Study on Process Mineralogy of a Tungsten Ore in Yunnan Province

-

摘要:

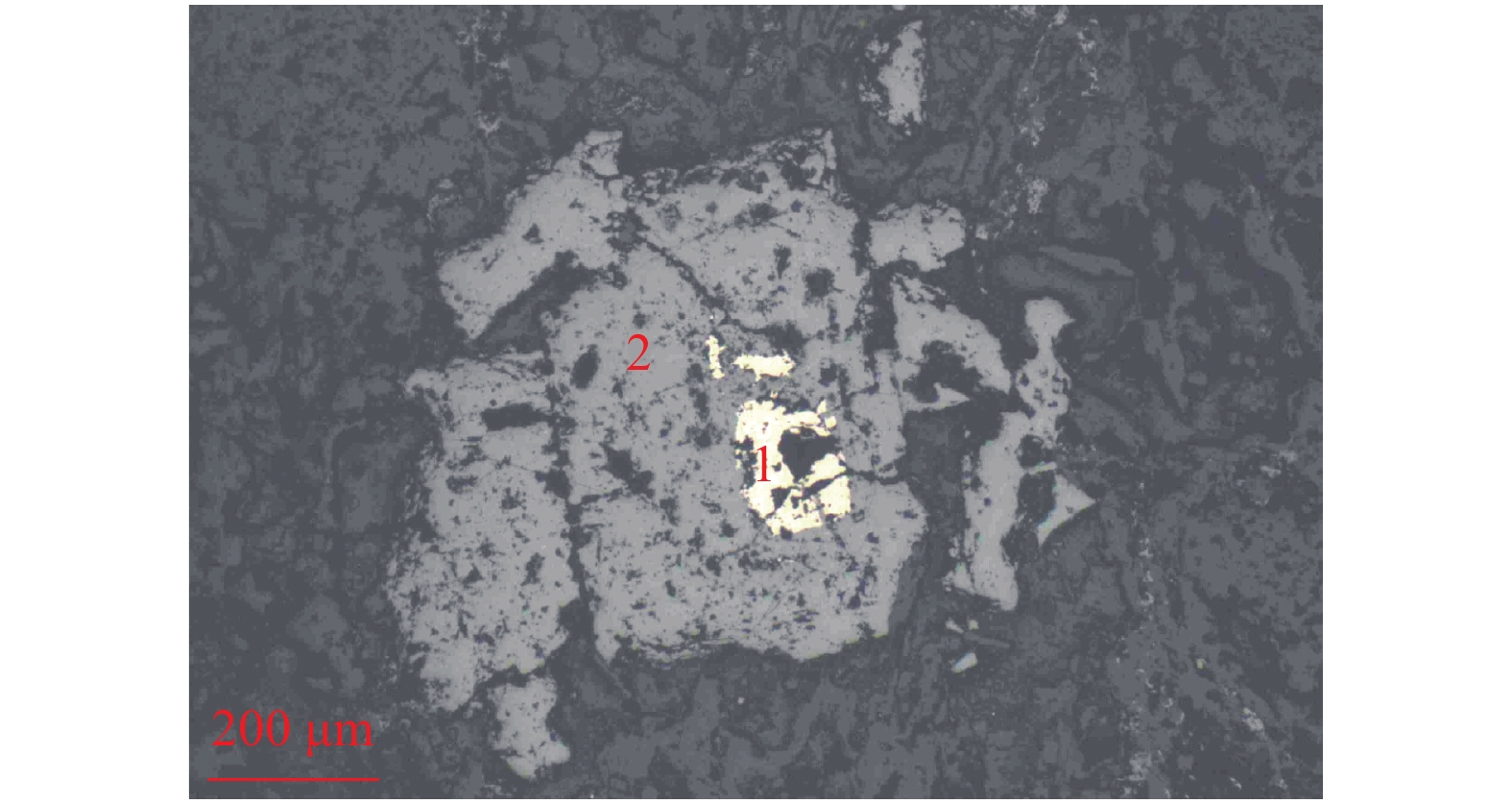

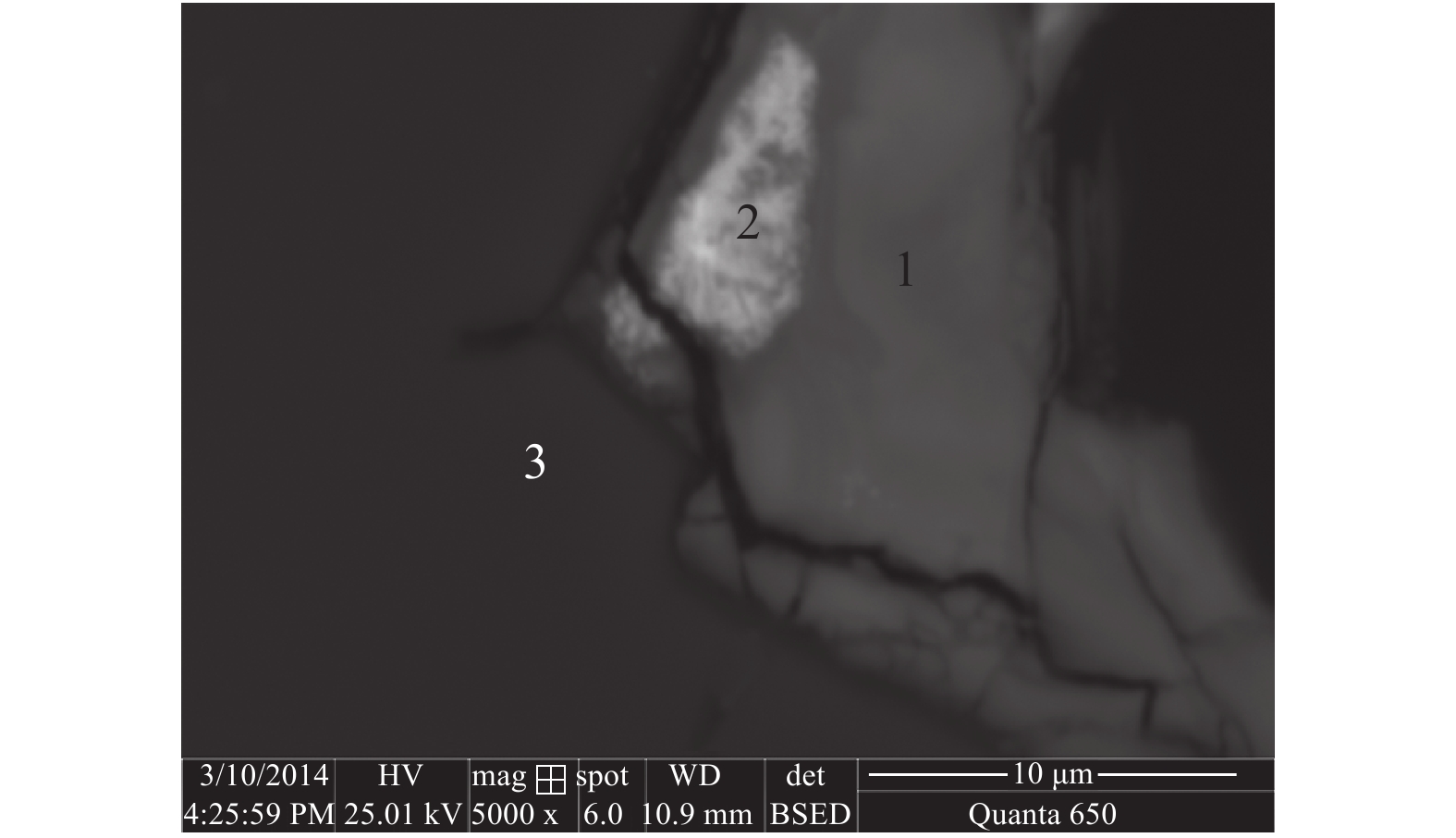

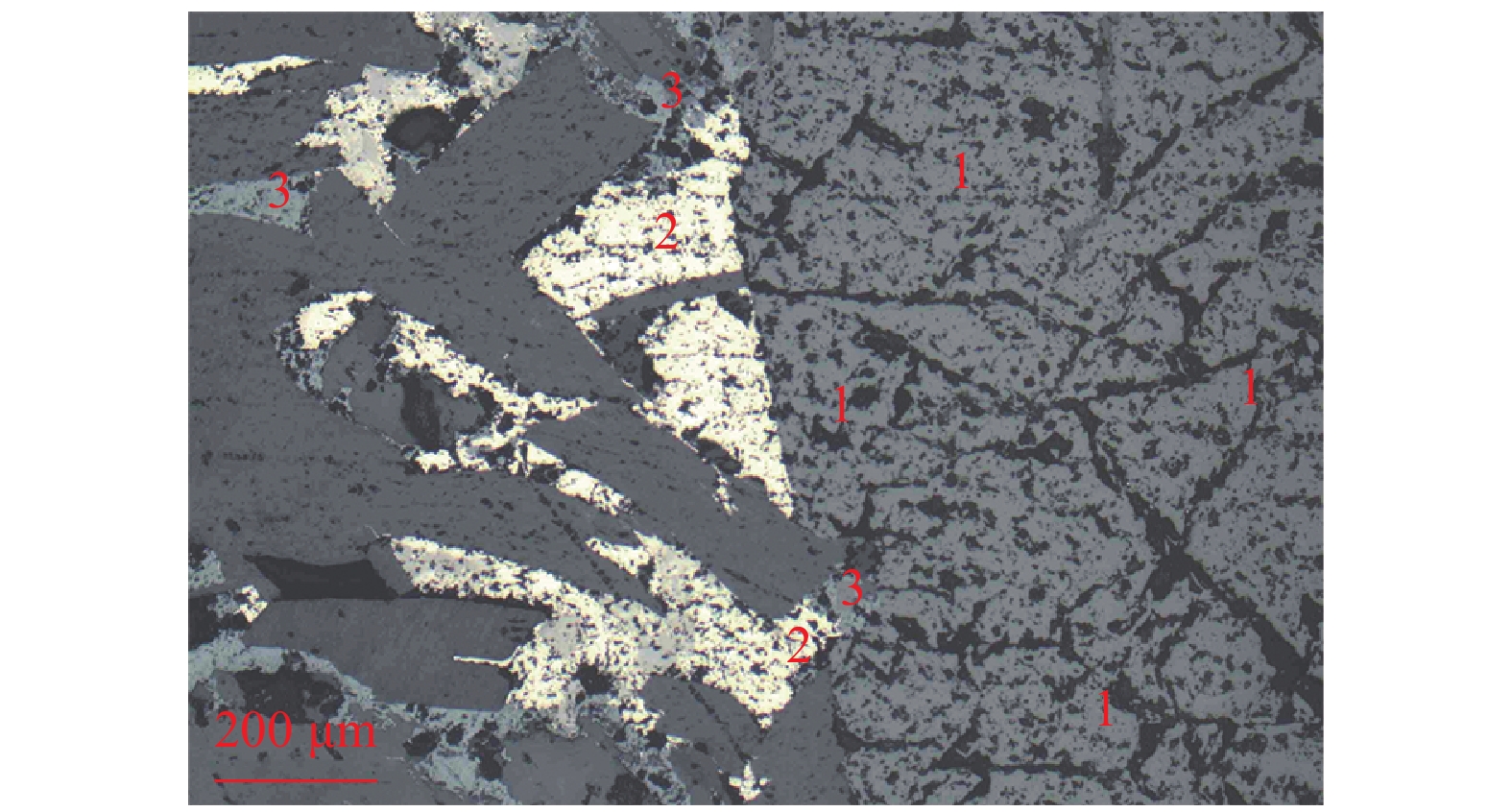

通过采用化学物相分析、MLA、扫描电镜、光学显微镜及能谱分析等方法,对云南某钨矿石的矿物组成、矿物的嵌布粒度和有价元素的赋存状态等进行了详细的工艺矿物学研究,并进行了矿石可选性分析,为有效选别该矿石提供了理论依据。结果表明,该矿石主要有价元素为钨,伴生有金、银等有价金属元素。钨以白钨矿形式存在且粒度较粗,适宜重选。白钨矿在矿石中主要呈块状—星点状分布于非金属矿物(石英、方解石)中,形成半规则连生或包含关系,需要提高磨矿细度以确保钨精矿的回收率。

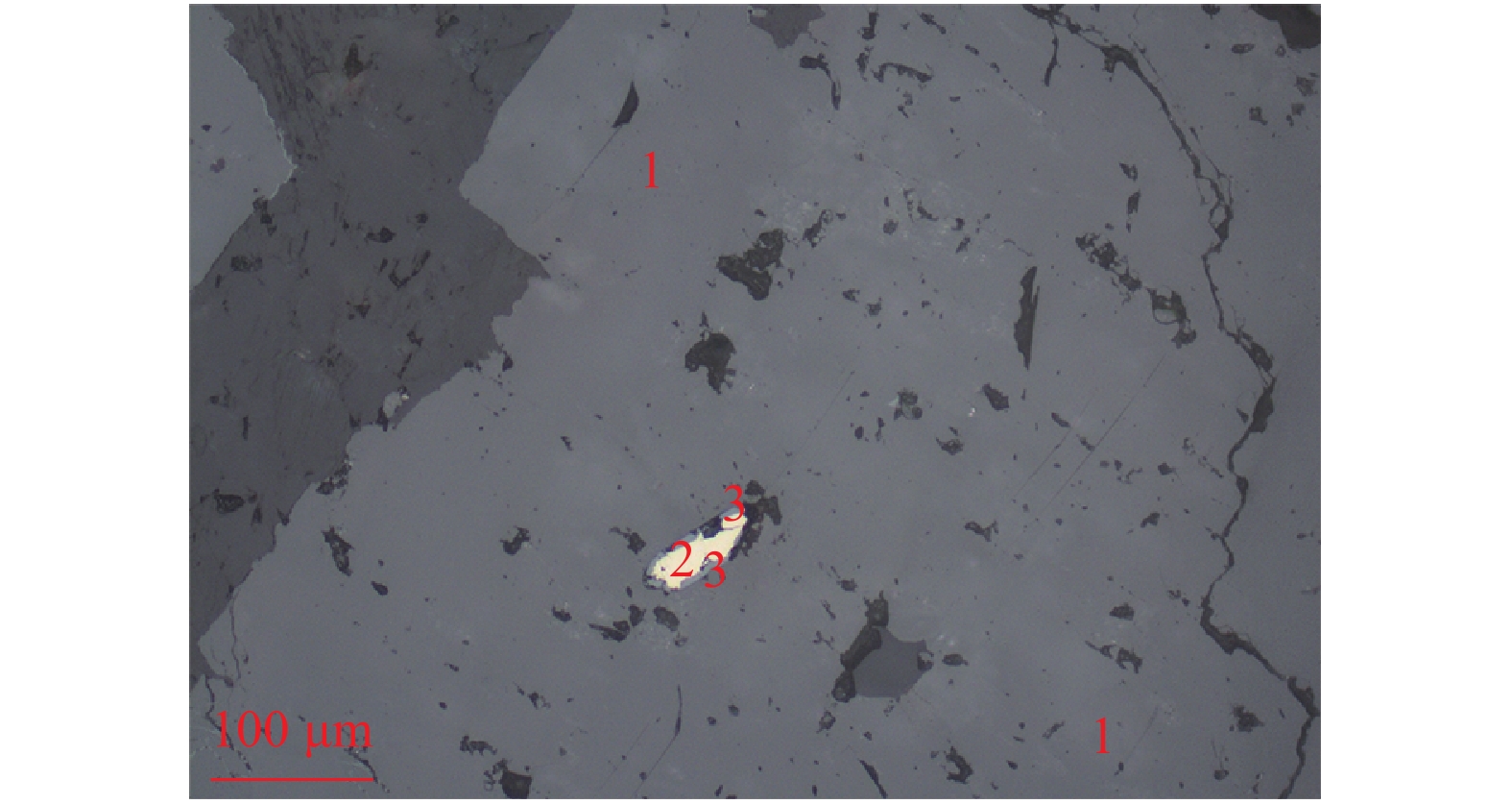

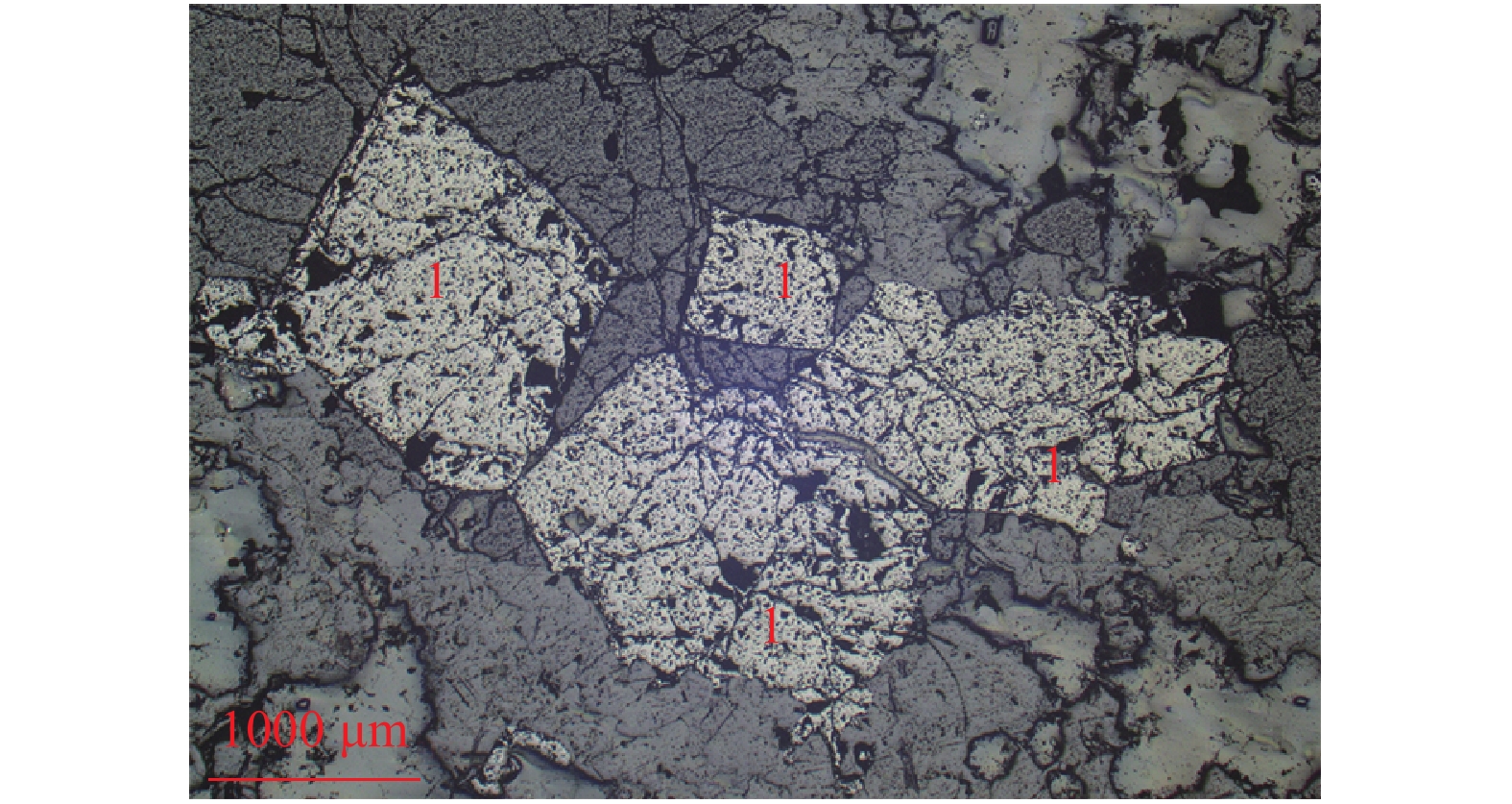

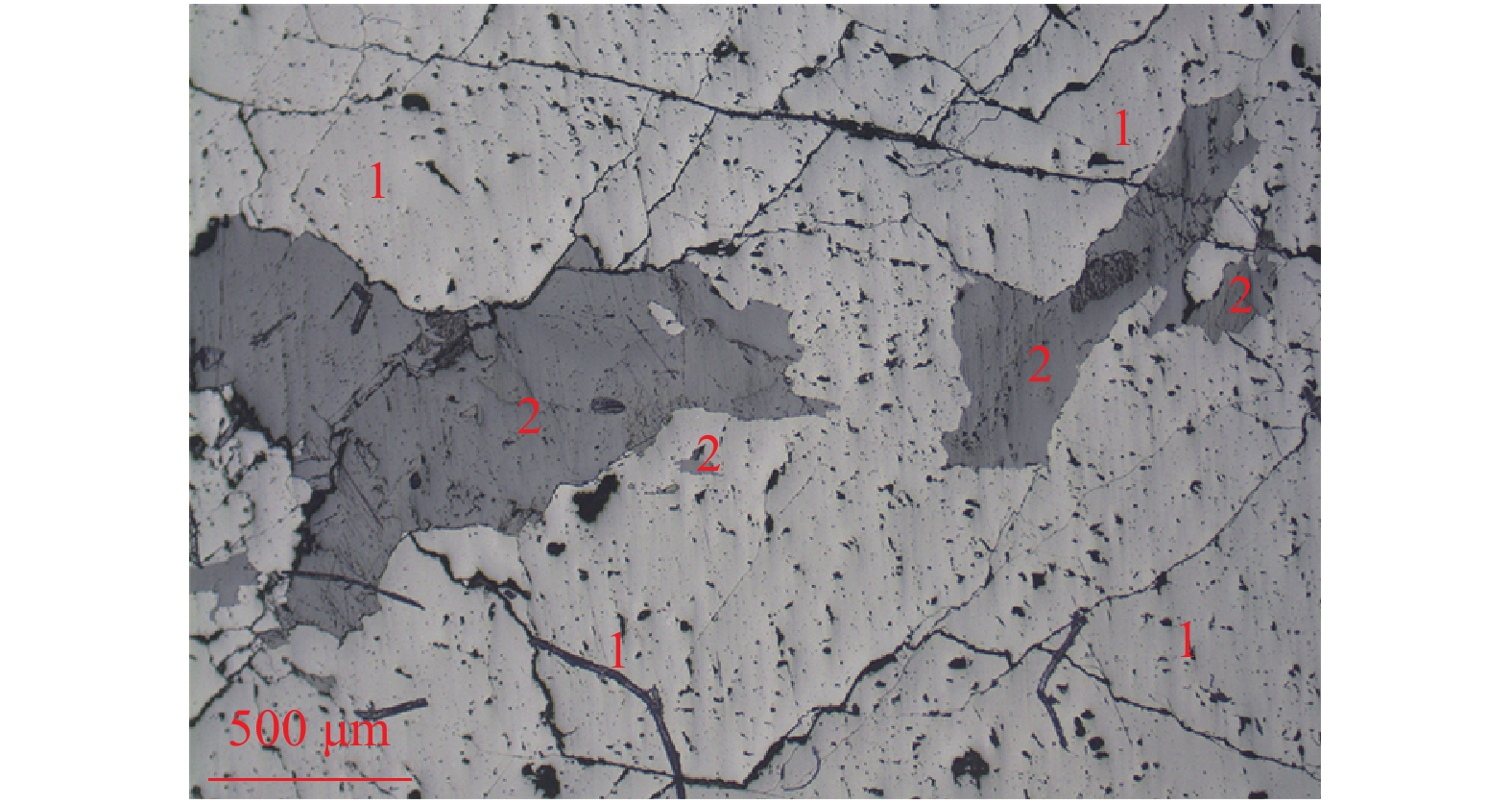

Abstract:By applying chemical phase analysis, mineral liberation analyzer (MLA), SEM, optical microscope and energy spectrum analysis, the mineral composition, grain size and occurrence states of valuable minerals are studied in this article, also the beneficiability of the ore is analyzed, which provides a theoretical basis for the effective separation of the ore. Results show that the valuable elements of the tungsten ore are WO3, Au and Ag. Tungsten exists in the form of scheelite and its particle size is coarse, so it is suitable for gravity separation. Scheelite is mainly distributed in non-metallic minerals (quartz and calcite) in the form of massive star point, forming a semi regular association or inclusion relationship, so it is necessary to improve the grinding fineness to ensure the recovery rate of tungsten concentrate.

-

Key words:

- Tungsten ore /

- Process mineralogy /

- Embedded features /

- Occurrence states

-

-

表 1 原矿多元素化学分析/%

Table 1. Main chemical composition analysis results of the ore

Au* Ag* Pb Cu Zn TFe SiO2 WO3 Cd Co Ni Sb 0.10 12 0.025 0.035 0.051 4.00 55.26 0.58 0.002 0.002 0.014 0.0002 Bi S Mo As CaO MgO Al2O3 K2O Na2O P 烧失量 0.0033 0.74 0.004 0.0055 11.96 3.46 5.10 2.35 0.14 0.076 11.15 *单位为:g/t。 表 2 矿石矿物组成及含量

Table 2. Mineral composition and content of the ore

矿物 含量/% 矿物 含量/% 白钨矿 0.58 石英 44.67 钨铅矿 少量 方解石 24.35 黄铜矿 0.03 白云石 4.78 磁黄铁矿 0.62 绢(白)云母 20.56 黄铁矿 0.71 萤石 0.35 褐铁矿 1.32 石墨 少量 闪锌矿、菱锌矿 0.05 绿泥石 少量 方铅矿、白铅矿 少量 菱锰矿 少量 辉银矿 两粒* 注:辉银矿仅见于扫描电镜下 表 3 原矿钨物相分析结果

Table 3. Phase analysis of tungsten ore

名称 钨华中

WO3白钨矿中

WO3黑钨矿中

WO3合计 含量/% 0.11 0.45 0.012 0.572 占有率/% 19.23 78.67 2.10 100.00 表 4 白钨矿化学成分/%

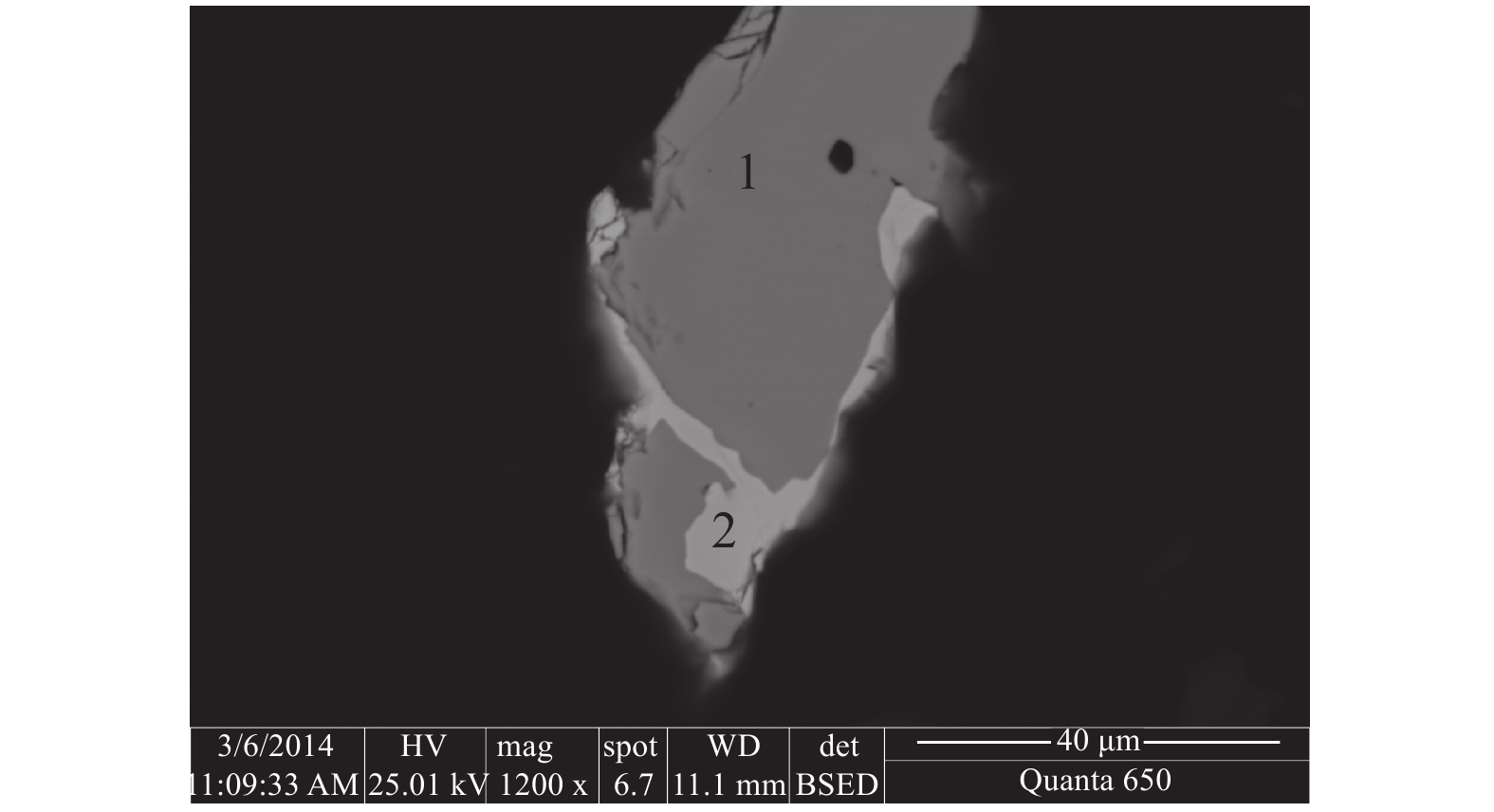

Table 4. Chemical composition of scheelite

名称 O Ca W 1 23.85 13.49 62.66 2 25.15 13.36 61.49 3 22.06 13.61 64.33 4 21.59 13.82 64.59 平均 23.16 13.57 63.27 理论值 63.92 表 5 白钨矿的粒度分析

Table 5. Particle size analysis of scheelite

粒级/mm 比粒径/d 颗粒数/n 体积含量/nd 分布率/% 备注 +1.28 128 12 1536 19.56 83.74 −1.28+0.64 64 23 1472 18.74 −0.64+0.32 32 36 1152 14.67 −0.32+0.16 16 85 1360 17.32 −0.16+0.08 8 132 1056 13.45 −0.08+0.04 4 204 816 10.39 16.26 −0.04+0.02 2 182 364 4.64 −0.02 1 97 97 1.24 合计 771 7853 100.00 -

[1] 宁湘菡, 冯博, 罗仙平, 等. 黄薯树胶在白钨矿-方解石浮选分离中的作用研究[J]. 有色金属(选矿部分), 2019(5):125-129.

NING X H, FENG B, LUO X P, et al. The role of tragacanth gum in the flotation separation of scheelite and calcite[J]. Nonferrous Metals (Mineral Processing Section), 2019(5):125-129.

[2] 邱峰, 黄万抚, 文金磊, 等. 某钨多金属矿矿石性质研究[J]. 矿产综合利用, 2017(4):83-85.

QIU F, HUANG W F, WEN J L, et al. Study on technological mineralogy properties of a tungsten polymetallic ore[J]. Multipurpose Utilization of Mineral Resources, 2017(4):83-85.

[3] 吕宪俊. 工艺矿物学[M]. 长沙: 中南大学出版社, 2011: 247-251.

LV X J. Process Mineralogy[M]. Changsha: Central South University Press, 2011: 247-251.

[4] 杨耀辉, 惠博, 严伟平, 等. 攀西微细粒钛铁矿工艺矿物学研究[J]. 矿产综合利用, 2020(3):131-135.

YANG Y H, HUI B, YAN W P, et al. Research on process mineralogy of fine ilmenite in Panxi area[J]. Multipurpose Utilization of Mineral Resources, 2020(3):131-135.

[5] 王延鹏, 李松奕. 某白钨矿伴生多金属硫化矿选矿试验研究[J]. 矿产综合利用, 2020(4):69-75.

WANG Y P, LI S Y. Experimental research on mineral processing technology for an associated polymetallic sulphide ore of a sheelite ore[J]. Multipurpose Utilization of Mineral Resources, 2020(4):69-75.

[6] 李淑菲, 李强. 白钨矿浮选研究现状[J]. 矿产综合利用, 2019(3):17-21.

LI S F, LI Q. Current research situation of scheelite flotation[J]. Multipurpose Utilization of Mineral Resources, 2019(3):17-21.

-

下载:

下载: