Novel Fatty Acid−based Collector in Low−temperature Desilication of Iron Ore by Flotation in Anshan City

-

摘要:

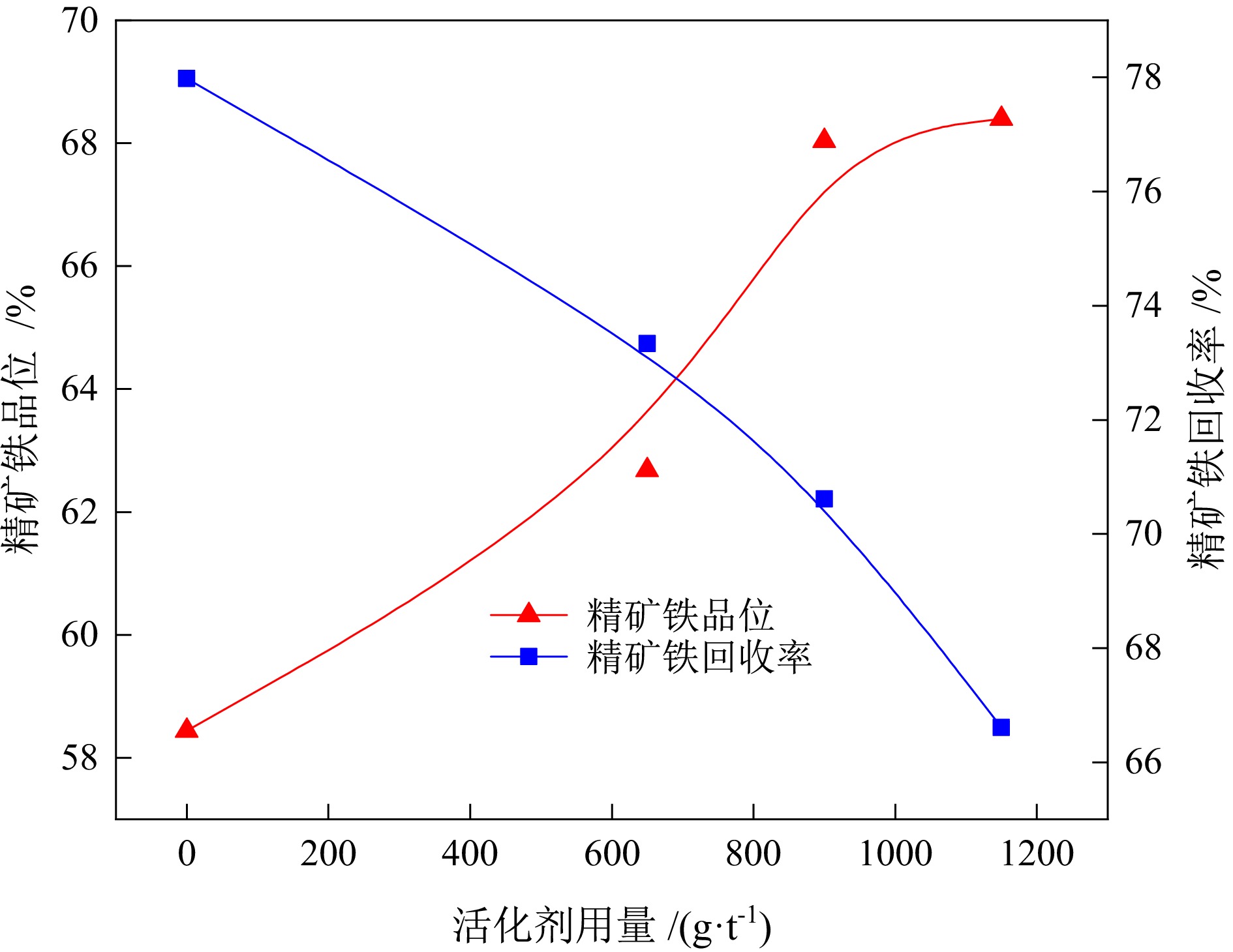

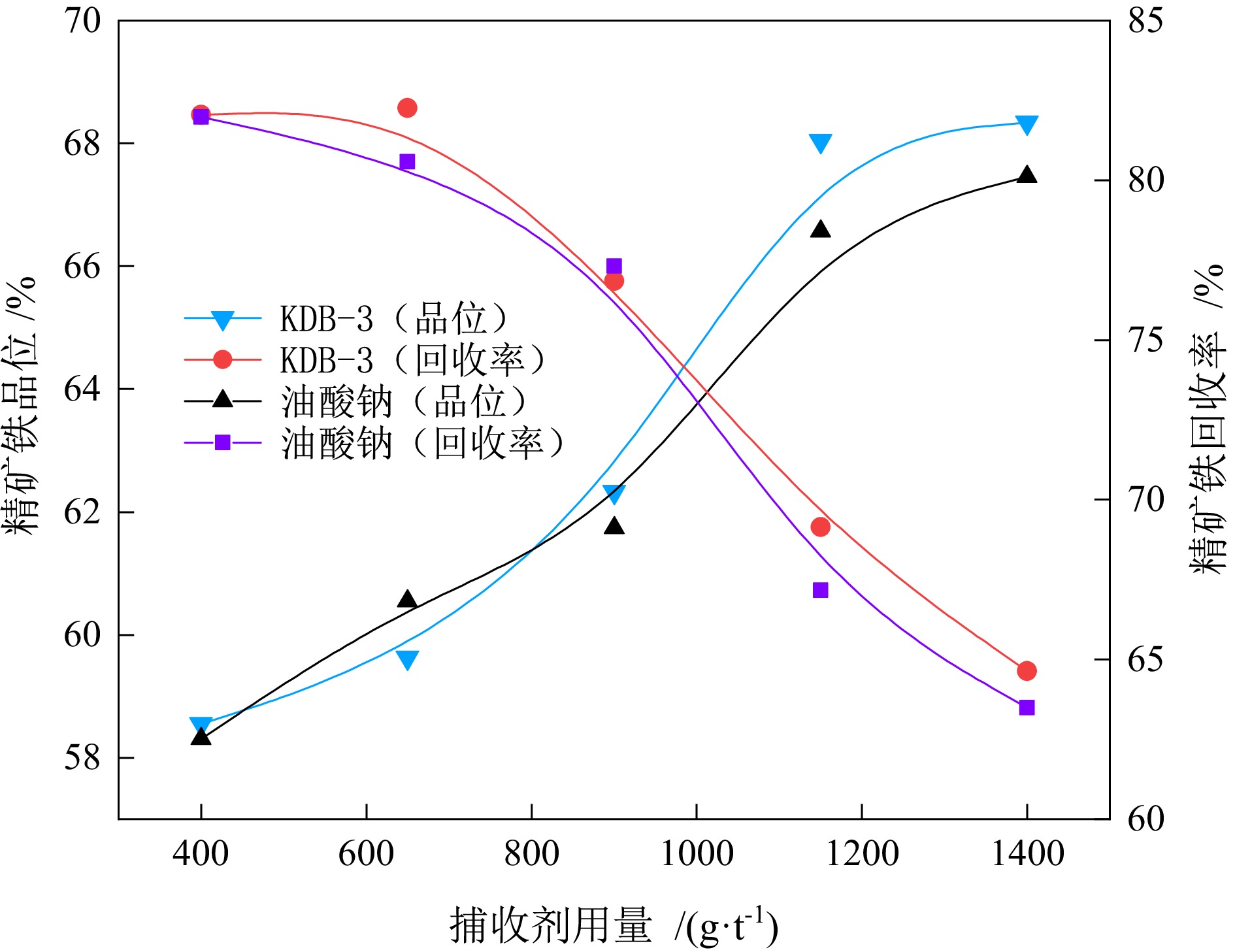

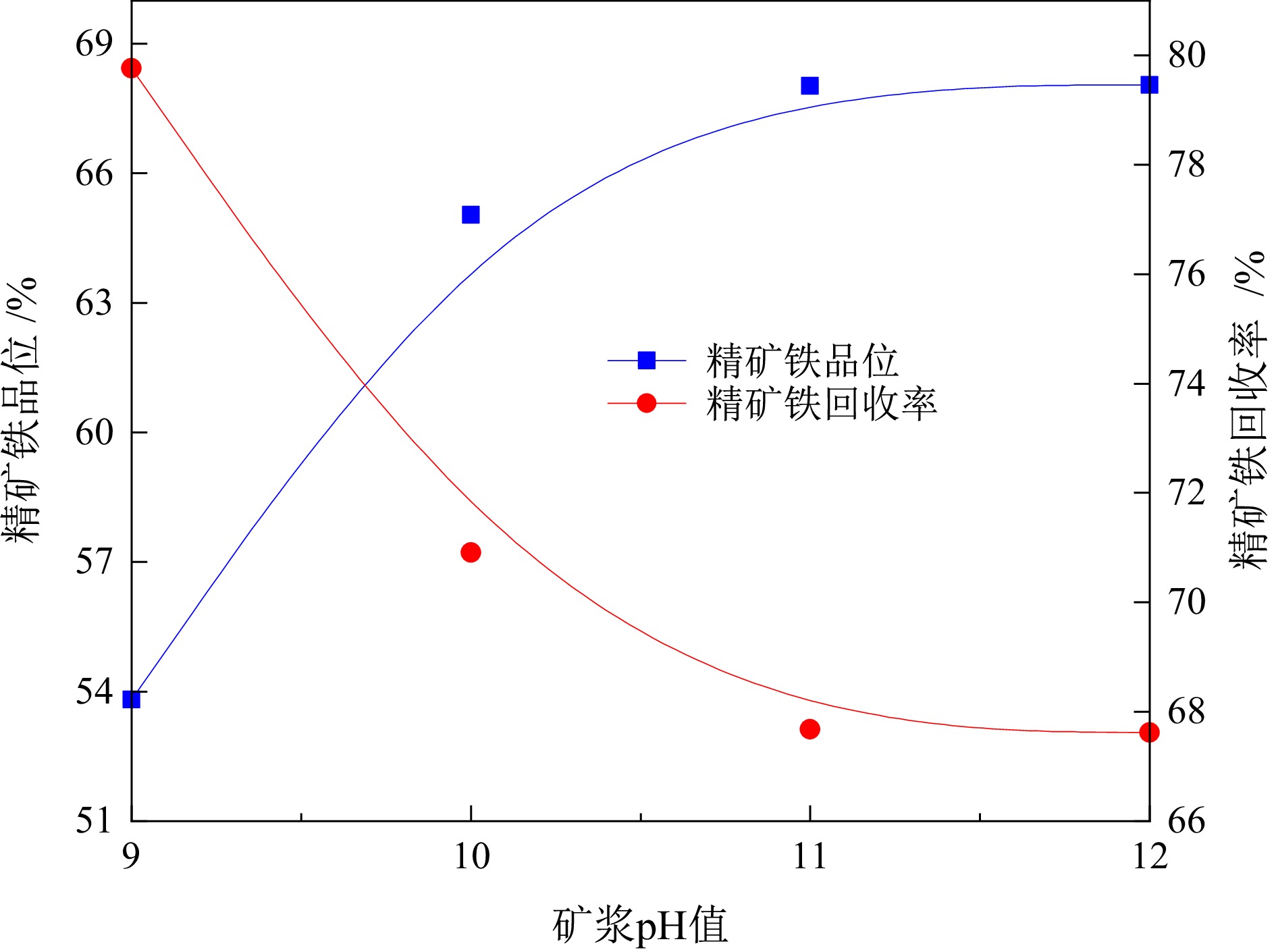

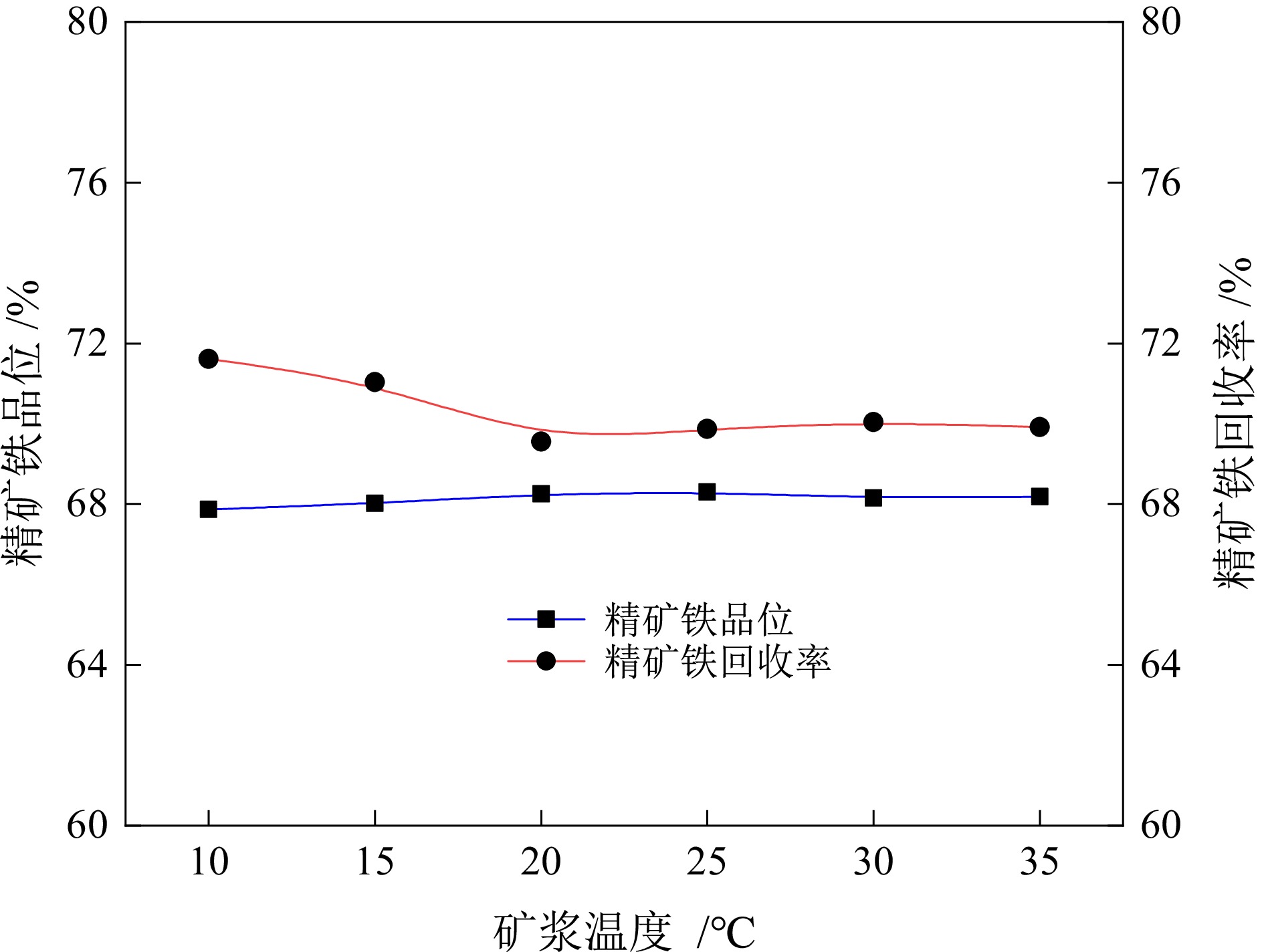

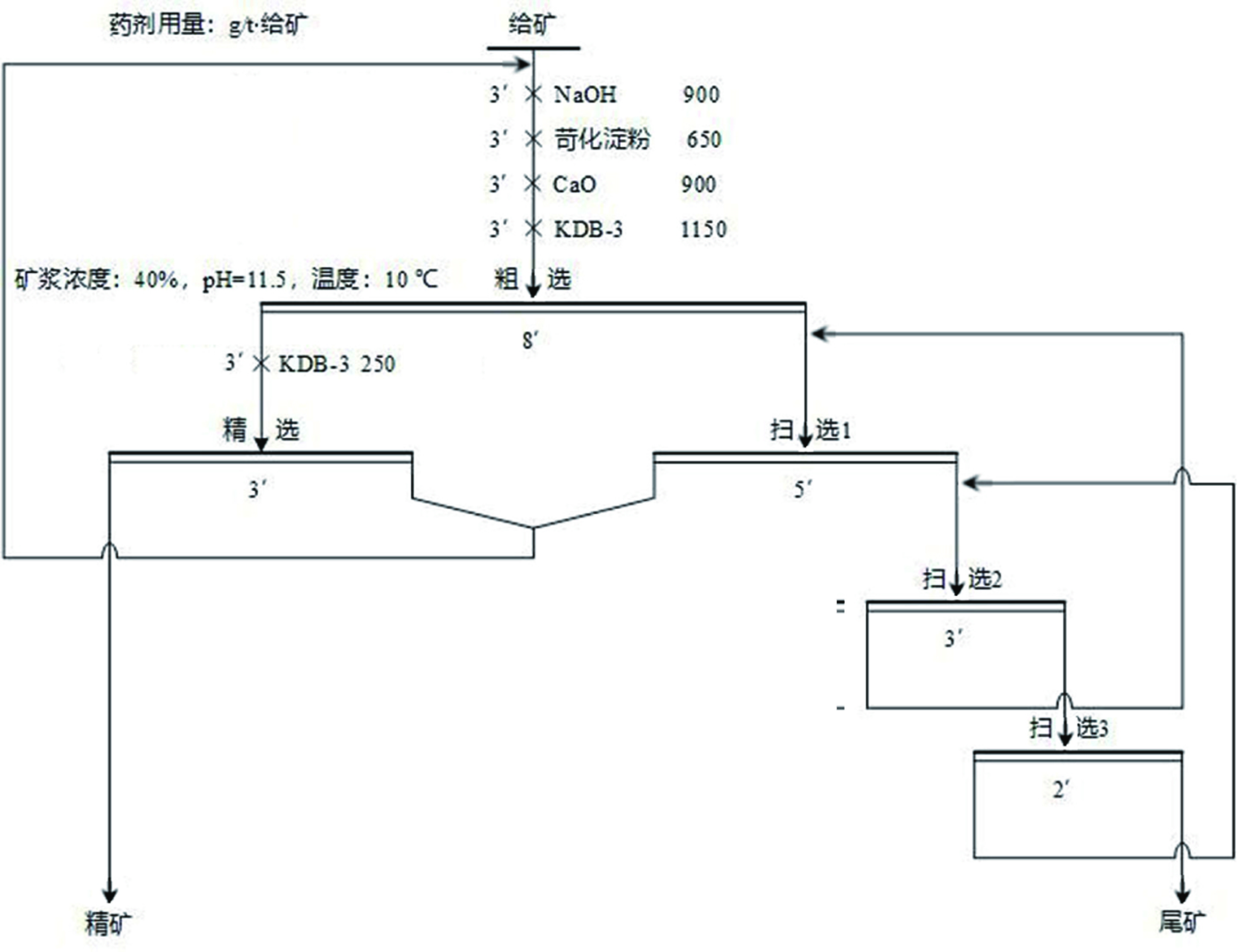

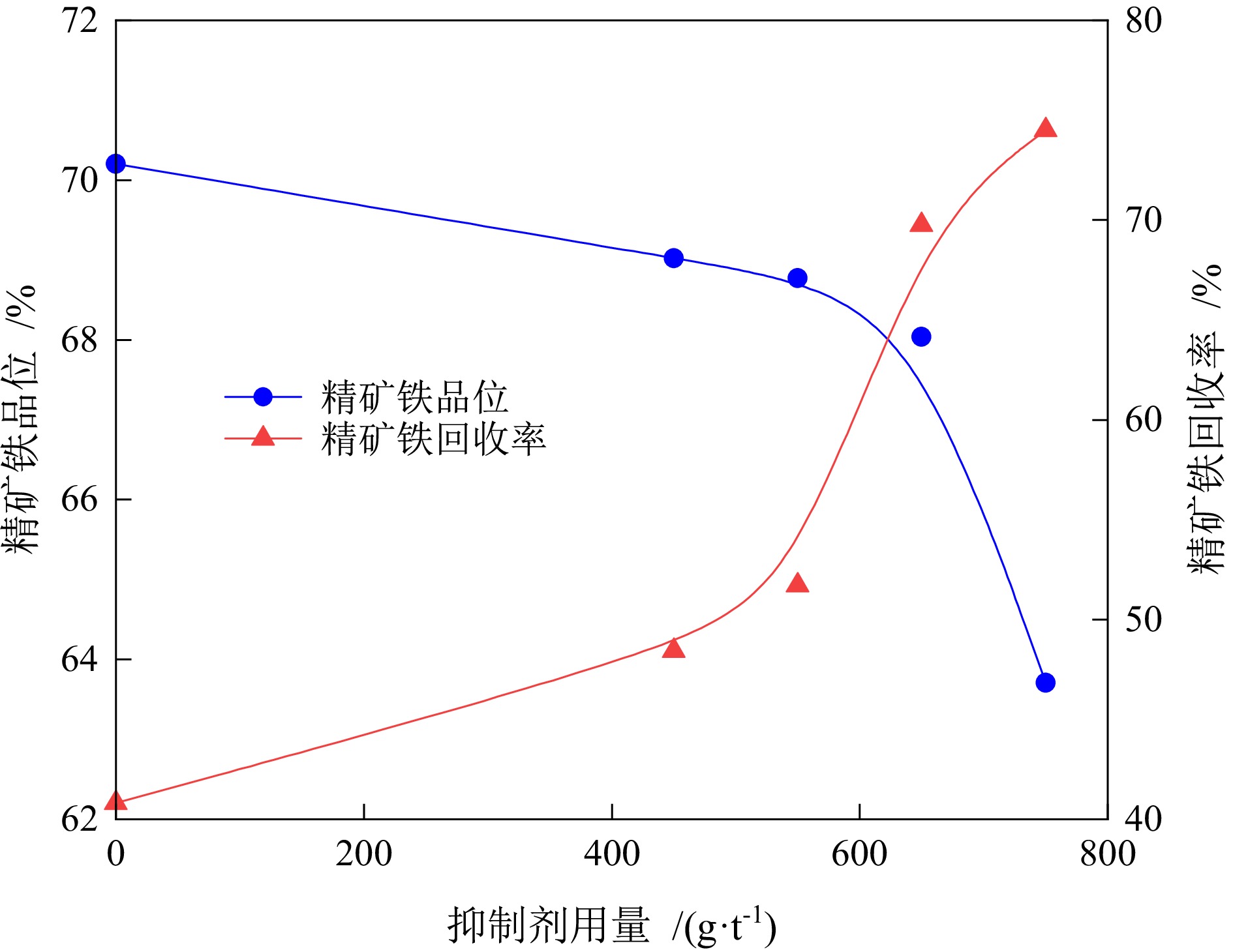

采用复配的新型脂肪酸类耐低温捕收剂KDB−3,针对鞍山某选厂的混合磁选精矿进行了低温反浮选实验研究。结果表明,在混合磁选精矿铁品位为50.10%时,采用“一次粗选一次精选三次扫选”的反浮选流程,在矿浆温度10~15 ℃、抑制剂苛化淀粉用量650 g/t、活化剂氧化钙用量900 g/t、捕收剂用量1150 g/t、调整剂氢氧化钠用量为900 g/t(pH值=11.5)粗选条件下,使用油酸钠作为捕收剂仅获得铁精矿铁品位66.57%、回收率67.16%,而相同条件下KDB−3捕收剂获得了铁精矿铁品位67.80%、回收率87.46%,比油酸钠分别高1.23百分点、20.30百分点,展现了良好的分选效果。浮选闭路实验结果表明,新型捕收剂KDB−3在常温(25 ℃)下获得了铁品位67.90%、回收率89.18%的铁精矿,低温条件(10~15 ℃)下的浮选指标也基本一致,展示出了新型脂肪酸类捕收剂KDB−3在低温与常温条件下都适用的特点。该药剂实现了对鞍山市某选厂铁矿石的有效低温浮选。

Abstract:A low−temperature reverse flotation experimental study was carried out on the mixed magnetic concentrate from a processing factory in Anshan using a new fatty acid−based low−temperature resistant collector KDB−3. The results showed that the reverse flotation process of "one stage rougher flotation, one stage cleaning and three stage scavenging" was adopted for the mixed magnetic concentrate with 50.10% iron grade. When the roughing slurry temperature was 10 ~ 15 ℃, the dosage of inhibitor caustic starch was 650 g/t, the dosage of activator calcium oxide was 900 g/t, the dosage of collector was 1 150 g/t, and the dosage of adjusting agent sodium hydroxide was 900 g/t, and the dosage of sodium hydroxide was 900 g/t (pH=11.5), an iron ore concentrate with iron grade of 67.80% and recovery of 87.46% was obtained using KDB−3, while only an iron ore concentrate with iron grade of 66.57 % and recovery of 67.16% was obtained using sodium oleate as collector under the same experimental conditions, showing the remarkable effect of the novel collector. When the novel collector KDB−3 was used, an iron ore concentrates with an iron grade of 67.90% was obtained at room temperature (25 ℃), with a recovery of 89.18%, which was similar to the indexes under low−temperature conditions, indicating the applicability of the novel fatty acid type collector KDB−3 under both low−temperature and room−temperature conditions. Effective low−temperature flotation of iron ore from a processing plant in Anshan city was achieved.

-

Key words:

- reverse flotation /

- low temperature /

- collector /

- iron ore /

- hematite /

- quartz

-

-

表 1 样品化学多元素分析结果

Table 1. Results of chemical multielement analysis of sample

/% 元素 Fe SiO2 MgO CaO Al2O3 含量 50.10 20.11 4.98 4.10 1.42 表 2 矿物组成测定结果

Table 2. Determination results of mineral composition of sample

/% 矿物名称 赤铁矿 磁赤铁矿 磁铁矿 菱铁矿 石英 其他 合计 矿物含量 31.35 28.20 8.00 4.05 16.01 12.39 100.00 矿物Fe含量 69.08 68.75 75.00 42.13 / / 50.10 铁分布率 43.22 38.70 11.98 3.41 / 2.69 100.00 表 3 浮选给矿试样粒级分布及铁含量测定结果

Table 3. Results of particle size distribution and iron content determination of flotation feed sample

粒级/mm 产率/% 铁品位/% 铁分布率/% +0.074 0.89 19.92 0.26 −0.074+0.043 12.82 20.03 4.83 −0.043+0.02 72.35 57.33 83.01 −0.02+0.01 10.30 44.79 9.02 −0.01 3.64 39.11 2.88 合计 100.00 50.26 100.00 表 4 浮选闭路实验结果

Table 4. Results of flotation closed−circuit tests

温度 产品名称 产率/% 铁品位/% 回收率/% 常温(25℃) 铁精矿 66.30 67.90 89.18 尾矿 33.70 16.20 10.82 给矿 100.00 50.48 100.00 低温(10~15℃) 铁精矿 64.71 67.80 87.46 尾矿 35.29 17.82 12.54 给矿 100.00 50.02 100.00 -

[1] 谷晓恬, 朱一民, 刘杰, 等. 新型低温捕收剂DGT−P对齐大山铁矿石的反浮选应用研究[J]. 矿产综合利用, 2023(2): 1−6. doi: 10.3969/j.issn.1000-6532.2023.02.001

GU X T, ZHU Y M, LIU J, et al. Research on the application of a new low−temperature collector DGT−P in Qidashan iron ore reverse flotation process[J]. Multipurpose Utilization of Mineral Resources, 2023(2): 1−6. doi: 10.3969/j.issn.1000-6532.2023.02.001

[2] 董振海, 智慧, 满晓霏, 等. 新型低温捕收剂反浮选齐大山选厂混磁精矿工艺研究[J]. 矿冶工程, 2023, 43(2): 52−56.

DONG Z H, ZHI H, MAN X F, et al. Reverse flotation of mixed magnetic concentrate in Qidashan concentrator with new low−temperature collector[J]. Mining and Metallurgical Engineering, 2023, 43(2): 52−56.

[3] 王长艳, 徐冬林, 史达, 等. 鞍千磁铁矿工艺矿物学研究[J]. 矿产综合利用, 2022(4): 193−199.

WANG C Y, XU D L, SHI D, et al. Research on process mineralogy of Anqian magnetite ore[J]. Multipurpose Utilization of Mineral Resources, 2022(4): 193−199.

[4] 朱一民, 葛婧, 刘杰, 等. 鞍千磁赤铁矿石磁选−反浮选工艺优化研究[J]. 矿产保护与利用, 2023, 43(3): 82−88.

ZHU Y M, GE J, LIU J, et al. Optimization study of magnetic separation−reverse flotation process for magnetic hematite ore in Anqian[J]. Conservation and Utilization of Mineral Resources, 2023, 43(3): 82−88.

[5] 徐冬林, 李佩昱, 李艳军, 等. 鞍千贫赤铁矿磁选精矿反浮选提纯实验[J]. 矿产保护与利用, 2020, 40(2): 70−73.

XU D L, LI P Y, LI Y J, et al. Reverse flotation for improving quality on magnetic concentrate of low−grade hematite ore from Anqian[J]. Conservation and Utilization of Mineral Resources, 2020, 40(2): 70−73.

[6] 潘鹏飞, 朱一民, 徐冬林, 等. 新型抑制剂DLW−4用于鞍千公司混磁精反浮选[J]. 金属矿山, 2015(6): 74−77. doi: 10.3969/j.issn.1001-1250.2015.06.016

PAN P F, ZHU Y M, XU D L, et al. Application of a new depressor DLW−4 to reverse flotation of the magnetic mixed concentrate from Anqian[J]. Metal Mine, 2015(6): 74−77. doi: 10.3969/j.issn.1001-1250.2015.06.016

[7] 杨晓峰, 马玉宁, 陈宇, 等. 组合捕收剂DYN−3在铁矿石浮选脱硅中的性能研究[J]. 金属矿山, 2023(4): 103−109.

YANG X F, MA Y N, CHEN Y, et al. Study on the performance of combined collector DYN−3 in iron ore desilication flotation[J]. Metal Mine, 2023(4): 103−109.

[8] 卜显忠, 陈帆帆, 张崇辉, 等. 溶剂合成法强化硫氮丙腈酯低温捕收性能的机理研究[J]. 有色金属工程, 2020, 10(1): 69−75.

BU X Z, CHEN F F, ZHANG C H, et al. Mechanism of solvent synthesis method for enhancing the low−temperature harvesting performance of thiazapropionitrile ester[J]. Nonferrous Metals Engineering, 2020, 10(1): 69−75.

[9] 张希哲. 铁矿耐低温捕收剂反浮选脱硅试验研究[D]. 武汉: 武汉理工大学, 2019.

ZHANG X Z. Experimental study on reverse flotation desilication of iron ore with low temperature collector[D]. Wuhan: Wuhan University of Technology, 2019.

[10] 吴文红, 吴承优, 王秋林, 等. 高效低温捕收剂选别关宝山铁矿实验[J]. 现代矿业, 2018, 34(1): 136−138+144.

WU W H, WU C Y, WANG Q L, et al. Study on efficient and low temperature collector sorting Guanbaoshan iron ore[J]. Modern Mining, 2018, 34(1): 136−138+144.

[11] 罗溪梅, 吴雪僮, 齐琳萍, 等. 四种胺类捕收剂体系中两相泡沫和赤铁矿/石英三相泡沫的稳定性[J]. 有色金属工程, 2022, 12(12): 84−90.

LUO X M, WU X T, QI L P, et al. Foam stability of two phase and hematite/quartz three phase in four amine collector systems[J]. Nonferrous Metals Engineering, 2022, 12(12): 84−90.

[12] 陈雯, 周瑜林, 李文风. 新型铁矿阴离子捕收剂的溶解特性研究及应用[J]. 矿冶工程, 2015, 35(6): 42−45.

CHEN W, ZHOU Y L, LI W F. Research on solubility properties of new anionic iron ore collector and corresponding application[J]. Mining and Metallurgical Engineering, 2015, 35(6): 42−45.

[13] 张行荣, 刘崇峻, 艾晶, 等. 新型耐低温捕收剂BK427在赤铁矿反浮选脱硅中的应用[J]. 中国矿业, 2014, 23(S2): 270−272.

ZHANG X R, LIU C J, AI J, et al. Applications of a new low−temperature−resistant collector BK427 in the reverse flotation for hematite desilication[J]. China Mining Magazine, 2014, 23(S2): 270−272.

[14] 郭文达, 朱一民, 王鹏, 等. 新型酰胺基羧酸捕收剂DWD−1用于铁矿反浮选实验研究[J]. 矿产保护与利用, 2016(3): 22−25+39.

GUO W D, ZHU Y M, WANG P, et al. Experimental study on a new amide−carboxylic acid collector DWD−1 used in reverse flotation of iron[J]. Conservation and Utilization of Mineral Resources, 2016(3): 22−25+39.

[15] 刘洁, 钟建玲, 李彬华, 等. 赤铁矿反浮选抑制剂变性淀粉的制备及应用性能[J]. 化工技术与开发, 2019, 48(6): 1−5. doi: 10.3969/j.issn.1671-9905.2019.06.001

LIU J, ZHONG J L, LI B H, et al. Preparation of modified starch and application as depressant on reverse flotation of hematite[J]. Technology & Development of Chemical Industry, 2019, 48(6): 1−5. doi: 10.3969/j.issn.1671-9905.2019.06.001

-

下载:

下载: