Mechanical properties and mechanism analyses of rice husk ash geopolymer solidified soil

-

摘要:

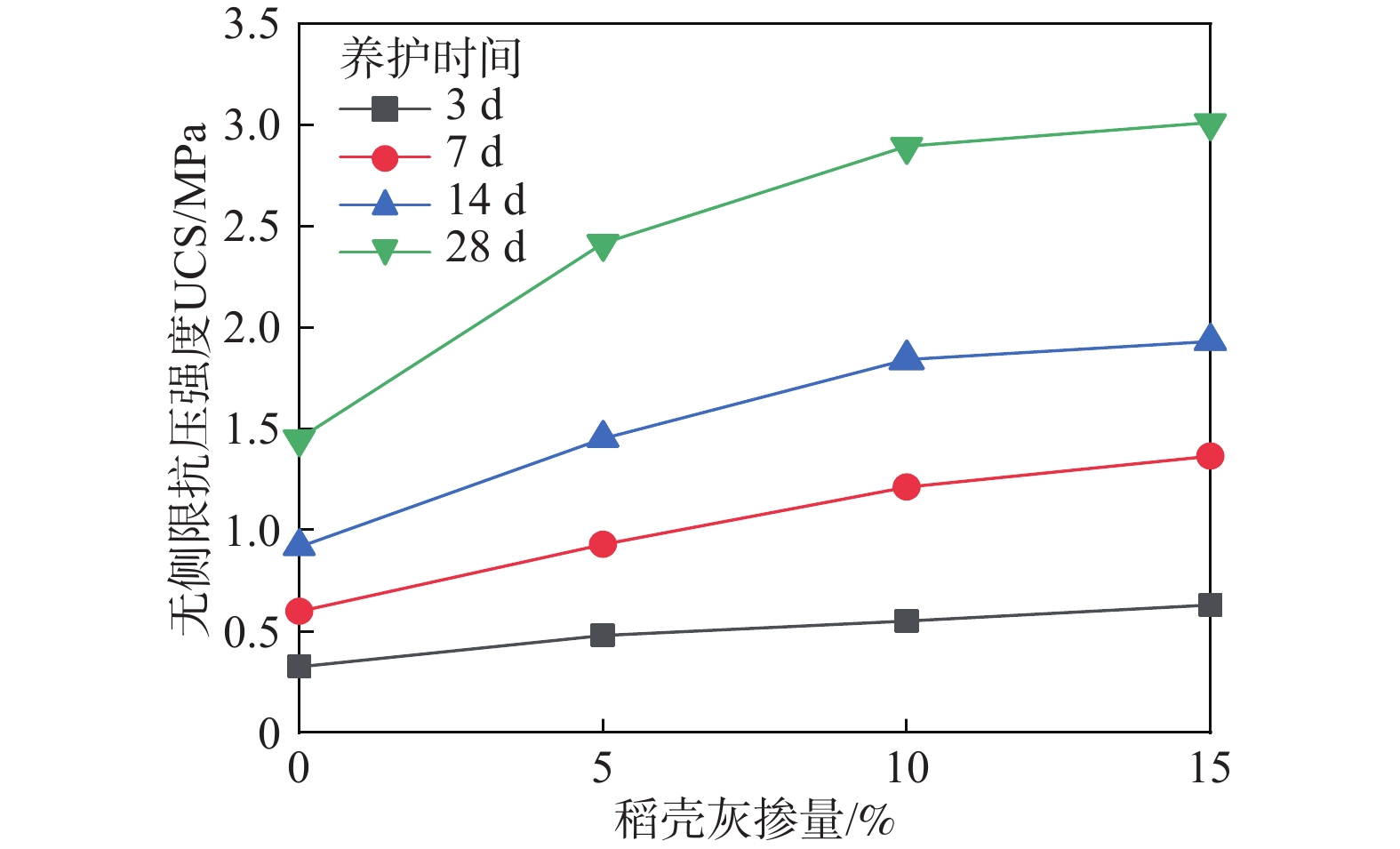

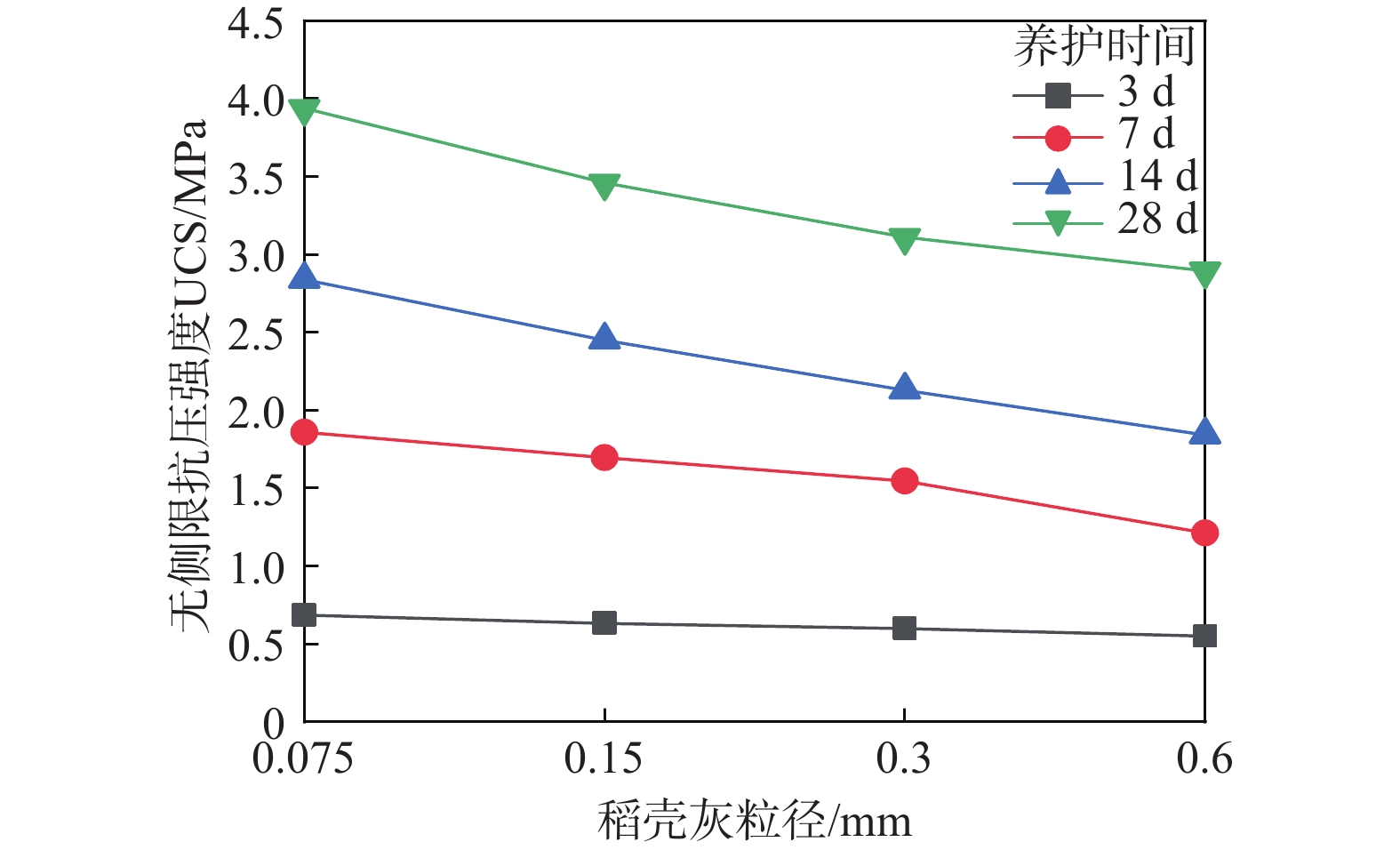

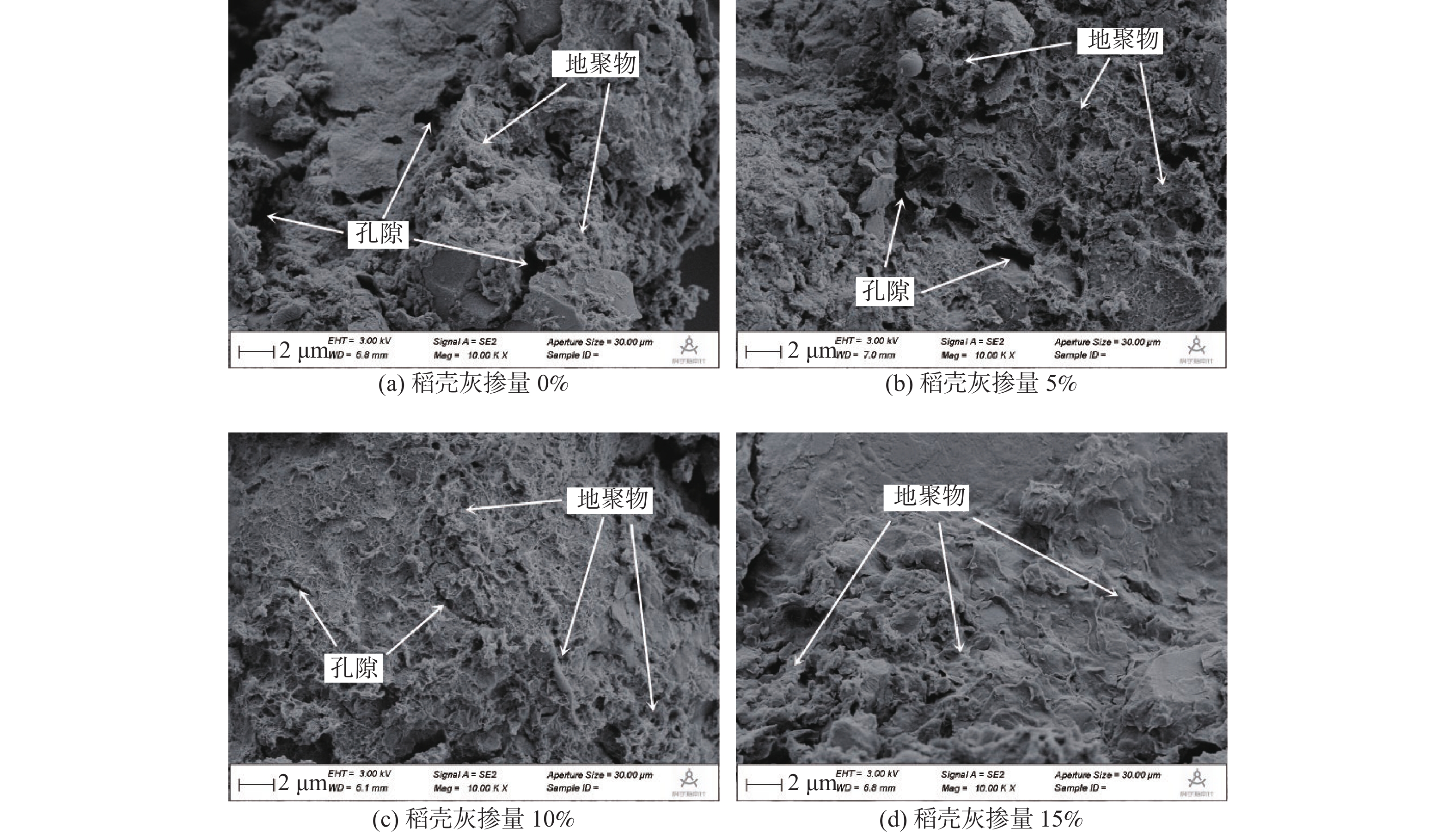

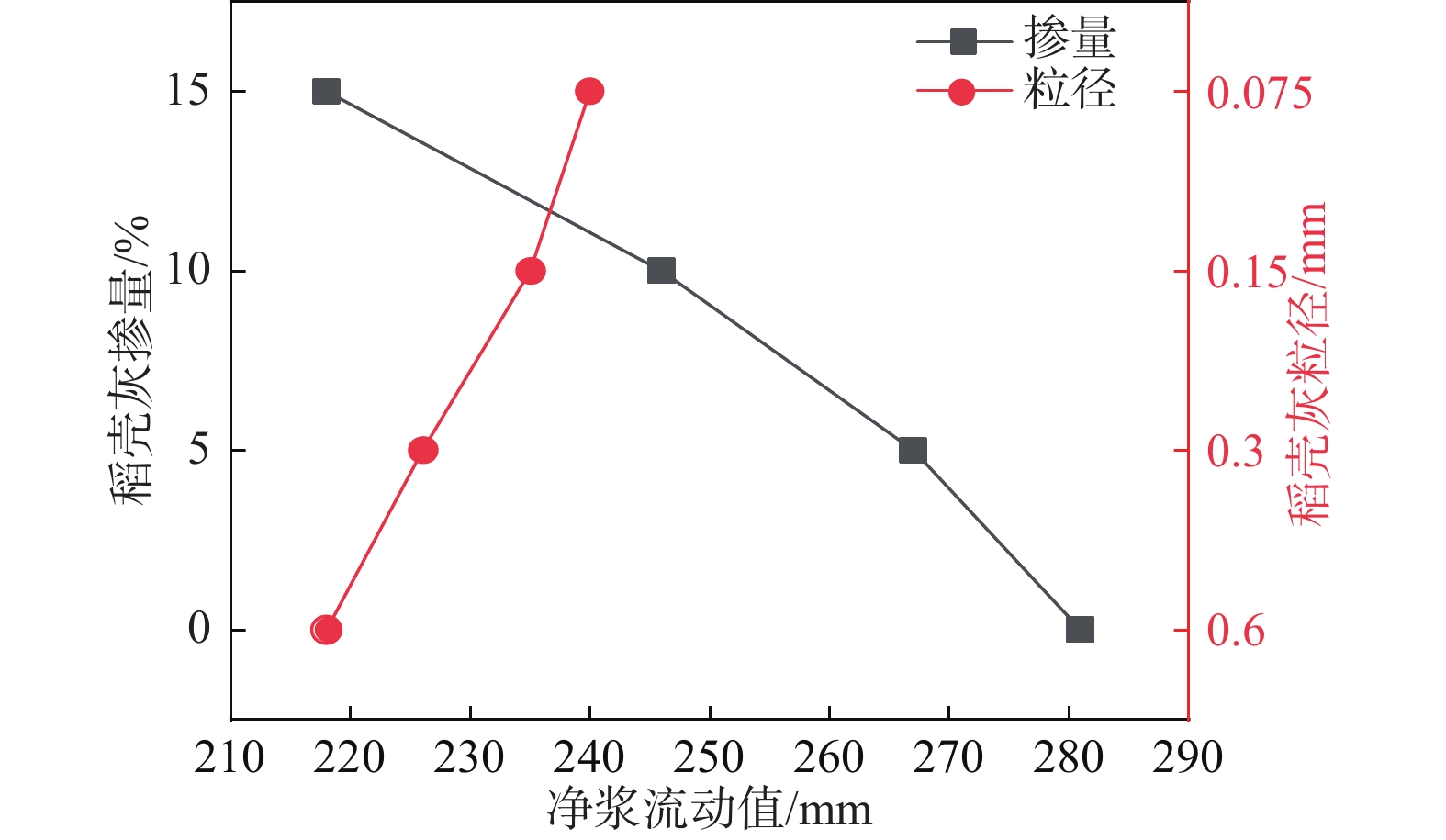

为了研究绿色环保新型流态固化土在狭窄肥槽回填等工程问题中的应用,提出稻壳灰联合地聚物固化工程渣土形成流态稻壳灰-地聚物固化土。采用无侧限抗压强度(UCS)试验、X射线衍射(XRD)、扫描电子显微镜(SEM)和X射线能谱分析(EDS)等测试方法,研究稻壳灰的掺量与粒径对稻壳灰-地聚物固化土的无侧限抗压强度(UCS)的影响规律,并探讨了稻壳灰掺量与粒径对其微观结构影响规律。结果表明:稻壳灰-地聚物固化土的净浆流动度与稻壳灰的掺量、粒径呈负相关关系,其凝结时间与稻壳灰掺量呈正相关关系,但与稻壳灰的粒径呈负相关关系;稻壳灰-地聚物固化土UCS值随着稻壳灰的掺量增加、粒径降低而显著提高,当稻壳灰的掺量增加到10%后,强度提升效能降低,初步判定稻壳灰的最优掺量为10%;固化过程中产生水化硅铝酸钠(N-A-S-H)和水化硅酸钙(C-S-H)2种凝胶,起到填充内部孔隙和胶结土颗粒的作用,使整体结构趋于完整,是稻壳灰-地聚物固化土强度提升的根本原因。研究成果可为稻壳灰在流态固化土的工程应用提供理论依据。

Abstract:In order to study the application of the green environmental protection fluid solidified soil in engineering problems such as backfilling of a narrow fertilizer tank, the rice husk ash and geopolymer solidified engineering residue forming the fluid rice husk ash geopolymer solidified soil is proposed. The effects of the content and particle size of the rice husk ash on the unconfined compressive strength (UCS) of the rice husk ash geopolymer stabilized soil are examined by using the test methods of the unconfined compressive strength (UCS), X-ray diffraction (XRD), scanning electron microscope (SEM) and X-ray energy spectrum analysis (EDS), and the effects of the content and particle size of the rice husk ash on the microstructure of the soil are discussed. The results show that the net pulp fluidity of the rice husk ash geopolymer solidified soil is negatively correlated with the content and particle size of the rice husk ash, and the setting time is positively correlated with the content of the rice husk ash, but is negatively correlated with the particle size of the rice husk ash. The UCS value of the rice husk ash geopolymer stabilized soil increases significantly with the increase of the content of the rice husk ash and with the decrease of the particle size. When the content of the rice husk ash increases to 10%, the strength improvement efficiency decreases, and the optimal content of the rice husk ash is 10%. During the curing process, two kinds of gels, namely hydrated sodium aluminosilicate (N-A-S-H) and hydrated calcium silicate (C-S-H), play the role of filling the internal pores and cemented soil particles, so that the whole structure tends to be complete, which is the fundamental reason for the strength improvement of the rice husk ash geopolymer stabilized soil. The research results can provide a theoretical basis for the engineering application of the rice husk ash in fluid solidified soils.

-

Key words:

- fluid solidified soil /

- geopolymer /

- rice husk ash /

- unconfined compressive strength /

- micro-mechanism

-

-

表 1 粉煤灰、GGBS、水泥、稻壳灰的化学组成

Table 1. Chemical compositions of the fly ash, GGBS, cement and rice husk ash

/% 材料 SiO2 Al2O3 Fe2O3 MgO CaO Na2O SO3 K2O 粉煤灰 63.34 27.00 2.00 1.00 3.00 1.11 1.10 1.05 GGBS 35.41 20.24 0.18 8.16 31.64 1.36 1.79 0.29 水泥 23.22 4.51 2.33 1.16 60.47 0.87 4.22 1.23 稻壳灰 84.00 1.35 1.45 3.17 0.932 表 2 固化土设计方案

Table 2. Design scheme of the solidified soil

试验编号 稻壳灰掺量/% 稻壳灰粒径/mm 碱激发剂掺量/% GFP 0 10 GFPD1-1 5 0.6 10 GFPD1-2 5 0.3 10 GFPD1-3 5 0.15 10 GFPD1-4 5 0.075 10 GFPD2-1 10 0.6 10 GFPD2-2 10 0.3 10 GFPD2-3 10 0.15 10 GFPD2-4 10 0.075 10 GFPD3-1 15 0.6 10 GFPD3-2 15 0.3 10 GFPD3-3 15 0.15 10 GFPD3-4 15 0.075 10 表 3 SEM图点1与点2的元素占比

Table 3. Element proportion of point 1 and point 2 in SEM

点号 O Si Ca Al Na 1 重量百分比 25.63 42.48 4.98 20.75 4.78 原子百分比 37.38 35.67 2.93 18.14 4.91 2 重量百分比 53.60 11.84 24.55 4.27 2.19 原子百分比 71.20 8.96 13.02 3.37 2.03 -

[1] DU Y J, YU B W, LIU K, et al. Physical, hydraulic, and mechanical properties of clayey soil stabilized by lightweight alkali-activated slag geopolymer[J]. Journal of Materials in Civil Engineering,2017,29(2):04016217. doi: 10.1061/(ASCE)MT.1943-5533.0001743

[2] PHUMMIPHAN I, HORPIBULSUK S, RACHAN R, et al. High calcium fly ash geopolymer stabilized lateritic soil and granulated blast furnace slag blends as a pavement base material[J]. Journal of Hazardous Materials,2018,341:257 − 267. doi: 10.1016/j.jhazmat.2017.07.067

[3] 俞家人, 陈永辉, 陈庚, 等. 地聚物固化软黏土的力学特征及机理分析[J]. 建筑材料学报,2020,23(2):364 − 371. [YU Jiaren, CHEN Yonghui, CHEN Geng, et al. Mechanical behaviour of geopolymer stabilized clay and its mechanism[J]. Journal of Building Materials,2020,23(2):364 − 371. (in Chinese with English abstract)

[4] 杨世玉, 赵人达, 靳贺松, 等. 粉煤灰地聚物砂浆早期强度的影响参数研究[J]. 工程科学与技术,2020,52(6):162 − 169. [YANG Shiyu, ZHAO Renda, JIN Hesong, et al. Research on influence parameters of early strength of fly ash-based geopolymer mortar[J]. Advanced Engineering Sciences,2020,52(6):162 − 169. (in Chinese with English abstract)

[5] 贾栋钦, 裴向军, 张晓超, 等. 改性糯米灰浆固化黄土的微观机理试验研究[J]. 水文地质工程地质,2019,46(6):90 − 96. [JIA Dongqin, PEI Xiangjun, ZHANG Xiaochao, et al. A test study of the microscopic mechanism of modified glutinous rice mortar solidified loess[J]. Hydrogeology & Engineering Geology,2019,46(6):90 − 96. (in Chinese with English abstract)

[6] 周恒宇, 王修山, 胡星星, 等. 地聚合物固化淤泥强度增长影响因素及机制分析[J]. 岩土力学,2021,42(8):2089 − 2098. [ZHOU Hengyu, WANG Xiushan, HU Xingxing, et al. Influencing factors and mechanism analysis of strength development of geopolymer stabilized sludge[J]. Rock and Soil Mechanics,2021,42(8):2089 − 2098. (in Chinese with English abstract)

[7] 何俊, 栗志翔, 石小康, 等. 侵蚀环境中碱渣-矿渣固化淤泥的力学性质[J]. 水文地质工程地质,2019,46(6):83 − 89. [HE Jun, LI Zhixiang, SHI Xiaokang, et al. Mechanical properties of the soft soil stabilized with soda residue and ground granulated blast furnace slag under the erosion environment[J]. Hydrogeology & Engineering Geology,2019,46(6):83 − 89. (in Chinese with English abstract)

[8] 邓永锋, 吴子龙, 刘松玉, 等. 地聚合物对水泥固化土强度的影响及其机理分析[J]. 岩土工程学报,2016,38(3):446 − 453. [DENG Yongfeng, WU Zilong, LIU Songyu, et al. Influence of geopolymer on strength of cement-stabilized soils and its mechanism[J]. Chinese Journal of Geotechnical Engineering,2016,38(3):446 − 453. (in Chinese with English abstract) doi: 10.11779/CJGE201603007

[9] 叶华洋, 张伟锋, 韦未, 等. 激发剂-地聚合物对软土固化试验研究[J]. 应用基础与工程科学学报,2019,27(4):906 − 917. [YE Huayang, ZHANG Weifeng, WEI Wei, et al. Experimental study on the curing of soft soil with activator-geopolymer[J]. Journal of Basic Science and Engineering,2019,27(4):906 − 917. (in Chinese with English abstract)

[10] 汪知文, 李碧雄. 稻壳灰应用于水泥混凝土的研究进展[J]. 材料导报,2020,34(9):9003 − 9011. [WANG Zhiwen, LI Bixiong. Research progress on application of rice husk ash in cement and concrete[J]. Materials Reports,2020,34(9):9003 − 9011. (in Chinese with English abstract) doi: 10.11896/cldb.19050098

[11] MUNTOHAR A S, WIDIANTI A, HARTONO E, et al. Engineering properties of silty soil stabilized with lime and rice husk ash and reinforced with waste plastic fiber[J]. Journal of Materials in Civil Engineering,2013,25(9):1260 − 1270. doi: 10.1061/(ASCE)MT.1943-5533.0000659

[12] GHORBANI A, SALIMZADEHSHOOIILI M. Dynamic characterization of sand stabilized with cement and RHA and reinforced with polypropylene fiber[J]. Journal of Materials in Civil Engineering,2019,31(7):04019095. doi: 10.1061/(ASCE)MT.1943-5533.0002727

[13] 厚荣斌. 钢渣、稻壳灰和生石灰改良膨胀土的性能研究[J]. 公路交通科技(应用技术版),2017,13(7):208 − 210. [HOU Rongbin. Study on properties of expansive soil improved by steel slag, rice husk ash and quicklime[J]. Journal of Highway and Transportation Research and Development(Application Technology Edition),2017,13(7):208 − 210. (in Chinese)

[14] NASIRI M, LOTFALIAN M, MODARRES A, et al. Optimum utilization of rice husk ash for stabilization of sub-base materials in construction and repair project of forest roads[J]. Croatian Journal of Forest Engineering,2016,37(2):333 − 343.

[15] GHADIR P, RANJBAR N. Clayey soil stabilization using geopolymer and Portland cement[J]. Construction and Building Materials,2018,188:361 − 371. doi: 10.1016/j.conbuildmat.2018.07.207

-

下载:

下载: