Review for High-purity Quartz (SiO2) (PartⅠ): Activation and Separation of Trace, Fine-grain Alumino Silicate Gangue

-

摘要:

高纯石英著以杂质含量极少、SiO2纯度极高,现已广泛地应用于光纤通信、光伏、航空航天、半导体显示等高新技术产业。铝硅酸盐矿物是石英矿中最典型的脉石矿物之一,主要包括钾、钠长石、云母等;以现有的常规分离工艺,难以有效、高效地去除这些顽固性的微量、微细粒的长石、云母。本文详细地阐述了高纯石英中铝硅酸盐脉石矿物分离的基本现状,对顽固性的微量、微细粒长石、云母活化与分离的前沿技术进行系统性地概述;基于近年来我国高纯石英基础理论研究进展,对高品质石英中晶体界面、内部包裹的微量、微细粒铝硅酸盐脉石矿物分离研究提出了合理化的科学建议。

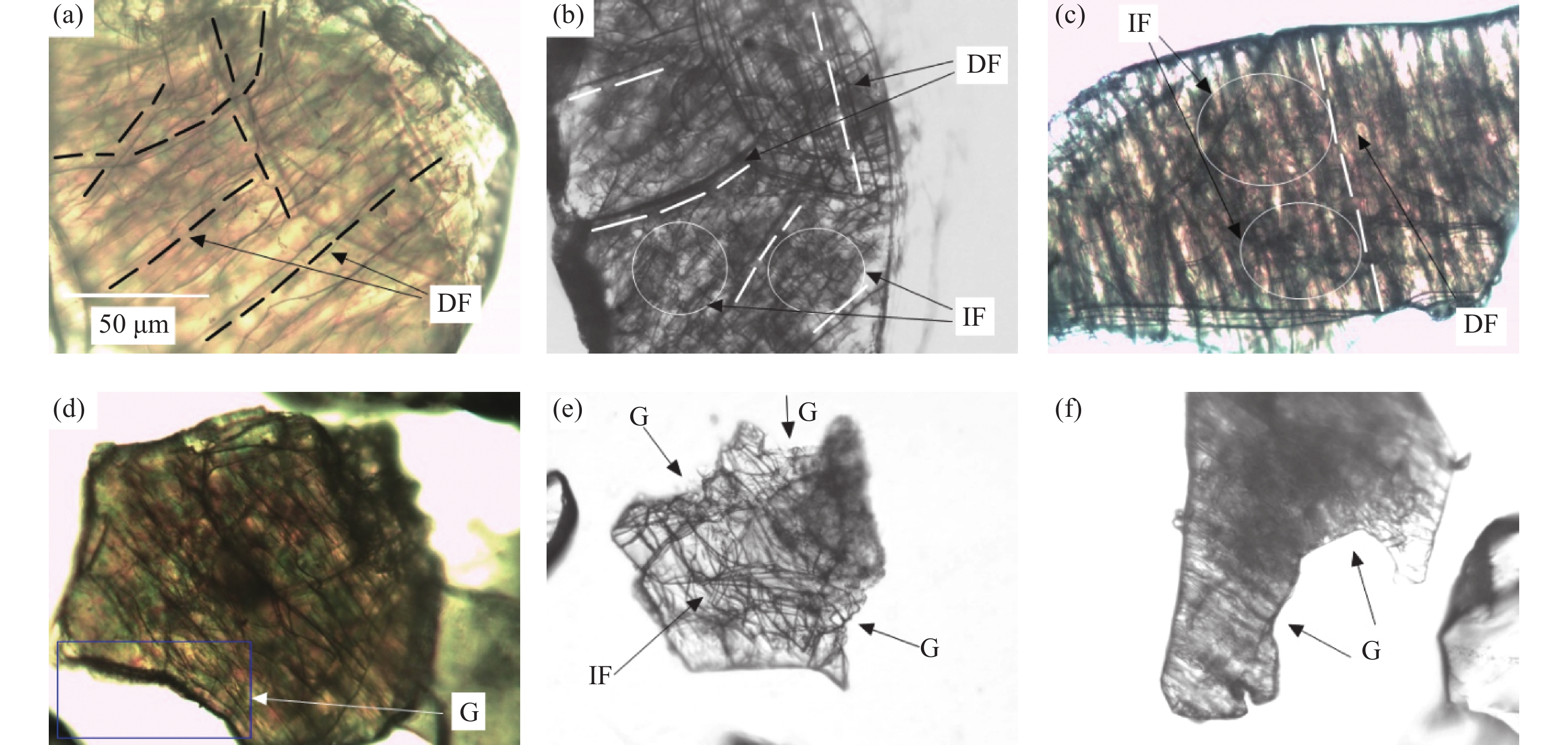

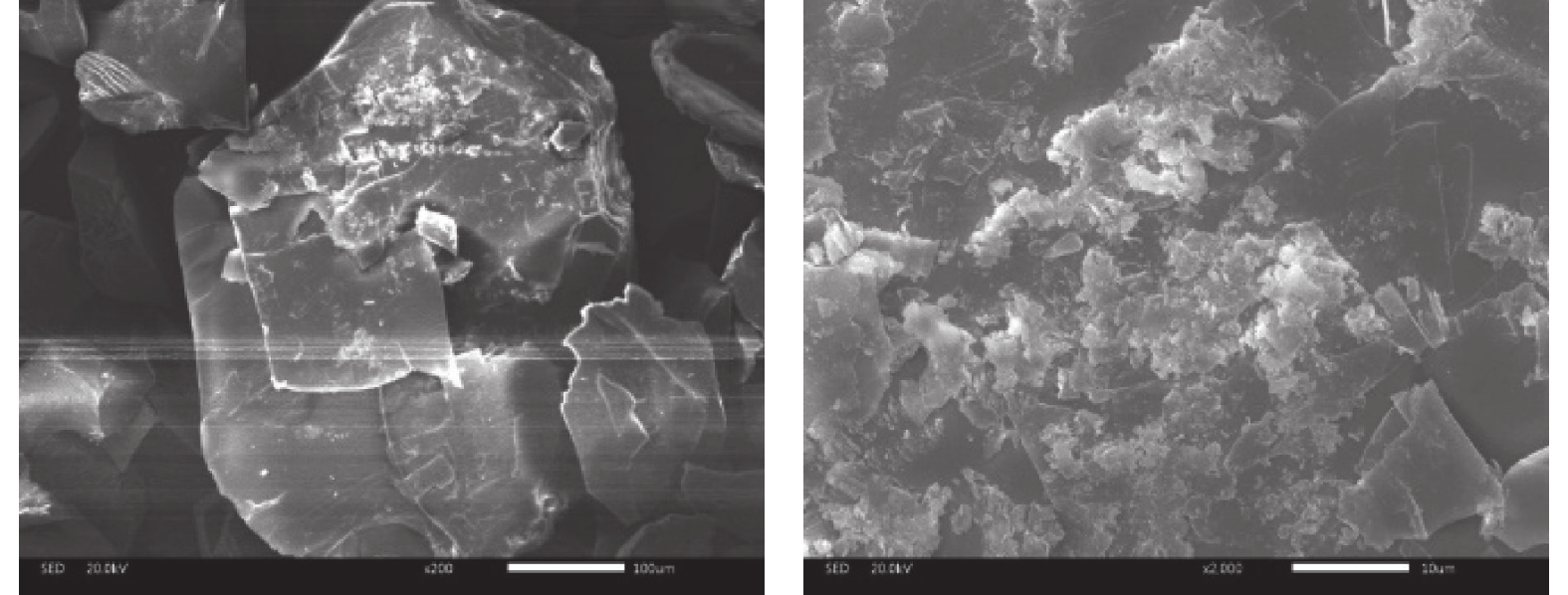

Abstract:High-purity quartz, famous for low impurities and high purity, has been widely used in optical fiber communication, photovoltaic, aerospace, semiconductor displayand other high-tech industries. Aluminosilicate mineral is one of the most typical gangue minerals in quartz ore, mainly including potassium, albite, mica, etc. With the existing conventional separation process, it is difficult to effectively and efficiently remove these intractable trace and micro-fine feldspar and mica. In this paper, the basic status of separation of aluminosilicate gangue minerals from high-purity quartz is described in detail, and the frontier technology of activation and separation of refractory trace and micro-fine feldspar and mica is systematically summarized. Based on the research progress of the basic theory of high-purity quartz in China in recent years, some reasonable scientific suggestions are put forward for the separation of micro-and micro-fine aluminosilicate gangue minerals in the crystal interface and inner encapsulation of high-quality quartz.

-

Key words:

- High-purity quartz /

- Trace /

- Fine-grain /

- Feldspar /

- Mica /

- Activation and separation

-

-

[1] 刘泽伟, 邹玄, 赵阳, 等. 某石英砂矿制取高纯石英工艺的研究[J]. 矿产综合利用, 2020(4):111-115. doi: 10.3969/j.issn.1000-6532.2020.04.018

LIU Z W, ZOU X, ZHAO Y, et al. Study on the process of producing high-purity quartz from a quartz sand mine[J]. Multipurpose Utilization of Mineral Resources, 2020(4):111-115. doi: 10.3969/j.issn.1000-6532.2020.04.018

[2] 申士富. 高纯石英砂研究与生产现状[J]. 中国非金属矿工业导刊, 2006(5):13-16. doi: 10.3969/j.issn.1007-9386.2006.05.004

SHEN S F. Research and production status of high-purity quartz sand[J]. China Non-Metallic Mineral Industry Guide, 2006(5):13-16. doi: 10.3969/j.issn.1007-9386.2006.05.004

[3] 雷绍民, 钟乐乐, 杨亚运, 等. 脉石英常压加热浸出制备高纯石英及反应机理[J]. 矿业研究与开发, 2015(3):16-19.

LEI S M, ZHONG L L, YANG Y Y, et al. Preparation of high-purity quartz by atmospheric heating leaching of vein quartz and its reaction mechanism[J]. Mining Research and Development, 2015(3):16-19.

[4] Lin M, Pei Z, Lei S. Trace muscovite dissolution separation from vein quartz by elevated temperature and pressure acid leaching using sulphuric acid and ammonia chloride solutions[J]. Physicochemical Problems of Mineral Processing, 2018, 54(2):448-458.

[5] Pei Z, Lin M, Liu Y, et al. Dissolution behaviors of trace muscovite during pressure leaching of hydrothermal vein quartz using H2SO4 and NH4Cl as leaching agents[J]. Minerals, 2018, 8(2):60-65. doi: 10.3390/min8020060

[6] 钟乐乐. 超高纯石英纯化制备及机理研究[D]. 武汉: 武汉理工大学, 2015.

ZHONG L L. Purification, preparation and mechanism of ultra-high purity quartz [D]. Wuhan: Wuhan University of Technology, 2015.

[7] 雷绍民, 谢飞翔, 林敏, 等. 石英提纯工业含氟废水净化试验研究[J]. 非金属矿, 2017, 40(2):3-9. doi: 10.3969/j.issn.1000-8098.2017.02.007

LEI S M, XIE F X, LIN M, et al. Experimental study on purification of industrial fluorine-containing wastewater from quartz purification[J]. Non-metallic Minerals, 2017, 40(2):3-9. doi: 10.3969/j.issn.1000-8098.2017.02.007

[8] LIN M, PEI Z Y, LIU Y Y, et al. High-efficiency trace Na extraction from crystal quartz ore used for fused silica — A pretreatment technology[J]. International Journal of Minerals, Metallurgy and Materials, 2017, 24(10):1075-1086. doi: 10.1007/s12613-017-1498-y

[9] LIN M, LIU Y Y, LEI S M, et al. High-efficiency extraction of Al from coal-series kaolinite and its kinetics by calcination and pressure acid leaching[J]. Applied Clay Science, 2018, 161:215. doi: 10.1016/j.clay.2018.04.031

-

下载:

下载: