Accuracy and Error Sources of the Rietveld Full Pattern Fitting Method in Quantitative Analysis of Illite Ores

-

摘要:

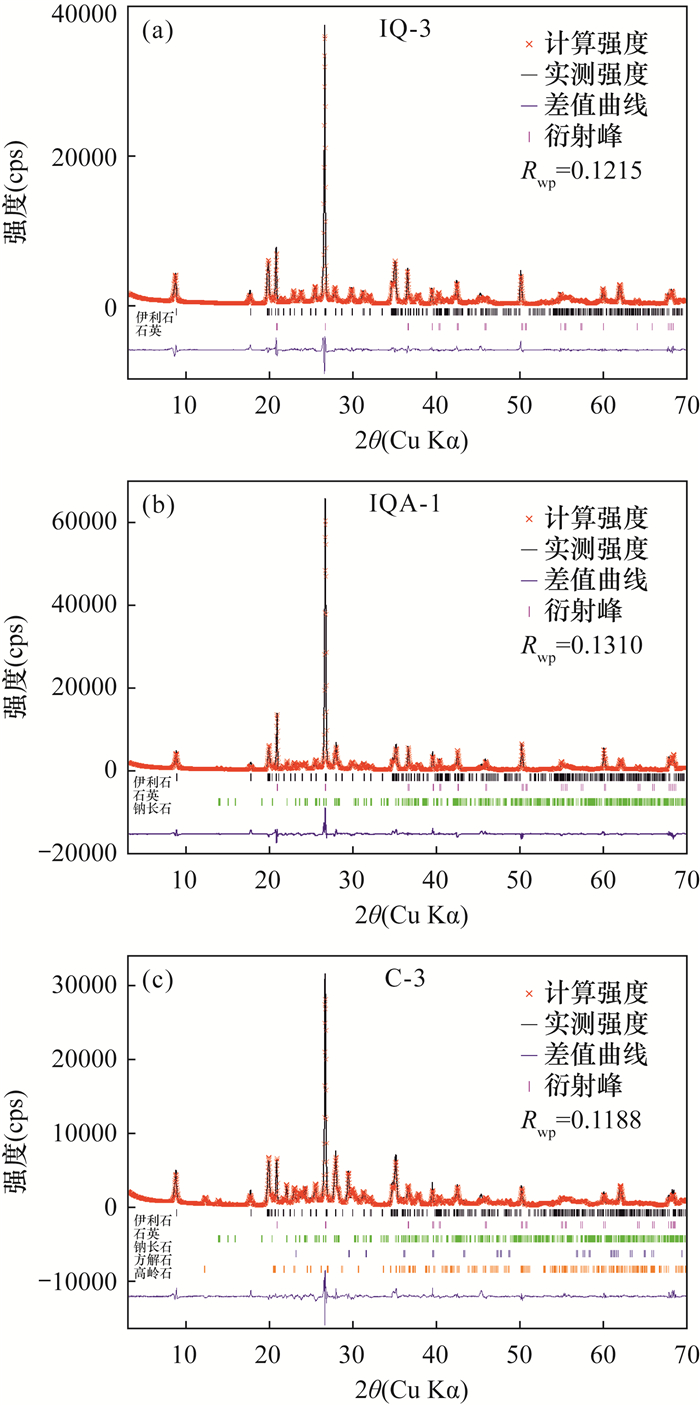

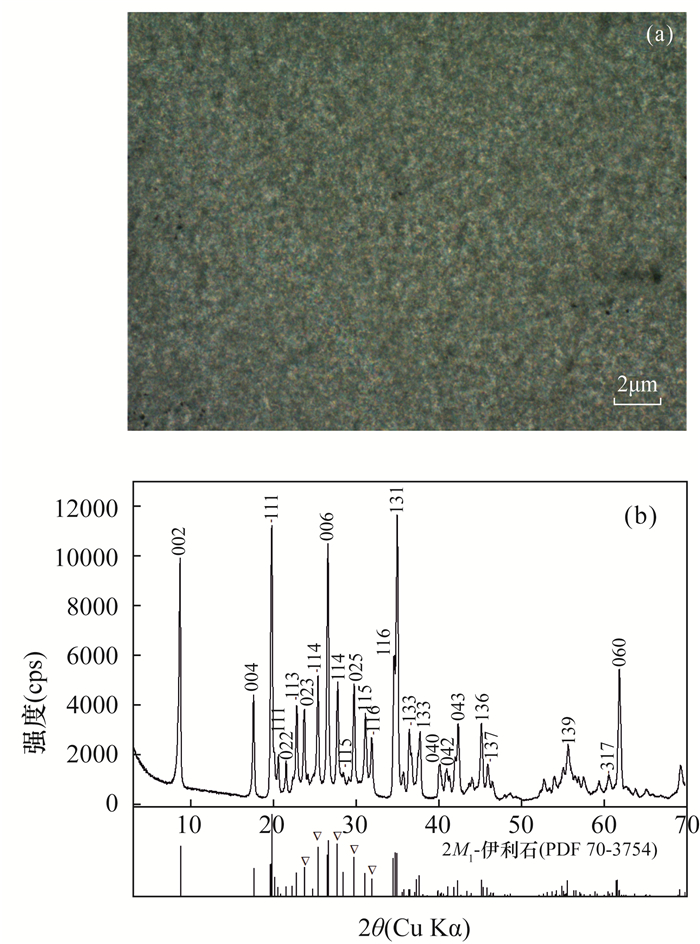

伊利石是一种重要的矿产资源,准确获得矿石中矿物组成和含量具有重要的理论和实际意义。Rietveld全图拟合法采用整个衍射图进行分析,具有较高的准确度。然而由于缺少纯的伊利石样品,目前对于该方法在分析伊利石矿样的精确度和误差来源尚不清楚。本文采用Rietveld全图拟合法对人工配制和天然的伊利石典型矿样进行了分析和计算,并与X射线荧光光谱(XRF)分析结果进行了对比,探讨了该方法的精确度及产生误差的因素。结果表明:人工配制的伊利石-石英二元混合物绝对误差范围为-0.9%~0.9%;伊利石-石英-钠长石三元混合物绝对误差范围为-1.9%~1.6%;伊利石-石英-钠长石-方解石-高岭石多元混合物绝对误差范围-2.3%~1.6%。天然伊利石矿样的Rietveld定量结果与XRF分析结果具有很好的一致性。表明该方法在分析伊利石矿样中具有较高的精确度,误差来源主要受伊利石结构模型、各物相中原子热振动参数Uiso取值合理性,以及择优取向等因素的影响。因此,在实际分析伊利石矿样时,建议根据实际情况选择合理的矿物结构模型,原子热振动Uiso取值应参考文献进行合理设定,制备试样应尽量减弱择优取向。

Abstract:BACKGROUND Illite is an important mineral resource. It is of great theoretical and practical significance to accurately obtain the mineral composition and content of illite ores. The Rietveld full pattern fitting method uses the whole diffraction pattern for analysis and shows high accuracy. However, due to the lack of pure illite samples, the accuracy and error sources of this method for analyzing the content of illite ores are not clearly known at present.

OBJECTIVES To understand the accuracy and error sources of the Rietveld full pattern fitting method in quantitative analysis of illite ores.

METHODS The Rietveld full pattern fitting method was used to quantitatively analyze artificial and natural illite ore samples. The results of X-ray fluorescence spectrometry (XRF) of natural illite ores were compared with the chemical compositions calculated from the mineral contents by the Rietveld method.

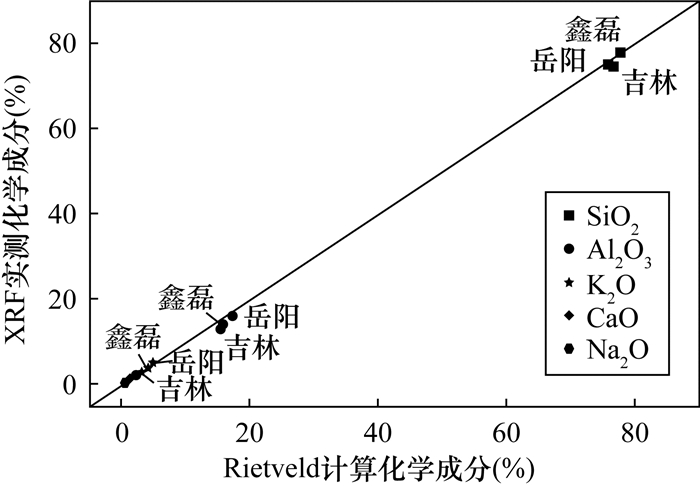

RESULTS The results showed that the maximum absolute error ranges of illite-quartz binary mixtures, illite-quartz-albite ternary mixtures, and illite-quartz-albite-calcite-kaolinite multiple mixtures were -0.9%-0.9%, -1.9%-1.6%, and -2.3%-1.6%, respectively. The chemical compositions of natural illite ores calculated by Rietveld method were in good agreement with the results of XRF. This indicated that the Rietveld method had high accuracy in the quantitative analysis of mineral contents of natural illite ore samples. The error sources were mainly affected by the illite structural model, atomic thermal displacement parameters Uiso, and preferred orientation.

CONCLUSIONS A reasonable structural model of illite should be chosen according to the actual samples. The values of atomic thermal vibration Uiso should be reasonably set according to the references. Preferred orientation should be decreased as much as possible during the sample preparation.

-

-

表 1 伊利石-石英二元混合物Rietveld定量分析结果

Table 1. Rietveld quantitative analysis results of illite-quartz binary mixtures

样品编号 理论值(%) Rietveld定量结果(%) 伊利石 石英 伊利石 绝对误差 相对误差 石英 绝对误差 相对误差 绝对误差范围 IQ-1 97.0 3.0 97.7 0.7 0.7 2.3 -0.7 -23.3 -0.7~0.7 IQ-2 90.0 10.0 89.4 -0.6 -0.7 10.6 0.6 6.0 -0.6~0.6 IQ-3 70.0 30.0 69.5 -0.5 -0.7 30.5 0.5 1.7 -0.5~0.5 IQ-4 50.0 50.0 50.9 0.9 1.8 49.1 -0.9 -1.8 -0.9~0.9 表 2 伊利石-石英-钠长石三元混合物Rietveld定量分析结果

Table 2. Rietveld quantitative analysis results of illite-quartz-albite ternary mixtures

样品编号 理论值(%) Rietveld定量结果(%) 伊利石 石英 钠长石 伊利石 绝对误差 相对误差 石英 绝对误差 相对误差 钠长石 绝对误差 相对误差 绝对误差范围 IQA-1 50 40 10 49.0 -1.0 -2.0 40.5 0.5 1.3 10.5 0.5 5.0 -1.0~0.5 IQA-2 50 30 20 50.2 0.2 0.4 28.2 -1.8 -6.0 21.6 1.6 8.0 -1.8~1.6 IQA-3 50 20 30 48.1 -1.9 -3.8 21.4 1.4 7.0 30.4 0.4 1.3 -1.9~1.4 IQA-4 50 10 40 50.1 0.1 0.2 8.7 -1.3 -13.0 41.2 1.2 3.0 -1.3~1.2 表 3 伊利石-石英-钠长石-方解石-高岭石多元混合物Rietveld定量分析结果

Table 3. Rietveld quantitative analysis results of illite-quartz-albite-calcite-kaolinite multiple mixtures

样品编号 理论值(%) Rietveld定量结果(%) 伊利石 石英 钠长石 方解石 高岭石 伊利石 绝对误差 相对误差 石英 绝对误差 相对误差 钠长石 绝对误差 相对误差 方解石 绝对误差 相对误差 高岭石 绝对误差 相对误差 绝对误差范围 C-1 20 50 20 2.5 7.5 18.9 -1.1 -5.5 50.2 0.2 0.4 20.6 0.6 3.0 2.4 -0.1 -4.0 7.9 0.4 5.3 -1.1~0.6 C-2 40 30 20 5 5 40.2 0.2 0.5 27.7 -2.3 -7.7 21.2 1.2 6.0 5.7 0.7 14.0 5.2 0.2 4.0 -2.3~1.2 C-3 60 15 15 5 5 58.8 -1.2 -2.0 16.6 1.6 10.7 15.1 0.1 0.7 4.3 -0.7 -14.0 5.2 0.2 4.0 -1.2~1.6 C-4 80 5 5 2.5 7.5 81.1 1.3 1.6 4.6 -0.4 -8.0 4.8 -0.2 -4.0 2.2 -0.3 12.0 7.1 -0.4 -5.3 -0.4~1.3 表 4 C-3样品10次Rietveld定量分析结果

Table 4. Rietveld quantitative analysis results of C-3 sample for ten times

矿物种类 10次Rietveld定量分析结果(%) 平均值(%) 标准偏差(%) 1 2 3 4 5 6 7 8 9 10 伊利石 58.8 59.1 59.7 59.4 59.3 59.4 59.6 58.9 59.3 59.5 59.30 0.29 石英 16.6 16.8 15.8 16.0 16.7 16.5 16.3 16.6 16.3 15.9 16.35 0.35 钠长石 15.1 14.4 14.6 14.8 14.2 14.5 14.4 15.0 14.6 14.8 14.64 0.28 方解石 4.3 5.1 5.1 5.3 5.1 5.0 5.1 4.8 5.3 5.2 5.03 0.29 高岭石 5.2 4.6 4.8 4.5 4.7 4.6 4.6 4.7 4.5 4.6 4.68 0.20 表 5 天然伊利石矿样Rietveld定量分析结果

Table 5. Rietveld quantitative analysis results of natural illite samples

样品来源 伊利石(%) 石英(%) 钠长石(%) 方解石(%) 高岭石(%) 岳阳 44.4 55.6 - - - 鑫磊 38.4 55.8 5.3 - 0.5 吉林 28.6 51.1 16.8 2.2 1.3 注:“-”表示不含该矿物。 表 6 天然伊利石矿样化学组成

Table 6. Chemical compositions of natural illite samples

样品来源 分析方法 SiO2 (%) Al2O3 (%) Fe2O3 (%) MgO (%) CaO (%) Na2O (%) K2O (%) MnO (%) TiO2 (%) P2O5 (%) LOI (%) 总和(%) 岳阳 XRF 74.77 15.89 0.69 0.20 0.06 0.29 4.68 0.008 0.07 0.03 2.05 98.16 Rietveld 75.89 17.18 - - - - 4.75 - - - - 97.82 鑫磊 XRF 77.53 13.84 0.94 0.32 0.15 0.38 3.92 0.02 0.10 0.04 1.96 99.19 Rietveld 77.76 15.54 - - - 0.58 4.35 - - - - 98.23 吉林 XRF 74.40 12.42 1.52 0.46 1.80 1.92 2.80 0.04 0.60 0.18 3.10 99.24 Rietveld 76.35 14.79 - - 1.47 2.03 3.03 - - - - 97.67 注:“-”表示未进行计算。 -

[1] 董发勤. 应用矿物学[M]. 北京: 高等教育出版社, 2015: 494-497.

Dong F Q. Applied mineralogy[M]. Beijing: Higher Education Press, 2015: 494-497.

[2] 历新宇. 天然矿物伊利石为原料提钾研究[D]. 延吉: 延边大学, 2019.

Li X Y. Study on extraction of patassium from natural mineral illite[D]. Yanji: Yanbian University, 2019.

[3] Alain M, Velde B. Illite[M]. Heidelberg: Springer, 2005: 189-240.

[4] 马礼敦. X射线晶体学的百年辉煌[J]. 物理学进展, 2014, 34(2): 47-117. https://www.cnki.com.cn/Article/CJFDTOTAL-WLXJ201402001.htm

Ma L D. Splendid century of X-ray crystallography[J]. Progress in Physics, 2014, 34(2): 47-117. https://www.cnki.com.cn/Article/CJFDTOTAL-WLXJ201402001.htm

[5] Zhou X, Liu D, Bu H, et al. XRD-based quantitative analysis of clay minerals using reference intensity ratios, mineral intensity factors, Rietveld, and full pattern summation methods: A critical review[J]. Solid Earth Sciences, 2018, 3: 16-29. doi: 10.1016/j.sesci.2017.12.002

[6] Runcevski T, Brown C M. The Rietveld refinement method: Half of a century anniversary[J]. Crystal Growth and Design, 2021, 21(9): 4821-4822. doi: 10.1021/acs.cgd.1c00854

[7] Kristian U, Mark D R. Application of the Rietveld method in the Reynolds cup contest[J]. Clays and Clay Minerals, 2017, 65(4): 286-297. doi: 10.1346/CCMN.2017.064063

[8] Bish D L, Howard S A. Quantitative phase analysis using the Rietveld method[J]. Journal of Applied Crystallography, 1988, 21: 86-91. doi: 10.1107/S0021889887009415

[9] Munson E O, Chalmers G R L, Bustin R M, et al. Utilizing smear mounts for X-ray diffraction as a fully quantitative approach in rapidly characterizing the mineralogy of shale gas reservoirs[J]. Journal of Unconventional Oil and Gas Resources, 2016, 14: 22-31. doi: 10.1016/j.juogr.2016.01.001

[10] Zhao W, Tan W F. Quantitative and structural analysis of minerals in soil clay fractions developed under different climate zones in China by XRD with Rietveld method, and its implications for pedogenesis[J]. Applied Clay Science, 2018, 162: 351-361. doi: 10.1016/j.clay.2018.05.019

[11] Prandel L V, Saab S C, Brinatti A M, et al. Mineralogical analysis of clays in hardsetting soil horizons, by X-ray fluorescence and X-ray diffraction using Rietveld method[J]. Radiation Physics and Chemistry, 2014, 95: 65-68. doi: 10.1016/j.radphyschem.2012.12.017

[12] Kleeberg R, Monecke T, Hillier S. Preferred orientation of mineral grains in sample mounts for quantitative XRD measurements: How random are powder samples?[J]. Clays and Clay Minerals, 2008, 56(4): 404-415. doi: 10.1346/CCMN.2008.0560402

[13] Gualtieri A F. Accuracy of XRPD QPA using the combined Rietveld—RIR method[J]. Journal of Applied Crystallography, 2000, 33(2): 267-278. doi: 10.1107/S002188989901643X

[14] 陈爱清, 谭伟, 杨宜坪, 等. X射线衍射旋转撒样法分析氟金云母多型组成与含量[J]. 岩矿测试, 2021, 40(4): 504-511. http://www.ykcs.ac.cn/article/doi/10.15898/j.cnki.11-2131/td.202101250014

Chen A Q, Tan W, Yang Y P, et al. Qualitative and quantitative analysis of fluorophlogopite polytype by the rotation-spray method of X-ray diffraction[J]. Rock and Mineral Analysis, 2021, 40(4): 504-511. http://www.ykcs.ac.cn/article/doi/10.15898/j.cnki.11-2131/td.202101250014

[15] Toby B H. EXPGUI, a graphical user interface for GSAS[J]. Journal of Applied Crystallography, 2001, 34: 210-213. doi: 10.1107/S0021889801002242

[16] Bish D L, Post J E. Quantitative mineralogical analysis using the Rietveld full-pattern fitting method[J]. American Mineralogist, 1993, 78: 932-940.

[17] Calvert C S, Palkowsky D A, Pevear D R. A combined X-ray powder diffraction and chemical method for the quantitative mineral analysis of geologic samples[M]. Colorado: Clay Minerals Society, 1989: 154-166.

[18] Moore D M, Reynolds R C. X-ray diffraction and the identification and analysis of clay minerals[M]. Oxford: Oxford University Press, 1997: 298-299.

[19] Hillier S. Accurate quantitative analysis of clay and other minerals in sandstones by XRD: Comparison of a Rietveld and a reference intensity ratio (RIR) method and the importance of sample preparation[J]. Clay Minerals, 2000, 35: 291-302. doi: 10.1180/000985500546666

[20] 付伟, 彭召, 罗鹏, 等. XRD-Rietveld全谱拟合法应用于土壤样品物相定量的准确性检验: 模拟实验与方法对比[J]. 光谱学与光谱分析, 2020, 40(3): 950-955. https://www.cnki.com.cn/Article/CJFDTOTAL-GUAN202003058.htm

Fu W, Peng Z, Luo P, et al. Accuracy testing of soil mieral quantification by XRD-Rietveld full-spectrum fitting method: Simulation experiments and comparison with traditional method[J]. Spectroscopy and Spectral Analysis, 2020, 40(3): 950-955. https://www.cnki.com.cn/Article/CJFDTOTAL-GUAN202003058.htm

[21] 郑振环, 李强. X射线多晶衍射数据Rietveld精修及GSAS软件入门[M]. 北京: 中国建材工业出版社, 2016: 20-23.

Zheng Z H, Li Q. Introduction to Rietveld refinement with X-ray powder diffraction data and GSAS software[M]. Beijing: China Building Material Industry Publishing House, 2016: 20-23.

[22] 陈爱清. 熔体中氟金云母生长机制与多型成因[D]. 北京: 中国科学院大学, 2019.

Chen A Q. Growtth mechanism and polytype genesis of synthetic fluorophlogopite from melt[D]. Beijing: University of Chinese Academy of Sciences, 2019.

[23] 马礼敦. X射线粉末衍射仪用试样的制作[J]. 上海计量测试, 2008(5): 2-6. doi: 10.3969/j.issn.1673-2235.2008.05.001

Ma L D. Preparation of the samples for X-ray powder diffractometers[J]. Shanghai Measurement and Testing, 2008(5): 2-6. doi: 10.3969/j.issn.1673-2235.2008.05.001

[24] 陈昊鸿, 雷芳. 粉末衍射理论和实践[M]. 北京: 北京教育出版社, 2016: 159-160.

Chen H H, Lei F. Powder diffraction theory and practice[M]. Beijing: Higher Education Press, 2016: 159-160.

[25] Jozanikohan G, Sahabi F, Norouzi G H, et al. Quantitative analysis of the clay minerals in the Shurijeh Reservoir Formation using combined X-ray analytical techniques[J]. Russian Geology and Geophysics, 2016, 57(7): 1048-1063. doi: 10.1016/j.rgg.2016.06.005

[26] Zviagina B B, Drits V A, Srodon J, et al. The illite-aluminoceladonite series: Distinguishing features and identification criteria from X-ray diffraction and infrared spectroscopy data[J]. Clays and Clay Minerals, 2015, 63(5): 378-394. doi: 10.1346/CCMN.2015.0630504

-

下载:

下载: