Mineral Composition and Hydrophilicity/Hydrophobicity of Solid Particles Isolated from Inner Mongolia Oil Sands

-

摘要:

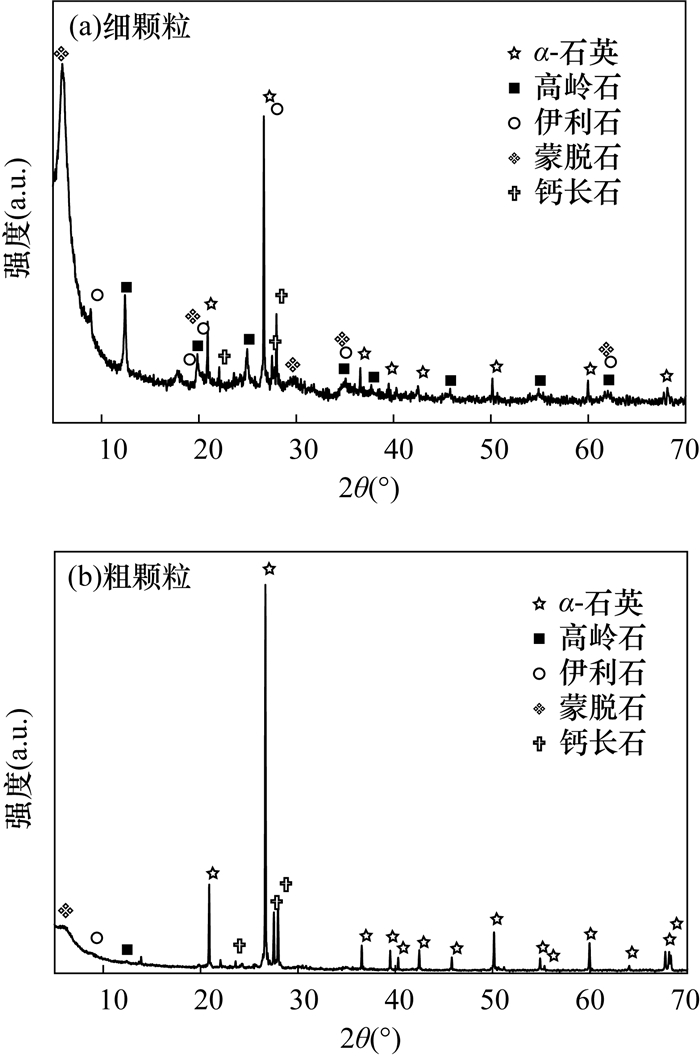

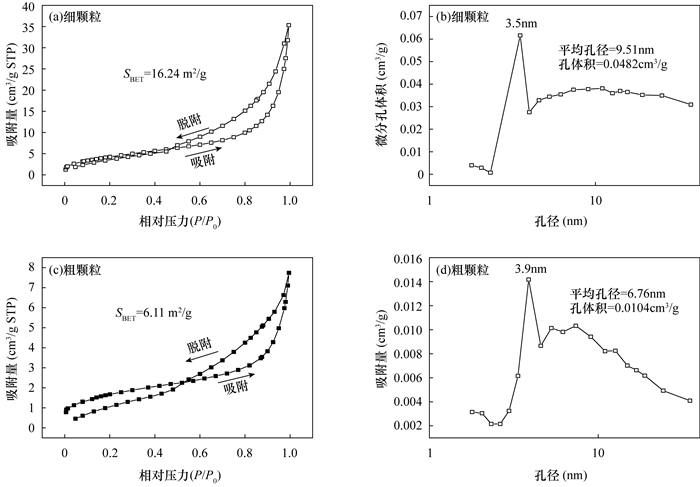

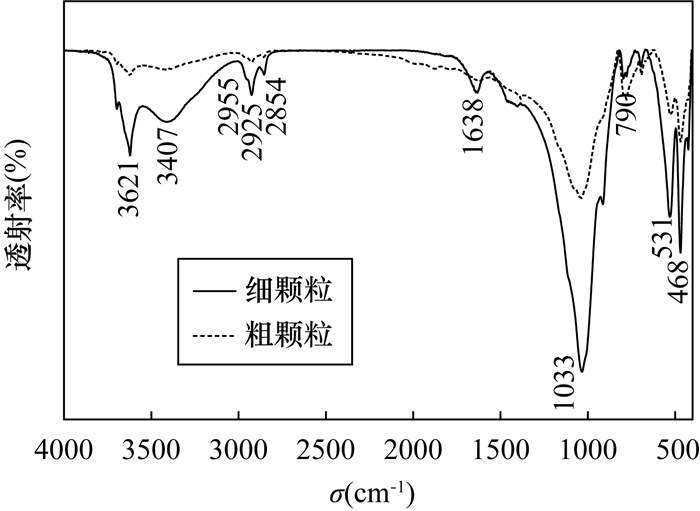

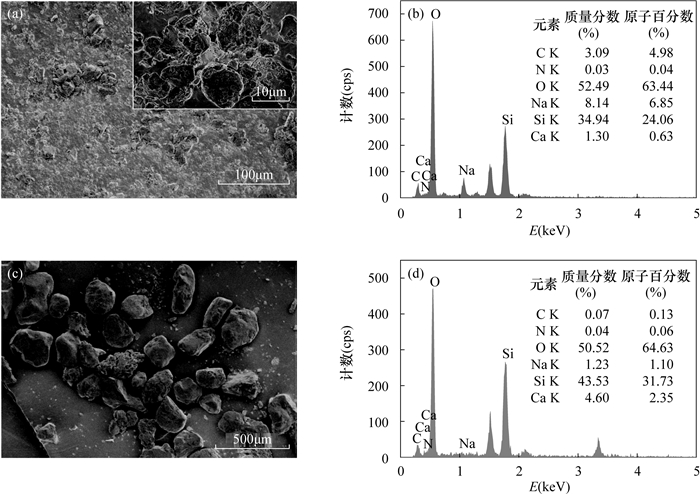

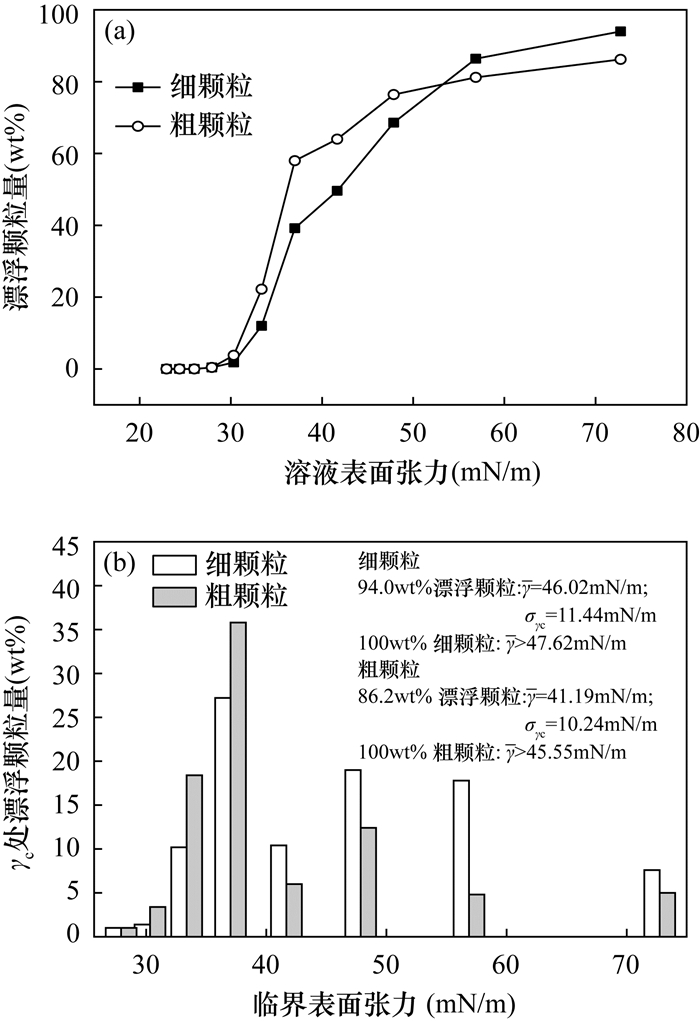

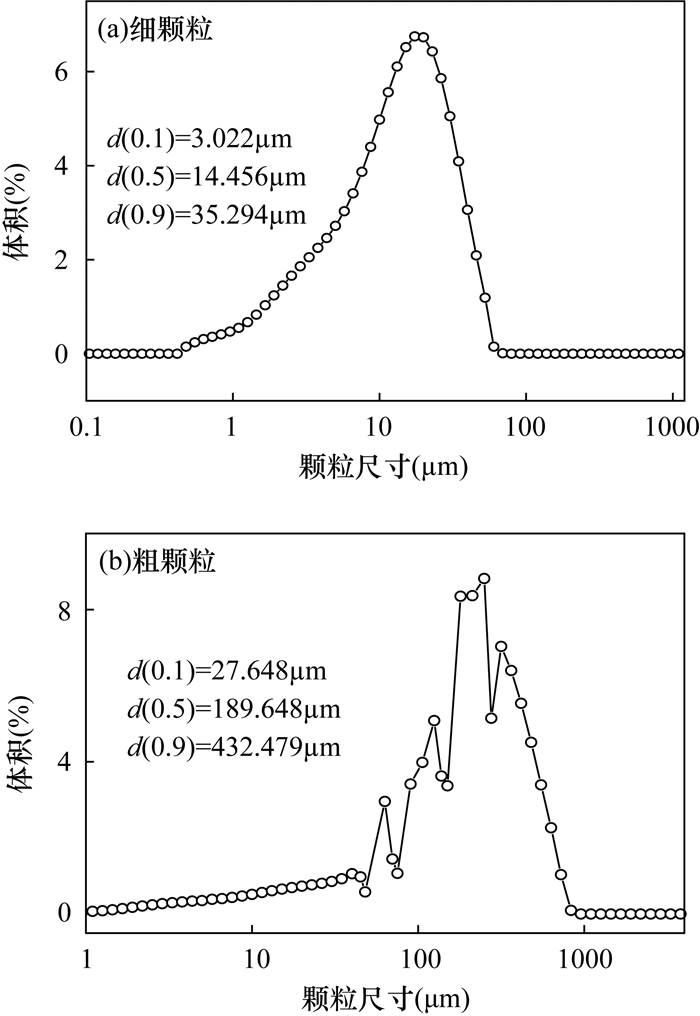

油砂是一种重要的非常规油气资源,由沥青、固体颗粒(包括粗颗粒和细颗粒)和水组成,其开发利用的关键在于提高其中沥青的提取效率。溶剂提取技术因其沥青提取效率高、环境友好等优点被认为有望取代现有水基提取技术。在溶剂提取过程中,主要存在沥青中固体颗粒残留率高和尾矿中有机溶剂回收效率低的问题,这与固体颗粒的组成结构和表面性质密切相关。因此,探明油砂中固体颗粒的矿物组成和表面性质(特别是亲疏水性)至关重要。中国内蒙古地区的油砂具有储量丰富、含油率高等特点,目前关于该地区油砂中固体颗粒的矿物组成和亲疏水性等特征尚不完全明确。本文对来自该地区油砂样品采用环己烷分离其中的沥青和固体颗粒,采用45μm标准筛分离固体颗粒中的细颗粒和粗颗粒,采用激光粒度分析仪、X射线衍射仪、比表面积及孔隙度分析仪、傅里叶变换红外光谱仪、有机元素分析仪、扫描电镜和能谱分析等多种手段对颗粒的矿物结构进行分析,采用表层浮选法和水蒸气吸附法对颗粒的亲疏水性进行评价。结果表明,油砂固体细颗粒和粗颗粒分别占总固体含量的53.4%和46.2%;固体细颗粒中含有蒙脱石、高岭石、伊利石、α-石英和钙长石等,粗颗粒中主要含有α-石英、钙长石及少量高岭石、伊利石和蒙脱石;细颗粒的沥青残留量、羟基含量均高于粗颗粒;细颗粒和粗颗粒的平均临界表面张力分别为>47.62mN/m和>45.55mN/m,单位面积水蒸气吸附量分别为1.27mg/m2和0.41mg/m2,固体粗颗粒的疏水性稍高于细颗粒。因疏水性固体颗粒对油砂沥青的分离提取和有机溶剂的回收有不利影响,因此应在关注固体细颗粒的同时,加强对固体粗颗粒影响的研究。

Abstract:BACKGROUND Oil sand is an important unconventional oil and gas resource, which is composed of bitumen, solid particles (including coarse and fine particles) and water. The key to its development and utilization is to improve the extraction efficiency of bitumen. Solvent extraction technology is expected to replace the existing water-based extraction technology due to its high bitumen extraction efficiency and environmental friendliness. The high residue rate of solid particles in bitumen and low recovery efficiency of organic solvent in gangues are two main problems during solvent extraction, which is closely related to the composition, structure and surface properties of solid particles. Therefore, it is very important to understand the mineral composition and surface properties, especially hydrophilicity/hydrophobicity, of solid particles in oil sand. The oil sands in Inner Mongolia, China are characterized by abundant reserves and high oil content. At present, the mineral composition and hydrophilicity/hydrophobicity of solid particles in the oil sands in this area are not clear.

OBJECTIVES To investigate the mineral composition and hydrophilicity/hydrophobicity of solid particles isolated from Inner Mongolia oil sands.

METHODS Cyclohexane was adopted to separate the bitumen and solid particles from the oil sands. Fine particles and coarse particles were then separated using a 45μm standard sieve. The composition and structure of the particles were investigated by laser particle size analyzer, X-ray diffraction analyzer, specific surface area and porosity analyzer, Fourier transform infrared spectroscopy, organic element analyzer, scanning electron microscopy-energy dispersive X-ray spectrometry (SEM-EDX). The hydrophilicity/hydrophobicity of the particles was determined by film floatation and water vapor adsorption methods.

RESULTS The contents of fine particles and coarse particles in the oil sands were 53.4% and 46.2%, respectively. The fine particles contained montmorillonite, kaolinite, illite, α-quartz and anorthite, while the coarse particles contained α-quartz and anorthite with minor kaolinite, illite and montmorillonite. The contents of bitumen and hydroxyl group in the fine particles were higher than those in the coarse particles. The mean critical surface tensions for fine particles and coarse particles were >47.62mN/m and >45.55mN/m, respectively, and the average water vapor adsorptions per unit area were 1.27mg/m2 and 0.41mg/m2, respectively, indicating that the coarse particles were more hydrophobic than the fine particles.

CONCLUSIONS Regarding the adverse effects of hydrophobic solid particles on the separation and extraction of oil sand bitumen and the recovery of organic solvents, it is necessary to pay attention to fine solid particles and strengthen the research on the influence of coarse solid particles.

-

-

[1] 庞惠文, 金衍, 高彦芳, 等. 风城油田齐古组油砂细观结构和渗流特征[J]. 新疆石油地质, 2021, 42(4): 487-494. https://www.cnki.com.cn/Article/CJFDTOTAL-XJSD202104015.htm

Pang H W, Jin Y, Gao Y F, et al. Study on meso-structures and flow characteristics of oil sands in Qigu Formation of fengcheng oilfield[J]. Xinjiang Petroleum Geology, 2021, 42(4): 487-494. https://www.cnki.com.cn/Article/CJFDTOTAL-XJSD202104015.htm

[2] 郝俊辉, 田原宇, 张金弘, 等. 油砂沥青分离技术研究进展[J]. 化工进展, 2018, 37(9): 3337-3345. https://www.cnki.com.cn/Article/CJFDTOTAL-HGJZ201809010.htm

Hao J H, Tian Y Y, Zhang J H, et al. Research progress on separation technologies of oil sand bitumen[J]. Chemical Industry and Engineering Progress, 2018, 37(9): 3337-3345. https://www.cnki.com.cn/Article/CJFDTOTAL-HGJZ201809010.htm

[3] Hooshiar A, Uhlik P, Ivey D G, et al. Clay minerals in nonaqueous extraction of bitumen from Alberta oil sands: Part 2. Characterization of clay minerals[J]. Fuel Processing Technology, 2012, 96(2): 183-194.

[4] Yu K, Wang Z B, Jin Y H, et al. Single-and multi-stage counter-current solvent extractions of bitumen from Xinjiang oil sand[J]. Energy & Fuels, 2013, 27(110): 6491-6500.

[5] 李锋, 仝立华. 全国油砂资源分布现状[N]. 中国矿业报, 2020-12-22(4).

Li F, Tong L H. Distribution status of oil sand resources in China[N]. China Mining News, 2020-12-22(4).

[6] 任嗣利. 水基提取技术用于油砂分离的研究进展[J]. 化工学报, 2011, 62(9): 2406-2412. doi: 10.3969/j.issn.0438-1157.2011.09.004

Ren S L. Research progress in water-based bitumen extraction from oil sands[J]. CIESC Journal, 2011, 62(9): 2406-2412. doi: 10.3969/j.issn.0438-1157.2011.09.004

[7] Ding M S, Ren S L. Wettability alteration of solid surface to enhance the bitumen liberation and the water-based processability of weathered oil sands[J]. The Canadian Journal of Chemical Engineering, 2020, 98(8): 1794-1802. doi: 10.1002/cjce.23736

[8] Han C, Li R, Lu Y. Study on synthesized thermoresponsive block copolymer for water-based oil sands extraction[J]. Energy & Fuels, 2020, 34(8): 9473-9482.

[9] Painter P, Williams P, Mannebach E. Recovery of bitumen from oil or tar sands using ionic liquids[J]. Energy & Fuels, 2010, 24(2): 1094-1098.

[10] Robinson J, Binner E, Saeid A. Microwave processing of oil sands and contribution of clay minerals[J]. Fuel, 2014, 135: 153-161. doi: 10.1016/j.fuel.2014.06.057

[11] Lin F, Stoyanov S R, Xu Y M. Recent advances in nonaqueous extraction of bitumen from mineable oil sands: A review[J]. Organic Process Research & Development, 2017, 21(4): 492-510.

[12] 刘金河, 刘银东, 李成杰, 等. 不同有机溶剂对新疆油砂沥青的组成性质影响[J]. 化工进展, 2019, 38(12): 5525-5531. https://www.cnki.com.cn/Article/CJFDTOTAL-HGJZ201912037.htm

Liu J H, Liu Y D, Li C J, et al. Impact of organic solvents on the composition and properties of Xinjiang oil sand bitumen in oil sand extraction process[J]. Chemical Industry and Engineering Progress, 2019, 38(12): 5525-5531. https://www.cnki.com.cn/Article/CJFDTOTAL-HGJZ201912037.htm

[13] Renaud R, Pal K, Weiβ T, et al. Vacuum drying of cyclohexane from solvent-extracted oil sands gangue[J]. The Canadian Journal of Chemical Engineering, 2016, 95(3): 459-465.

[14] Nikakhtari H, Pal K, Wolf S, et al. Solvent removal from cyclohexane-extracted oil sands gangue[J]. The Canadian Journal of Chemical Engineering, 2016, 94(3): 408-414. doi: 10.1002/cjce.22403

[15] Osacký M, Geramian M, Uhlík P, et al. Mineralogy and surface chemistry of Alberta oil sands: Relevance to nonaqueous solvent bitumen extraction[J]. Energy & Fuels, 2017, 31: 8910-8924.

[16] Geramian M, Liu Q, Ivey D G, et al. Influence of oil sands composition on bitumen quality during non-aqueous bitumen extraction from the Athabasca deposit[J]. The Canadian Journal of Chemical Engineering, 2019, 97(1): 268-280. doi: 10.1002/cjce.23340

[17] Geramian M, Ivey D G, Liu Q, et al. Characterization of four petrologic end members from Alberta oil sands and comparison between different mines and sampling times[J]. Canadian Journal of Chemical Engineering, 2018, 96(1): 49-61. doi: 10.1002/cjce.23034

[18] Nikakhtari H, Wolf S, Choi P, et al. Migration of fine solids into product bitumen from solvent extraction of Alberta oil sands[J]. Energy & Fuels, 2014, 28(5): 2925-2932.

[19] Li X G, Bai Y, Sui H, et al. Understanding desorption of oil fractions from mineral surfaces[J]. Fuel, 2018, 232: 257-266. doi: 10.1016/j.fuel.2018.05.112

[20] Tan X L, Vagi L, Liu Q, et al. Sorption equilibrium and kinetics for cyclohexane, toluene, and water on Athabasca oil sands solids[J]. The Canadian Journal of Chemical Engineering, 2016, 94(2): 220-230. doi: 10.1002/cjce.22389

[21] Wang C, Geramian M, Liu Q, et al. Comparison of different methods to determine the surface wettability of fine solids isolated from Alberta oil sands[J]. Energy & Fuels, 2015, 29(6): 3556-3565.

[22] Wang C, Liu Q, Ivey D G, et al. Bi-wetting property of oil sands fine solids determined by film flotation and water vapor adsorption[J]. Fuel, 2017, 197: 326-333. doi: 10.1016/j.fuel.2017.02.043

[23] 马姗姗. 离子液体及低共熔溶剂辅助有机溶剂萃取油砂沥青的研究[D]. 沈阳: 辽宁大学, 2018.

Ma S S. Solvent enhanced organic solvent extraction of oil sand bitumen[D]. Shenyang: Liaoning University, 2018.

[24] Wang C, Leng S Z, Guo H D, et al. Acid and alkali treatments for regulation of hydrophilicity/hydrophobicity of natural zeolite[J]. Applied Surface Science, 2019, 478: 319-326. doi: 10.1016/j.apsusc.2019.01.263

[25] 王娜, 徐铁民, 魏双, 等. 微波消解-电感耦合等离子体质谱法测定超细粒度岩石和土壤样品中的稀土元素[J]. 岩矿测试, 2020, 39(1): 68-76. http://www.ykcs.ac.cn/article/doi/10.15898/j.cnki.11-2131/td.201904010043

Wang N, Xu T M, Wei S, et al. Determination of rare earth elements in ultra-fine rock and soil samples by ICP-MS using microwave digestion[J]. Rock and Mineral Analysis, 2020, 39(1): 68-76. http://www.ykcs.ac.cn/article/doi/10.15898/j.cnki.11-2131/td.201904010043

[26] 马真乾, 王英滨, 于炳松. 渝东南地区下寒武统牛蹄塘组页岩孔径分布测试方法研究[J]. 岩矿测试, 2018, 37(3): 244-255. http://www.ykcs.ac.cn/article/doi/10.15898/j.cnki.11-2131/td.201801090003

Ma Z Q, Wang Y B, Yu B S. Study on analytical method for pore size distribution of the Lower Cambrian Niutitang Formation shale in southeastern Chongqing[J]. Rock and Mineral Analysis, 2018, 37(3): 244-255. http://www.ykcs.ac.cn/article/doi/10.15898/j.cnki.11-2131/td.201801090003

[27] 张烨毓, 曹茜, 黄毅, 等. 应用高温甲烷吸附实验研究川东北地区五峰组页岩甲烷吸附能力[J]. 岩矿测试, 2020, 39(2): 188-198. http://www.ykcs.ac.cn/article/doi/10.15898/j.cnki.11-2131/td.201908210126

Zhang Y M, Cao Q, Huang Y, et al. Application of high-temperature methane adsorption experiment to study the adsorption capacity of methane in shales from the Wufeng Formation, northeast Sichuan[J]. Rock and Mineral Analysis, 2020, 39(2): 188-198. http://www.ykcs.ac.cn/article/doi/10.15898/j.cnki.11-2131/td.201908210126

[28] 刘珍, 曲希玉, 王伟庆, 等. 比表面积氮气吸附法在蒙脱石碱性溶蚀表征中的应用[J]. 岩矿测试, 2016, 35(6): 603-611. http://www.ykcs.ac.cn/article/doi/10.15898/j.cnki.11-2131/td.2016.06.006

Liu Z, Qu X Y, Wang W Q, et al. Application of specific surface area nitrogen adsorption method to characterize the alkaline dissolution of montmorillonite[J]. Rock and Mineral Analysis, 2016, 35(6): 603-611. http://www.ykcs.ac.cn/article/doi/10.15898/j.cnki.11-2131/td.2016.06.006

[29] Meshref M N A, Ibrahim M D, Huang R F, et al. Fourier transform infrared spectroscopy as a surrogate tool for the quantification of naphthenic acids in oil sands process water and groundwater[J]. Science of the Total Environment, 2020, 734: 139191. doi: 10.1016/j.scitotenv.2020.139191

[30] Nafie G, Manasrah A D, Mackay B, et al. Oxy-cracking reaction for enhanced settling and dewaterability of oil sands tailings[J]. Industrial & Engineering Chemistry Research, 2019, 58(12): 4988-4996.

[31] Hao J H, Feng W, Qiao Y Y, et al. Thermal cracking behaviors and products distribution of oil sand bitumen by TG-FTIR and Py-GC/TOF-MS[J]. Energy Conversion and Management, 2017, 151: 227-239. doi: 10.1016/j.enconman.2017.08.083

[32] Mercier P H J, Tyo D D, Zborowski A, et al. First quantification of < 2μm clay, < 0.2μm ultrafines and solids wettability in process streams from naphthenic froth treatment plant at commercial mined oil sands operations[J]. Fuel, 2017, 237: 961-976.

[33] Couillard M, Tyo D D, Kingston D M, et al. Structure and mineralogy of hydrophilic and biwettable sub-2μm clay aggregates in oil sands bitumen froth[J]. Minerals, 2020, 10(11): 1040. doi: 10.3390/min10111040

[34] Elmes M C, Thompson D K, Price J S, et al. Changes to the hydrophysical properties of upland and riparian soils in a burned fen watershed in the Athabasca oil sands region, northern Alberta, Canada[J]. Catena, 2019, 181: 104077. doi: 10.1016/j.catena.2019.104077

-

下载:

下载: