Research on Mechanical and High Temperature Resistance Properties of Recycled Aggregate Concrete Containing Mineral Admixtures

-

摘要:

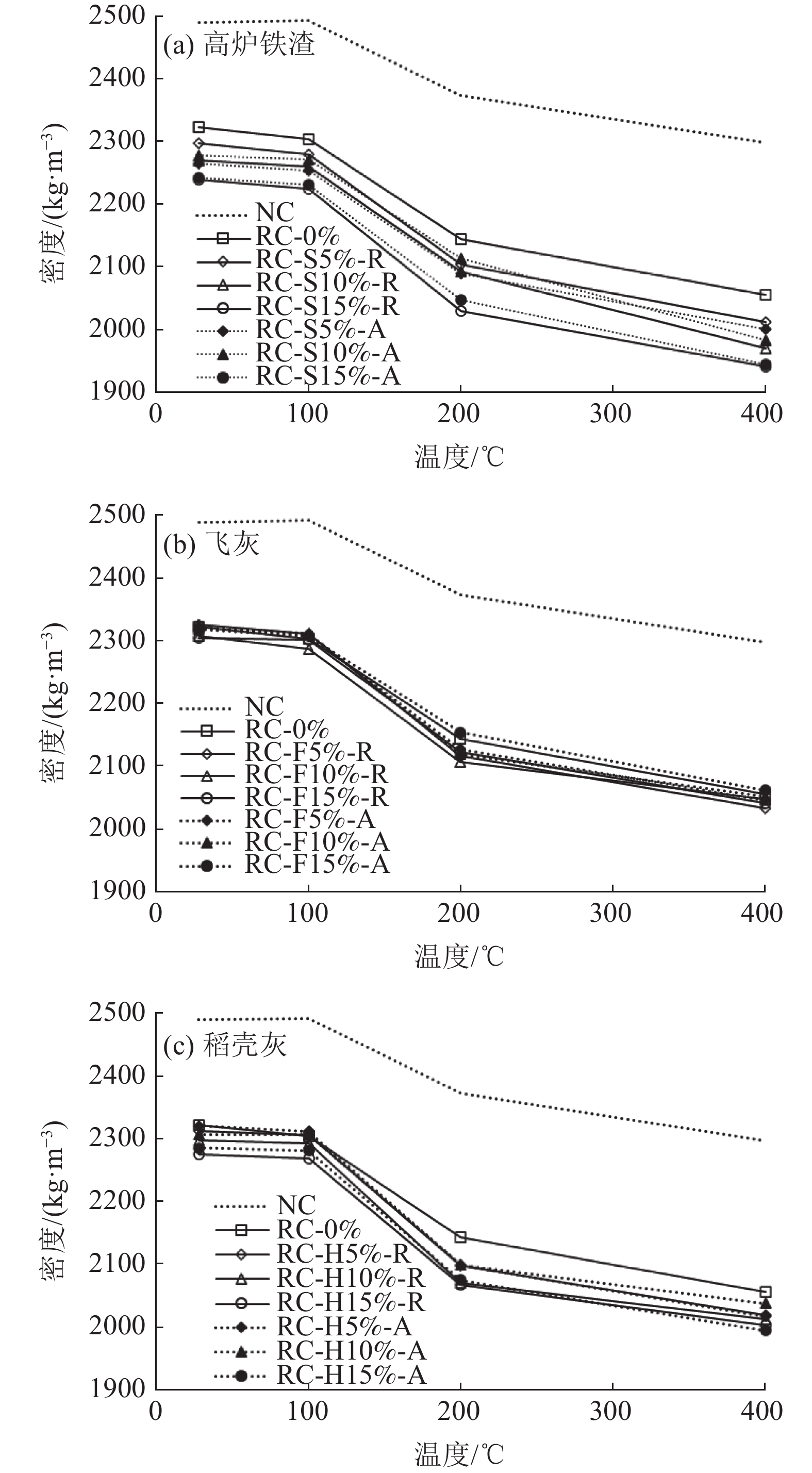

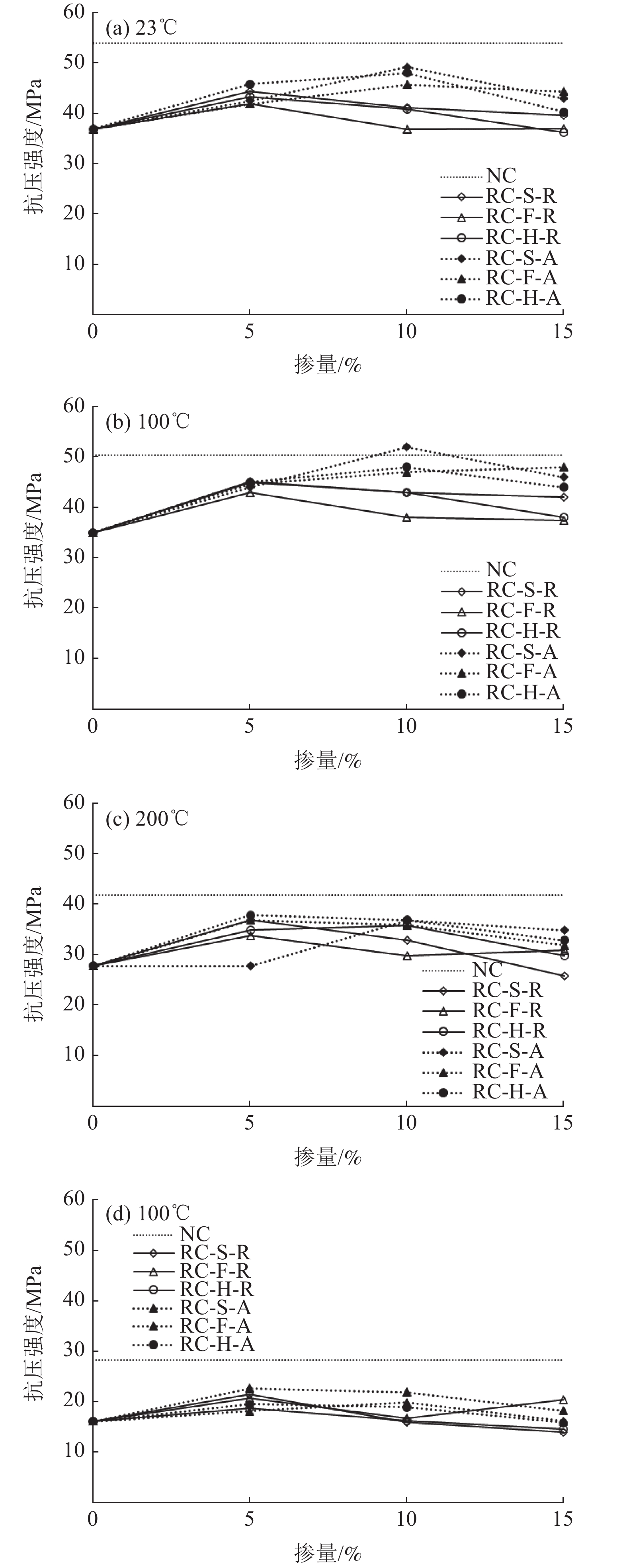

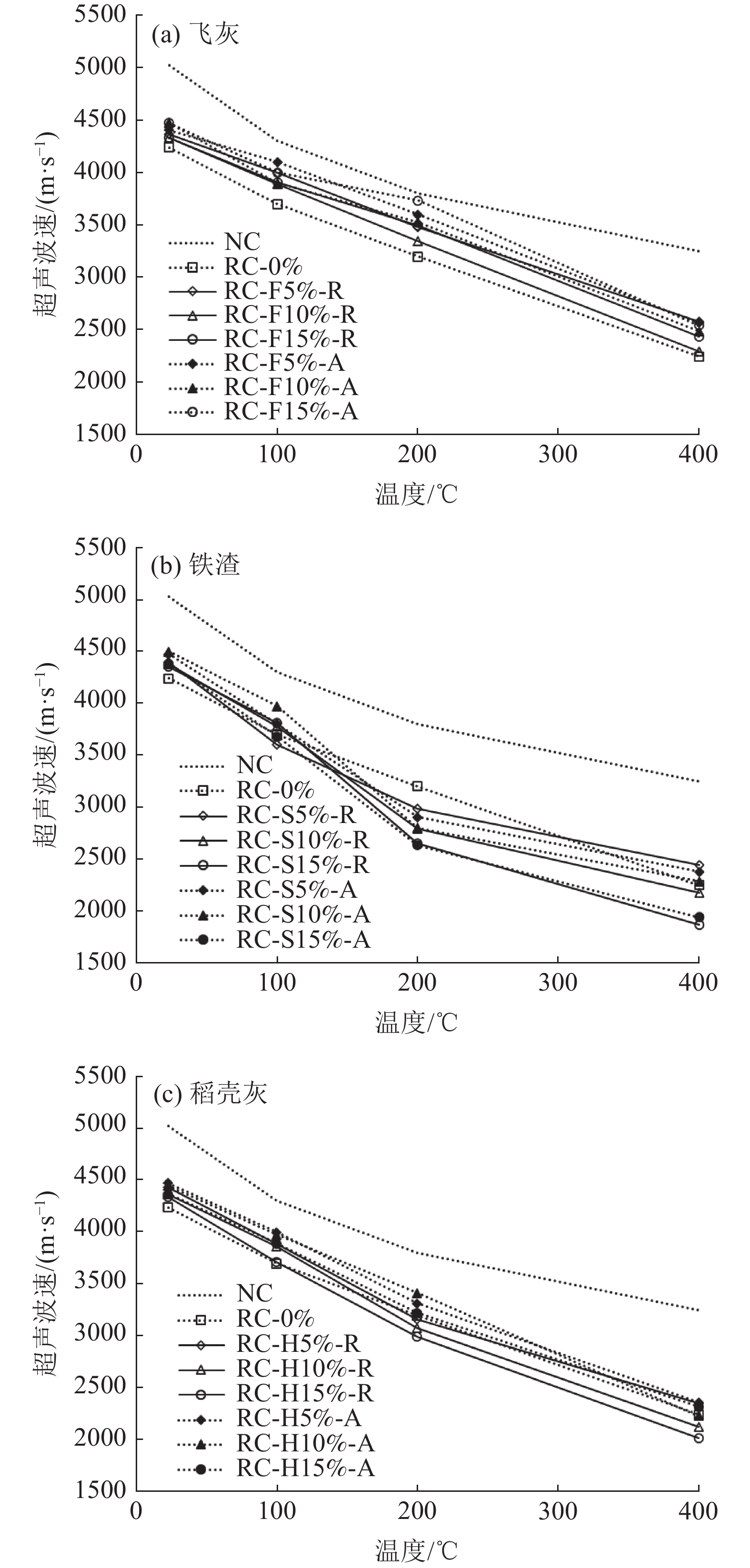

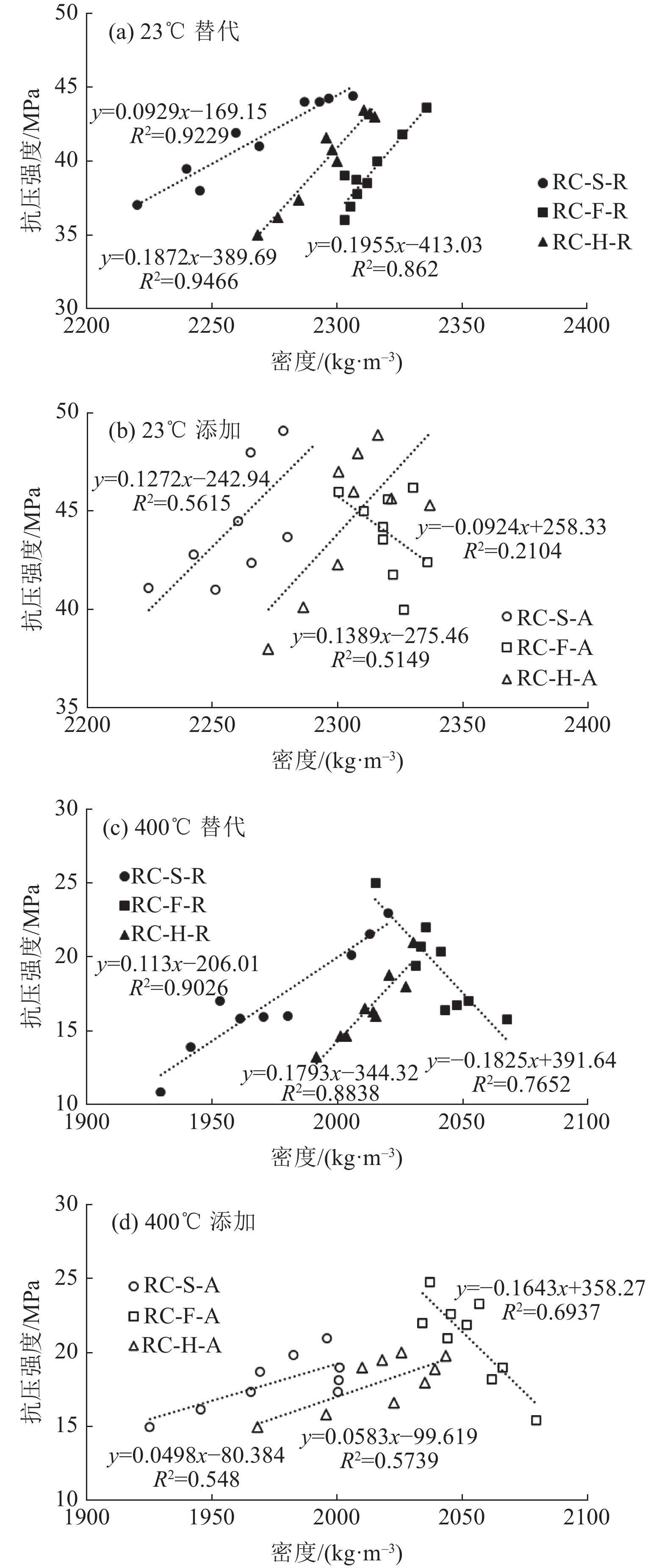

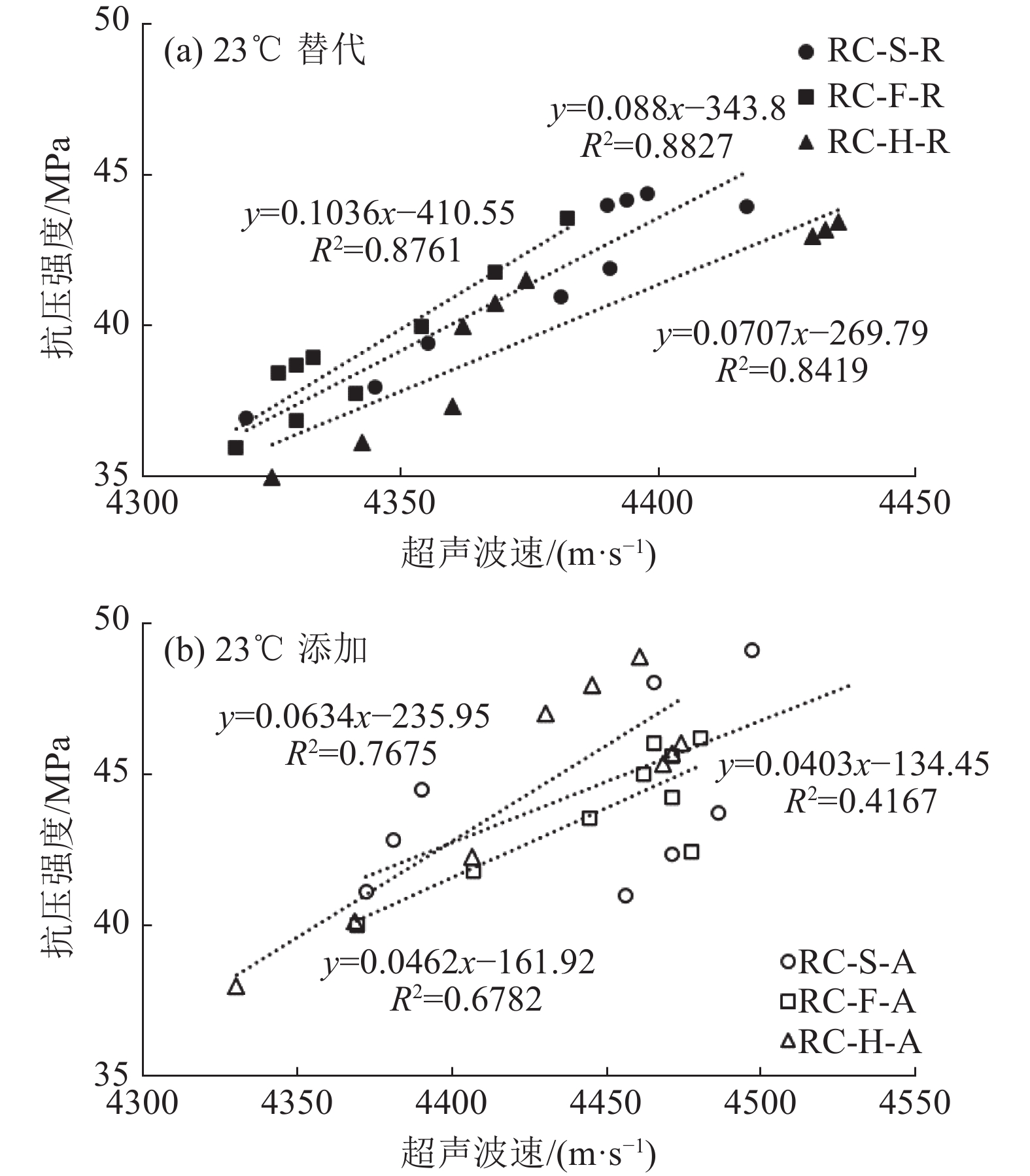

为了研究矿物掺合料对再生骨料混凝土的基本特性及耐高温特性的影响,利用飞灰、铁渣和稻壳灰对再生骨料混凝土进行改性,并进行高温和力学实验。结果表明,随着温度的升高,试样的密度和超声波速不断下降;添加法制备的试样的密度和超声波速大于替代法制备的试样;抗压强度和相对弹性模量随着矿物掺量的增加先增后减,在5%~10%时达到较大值。随着温度的增加,抗压强度先增后减,在100℃时达到较大值;且以添加法掺入矿物掺合料时,试样的强度和弹性模量较高。对再生骨料混凝土耐高温性能的增强作用飞灰>铁渣>稻壳灰。此外,采用替代法时混凝土的密度与抗压强度、密度与和弹性模量和超声波速与抗压强度间的相关性较好;而采用添加法时各个参数之间的相关性较差。

Abstract:To study the influence of mineral admixtures on the basic characteristics and high temperature resistance of recycled aggregate concrete, fly ash, iron slag and rice husk ash were used to modify recycled aggregate concrete. High temperature and mechanical tests were carried out. The results show that with the increase of temperature, the density and ultrasonic velocity of the sample continue to decrease; the density and ultrasonic velocity of the sample prepared by the additive method are greater than that of the sample prepared by the alternative method; the compressive strength and relative elastic modulus increase first and then decreases with the increase of the mineral, reaching the maximum at 5%~10%. As the temperature increases, the compressive strength first increases and then decreases, reaching the maximum at 100°C; and when the mineral admixture is added by the additive method, the strength and elastic modulus of the sample are higher. Enhancement of high temperature resistance of recycled aggregate concrete: fly ash>iron slag>rice husk ash. In addition, the concrete density and compressive strength, density and elastic modulus, ultrasonic velocity and compressive strength have a better correlation when using the alternative method; however, the correlation between the various parameters is poor when the additive method is used.

-

-

表 1 材料的化学成分/%

Table 1. Chemical composition of the material

名称 SiO2 Al2O3 Fe2O3 CaO MgO SO3 TiO2 烧失量 水泥 22.66 4.88 3.58 64.74 0.88 2.14 0.00 1.12 飞灰 93.05 2.24 1.21 0.31 0.97 0.11 0.86 1.25 高炉铁渣 33.91 21.35 1.45 30.22 9.48 0.19 0.85 2.55 稻壳灰 29.30 13.79 4.94 45.35 3.92 0.28 0.73 1.69 表 2 骨料的物理性质

Table 2. Physical properties of aggregate

名称 最大粒径/

mm密度/

(kg·m-3)吸水率/

%堆积密度/

(kg·m-3)河砂 5 2640 2.44 2620 天然粗骨料 20 2830 1.29 2450 再生粗骨料 20 2410 0.85 2310 表 3 试样分组及混凝土配合比/(kg·m-3)

Table 3. Grouping of samples and concrete mix ratio

分组 样本编号 水泥 水灰比

W/C飞灰 高炉铁渣 稻壳灰 河砂 粗骨料 减水剂 对照组 NC 429 0.45 725 973 35 RC-0% 429 0.45 747.5 832 35 A(添加) RC-F5%-A 429 0.45 21.5 747.5 832 35 RC-F10%-A 429 0.45 42.9 747.5 832 35 RC-F15%-A 429 0.45 64.5 747.5 832 35 RC-S5%-A 429 0.45 21.5 747.5 832 35 RC-S10%-A 429 0.45 42.9 747.5 832 35 RC-S15%-A 429 0.45 64.5 747.5 832 35 RC-H5%-A 429 0.45 21.5 747.5 832 35 RC-H10%-A 429 0.45 42.9 747.5 832 35 RC-H15%-A 429 0.45 64.5 747.5 832 35 S(替代) RC-F5%-S 407 0.45 21.5 739 832 35 RC-F10%-S 386 0.45 42.9 734 832 35 RC-F15%-S 364 0.45 64.5 726 832 35 RC-S5%-S 407 0.45 21.5 739 832 35 RC-S10%-S 386 0.45 42.9 734 832 35 RC-S15%-S 364 0.45 64.5 726 832 35 RC-H5%-S 407 0.45 21.5 739 832 35 RC-H10%-S 386 0.45 42.9 734 832 35 RC-H15%-S 364 0.45 64.5 726 832 35 -

[1] 卓庆奉, 巴蕾, 王奇峰. 掺粉煤灰的混合充填骨料配比优化实验[J]. 矿产综合利用, 2021(3):187-192. doi: 10.3969/j.issn.1000-6532.2021.03.030

ZHUO Q F, BA L, WANG Q F. Optimum experiment of aggregate proportion for mixed filling with fly ash[J]. Multipurpose Utilization of Mineral Resources, 2021(3):187-192. doi: 10.3969/j.issn.1000-6532.2021.03.030

[2] 罗素蓉, 黄海生, 郑建岚. 再生骨料混凝土徐变性能试验研究[J]. 建筑结构学报, 2016, 37(S2):115-120. doi: 10.14006/j.jzjgxb.2016.s2.017

LUO S R, HUANG H S, ZHENG J L. Experimental study on creep performance of recycled aggregate concrete[J]. Journal of Building Structures, 2016, 37(S2):115-120. doi: 10.14006/j.jzjgxb.2016.s2.017

[3] 孙柯华, 沈阳, 王伟, 等. 不同材料增强处理再生骨料对混凝土抗压强度的影响[J]. 混凝土与水泥制品, 2021(5):95-99. doi: 10.19761/j.1000-4637.2021.05.095.05

SUN K H, SHEN Y, WANG W, et al. Effects of different materials reinforced with recycled aggregates on the compressive strength of concrete[J]. Concrete and Cement Products, 2021(5):95-99. doi: 10.19761/j.1000-4637.2021.05.095.05

[4] 李文贵, 罗智予, 龙初, 等. 纳米再生骨料混凝土的动态力学性能试验研究[J]. 湖南大学学报(自然科学版), 2017, 44(9):92-99. doi: 10.16339/j.cnki.hdxbzkb.2017.09.011

LI W G, LUO Z Y, LONG C, et al. Experimental study on dynamic mechanical properties of nano-recycled aggregate concrete[J]. Journal of Hunan University(Natural Science Edition), 2017, 44(9):92-99. doi: 10.16339/j.cnki.hdxbzkb.2017.09.011

[5] 朱勇年, 张鸿儒, 孟涛, 等. 纳米SiO2改性再生骨料混凝土工程应用研究及实体性能监测[J]. 混凝土, 2014(7):138-144. doi: 10.3969/j.issn.1002-3550.2014.07.037

ZHU Y N, ZHANG H R, MENG T, et al. Engineering application research and physical performance monitoring of nano-SiO2 modified recycled aggregate concrete[J]. Concrete, 2014(7):138-144. doi: 10.3969/j.issn.1002-3550.2014.07.037

[6] Mukharjee B B, Barai S V. Influence of Nano-Silica on the properties of recycled aggregate concrete[J]. Construction & Building Materials, 2014, 55(3):29-37.

[7] 白卫峰, 李汶昊, 杨光, 等. 硅粉掺量对再生骨料混凝土单轴压缩性能的影响研究[J]. 华北水利水电大学学报(自然科学版), 2020, 41(6):59-66. doi: 10.19760/j.ncwu.zk.2020077

BAI W F, LI W H, YANG G, et al. Research on the effect of silica fume content on the uniaxial compression performance of recycled aggregate concrete[J]. Journal of North China University of Water Resources and Electric Power(Natural Science Edition), 2020, 41(6):59-66. doi: 10.19760/j.ncwu.zk.2020077

[8] 李军卫, 刘长明, 单雪峰. 水泥改良铁尾矿砂路基填料的力学特性研究[J]. 矿产综合利用, 2021(3):193-199.

LI J W, LIU C M, SHAN X F. Research on mechanical properties of cement-improved iron tailings sand roadbed filler[J]. Multipurpose Utilization of Mineral Resources, 2021(3):193-199.

[9] Sun J, Feng J, Chen Z. Effect of ferronickel slag as fine aggregate on properties of concrete[J]. Construction and Building Materials, 2019, 206(5):201-209.

[10] Sunayana S, Barai S V. Recycled aggregate concrete incorporating fly ash: Comparative study on particle packing and conventional method[J]. Construction & Building Materials, 2017, 156:376-38.

-

下载:

下载: