Experimental Research on Nelson Gravity Separation from a Gold Mine Flotation Tailings in Subei

-

摘要:

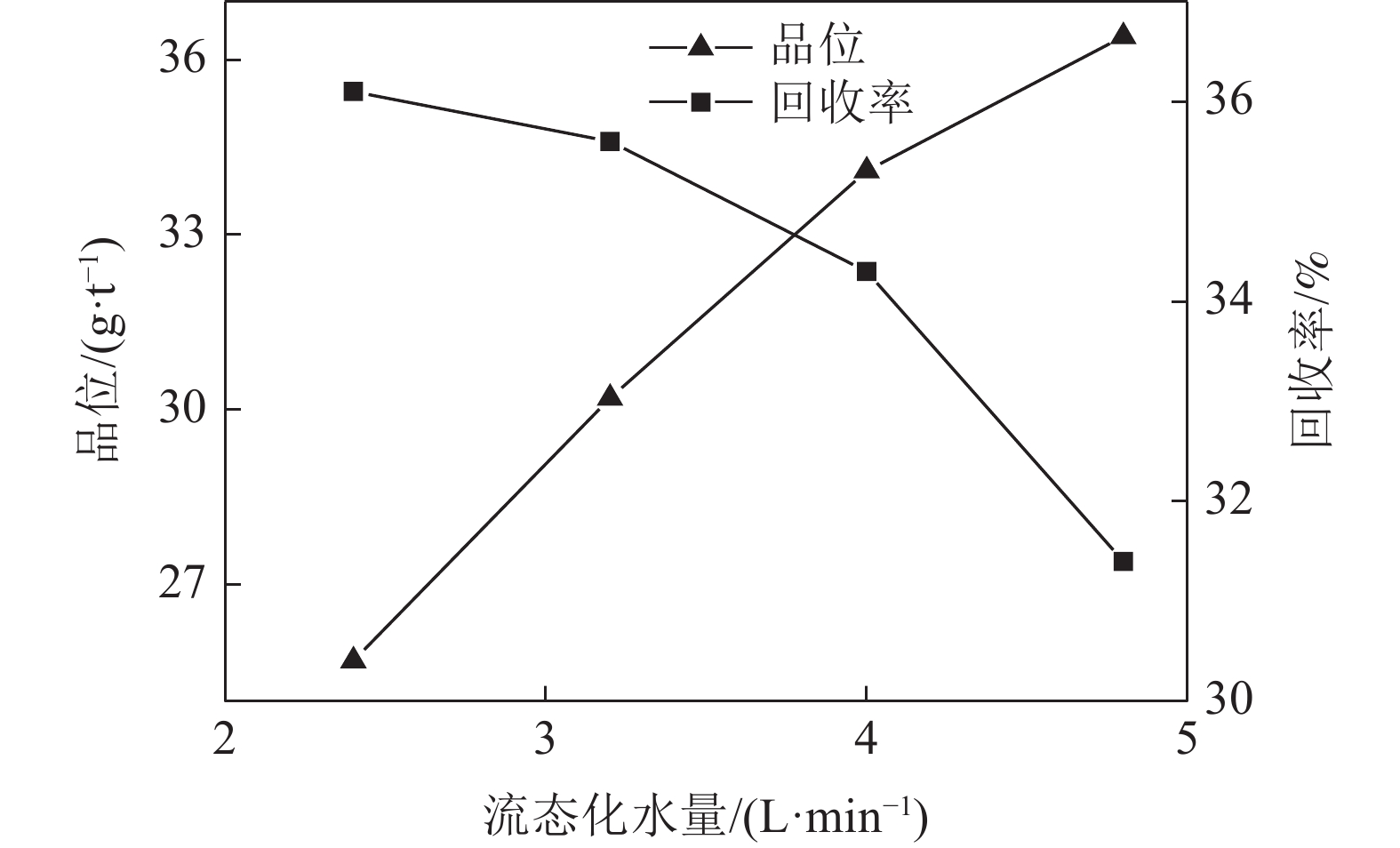

肃北某金矿选厂采用浮选工艺处理原矿石,近期由于原矿性质变化较大,金嵌布粒度变粗,造成选厂跑尾严重,尾矿金品位约为0.70~0.90 g/t。工艺矿物学研究表明其主要金属矿物为黄铁矿、黄铜矿,主要脉石矿物为石英、长石、高岭土等,矿物组成较复杂。从尾矿筛析结果来看,金主要以粗、中粒金为主,适宜采用尼尔森进行回收。在扩大重力倍数60 G、流态化水量3.2 L/min、给矿速度10 kg/h、原矿品位0.87 g/t的条件下,可以取得金精矿品位33.42 g/t,回收率35.27%的良好指标。

Abstract:A gold mine in Subei adopts flotation process to treat ores. Recently, due to the large change of the ore properties, the size of the gold inlay becomes thicker, resulting in gold entering tailings. The gold grade of the tailings is about 0.70~0.90 g/t. Process mineralogical studies show that the main metal minerals are pyrite and chalcopyrite. The mineral composition is more complicated, and the main gangue minerals are quartz, feldspar, kaolin, etc. From the results of tailings screening, gold is mainly composed of coarse and medium-grain, which is suitable for recycling with Nelson. Under the conditions of expanding gravity multiplier 60 G, fluidized water volume 3.2 L/min, feeding rate 10 kg/h, and ore grade 0.87 g/t, a good index of 33.42 g/t gold concentrate grade and 35.27% recovery rate can be obtained.

-

Key words:

- Gold mine /

- Flotation tailings /

- Nelson /

- Gravity separation

-

-

表 1 原矿化学多元素分析结果/%

Table 1. Results of chemistry multi-element analysis of the raw ore

Au* Cu Pb Zn Fe S As 0.87 0.06 0.052 0.037 5.09 1.34 <0.05 Ag* SiO2 CaO MgO Al2O3 Mn Sb 0.43 72.54 3.45 0.72 10.46 0.07 <0.01 *单位为:g/t。 表 2 金物相分析结果

Table 2. Gold phase analysis

名称 单体

裸露金连生体 硫化物中包裹金 石英中包裹金 碳酸盐中包裹金 褐铁矿中包裹金 总金 品位/(g·t-1) 0.53 0.18 0.11 0.03 0.01 0.01 0.87 占有率/% 60.92 20.69 12.64 3.45 1.15 1.15 100.00 表 3 自然金矿物粒度统计

Table 3. Particle size statistics of the natural gold

粒 级 巨粒 粗粒 中粒 细粒 微粒 粒级范围/mm +0.3 -0.3+0.074 -0.074+0.037 -0.037+0.01 -0.01+0.0005 分布率/% 5.17 40.79 23.83 10.62 19.59 表 4 自然金矿物形态统计

Table 4. Morphology statistics of the natural gold

矿物颗粒形态 滚圆状 板片状 麦粒状 细脉状 枝杈状 星点状 不规则状 含量/% 9.30 35.20 2.40 26.80 7.60 15.00 3.70 表 5 筛析实验结果

Table 5. Results of screening test

粒级/μm 产 率/% Au品位/(g·t-1) Au金属分布率/% +74 31.07 1.44 51.65 -74+45 16.95 0.69 13.50 -45+37 6.78 0.32 2.50 -37 45.20 0.62 32.35 合计 100.00 0.87 100.00 表 6 尼尔森尾矿筛析实验结果

Table 6. Results of Nelson tailing screening test

粒级/μm 产 率/% 金品位/(g·t-1) 金属分布率/% +74 30.39 0.31 16.64 -74+45 16.05 0.49 13.89 -45+37 6.27 0.54 5.98 -37 47.29 0.76 63.49 合计 100.00 0.57 100.00 -

[1] 黄晟, 吕兵超, 廖银英, 等. 某含金多金属矿尼尔森重选试验研究[J]. 矿产综合利用, 2019(2):51-56. doi: 10.3969/j.issn.1000-6532.2019.02.010

HUANG S, LV B C, LIAO Y Y, et al. Study on nelson gravity separation of a polymetallic ore bearing gold[J]. Multipurpose Utilization of Mineral Resources, 2019(2):51-56. doi: 10.3969/j.issn.1000-6532.2019.02.010

[2] 李长根. 俄罗斯诺里尔斯克镍矿冶公司北极圈分公司镍-铜-铂族金属矿山[J]. 矿产综合利用, 2013(6):69-75. doi: 10.3969/j.issn.1000-6532.2013.06.019

LI C G. Nickel-copper-platinum group metal mine of Arctic circle branch of russian norilsk nickel mining and metallurgy company[J]. Multipurpose Utilization of Mineral Resources, 2013(6):69-75. doi: 10.3969/j.issn.1000-6532.2013.06.019

[3] 赵敏捷, 方建军, 李国栋, 等. 尼尔森选矿机在国内外选矿中的应用与研究进展[J]. 矿产保护与利用, 2016(4):73-78. doi: 10.13779/j.cnki.issn1001-0076.2016.04.015

ZHAO M J, FANG J J, LI G D, et al. Application and research progress of Nielsen concentrator in ore beneficiation at home and abroad[J]. Mineral Resources Conservation and Utilization, 2016(4):73-78. doi: 10.13779/j.cnki.issn1001-0076.2016.04.015

[4] 刘静宇. 某金矿重选尾矿回收金、铜的工艺研究[J]. 矿产综合利用, 2020(1):112-115. doi: 10.3969/j.issn.1000-6532.2020.01.023

LIU J Y. Recovery of gold and copper from tailings of gravity separation in a gold ore[J]. Multipurpose Utilization of Mineral Resources, 2020(1):112-115. doi: 10.3969/j.issn.1000-6532.2020.01.023

[5] 李军, 王露, 李朋, 等. 西藏某石英脉型金矿选矿试验研究[J]. 中国矿业, 2018, 27(7):108-111. doi: 10.12075/j.issn.1004-4051.2018.07.015

LI J, WANG L, LI P, et al. Experimental research on mineral processing of a quartz vein type gold deposit in Xizang[J]. China Mining, 2018, 27(7):108-111. doi: 10.12075/j.issn.1004-4051.2018.07.015

[6] 惠学德, 邹蔚蔚. 尼尔森选矿机的应用与发展[J]. 国外金属矿选矿, 1994, 31(3):46-50.

HUI X D, ZOU W W. Application and development of Nielsen concentrator[J]. Foreign Metallic Mineral Processing, 1994, 31(3):46-50.

-

下载:

下载: