Study on Process Mineralogy of a Refractory Gold Ore

-

摘要:

某金矿部分矿区属于蚀变型金矿,含金蚀变带系由花岗岩热液蚀变而发生的绢云母、硅化、黄铁矿化组成。矿体大部分赋存在黄铁绢云岩内,部分赋存在黄铁绢英岩化花岗岩内。利用光学显微镜、矿物分析系统(BPMA)、扫描电子显微镜及能谱对矿物进行工艺矿物学特性分析,分析发现矿石中以硫化矿为主,氧化带深度很浅。金品位5.23 g/t,主要金矿物有自然金、银金矿,主要金属矿物为黄铁矿、磁黄铁矿、方铅矿、黄铜矿、闪锌矿等硫化矿和磁铁矿等氧化矿物,脉石矿物主要有石英、绢云母、长石等。金的嵌布粒度较细,全部分布在37 μm以下,嵌布粒度较细。根据金矿物的赋存状态来看,以单体形式存在和与黄铁矿共生的含金矿物含量83.18%,这部分金矿物易于回收;与绢云母、石英和磁铁矿共生的含金矿物含量为16.82%,这部分是导致浮选过程中金回收率低的主要原因。

Abstract:Part of a gold deposit belongs to altered type gold deposit. The gold bearing alteration zone is composed of sericite, silicification and pyritization caused by hydrothermal alteration of granite. Most of the ore bodies are hosted in pyrite sericite and some in pyrite sericite granite. Using optical microscope, mineral analysis system (BPMA), scanning electron microscope and energy spectrum, the process mineralogical characteristics of minerals were analyzed. It was found that sulfide ore was the main ore and the depth of oxidation zone was very shallow. The gold grade is 5.23 g/t. The main gold minerals are natural gold and silver gold. The main metal minerals are pyrite, pyrrhotite, galena, chalcopyrite, sphalerite and other sulfide minerals and magnetite and other oxide minerals. Gangue minerals mainly include quartz, sericite, feldspar, etc. The size of gold is fine, all of which are below 37 μm. According to the occurrence state of gold minerals, the content of gold bearing minerals existing in monomer form and coexisting with pyrite is 83.18%, which is easy to recover; the content of gold minerals associated with sericite, quartz and magnetite is 16.82%, which is the main reason for the low gold recovery rate in flotation process.

-

Key words:

- Altered gold deposit /

- Process mineralogy /

- Occurrence state /

- Disseminated grain size

-

-

表 1 难选金矿物样品的多元素分析结果/%

Table 1. Multi-element analysis results of refractory gold mineral samples

Au* Ag* Pb Zn Fe Cu S 5.23 19.25 0.15 0.13 18.26 0.11 12.31 SiO2 Al2O3 MgO CaO Na2O K2O 46.27 8.71 1.27 1.52 0.81 2.70 *单位为:g/t。 表 2 矿物组成及相对含量

Table 2. Mineral composition and relative content

矿物 含量/% 矿物 含量/% 黄铁矿 28.07 石英 28.43 磁黄铁矿 1.92 普通辉石 0.72 磁铁矿 2.46 方解石 0.96 水钼铁矿 1.31 云母 26.13 方铅矿 0.17 长石 5.71 黄铜矿 0.22 绿钠闪石 1.62 闪锌矿 0.19 整柱石 1.48 其他 0.21 其他 0.40 小计 34.55 小计 65.45 合计 100.00 表 3 Au物相分析结果

Table 3. Distribution results of Au in the samples

名称 自然金中金 银金矿中金 合计 含量/(g·t-1) 0.36 4.87 5.23 占有率/% 6.81 93.19 100.00 表 4 样品中金矿物的解离特征

Table 4. Dissociation characteristics of gold minerals in samples

解离度

X单体

X=100%75%≤X<100% 50%≤X<75% 25%≤X<50% 0<X<25% 包裹

X=0合计 金矿物 10.39 6.69 76.88 1.21 0.19 4.64 100.00 表 5 样品中金矿物粒度分析

Table 5. Particle size analysis of gold minerals in samples

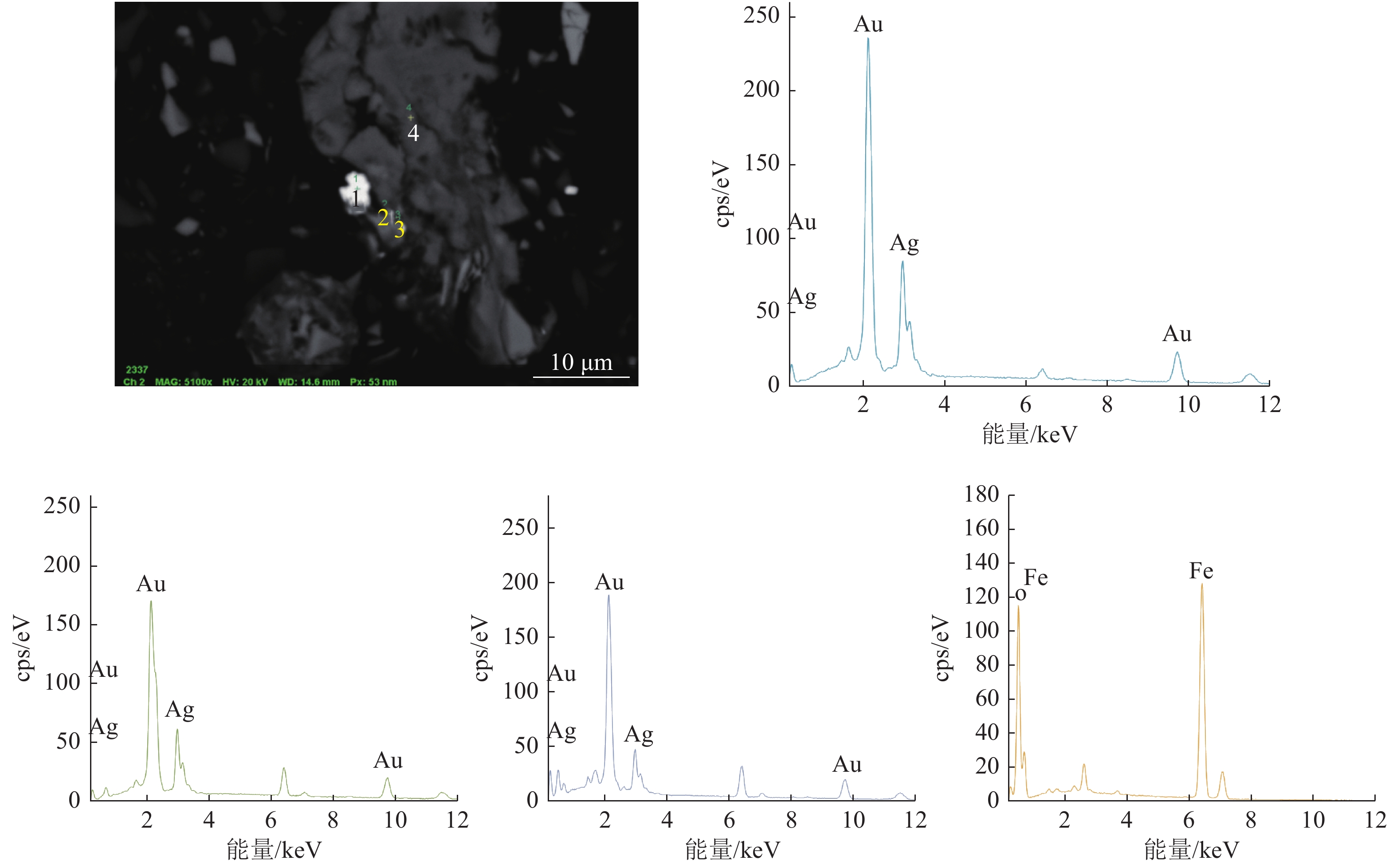

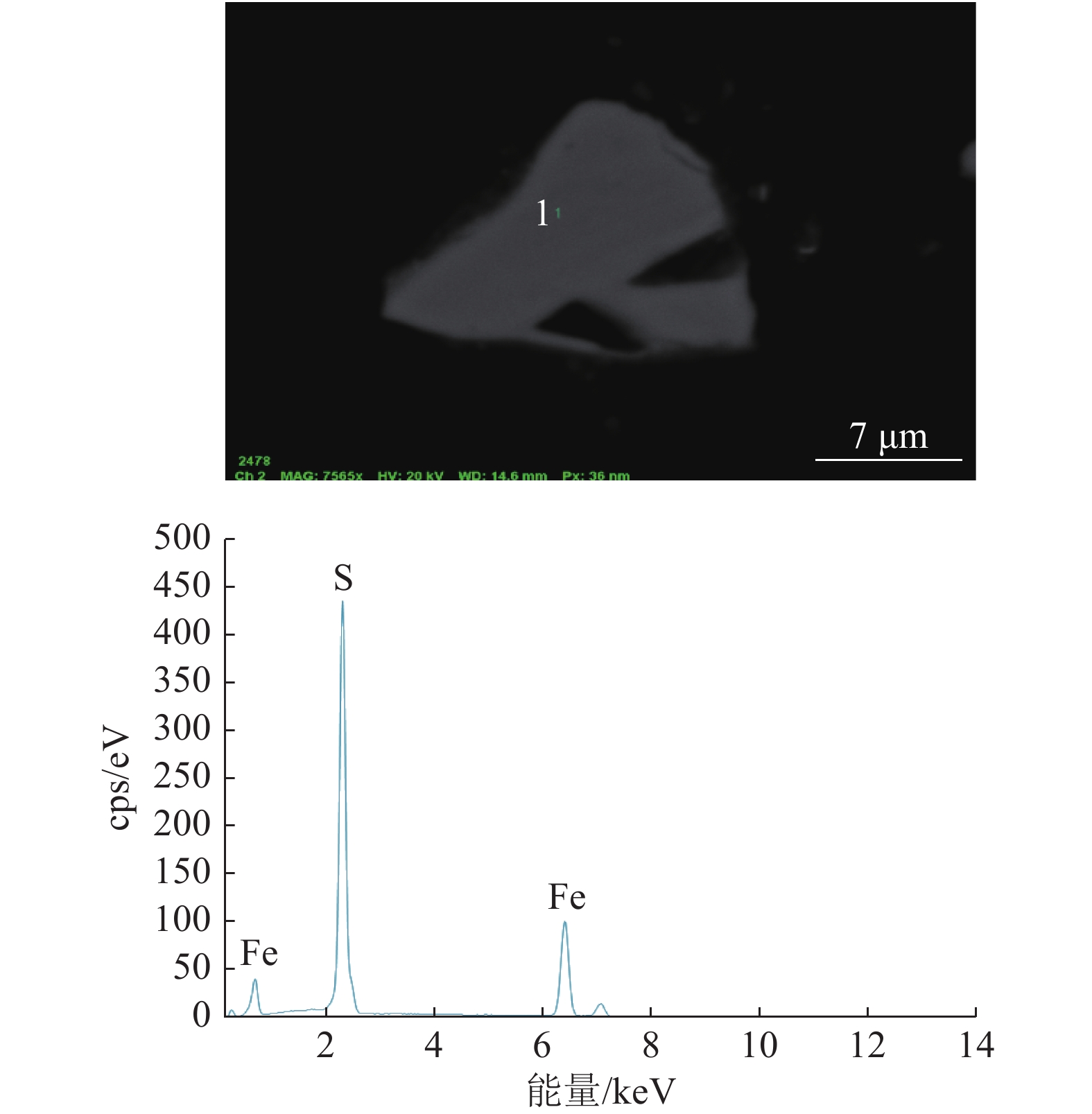

分级/μm 含量/% 累积量/% 中粒 -74+37 0 0 细粒 -37+10 55.76 55.76 微细 -10+5 28.29 84.05 -5 15.95 100.00 表 6 样品中部分含金矿物能谱定量结果

Table 6. Quantitative results of energy spectrum of some gold-bearing minerals in the samples

序号 矿物名称 Au/% Ag/% 分布特征 1 自然金 80.19 19.81 黄铁矿连生 2 自然金 81.52 18.48 黄铁矿连生 3 自然金 80.31 19.69 绢云母连生 4 银金矿 71.51 28.49 黄铁矿连生 5 银金矿 70.92 29.08 黄铁矿与石英晶间金 6 银金矿 63.07 36.93 磁铁矿连生 7 银金矿 72.53 27.47 绢云母连生 8 银金矿 70.06 29.94 磁铁矿连生 9 银金矿 74.18 25.82 黄铁矿连生 10 银金矿 66.34 33.66 黄铁矿包裹 11 银金矿 68.14 31.86 单体 12 银金矿 74.47 25.53 单体 13 银金矿 64.14 35.86 单体 14 银金矿 69.97 30.03 单体 15 银金矿 52.13 47.87 黄铁矿包裹 16 银金矿 67.04 32.96 黄铁矿连生 17 银金矿 65.42 34.58 石英包裹 18 银金矿 63.51 36.49 黄铁矿连生 19 银金矿 62.47 37.53 单体 20 银金矿 61.38 38.62 黄铁矿连生 21 银金矿 67.85 32.15 黄铁矿连生 平均 68.91 31.09 表 7 样品中主要含金矿物嵌布程度统计

Table 7. Statistics of the degree of embedment of the main gold-bearing minerals in the samples

矿物 单体/% 共生体/% 合计/% 黄铁矿 绢云母 磁铁矿 石英 含金矿物 10.39 72.79 4.75 6.92 5.15 100.00 表 8 黄铁矿矿物粒度分布情况

Table 8. Particle size distribution of pyrite minerals

粒级/μm 含量/% 正累积/% +147 0.00 0.00 -147+74 11.11 11.11 -74+38 32.31 43.42 -38+20 19.41 62.83 -20+15 14.50 77.33 -15+10 10.41 87.74 -10+5 10.40 98.14 -5 1.86 100.00 表 9 主要矿物嵌布特征

Table 9. Distribution characteristics of main minerals

矿物名称 单体/% 共生体/% 合计/% 金属硫化物 其他脉石矿物 黄铁矿 54.07 6.64 39.29 100.00 表 10 主要矿物解离分析

Table 10. Dissociation analysis of main minerals

矿物名称 目标矿物占比/% 0 <X ≤10 10<X≤20 20<X≤30 30 <X≤40 40 <X≤50 50<X≤60 黄铁矿 0.76 0.76 0.96 2.05 1.89 2.26 矿物名称 目标矿物占比/% 合计 60 <X≤70 70 <X≤80 80 <X≤90 90 <X< 100 100 黄铁矿 2.79 3.53 6.88 24.05 54.07 100.00 -

[1] 蒋琳, 李阿俊. 内蒙古某含银铅锌矿工艺矿物学研究[J]. 矿产综合利用, 2020(1):94-97. doi: 10.3969/j.issn.1000-6532.2020.01.019

JIANG L, LI A J. Study on process mineralogy for a silver-containing lead-zinc ore in Inner Mongolia[J]. Multipurpose Utilization of Mineral Resources, 2020(1):94-97. doi: 10.3969/j.issn.1000-6532.2020.01.019

[2] 陈慧杰, 张莉, 蒋升国, 等. 某微细粒难选金矿石选矿工艺研究[J]. 金属矿山, 2018(7):131-134. doi: 10.19614/j.cnki.jsks.201807026

CHEN H J, ZHANG L, JIANG S G, et al. Research on the beneficiation process of a fine-grained refractory gold ore[J]. Metal Mine, 2018(7):131-134. doi: 10.19614/j.cnki.jsks.201807026

[3] 杨耀辉, 惠博, 严伟平, 等. 攀西微细粒钛铁矿工艺矿物学研究[J]. 矿产综合利用, 2020(3):131-135. doi: 10.3969/j.issn.1000-6532.2020.03.022

YANG Y H, HUI B, YAN W P, et al. Research on process mineralogy of fine ilmenite in Panxi area[J]. Multipurpose Utilization of Mineral Resources, 2020(3):131-135. doi: 10.3969/j.issn.1000-6532.2020.03.022

[4] 陈智杰, 喻福涛, 高惠民, 等. 陕西某石墨矿工艺矿物学与选矿研究[J]. 矿产综合利用, 2019(1):66-69. doi: 10.3969/j.issn.1000-6532.2019.01.014

CHEN Z J, YU F T, GAO H M, et al. Research on process mineralogy and beneficiation of a graphite mine in Shaanxi[J]. Multipurpose Utilization of Mineral Resources, 2019(1):66-69. doi: 10.3969/j.issn.1000-6532.2019.01.014

[5] 周利华, 陈晓芳, 苏妤芸. 山西某斑岩型金矿工艺矿物学特性[J]. 矿产综合利用, 2020(3):143-147. doi: 10.3969/j.issn.1000-6532.2020.03.024

ZHOU L H, CHEN X F, SU S Y. Technological and mineralogical characteristics of a porphyry gold deposit in Shanxi province[J]. Multipurpose Utilization of Mineral Resources, 2020(3):143-147. doi: 10.3969/j.issn.1000-6532.2020.03.024

[6] 王广伟, 杨德明, 任琪, 等. 青海某金矿浮选尾矿工艺矿物学研究[J]. 矿冶, 2018(2):101-104. doi: 10.3969/j.issn.1005-7854.2018.02.023

WANG G W, YANG D M, REN Q, et al. Study on process mineralogy of flotation tailings of a gold mine in Qinghai[J]. Mining and Metallurgy, 2018(2):101-104. doi: 10.3969/j.issn.1005-7854.2018.02.023

[7] 邓元良, 明平田, 王广伟, 等. 某金精矿焙烧氧化- 氰化尾矿工艺矿物学研究[J]. 矿产综合利用, 2020(4):121-125. doi: 10.3969/j.issn.1000-6532.2020.04.020

DENG Y L, MING P T, WANG G W, et al. Research on process mineralogy of roasting oxidation-cyanide tailings of a gold concentrate[J]. Multipurpose Utilization of Mineral Resources, 2020(4):121-125. doi: 10.3969/j.issn.1000-6532.2020.04.020

-

下载:

下载: