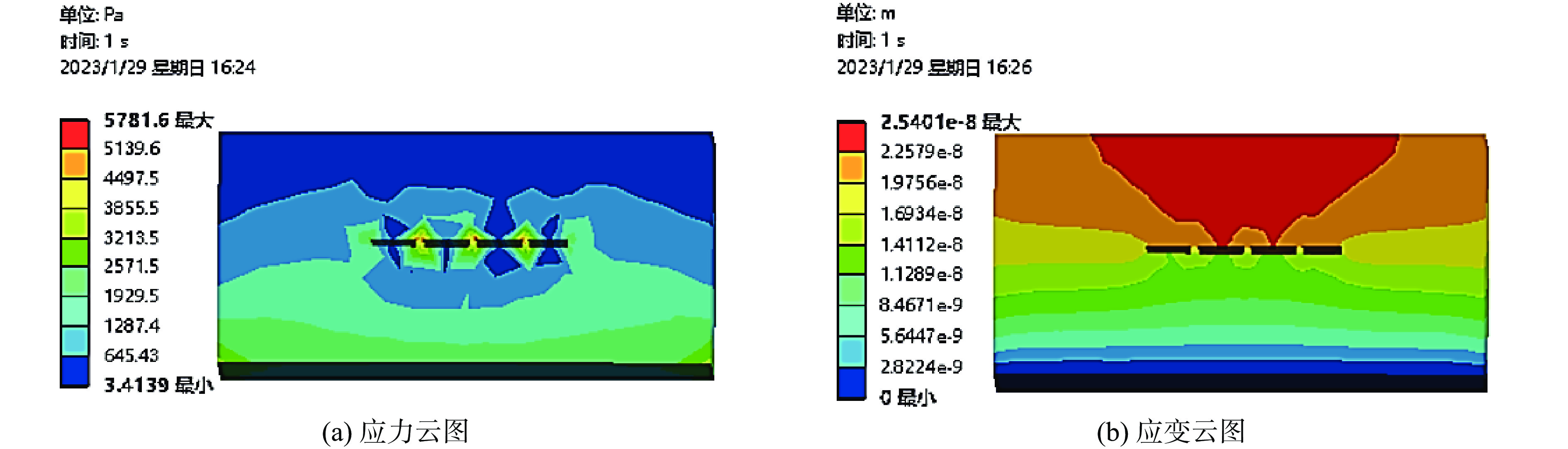

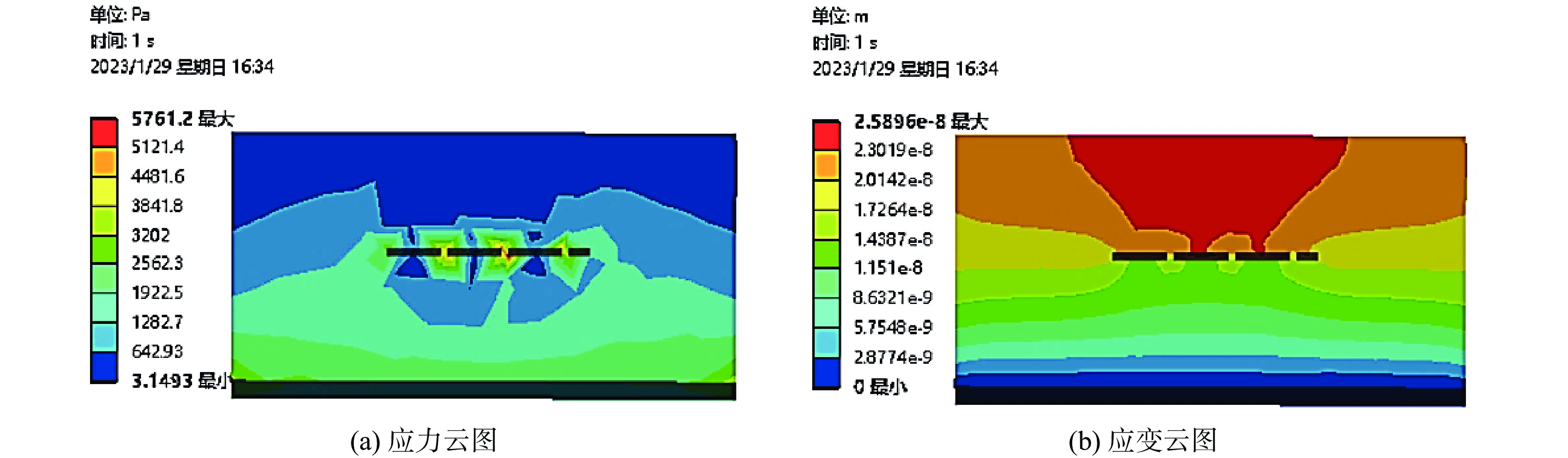

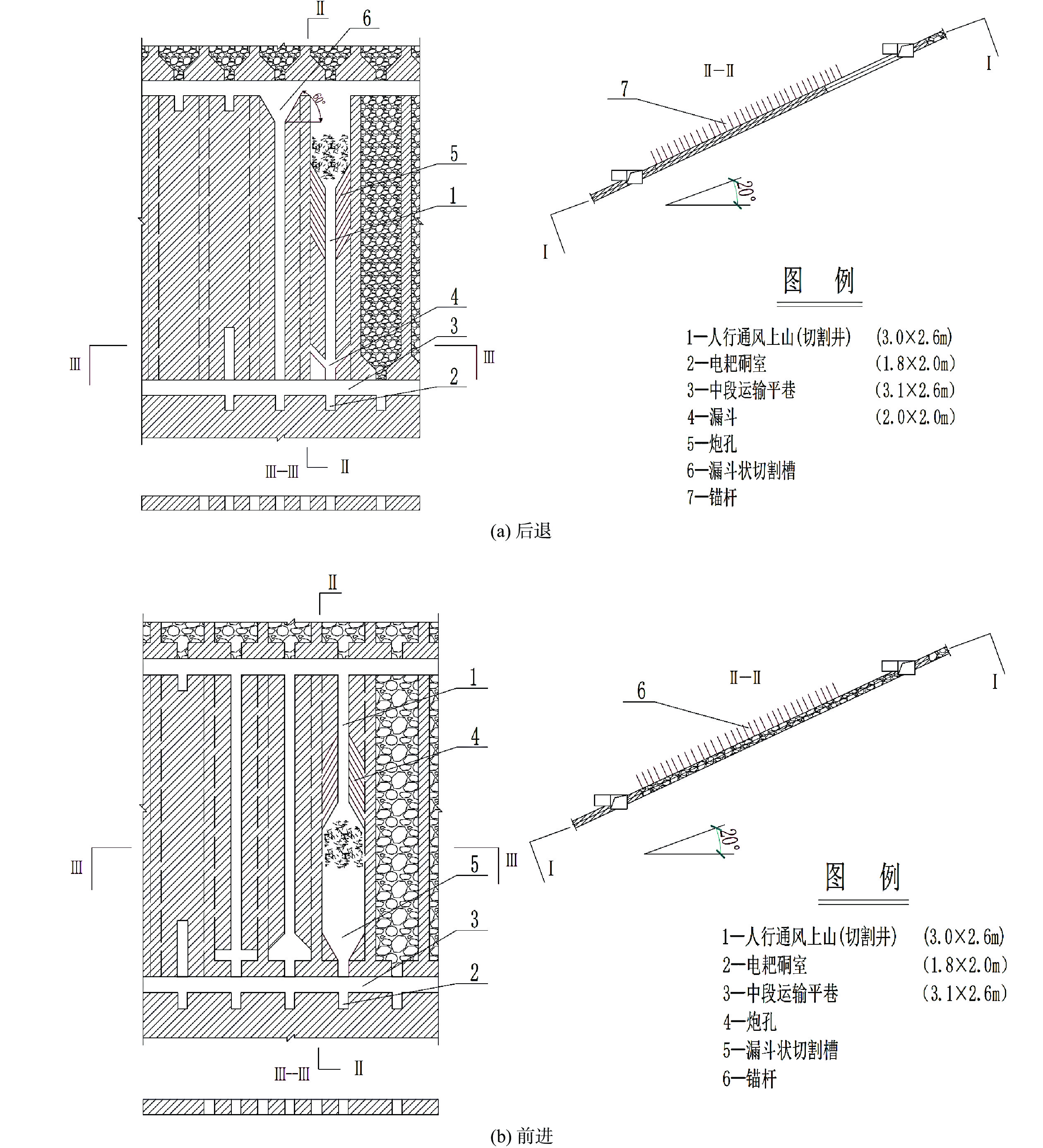

为实现某锰矿顶板破碎低品位缓倾斜薄矿体安全高效经济开采,首先根据开采条件设计出5种技术可行的采矿方法,然后基于贝叶斯(Bayes)和蒙特卡洛(Monte Carlo)方法建立涵盖技术和经济共17项评价指标的采矿方法优选体系进行采矿方法优选。研究结果表明,浅孔进路V型掏槽后退/前进采矿法、中深孔进路V型掏槽/平行抛掷采矿法和浅孔接钎头斜向掏槽采矿法的综合得分依次为0.524、0.193、0.214、0.228和0.221,浅孔进路V型掏槽后退采矿法最优。最后采用MIDAS数值模拟对优选出的采矿方法的4种不同跨度采场的稳定性进行分析,其采场跨度12 m时可在采场稳定性和矿石回收率之间取得较好平衡。综合考虑技术、经济和安全指标的采矿方法及采场结构参数优化思路,可为该矿山选出安全高效采矿方案,并可供类似矿山参考借鉴。

Abstract:To achieve safe, efficient, and economically viable mining of a manganese mine with a fractured, low−grade, gently sloping, thin ore body, five technically feasible mining methods were first designed based on the mining conditions. Subsequently, a mining method optimization was conducted, utilizing a system established on Bayes and Monte Carlo methods, encompassing 17 evaluation criteria covering both technical and economic aspects. The research findings indicated that the comprehensive scores of the shallow hole approach V−cut retreat/advance mining method, the medium−deep hole approach V−cut/parallel throw mining method, and the shallow hole drill head oblique cut mining method were 0.524, 0.193, 0.214, 0.228, and 0.221, respectively. The shallow hole approach V−cut retreat mining method was found to be the most optimal. Finally, MIDAS numerical simulation was employed to analyze the stability of four different span stops of the selected mining methods. A span of 12 meters was found to achieve a favorable balance between stope stability and ore recovery rate. Considering technical, economic, and safety indicators, the optimization approach for mining methods and stope structural parameters can assist in selecting a safe and efficient mining scheme for the mine, and can also serve as a reference for similar mines to improve their operations.

-

-

表 1 5种采矿方法技术指标

Table 1. Technical indexes of five mining methods

技术指标 代号 A1 A2 A3 A4 A5 矿块生产能力/(t·a−1)

92 92 111 144 148 采切工程量/m³

383.69 399.04 690.07 582.78 1003.18 采矿效率/(t·班−1)

5.09 5.09 6.18 8.01 8.24 采切比/(10−3m·t−1)

261 275 340 333 343 贫化率/%

6 6 8 10 10 损失率/%

24 24 12 28 6 采矿设备/万元

462 462 368 368 470 采矿成本/万元

14.15 14.15 21.3 24.6 52.4 表 2 5种采矿方法经济指标

Table 2. Economic indicators of five mining methods

序号 经济指标 A1 A2 A3 A4 A5 1 投资收益率(B1)/% 26.38 25.42 18.45 20.43 15.89 2 贷款偿还期/a 2.8 3.3 3.6 2.8 3.4 3 净利润率(B2)/% 42.53 38.56 45.86 42.73 25.31 4 投资回收期/a 3.2 3.8 4.1 3.6 4.8 5 投资利税率(B3)/% 24.81 23.62 40.31 42.51 51.83 6 净现值/万元 68571.8 54324.1 35862.4 48581.7 29431.5 7 内部收益率(B4)/% 30.18 28.43 19.83 21.75 16.21 8 自有资金内部

收益率/%37.63 30.82 25.74 32.96 25.46 9 盈亏平衡点(B5)/% 28.42 31.56 38.31 42.51 58.78 表 3 数值计算岩体强度参数表

Table 3. Numerical calculation of rock mass strength parameters table

名称 密度

/(kg·m−3)弹性模量

/GPa内摩擦角

/(°)黏聚力

/MPa泊松比 抗拉强度

/MPa矿体 2860 8.45 35.9 2.54 0.353 0.13 顶板 2450 4.61 24.2 0.93 0.312 0.11 底板 2820 9.36 38.1 4.75 0.265 0.21 -

[1] 薛田喜, 常洋凯. 中厚倾斜破碎矿体下向进路法开采工艺及稳定性研究[J]. 矿业研究与开发, 2023, 43(6): 15−21.

XUE T X, CHANG Y K. Study on mining technology and stability of downward filling mining method for medium−thick inclined broken ore body[J]. Mining Research and Development, 2023, 43(6): 15−21.

[2] 李杨, 宋卫东, 杜云龙, 等. 深部倾斜破碎金矿体高效开采技术研究[J]. 金属矿山, 2023(3): 29−35.

LI Y, SONG W D, DU Y L, et al. Study on the high−efficient mining technique for deep inclined broken gold ore−body[J]. Metal Mine, 2023(3): 29−35.

[3] 陈能飞. 倾斜薄矿体房柱采矿法的实践[J]. 中国锰业, 2021, 39(5): 26−28.

CHEN N F. A practice of room pillar mining method for inclined thin orebody[J]. China Manganese Industry, 2021, 39(5): 26−28.

[4] 刘嘉伟, 黄明清, 陈霖, 等. 缓倾斜破碎矿体集群式液压支柱护顶空场嗣后充填采矿法研究[J]. 矿业研究与开发, 2022, 42(8): 1−6.

LIU J W, HUANG M Q, CHEN L, et al. Open stoping and subsequent backfill under clustered hydraulic prop roof support for gently−Inclined broken orebody[J]. Mining Research and Development, 2022, 42(8): 1−6.

[5] 张芫涛, 林卫星, 欧任泽, 等. 深埋复杂倾斜薄矿体高效回采方案研究[J]. 矿业研究与开发, 2023, 43(10): 1−5.

ZHANG Y T, LIN W X, OU R Z, et al. Research on efficient mining scheme for deep buried complex inclined thin orebody[J]. Mining Research and Development, 2023, 43(10): 1−5.

[6] 林友, 尤本勇, 董继德, 等. 观天厂铜矿倾斜薄矿体开采工艺研究[J]. 金属矿山, 2018(2): 46−49.

LIN Y, YOU B Y, DONG J D, et al. Study on mining technology of inclined thin orebody in Guantianchang copper mine[J]. Metal Mine, 2018(2): 46−49.

[7] 张东杰, 拓明轩, 刘树新, 等. 急倾斜中厚破碎矿体空场嗣后充填安全开采技术研究[J]. 金属矿山, 2022(5): 50−55.

ZHANG D J, TUO M X, LIU S X, et al. Study on safe mining technology of open stoping with subsequent filling in steeply inclined medium−thick broken orebody[J]. Metal Mine, 2022(5): 50−55.

[8] 陈焰苗, 罗来和, 付毅, 等. 缓倾斜薄矿体群壁式空场嗣后充填采矿法试验[J]. 矿业研究与开发, 2019, 39(6): 22−25.

CHEN Y M, LUO L H, FU Y, et al. Experiment on group−wall open stoping with subsequent backfilling method in gently inclined and thin ore body[J]. Mining Research and Development, 2019, 39(6): 22−25.

[9] 李冬萍, 张浩强. 金矿破碎矿体高分段嗣后充填采矿技术优化研究[J]. 金属矿山, 2021(12): 102−105.

LI D P, ZHANG H Q. Study on optimization of high sublevel backfill mining technology for broken orebody in a gold mine[J]. Metal Mine, 2021(12): 102−105.

[10] 万串串, 郑志杰, 黄丹, 等. 基于二维FDEM的金属矿破碎矿体进路法开挖方式与参数优化研究[J/OL]. 矿业研究与开发, 2024, 44(3): 16−22.

WAN C C, ZHENG Z J, HUANG D, et al. Research on excavation method and parameter optimization of broken ore in metal mine based on two−dimensional FDEM[J/OL]. Mining Research and Development, 2024, 44(3): 16−22.

[11] 丁航行, 韩智勇, 任凤玉, 等. 谦比西铜矿缓倾斜中厚破碎矿体分流出矿技术[J]. 金属矿山, 2016(1): 13−16.

DING H X, HAN Z Y, REN F Y, et al. Divided−flow drawing technology of gently inclined medium−thick broken ore bodies in Chambishi copper mine[J]. Metal Mine, 2016(1): 13−16.

[12] 马天勇, 行鹏飞. 阶段矿房法在缓倾斜厚矿体中的应用[J]. 矿产保护与利用, 2013(1): 11−13.

MA T Y, XING P F. Application of sublevel room mining on slightly dipped thick orebody[J]. Conservation and Utilization of Mineral Resources, 2013(1): 11−13.

[13] 张宏伟, 张富兴, 孙胜, 等. 缓倾斜破碎矿体高效进路充填采矿方法研究与应用[J]. 黄金科学技术, 2021, 29(6): 899−907.

ZHANG H W, ZHANG F X, SUN S, et al. Research and application of high−efficiency drift backfill mining method in gently inclined broken orebody[J]. Gold Science and Technology, 2021, 29(6): 899−907.

[14] 何宇翔, 杨溢, 张志华, 等. 基于模糊数学在采矿方法中的优化[J]. 矿冶, 2018, 27(4): 41−44.

HE Y X, YANG Y, ZHANG Z H, et al. Optimization of mining method based on fuzzy mathematics[J]. Mining and Metallurgy, 2018, 27(4): 41−44.

[15] 杨世兴, 付玉华, 侯永强. 基于层次分析对某铁矿的采矿方法选择[J]. 有色金属科学与工程, 2017, 8(4): 86−90.

YANG S X, FU Y H, HOU Y Q. Selection of mining method for a certain iron ore based on analytic hierarchy process[J]. Nonferrous Metals Science and Engineering, 2017, 8(4): 86−90.

[16] 曹楠. 基于层次分析法的采矿方法选择研究[J]. 煤矿现代化, 2018, 8(4): 108−110.

CAO N. Mining methods selection based on analytic hierarchy rocess[J]. Coal Mine Modernization, 2018, 8(4): 108−110.

[17] 张卫中, 王维庆, 彭亚利, 等. 基于AHP−FUZZY的瓦屋磷矿Ⅳ矿段房柱法出矿方式优选[J]. 金属矿山, 2022(9): 18−24.

ZHANG W Z, WANG W Q, PENG Y L, et al. Based on AHP−FUZZY, optimization of room−and−pillar mining method extraction for section Ⅳ of Wawu phosphate mine based on AHP−FUZZY[J]. Metal Mine, 2022(9): 18−24.

[18] 邓龙鑫, 陈建宏. 基于博弈论的主客观组合权重TOPSIS采矿方法优选[J]. 黄金科学技术, 2022, 30(2): 282−290.

DENG L X, CHEN J H. Optimization of mining method with subjective and objective combination weight TOPSIS based on game theory[J]. Gold Science and Technology, 2022, 30(2): 282−290.

[19] 吴姗, 郭利杰. 基于模糊聚类及BP神经网络的采矿方法选择研究[J]. 中国矿业, 2016, 25(S2): 281−285.

WU S, GUO L J. Mining method optimization based on the fuzzy clustering and the BP neural network[J]. China Mining Magazine, 2016, 25(S2): 281−285.

[20] 刘志祥, 刘进. 基于变权重理论和TOPSIS法的采矿方法优选[J]. 有色金属工程, 2019, 9(3): 76−81+107.

LIU Z X, LIU J. Optimization of mining methods based on variable weight theory and TOPSIS[J]. Nonferrous Metals Engineering, 2019, 9(3): 76−81+107.

[21] 何金城, 何治良, 郑航竹, 等. FAHP−Entropy耦合定权法在采矿方法优选中的应用[J]. 矿业研究与开发, 2018, 38(11): 9−14.

HE J C, HE Z L, ZHENG H Z, et al. The application of FAHP−Entropy coupling weighting method in the optimal selection of mining method[J]. Mining Research and Development, 2018, 38(11): 9−14.

[22] 李宁, 孙刚友, 王合祥, 等. 基于信息熵与模糊决策理论优选采矿方法[J]. 铀矿冶, 2018, 37(3): 166−170.

LI N, SUN G Y, WANG H X, et al. Optimization of mining method based on information entropy and decision theory[J]. Uranium Mining and Metallurgy, 2018, 37(3): 166−170.

[23] 杨洋, 黄德镛, 耿元玲, 等. 基于FAHP−CRITIC组合赋权的采矿方法优选[J]. 化工矿物与加工, 2022, 51(1): 6−11+22.

YANG Y, HUANG D Y, GENG Y L, et al. Optimization of mining methods based on FAHP−CRITIC combined weighting process[J]. Industrial Minerals & Processing, 2022, 51(1): 6−11+22.

[24] WANG Y Z, ZHAO J, WANG Y, et al. Multi−objective optimization and grey relational analysis on configurations of organic Rankine cycle[J]. Applied Thermal Engineering, 2016, 114: 1355−1363.

[25] XIA X F, SUN Y, WU K, et al. Optimization of a straw ring−die briquetting process combined analytic hierarchy process and grey correlation analysis method[J]. Fuel Processing Technology, 2016, 152: 303−309. doi: 10.1016/j.fuproc.2016.06.018

[26] 柯丽华, 孟欢欢, 姚囝, 等. 基于区间灰数白化变权关联算法的采矿方法决策模型及应用[J]. 金属矿山, 2021(12): 96−101.

KE L H, MENG H H, YAO J, et al. Decision model of mining method based on interval grey number whitening variable weigh correlation algorithm and its application[J]. Metal Mine, 2021(12): 96−101.

[27] 杨静, 陈冬, 程小红. 贝叶斯公式的几个应用[J]. 大学数学, 2011, 27(2): 166−169.

YANG J, CHEN D, CHENG X H. Some applications of Bayesian formula[J]. College Mathematics, 2011, 27(2): 166−169.

[28] 孙同云. 模糊软集合和贝叶斯公式在确定指标权重中的应用[J]. 重庆工商大学学报(自然科学版), 2014, 31(5): 34−38.

SUN T Y. Application of fuzzy soft set and Bayesian formula to index weight determination[J]. Journal of Chongqing Technology and Business University (Natural Science Edition), 2014, 31(5): 34−38.

[29] 林晓辉. 模糊事件贝叶斯公式[J]. 数学的实践与认识, 2004, 34(4): 126−132.

LIN X H. The Bayes' formula on fuzzy event[J]. Mathematics in Practice and Theory, 2004, 34(4): 126−132

[30] 徐泽水. 多属性决策的两种方差最大化方法[J]. 管理工程学报, 2001, 15(2): 11−13.

XU Z S. Two methods of maximizing deviations of multi−attribute decision making[J]. Journal of Industrial Engineering and Engineering Management, 2001, 15(2): 11−13.

[31] 金畅. 蒙特卡洛方法中随机数发生器和随机抽样方法的研究[D]. 大连: 大连理工大学, 2006.

JIN C. Study on random number generator and random sampling in Monte Carlo method[D]. Dalian: Dalian University of Technology, 2006.

[32] 赵凯, 刘阳, 常瑛, 等. 基于蒙特卡洛模拟评价新生儿万古霉素给药方案[J]. 儿科药学杂志, 2024, 30(4): 20−26.

ZHAO K, LIU Y, CHANG Y, et al. Evaluation on administration regimen of vancomycin in neonates based on Monte Carlo simulation[J]. Journal of Pediatric Pharmacy, 2024, 30(4): 20−26.

[33] 张鑫, 刘欣荣, 王慧鹏. 成形磨削人字齿轮齿面扭曲消减设计方法[J]. 机械传动, 2024, 48(3): 161−169.

ZHANG X, LIU X R, WANG H P. Design method for twisting and reducing tooth surfaces of herringbone gears for form grinding[J]. Journal of Mechanical Transmission, 2024, 48(3): 161−169.

[34] 赵杰, 刘森, 殷齐康, 等. 碱金属修饰的萘炔/萘二炔对CO2选择性吸附分离的理论计算[J]. 无机化学学报, 2024, 40(3): 515−522.

ZHAO J, LIU S, YIN Q K, et al. Theoretical calculation of selective adsorption and separation of CO2 by alkali metal modified naphthalene/naphthalenediyne[J]. Chinese Journal of Inorganic Chemistry, 2024, 40(3): 515−522.

[35] 孙国祥, 黄银锋, 汪小旵, 等. 基于LIO−SAM建图和激光视觉融合定位的温室自主行走系统[J]. 农业工程学报, 2024, 40(3): 227−239.

SUN G X, HUANG Y F, WANG X C, et al. Autonomous navigation system in a greenhouse using LIO−SAM mapping and laser vision fusion localization[J]. Transactions of the Chinese Society of Agricultural Engineering, 2024, 40(3): 227−239.

[36] 王丹华, 路增祥. 基于贝叶斯公式的采矿方法优选模型[J]. 金属矿山, 2020(3): 36−41.

WANG D H, LU Z X. Optimization selection model of mining method based on Bayesian formula[J]. Metal Mines, 2020(3): 36−41.

[37] 王少特, 张耀平, 刘书瑶, 等. 某矿山地表移动及岩层监测稳定性研究[J]. 有色金属科学与工程, 2023, 14(4): 543−552.

WANG S T, ZHANG Y P, LIU S Y, et al. Study on the stability of surface movement and strata monitoring in a mine[J]. Nonferrous Metals Science and Engineering, 2023, 14(4): 543−552.

[38] 马栋, 周传波, 夏宇磬, 等. 基于爆破损伤的Hoek−Brown强度准则修正[J]. 地下空间与工程学报, 2022, 18(2): 397−404.

MA D, ZHOU C B, XIA Y Q, et al. Modification of Hoek−Brown strength criterion based on cumulative damage of blasting[J]. Chinese Journal of Underground Space and Engineering, 2022, 18(2): 397−404.

-

下载:

下载: