Study on Process Mineralogy and Mineral Processing Technology of A Low Grade Copper-Molybdenum Ore

-

摘要:

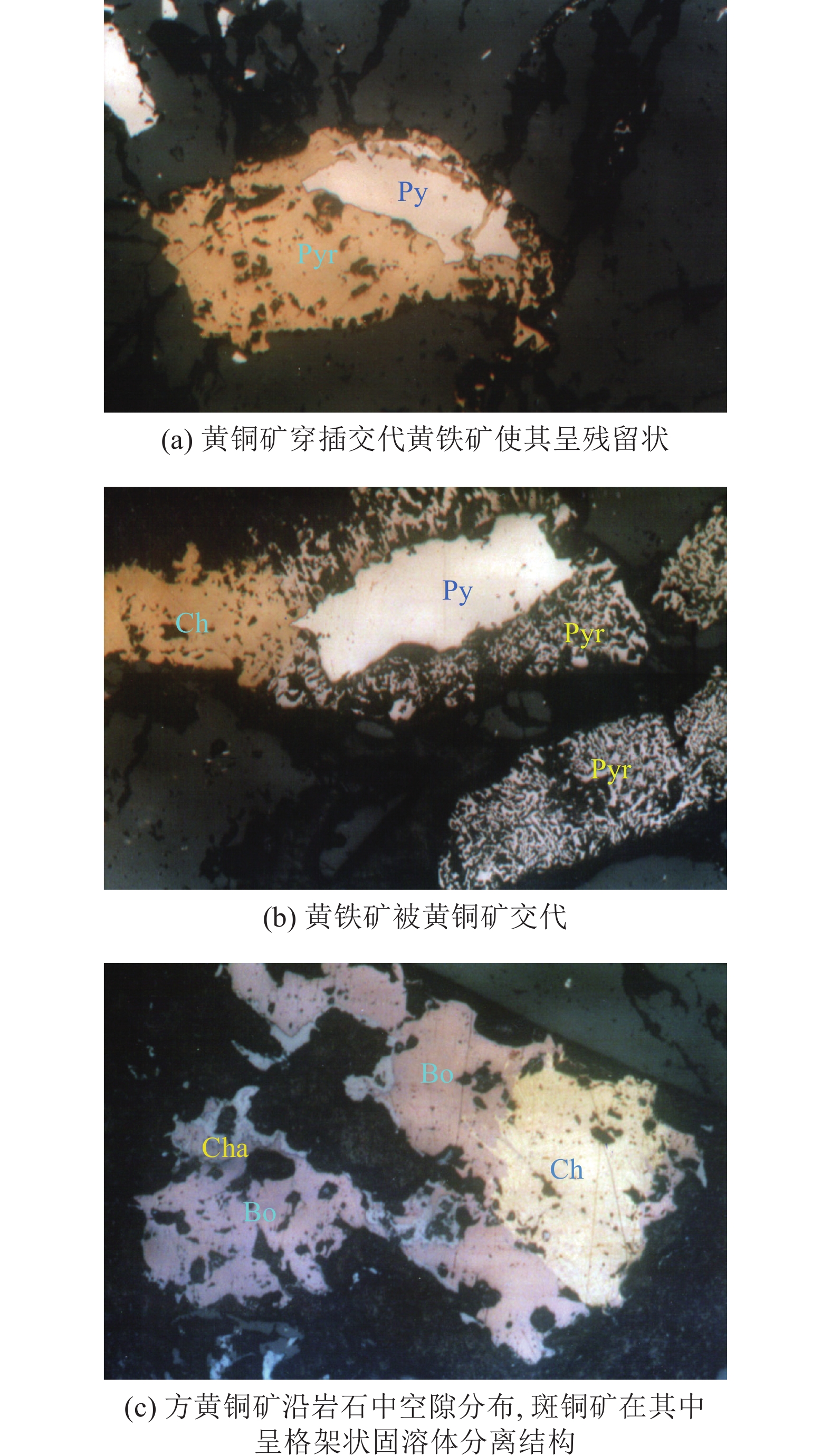

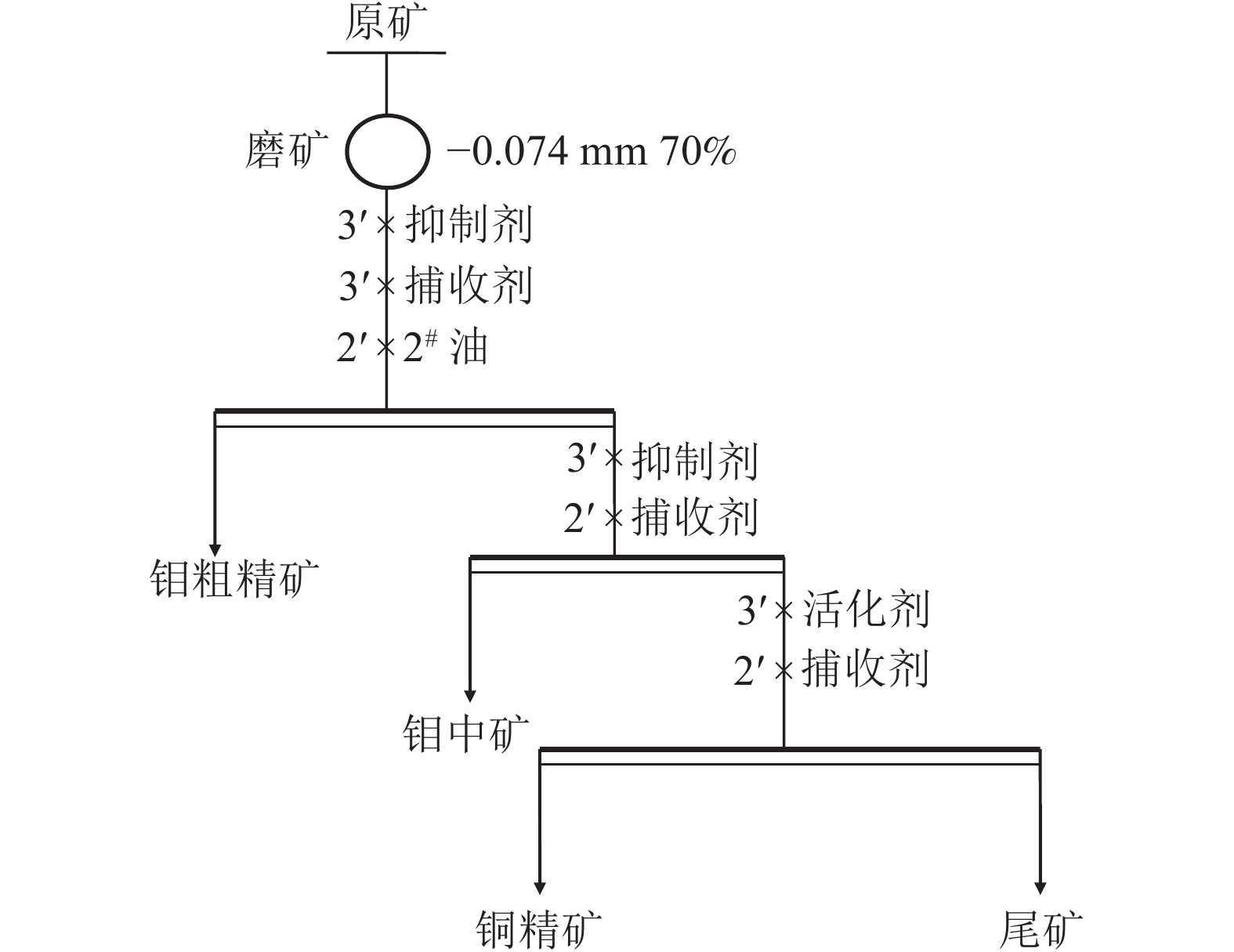

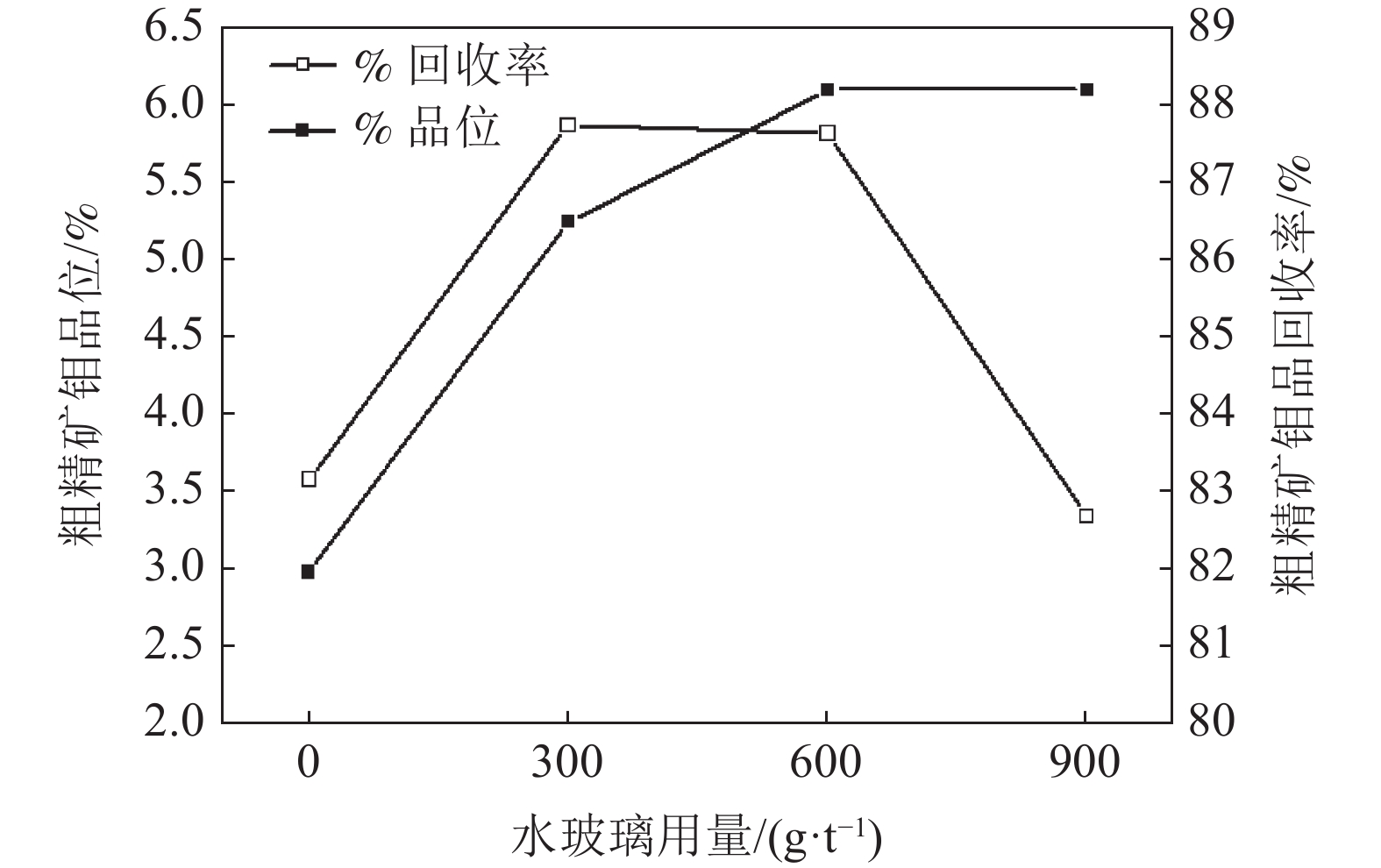

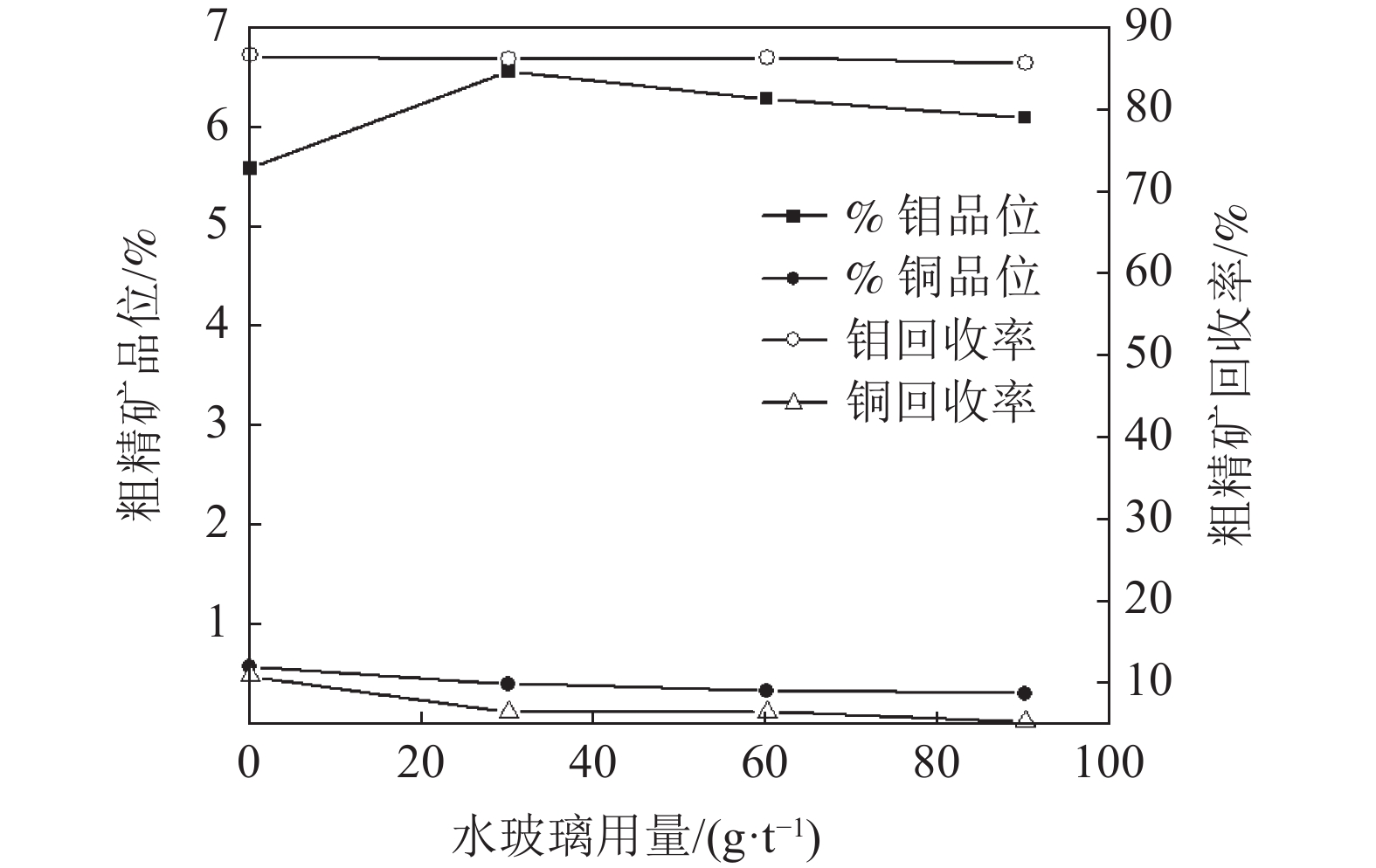

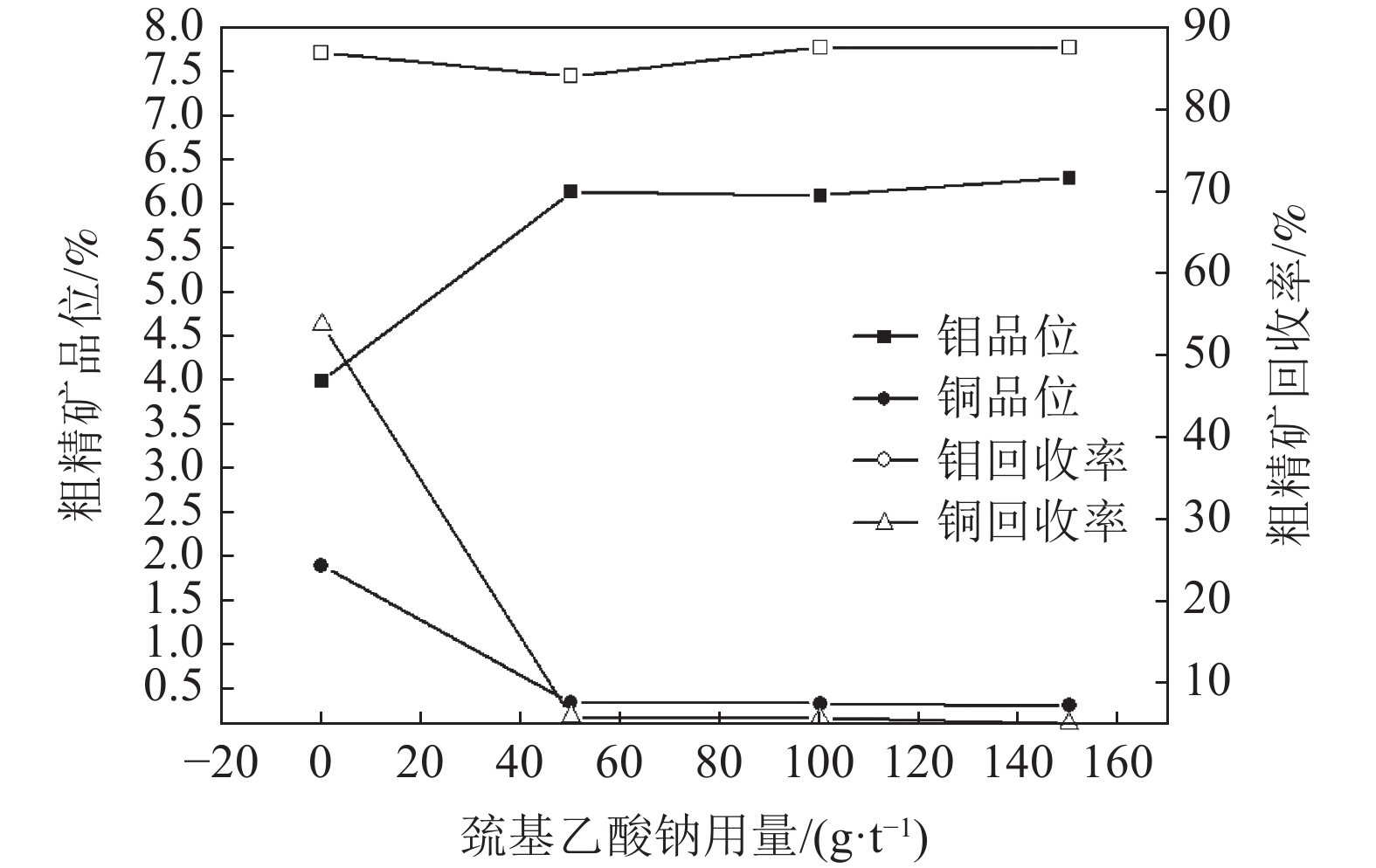

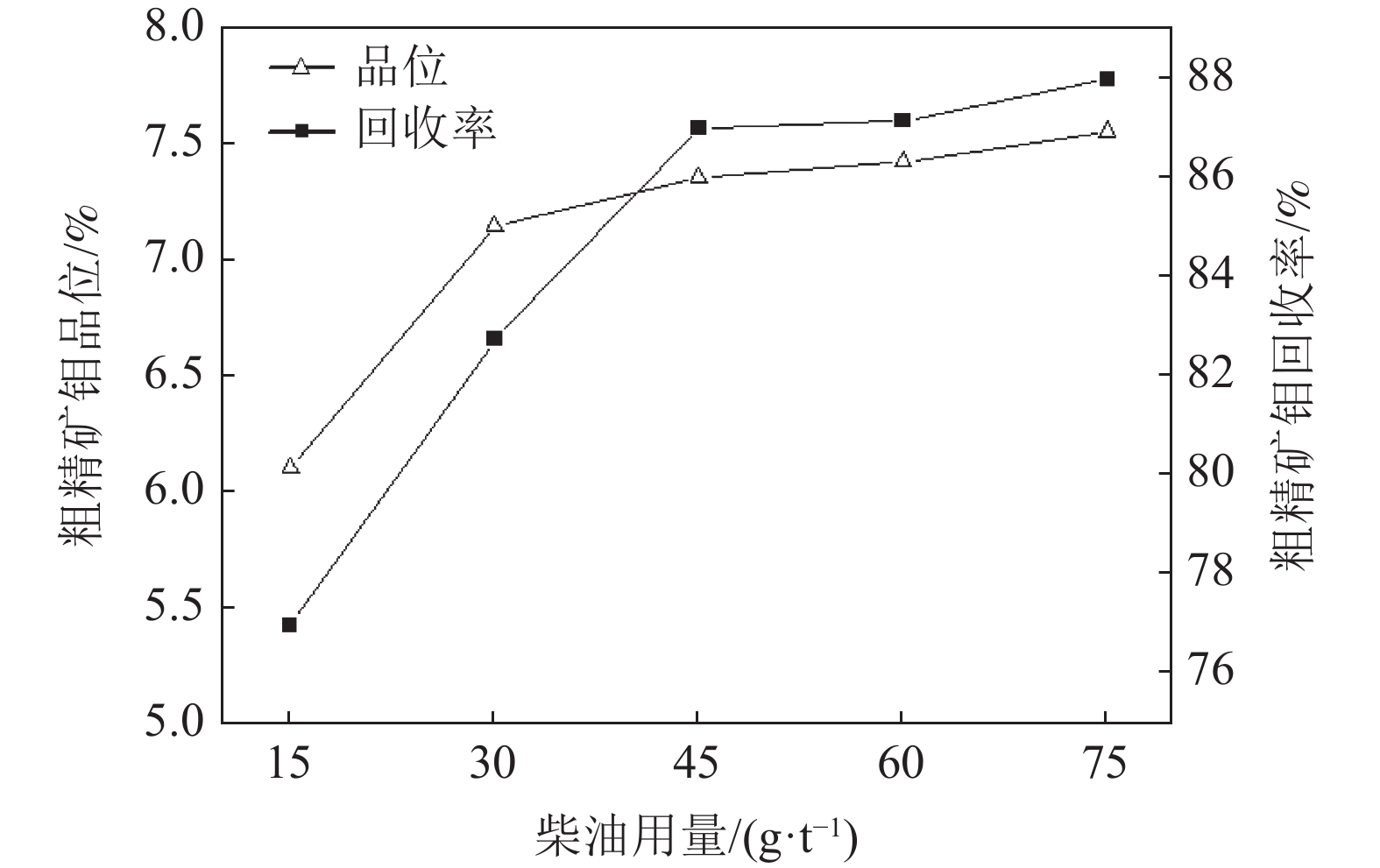

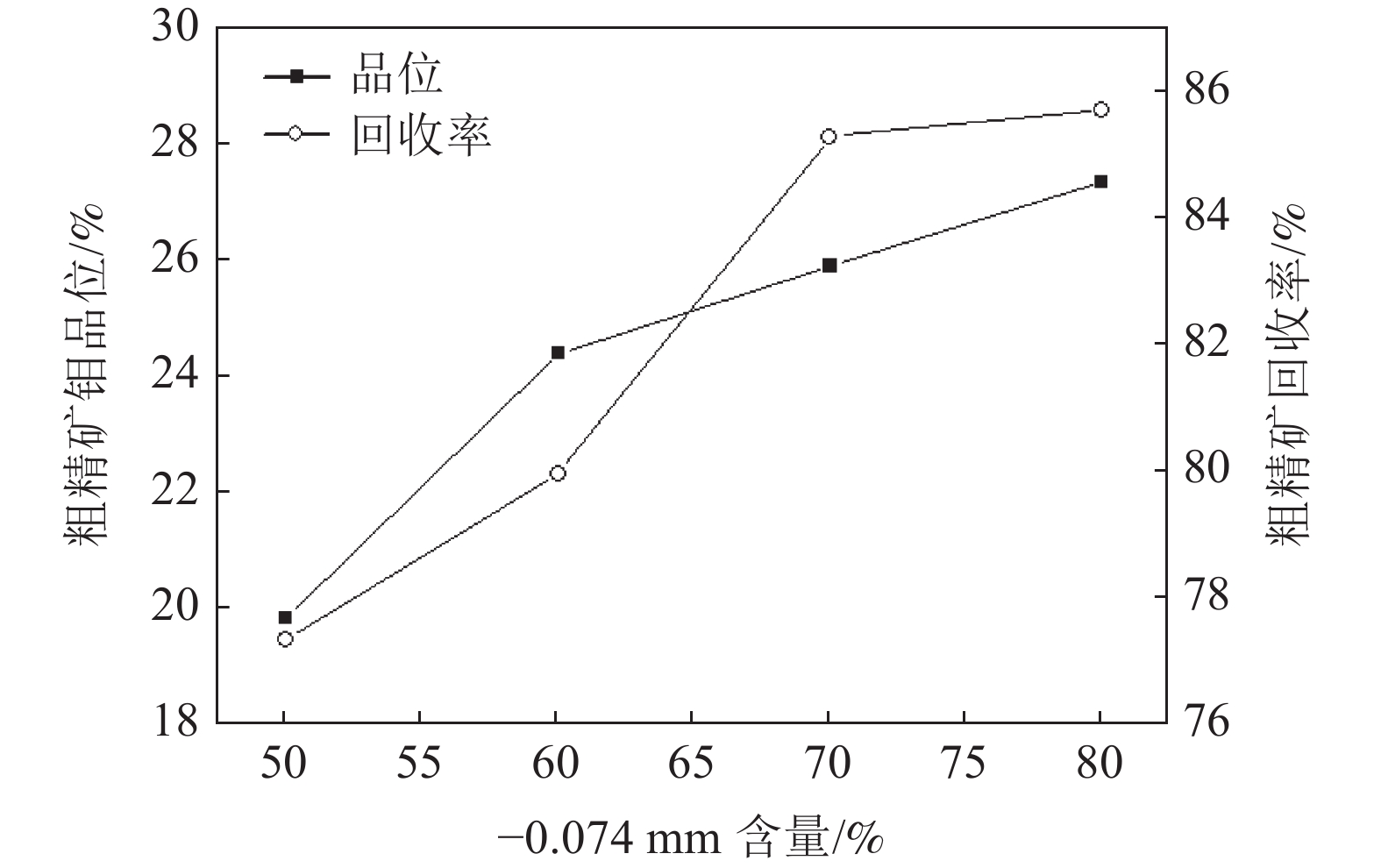

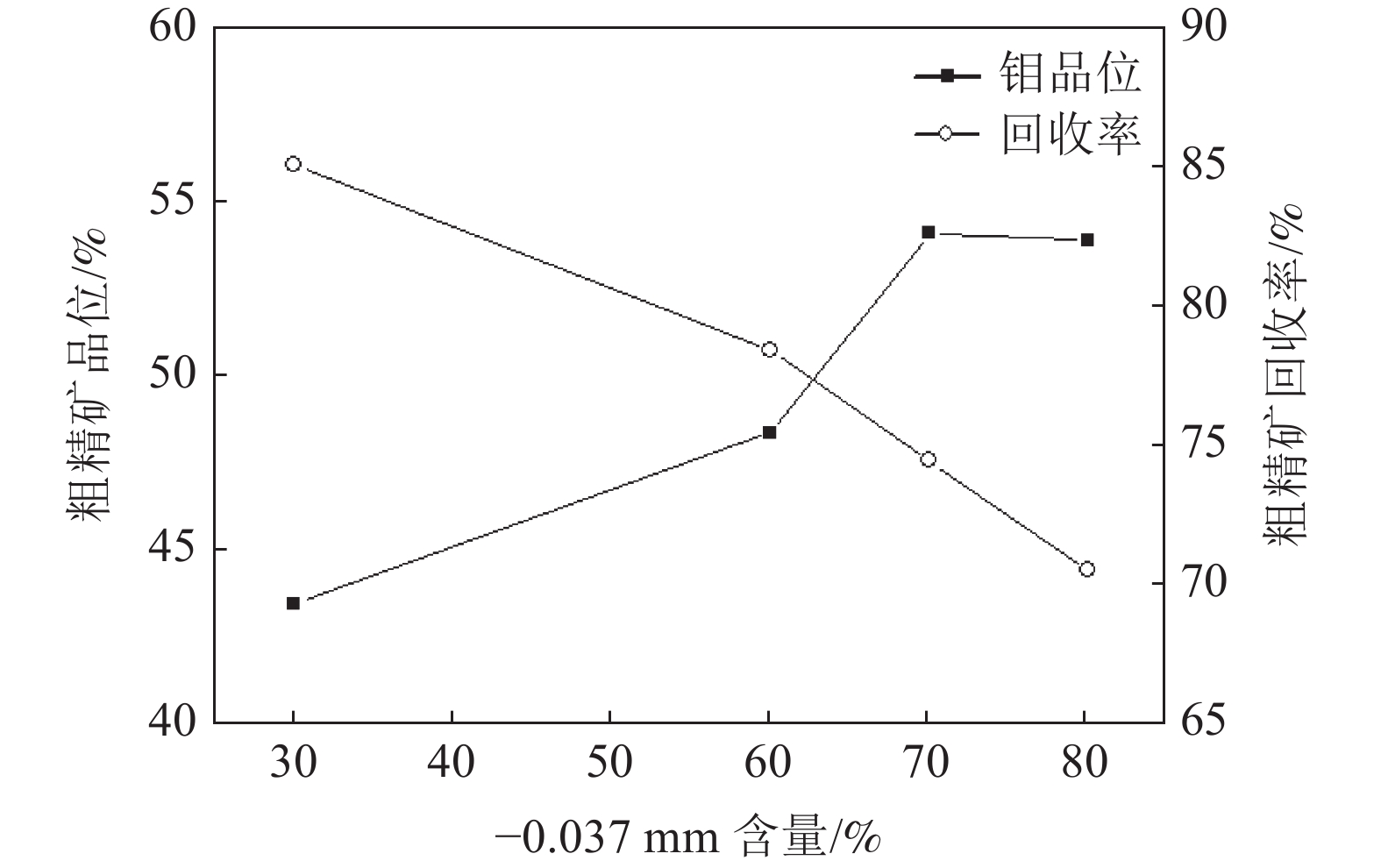

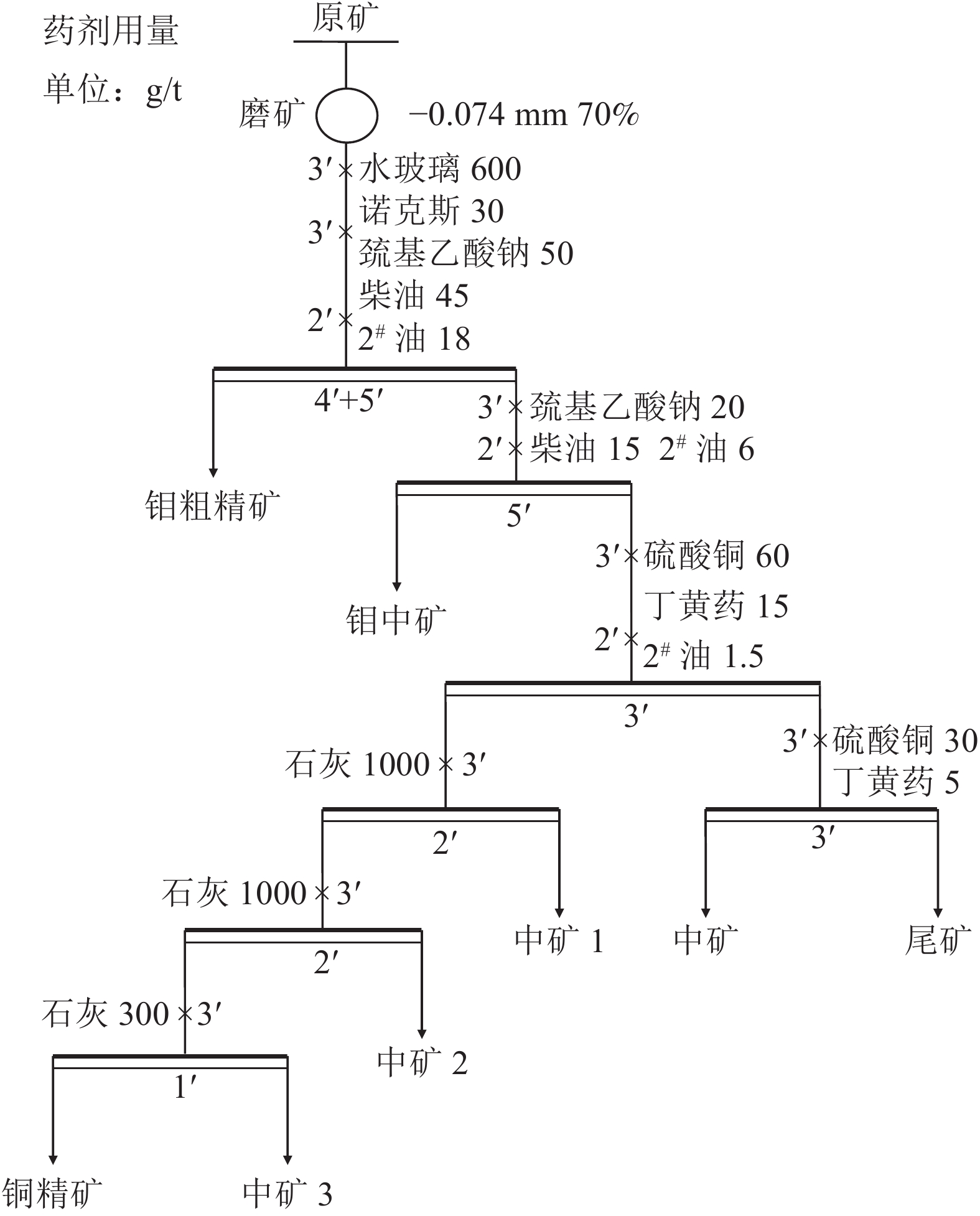

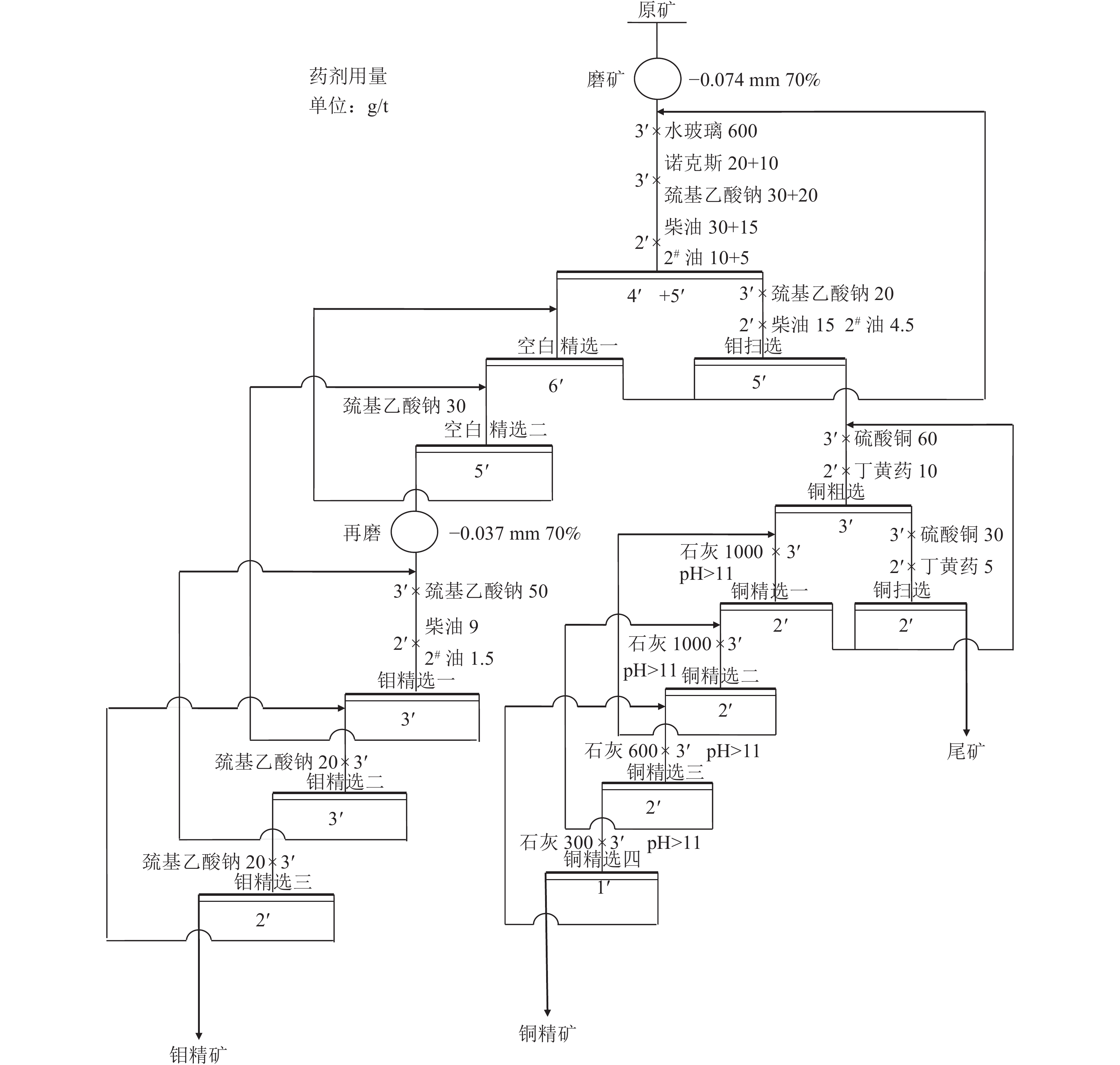

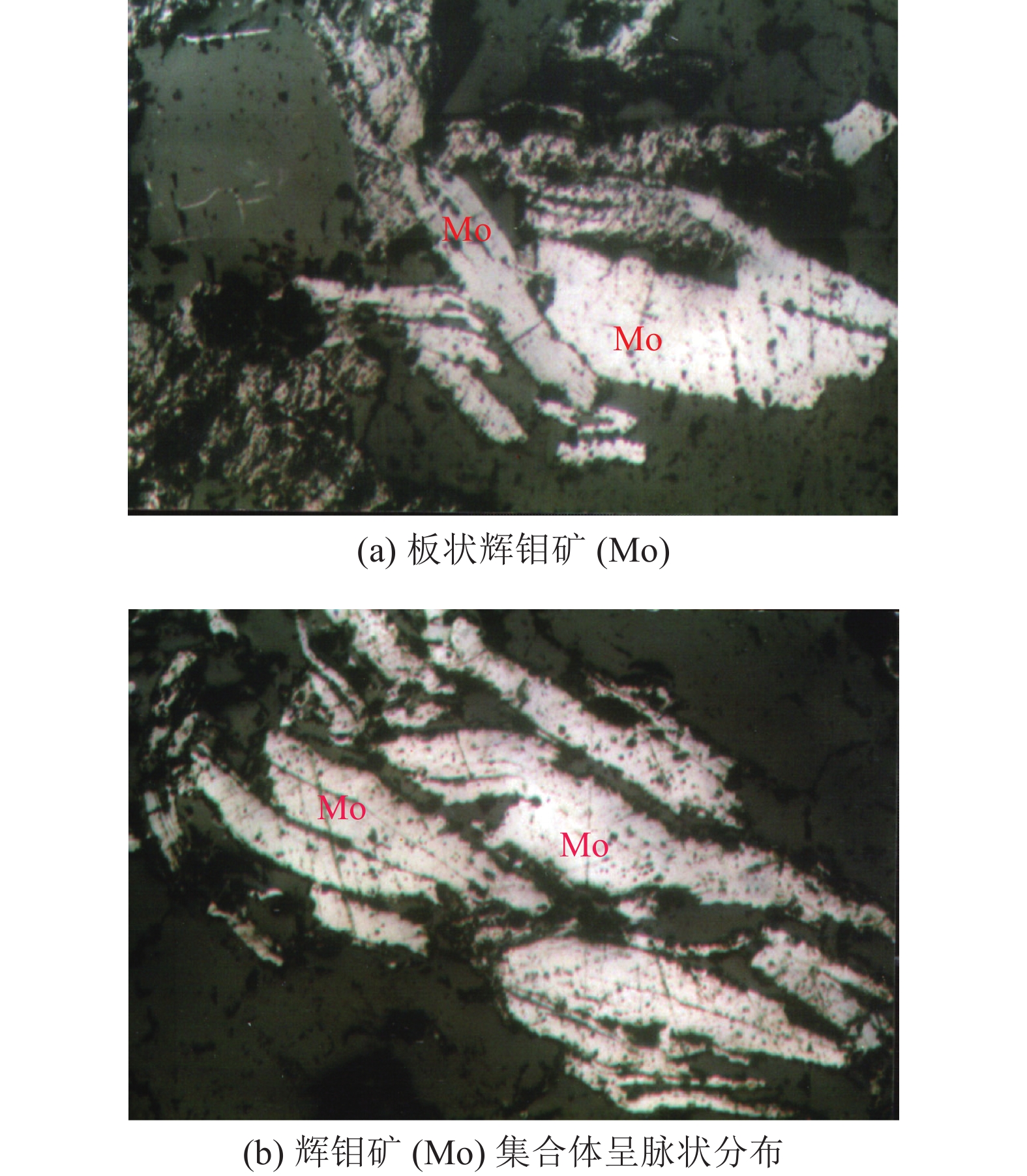

青海某铜钼矿含钼0.084%,铜含量0.067%。工艺矿物学研究表明,原矿中钼主要以辉钼矿形式存在,铜以黄铜矿、辉铜矿及斑铜矿等形式赋存。针对矿石性质,结合探索实验,最终采用铜钼优先浮选工艺处理该矿石。在磨矿细度为-74 μm 70%条件下,经一次粗选一次扫选两次空白精选得钼粗精矿,钼粗精矿再磨后经三次精选获得了钼品位50.21%、回收率85.21%的钼精矿;钼浮选尾矿用硫酸铜活化后经一次粗选一次扫选四次精选,获得了品位15.32%、回收率54.92%的铜精矿,实现了有价元素的综合回收。

Abstract:A copper-molybdenum ore in Qinghai contains 0.084% Mo and 0.067% Cu. Process mineralogical study shows that molybdenum in the ore mainly exists in the form of molybdenite, while copper in the form of chalcopyrite, chalcocite and bornite. Based on the molybdenum ore property, the flowsheet of selective flotation was adopted.Copper and molybdenum were comprehensively recovered by flotation process. Under the condition of grinding fineness of 74 μm 70%, molybdenum concentrate was obtained by one roughing, one scavenging and two blank cleaning. After regrinding, molybdenum concentrate with molybdenum grade of 50.21% and recovery of 85.21% was obtained by three cleaning. After molybdenum flotation tailings were activated with copper sulfate, copper concentrate with grade of 15.32% and recovery of 54.92% was obtained by one roughing, one scavenging and four cleaning. The comprehensive recovery of valuable elements was realized.

-

Key words:

- Molybdenite /

- Process mineralogy /

- Flotation /

- Comprehensive recovery

-

-

表 1 原矿多元素分析结果/%

Table 1. Results of chemical analysis of the ore

Mo Cu Pb Zn S TFe Ni Mn SiO2 Al2O3 CaO MgO Na2O P TiO2 As 0.084 0.067 0.013 0.019 1.63 2.54 0.002 0.092 68.77 11.87 1.96 1.08 0.76 0.039 0.37 0.0036 表 2 原矿钼物相分析结果

Table 2. Analysis results of molybdenum phase in raw ore

名称 硫化钼中钼 氧化钼中钼 相和 含量/% 0.081 0.004 0.085 分布率/% 95.29 4.71 100.00 表 3 钼浮选尾矿综合回收铜实验结果

Table 3. Results of comprehensive recovery of copper from molybdenum flotation tailings

产品名称 产率/% 品位/% 回收率/% Mo Cu Mo Cu 钼粗精矿 1.14 6.49 0.21 85.74 3.51 钼中矿 0.50 0.28 0.19 1.62 1.37 铜精矿 0.20 0.12 17.42 0.23 50.18 中矿3 1.17 0.023 0.64 0.35 10.79 中矿2 1.37 0.020 0.32 0.35 6.31 中矿1 0.53 0.052 0.64 0.35 4.88 中矿 0.13 0.20 1.31 0.35 2.45 尾矿 94.96 0.010 0.015 11.01 20.51 原矿 100.00 0.086 0.069 100.00 100.00 表 4 闭路实验结果

Table 4. Test results of closed-circuit flotation

产品名称 产率/% 品位 /% 回收率 /% Mo Cu Mo Cu 钼精矿 0.14 50.21 0.20 85.21 0.43 铜精矿 0.24 0.07 15.32 0.24 54.92 尾 矿 99.62 0.012 0.03 14.55 44.65 原 矿 100.00 0.083 0.067 100.00 100.00 -

[1] 张亮, 杨卉芃, 冯安生. 全球钼矿资源现状及市场分析[J]. 矿产综合利用, 2019(3):11-16. ZHANG L, YANG H P, FENG A S. Study on general situation and analysis of supply and demand of global molybdenum resource[J]. Multipurpose Utilization of Mineral Resources, 2019(3):11-16. doi: 10.3969/j.issn.1000-6532.2019.03.003

[2] 张汉鑫, 李慧, 梁精龙, 等. 稀有金属钼资源回收现状及进展[J]. 矿产综合利用, 2020(1):47-49. ZHANG H X, LI H, LIANG J L, et al. Current status and progress of rare metal molybdenum resource recovery[J]. Multipurpose Utilization of Mineral Resources, 2020(1):47-49. doi: 10.3969/j.issn.1000-6532.2020.01.009

[3] 孙小俊, 李建华. 湖北某铜钼矿浮选试验研究[J]. 矿冶工程, 2017, 37(4):61-64. SUN X J, LI J H. Experimental study on flotation of copper-molybdenum ore from Hubei[J]. Mining and Metallurgical Engineering, 2017, 37(4):61-64. doi: 10.3969/j.issn.0253-6099.2017.04.017

[4] 赵开乐, 闫武, 刘飞燕, 等. 细粒嵌布硫化钼矿铜钼高效分离技术[J]. 矿产综合利用, 2021(2):1-7. ZHAO K L, YAN W, LIU F Y, et al. High efficiency separation of chalcopyriten from a fine disseminated molybdenite[J]. Multipurpose Utilization of Mineral Resources, 2021(2):1-7. doi: 10.3969/j.issn.1000-6532.2021.02.001

[5] 杨凯志, 陈红兵, 胡真, 等. 广东某铜钼多金属硫化矿混合精矿中钼的高效分离[J]. 矿产综合利用, 2020(2):44-48. YANG K Z, CHEN H B, HU Z, et al. Research on efficient separation Mo for Cu-Mo mixed concentrate from Guangdong copper-molybdenum polymetallic sulfide ore[J]. Multipurpose Utilization of Mineral Resources, 2020(2):44-48. doi: 10.3969/j.issn.1000-6532.2020.02.007

[6] 简胜, 胡岳华, 孙伟. 西藏某低品位铜钼矿选矿工艺[J]. 矿产综合利用, 2019(5):32-36. JIAN S, HU Y H, SUN W. Process of a low-grade mineral copper-molybdenum ore in Tibet[J]. Multipurpose Utilization of Mineral Resources, 2019(5):32-36. doi: 10.3969/j.issn.1000-6532.2019.05.007

[7] 王昊伟, 周兴龙, 徐翔, 等. 云南某低品位铜钼矿选矿试验研究[J]. 矿产综合利用, 2017(2):63-67. WANG H W, ZHOU X L, XU X, et al. Experimental study on beneficiation of a low grade copper-molybdenum ore in Yunnan[J]. Multipurpose Utilization of Mineral Resources, 2017(2):63-67. doi: 10.3969/j.issn.1000-6532.2017.02.015

[8] 乔吉波, 王少东, 张晶, 等. 迪庆铜钼矿选矿工艺研究[J]. 矿冶工程, 2017, 37(5):60-63. QIAO J B, WANG S D, ZHANG J, et al. Beneficiation technique for copper-molybdenum ore from Diqing[J]. Mining and Metallurgical Engineering, 2017, 37(5):60-63. doi: 10.3969/j.issn.0253-6099.2017.05.014

[9] 朱贤文, 李世纯, 王阳, 等. 青藏高原某斑岩型铜钼矿选矿试验[J]. 金属矿山, 2020(2):71-76. ZHU X W, LI S C, WANG Y, et al. Mineral processing test of a porphyry type copper-molybdenum ore in Tibetan Plateau[J]. Metal Mine, 2020(2):71-76. doi: 10.19614/j.cnki.jsks.202002013

[10] 李莹, 龚丽, 梁泽跃. 云南某斑岩型铜钼矿混合浮选捕收剂实验及工业应用[J]. 矿产综合利用, 2021(2):23-26. LI Y, GONG L, LIANG Z Y. Experiment and application research on mixed flotation collector of copper-molybdenum porphyry mine in Yunnan[J]. Multipurpose Utilization of Mineral Resources, 2021(2):23-26. doi: 10.3969/j.issn.1000-6532.2021.02.005

-

下载:

下载: