A study of the application of turbine coring drilling technology to hot dry rock drilling

-

摘要:

我国干热岩勘探刚刚起步。为准确评价干热岩型地热资源的资源量,需要钻获高质量的干热岩岩心,但目前针对高温、高硬度、高研磨工况下的干热岩取芯钻进工艺研究较少,严重制约了干热岩型地热资源的准确评价。为此,自主研发了Φ127 mm涡轮钻具,在福建漳州HDR-1井和青海共和GR1井进行了干热岩钻井取芯应用研究,研究验证了研发的涡轮钻具与KT-140取芯钻具的适配性、涡轮钻具与金刚石取芯钻头的匹配性,揭示了高温和硬岩井况下涡轮钻具工作特性,经受住了孔底236 ℃高温考验,钻获了高质量岩心,取得了涡轮钻具现场测试应用的各项参数;涡轮取芯钻进工艺与常规取芯钻进工艺相比,既充分发挥了涡轮钻具高转速的性能,也发挥了其耐高温、耐研磨、耐高地应力、使用寿命长和现场劳动强度低的特性,干热岩取芯钻速和质量大大提高。该工艺是高温深孔干热岩井下动力回转钻具驱动取芯钻头进行取芯钻进的首次成功尝试,为干热岩涡轮钻具复合取芯钻井技术的进一步科研攻关、现场试验与推广应用提供了宝贵的施工应用经验和借鉴,也将为我国干热岩科学钻探与深部地热资源勘探提供新的技术支撑。

Abstract:Exploration of hot dry rock in China has just started. In order to accurately evaluate the amount of hot dry rock geothermal resources in China, high-quality hot dry rock drilling cores are needed. However, there are few researches on coring drilling of hot dry rock under the conditions of high temperature, high hardness and high grinding, which seriously restricts the accurate evaluation of hot dry rock geothermal resources. Therefore, independent research and development of the turbodrill Φ127 mm are carried out. The HDR-1 well in Zhangzhou of Fujian and the GR1 well in Gonghe of Qinghai were drilled and the research and application of hot dry rock drilling coring were performed to verify the research and development of turbodrill and the suitability of the KT-140 coring drilling tools and the matching of turbodrill and diamond core bit. The high temperature and hard rock characteristics of turbodrill working under the well conditions are revealed, the test of high temperature of 236 ℃ at the bottom of the bore is withstood, and the application test of turbodrill parameters is obtained. Compared with the conventional coring drilling technology, the turbodrill composite coring drilling technology not only plays an important role in the performance of high rotating speed of the turbodrill, but also makes full use of the characteristics of high temperature resistance, grinding resistance, high ground stress resistance, long service life and low on-site labor intensity, which greatly improves the drilling speed of hot dry rock. The method is of high temperature deep hole hot dry rock underground rotary drill driving core bit coring drilling and is the first successful attempt for hot dry rock of turbodrill coring drilling technology. The field test and application may provide valuable construction experience. The results will also provide a new technical support for hot dry rock scientific drilling and deep geothermal resource exploration in China.

-

Key words:

- hot dry rock /

- combined dynamic drilling process /

- turbodrill /

- HDR-1 /

- GR1 /

- Zhangzhou /

- Gonghe

-

-

表 1 钻孔基本情况

Table 1. Basic conditions of drilling

钻孔 位置 孔深/m 孔底温度/℃ 钻机型号 目的地层 HDR-1 福建漳州 4 000 109 ZJ30/1 700 晚白垩世早期细粒花岗岩 GR1 青海共和 3 705 236 大庆130/2 250 古近系三垛组侵入粗粒花岗岩 表 2 主要附属设备

Table 2. Main ancillary equipment

设备 参数 现场主要附属设备 缸径/mm 140 150 160 170 180 190 3NB-1300D泥浆泵 排量/ (L·s−1) 28.16 32.32 36.78 41.51 46.54 51.85 压力/MPa 31 27 24 21 19 17 冲程:305 mm; 冲数:120 spm; 标配电机:956 kW 固控设备 振动筛1台型号:ZSL×1.15×2-2;离心机1台型号:LW450-842N 涡轮钻具规格参数 钻具外径132 mm,涡轮长度6.5 m,支撑节长度1.6 m,额定排量15 L/s,制动扭矩900 N·m 表 3 目的层钻孔结构

Table 3. Borehole structure in the target layer

井号 开钻次序 井深/m 钻头尺寸/mm 套管尺寸/mm 钻机型号 取芯段岩性 HDR-1 三开 2 860 215.9 177.8 ZJ30/1700 晚白垩世早期细粒花岗岩 四开 4 000 152.4 − GR1 三开 3 361 215.9 177.8 大庆130/1700 古近系三垛组侵入中粗粒花岗岩 四开 2 705 152.4 − 大庆130/2250 表 4 涡轮复合取芯钻进与常规取芯钻进对比

Table 4. Comparison of turbine composite coring drilling and ordinary coring drilling

井号 取芯钻进方式 取芯次数 取芯进尺/m 平均机械

钻速/(m·h−1)岩心采

取率/%HDR-1 常规 25 75 1.03 73.1 复合 6 15 1.52 74.4 对比提高 − − 0.49 1.3 GR1 常规 20 60 1.16 82.2 复合 5 13 1.74 83.6 对比提高 − − 0.58 1.4 表 5 钻头使用情况

Table 5. Usage of drill bits

使用地点及井号 取芯钻进方式 钻头转速/rpm 单个钻头平均取芯进尺/m 福建漳州HDR-1 常规 93 12.5 复合 550 5.9 对比 − 使用寿命、进尺缩短 青海共和GR1 常规 93 13.6 复合 550 6.3 对比 − 使用寿命、进尺缩短 -

[1] 陆川, 王贵玲. 干热岩研究现状与展望[J]. 科技导报,2015,33(19):13 − 21. [LU Chuan, WANG Guiling. Current status and prospect of hot dry rock research[J]. Science & Technology Review,2015,33(19):13 − 21. (in Chinese with English abstract) doi: 10.3981/j.issn.1000-7857.2015.19.001

[2] 董明键, 肖新磊, 边培明. 复合钻井技术在元坝地区陆相地层中的应用[J]. 石油钻探技术,2010,38(4):38 − 40. [DONG Mingjian, XIAO Xinlei, BIAN Peiming. Application of compound drilling technology in terrestrial formation in yuanba area[J]. Petroleum Drilling Techniques,2010,38(4):38 − 40. (in Chinese with English abstract)

[3] DERKACH N D, KRUTIK E N, KOROTAEV Y A. Gear reduction turbodrills improve drilling results[C]//SPE Annual Technical Conference and Exhibition. New Orleans, Louisiana. Society of Petroleum Engineers, 1998: 27 − 30.

[4] HEYWOOD C, CURRIE A J, ROBSON D, et al. Recent material and geometrical changes in impreg technology on turbine drive lead to reduced drilling costs in hard rock[C]//SPE/IADC Middle East Drilling Technology Conference and Exhibition. Dubai, United Arab Emirates. Society of Petroleum Engineers, 2005: 12 − 14.

[5] REYNOLDS S D, MILDREN S D, HILLIS R R, et al. The in situ stress field of the Cooper Basin and its implications for hot dry rock geothermal energy development[R]. PESA Eastern Australian Basins Symposium II, 2004, 431 − 440.

[6] LANGILLE P, DEEN C A, KLASSEN J. Minimizing risks, maximizing on-bottom drilling time: turbodrilling with impregnated bits improves efficiency and circumvents trouble time, southern Oklahoma[C]//SPE/IADC Drilling Conference and Exhibition. Amsterdam, The Netherlands. Society of Petroleum Engineers, 2009: 17 − 19.

[7] ALBRECHT M, FEROZE N, CARRILLO G, et al. Innovative solution for drilling pre khuff formations in Saudi Arabia utilizing turbodrill and impregnated bits[C]//SPE Middle East Oil and Gas Show and Conference. Manama, Bahrain. Society of Petroleum Engineers, 2009: 15 − 18.

[8] BAHRAMI D, DANKO G, FU P, et al. Poroelastic and self-propped single fracture THM models for EGS studies [C]//Proceedings of Fortieth Workshop On Geothermal Reservoir Engineering. California: Stanford University Press, 2015 : 1 − 20.

[9] BROWN D W, DUCHANE D V, HEIKEN G, et al. The enormous potential for hot dry rock geothermal energy[C]//Mining the Earth's Heat: Hot Dry Rock Geothermal Energy. Berlin, Heidelberg: Springer Berlin Heidelberg, 2012: 17 − 40.

[10] DE SIMONE S, VILARRASA V, CARRERA J, et al. Thermal coupling may control mechanical stability of geothermal reservoirs during cold water injection[J]. Physics and Chemistry of the Earth, Parts A/B/C,2013,64:117 − 126. doi: 10.1016/j.pce.2013.01.001

[11] FRIÐLEIFSSON G Ó, ELDERS W A. Successful drilling for supercritical geothermal resources at reykjanes in SW Iceland. GRC Transactions[R].2017: 1095 − 1107.

[12] MIT-led Interdisciplinary Panel. The future of geothermal energy: Impact of enhanced geothermal systems (EGS) on the United States in the 21st century [R]. Idaho: Idaho National Library, 2006: 1 − 255.

[13] FRIDLEIFSSON I B, R BERTANI, E HUENGES, et al. The possible role and contribution of geothermal energy to the mitigation of climate change[ C]//Hohmeyer O, Trittin T. IPCC Scoping Meeting on Renewable Energy Sources Proceedings. Luebeck, Germany: IPCC, 2008: 59 − 80.

[14] BERTANI R. Geothermal generation in the world 2005-2010 update report [C]// WGC Technical Programme Committee. Proceedings World Geothermal Congress 2010. Bali, Indonesia: WGC, 2010: 8.

[15] GENTER, A N CUENOT, B MELCHERT, et al. Main achievements from the multi-well EGS Soultz project during geothermal exploration from 2010 and 2012 [C]//Proceedings of EGC 2013. Italy: EGEC. 2013: PS1 − 01.

[16] LEAT P T. Geological evolution of the trachytic caldera volcano Menengai, Kenya Rift Valley[J]. Journal of the Geological Society,1984,141(6):1057 − 1069. doi: 10.1144/gsjgs.141.6.1057

[17] 成海, 郑卫建, 夏彬, 等. 国内外涡轮钻具钻井技术及其发展趋势[J]. 石油矿场机械,2008,37(4):28 − 31. [CHENG Hai, ZHENG Weijian, XIA Bin, et al. The development trend of turbodrilling technology[J]. Oil Field Equipment,2008,37(4):28 − 31. (in Chinese with English abstract) doi: 10.3969/j.issn.1001-3482.2008.04.007

[18] 刘新义, 张东清. 川东北地区探井快速钻井技术[J]. 石油钻探技术,2008,36(3):37 − 40. [LIU Xinyi, ZHANG Dongqing. Rapid drilling technology used in exploratory wells in northeast Sichuan area[J]. Petroleum Drilling Techniques,2008,36(3):37 − 40. (in Chinese with English abstract) doi: 10.3969/j.issn.1001-0890.2008.03.009

[19] 蒋祖军, 肖国益, 李群生. 川西深井提高钻井速度配套技术[J]. 石油钻探技术,2010,38(4):30 − 34. [JIANG Zujun, XIAO Guoyi, LI Qunsheng. Technology to increase deep well drilling speed in western Sichuan[J]. Petroleum Drilling Techniques,2010,38(4):30 − 34. (in Chinese with English abstract)

[20] 高航献, 瞿佳, 曾鹏珲. 元坝地区钻井提速探索与实践[J]. 石油钻探技术,2010,38(4):26 − 29. [GAO Hangxian, QU Jia, ZENG Penghui. Research and practice to improve drilling speed in Yuanba area[J]. Petroleum Drilling Techniques,2010,38(4):26 − 29. (in Chinese with English abstract)

[21] 陈天成, 白彬珍. 涡轮钻井技术适应性分析与应用探析[J]. 钻采工艺,2010,33(6):1 − 5. [CHEN Tiancheng, BAI Binzhen. Adaptability analysis of turbine drilling technology[J]. Drilling & Production Technology,2010,33(6):1 − 5. (in Chinese with English abstract)

[22] 谭春飞, 蔡镜仑. 利用涡轮钻具提高深井钻速的试验研究[J]. 石油钻探技术,2003,31(5):30 − 32. [TAN Chunfei, CAI Jinglun. Trial tests for full exert advantages of turbodrill to improve ROP in deep wells[J]. Petroleum Drilling Techniques,2003,31(5):30 − 32. (in Chinese with English abstract) doi: 10.3969/j.issn.1001-0890.2003.05.010

[23] 李伟廷. 元坝1井超深井钻井技术[J]. 石油钻探技术,2009,37(2):94 − 99. [LI Weiting. Ultra-deep drilling technologies used on well yuanba-1[J]. Petroleum Drilling Techniques,2009,37(2):94 − 99. (in Chinese with English abstract) doi: 10.3969/j.issn.1001-0890.2009.02.025

[24] 王光磊, 侯健, 于承朋, 等. 元坝1井钻井设计与施工[J]. 石油钻探技术,2008,36(3):41 − 45. [WANG Guanglei, HOU Jian, YU Chenpeng, et al. Drilling design and operation of well yuanba-1[J]. Petroleum Drilling Techniques,2008,36(3):41 − 45. (in Chinese with English abstract) doi: 10.3969/j.issn.1001-0890.2008.03.010

[25] 冉恒谦, 冯起赠. 我国干热岩勘查的有关技术问题[J]. 探矿工程(岩土钻掘工程),2010,37(10):17 − 21. [RAN Hengqian, FENG Qizeng. Some technical issues on hot dry rock exploration in China[J]. Exploration Engineering (Rock & Soil Drilling and Tunneling),2010,37(10):17 − 21. (in Chinese with English abstract)

[26] 光新军, 王敏生. 高温地热高效开发钻井关键技术[J]. 地质与勘探,2016,52(4):718 − 724. [GUANG Xinjun, WANG Minsheng. Key drilling technologies for efficient development of high-temperature geothermal resources[J]. Geology and Exploration,2016,52(4):718 − 724. (in Chinese with English abstract)

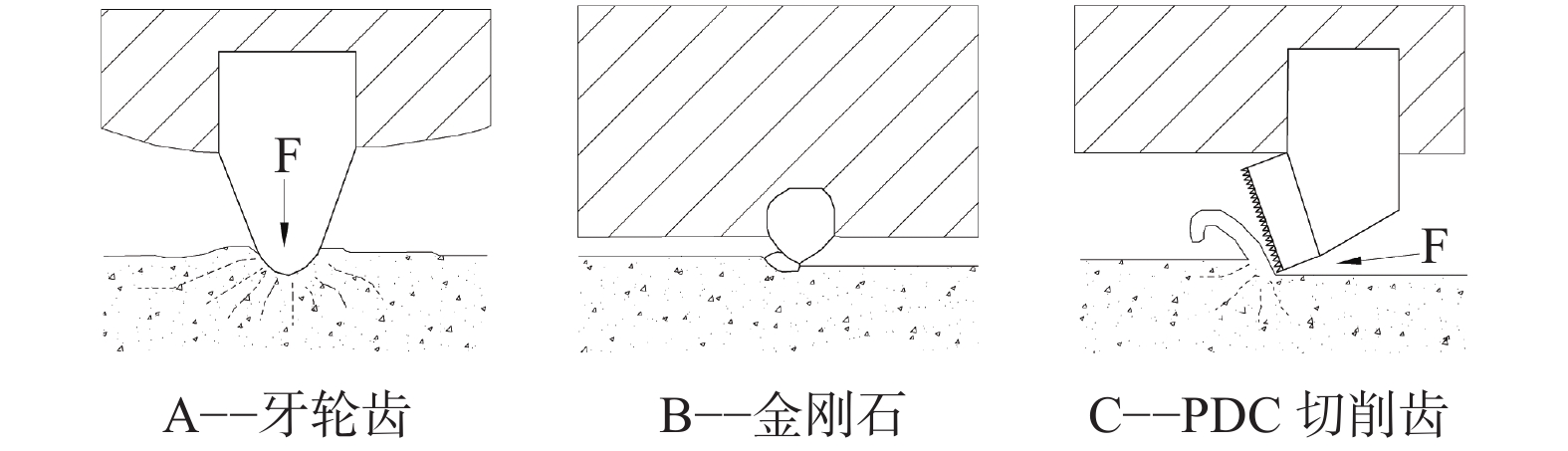

[27] 贾美玲, 蔡家品, 黄玉文, 等. 大陆科学钻探用新型镶嵌式钻头的研究[J]. 探矿工程(岩土钻掘工程),2003,30(增刊1):289 − 291. [JIA Meiliang, CAI Jiapin, HUANG Yuwen, et al. Research on new type of inserted bits used in scientific drilling[J]. Exploration Engineering (Drilling & Tunneling),2003,30(Sup1):289 − 291. (in Chinese with English abstract)

[28] 沈立娜, 阮海龙. 国内外金刚石钻头的部分技术进展[J]. 探矿工程(岩土钻掘工程),2011,38(5):78 − 80. [SHEN Lina, RUAN Hailong. Some technical development of diamond bit both in China and abroad[J]. Exploration Engineering (Rock & Soil Drilling and Tunneling),2011,38(5):78 − 80. (in Chinese with English abstract)

[29] 贾军, 张德龙, 翁炜, 等. 干热岩钻探关键技术及进展[J]. 科技导报,2015,33(19):40 − 44. [JIA Jun, ZHANG Delong, WENG Wei, et al. Key technology and development of hot dry rock drilling[J]. Science & Technology Review,2015,33(19):40 − 44. (in Chinese with English abstract) doi: 10.3981/j.issn.1000-7857.2015.19.005

-

下载:

下载: