Mineral Characteristics Research and Tests of Improving Quality of Vanadium Titanium Iron Concentrate in Panxi Area

-

摘要:

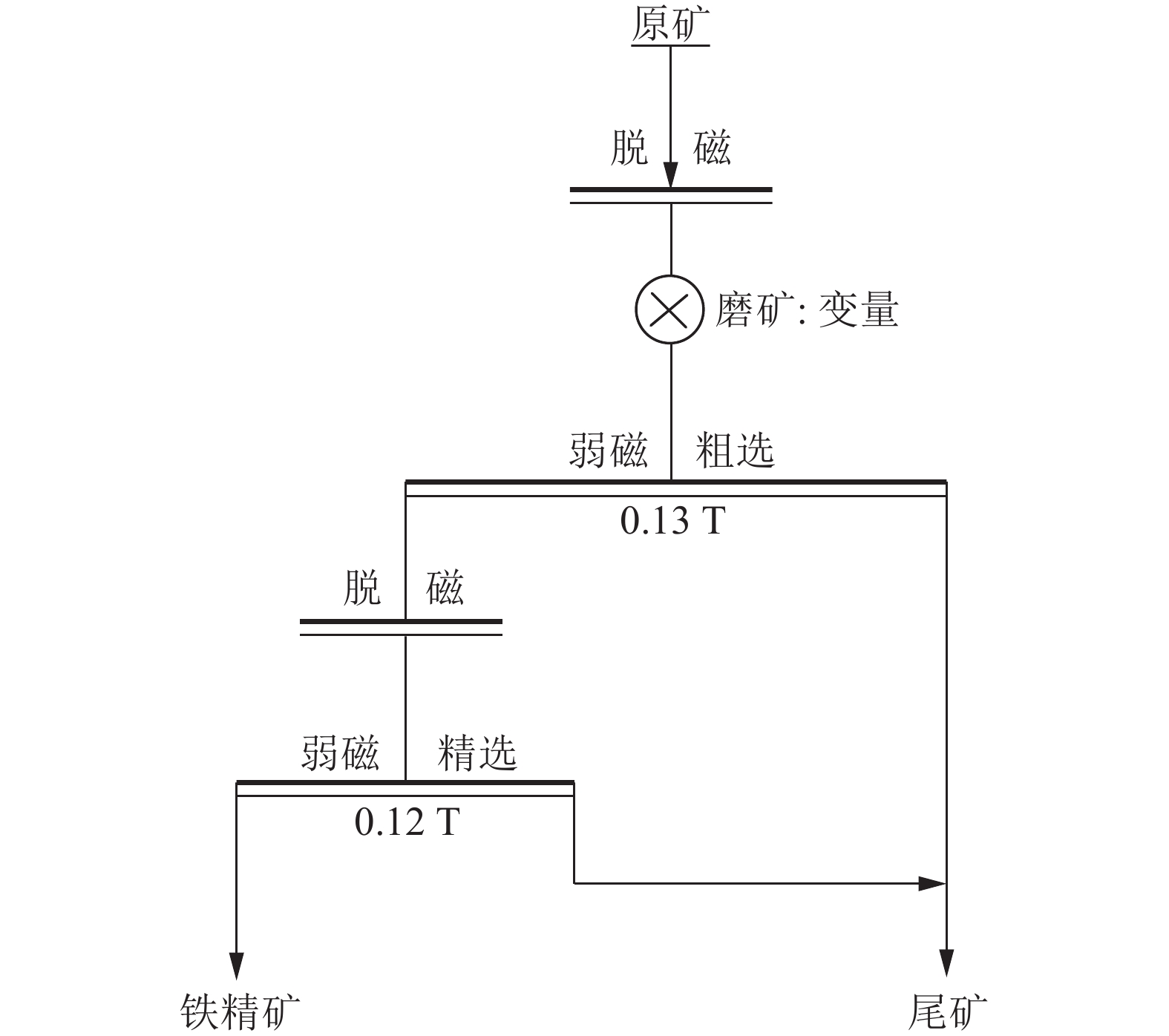

这是一篇矿物加工工程领域的论文。利用筛析、偏光显微镜、X射线衍射仪、Zeiss Sigma 500扫描电子显微镜+Bruker能谱仪+AMICS自动矿物分析系统对攀西某钒钛铁精矿样品进行了矿物特性研究。样品主要脉石矿物为磁黄铁矿、粒状钛铁矿及辉石、长石等,粗细粒级TFe、S、SiO2、Al2O3和MgO及脉石矿物含量有较大差异,Fe少量以钛铁矿、磁黄铁矿及非金属矿物存在,Ti主要以钛磁铁矿形式存在,钛铁矿及镁铝尖晶石以格片状、细脉状、细条带状、网格状及针状镶嵌于钛磁铁矿中,且客晶矿物粒度很细,磨矿解离、选别分离及产品后处理难度较大,物理选矿方法降低其TiO2较难。采用磨矿磁选工艺可使钒钛铁精矿TFe品位提高2~3个百分点,提质本质为降低精矿中SiO2、Al2O3、MgO,降幅SiO2>MgO>Al2O3,提质过程精矿TiO2含量虽变化不大,但可使Fe/TiO2由4.29提高至4.50左右,该过程Fe及V金属有一定损失,S具一定的脱除效果。

Abstract:This is a paper in the field of mineral processing engineering. The mineral characteristics of a vanadium titanium iron concentrate sample from Panxi were studied using sieve analysis, polarizing microscope, X-ray diffractometer, Zeiss Sigma 500 scanning electron microscope, Bruker energy spectrometer, and AMICS automatic mineral analysis system. The main gangue minerals in the sample are magnetite pyrite, granular ilmenite, pyroxene, feldspar, etc. The contents of coarse and fine products TFe, S, SiO2, Al2O3, MgO, and gangue minerals are quite different. A small amount of Fe exists in ilmenite, magnetic pyrite, and non-metallic minerals. Ti mainly exists in the form of titanium magnetite. ilmenite and magnesium aluminum spinel are inlaid on the base of titanium magnetite in lamellar, veinlet, thin strip, grid, and needle shapes, The particle size of the guest crystal mineral is very fine, making it difficult to grind, separate, and post treat the product. The use of grinding magnetic separation can increase the TFe grade of vanadium titanium iron concentrate by 2-3 percentage points. The essence of the improvement is a significant decrease in the content of SiO2, Al2O3, and MgO in the concentrate, with a decrease of SiO2>MgO>Al2O3. The TiO2 content of the concentrate does not change much during the improvement process, with Fe/TiO2 increasing from 4.29 to 4.50, V2O5 grade slightly increasing, and S grade slightly decreasing.

-

-

表 1 矿样化学成分分析结果/ %

Table 1. Chemical composition analysis results of the sample

TFe FeO TiO2 V2O5 Co S Cu Ni Pb Zn 53.25 33.28 13.02 0.562 <0.01 0.84 0.012 <0.01 <0.01 0.045 SiO2 Al2O3 CaO MgO Mn P As Na2O K2O / 3.87 4.09 1.14 2.78 0.271 <0.005 <0.01 0.104 0.101 / 表 2 矿样粒度分析及主要成分沿粒度分布规律

Table 2. Regularities of distribution of chemical components with the changes of grading of the sample

粒级/mm 产率/% 品位/% 分布率/% TFe TiO2 V2O5 S SiO2 Al2O3 MgO TFe TiO2 V2O5 S SiO2 Al2O3 MgO +0.25 3.20 41.75 12.67 0.437 0.444 12.42 6.54 4.53 2.51 3.13 2.49 1.76 10.04 5.12 5.10 -0.25+0.15 9.71 49.31 13.38 0.523 0.428 6.46 4.95 3.49 9.01 10.03 9.04 5.15 15.84 11.76 11.92 -0.15+0.10 16.09 52.38 13.19 0.559 0.509 4.40 4.34 3.11 15.87 16.39 16.02 10.16 17.89 17.09 17.61 -0.10+0.074 14.69 53.50 13.30 0.570 0.626 3.77 4.15 2.87 14.81 15.10 14.92 11.42 14.00 14.93 14.84 -0.074+0.043 15.48 54.00 13.06 0.579 0.709 2.97 3.89 2.65 15.75 15.62 15.97 13.62 11.62 14.74 14.44 -0.043+0.038 7.16 54.38 13.06 0.588 0.872 2.67 3.73 2.53 7.33 7.22 7.49 7.74 4.83 6.53 6.37 -0.038 33.67 54.75 12.50 0.568 1.200 3.03 3.62 2.51 34.72 32.51 34.07 50.14 25.78 29.83 29.73 合计 100.00 53.10 12.95 0.561 0.806 3.96 4.09 2.84 100.00 100.00 100.00 100.00 100.00 100.00 100.00 表 3 矿物组成及含量

Table 3. Mineral contents and compositions of the sample

矿物名称 含量/% 矿物名称 含量/% 钛磁铁矿 83.61 橄榄石 0.36 钛铁矿 3.76 黄铁矿 0.06 磁黄铁矿 2.18 榍石 0.51 钠长石 0.05 镁橄榄石 0.21 普通辉石 2.70 铁铝尖晶石 0.32 透辉石 1.28 黑云母 0.02 钙长石 1.03 黄铜矿 0.05 绿帘石 0.12 铁镁铝尖晶石 0.06 角闪石 1.22 拉长石 1.29 钛辉石 1.17 合计 100.00 表 4 样品Fe、Ti、S元素赋存状态分析结果

Table 4. Analysis results of the forms of chemical elements such as Fe and Ti and S in the sample

矿物名称 Fe元素分布率 /% S元素分布率 /% Ti 元分布率 /% 钛磁铁矿 92.25 0.00 81.68 绿泥石 1.09 0.92 1.26 镁橄榄石 0.21 0.00 0.00 钛辉石 0.68 0.00 0.83 磁黄铁矿 2.03 98.67 0.00 钙长石 0.04 0.00 0.02 透辉石 0.42 0.00 0.33 钛铁矿 2.67 0.00 13.63 镁铝尖晶石 0.03 0.00 0.00 榍石 0.10 0.00 1.06 拉长石 0.00 0.00 0.00 铁橄榄石 0.47 0.00 1.18 硫钴矿 0.00 0.41 0.00 合计 100.00 100.00 100.00 表 5 样品中各粒级产品矿物组成及连生关系

Table 5. Mineral compositions and intercrescence relationships of all fractions in the sample

粒级/mm 矿物组成 连生关系 +0.15 金属矿物:钛磁铁矿90%左右,磁黄铁矿<1%;

非金属矿物:5%~10%钛磁铁矿:90%以上为单体,10%左右为连生体;连生体大多为与脉石矿物连生,少量与磁黄铁矿连生。

磁黄铁矿:50%左右为单体;50%左右为连生体;与钛磁铁矿连生的连生体占90%左右,与脉石连生的连生体占10%左右。

脉石:70%左右为单体,30%左右为连生体;连生体多为与钛磁铁矿连生,少量与磁黄铁矿连生。-0.15+0.10 金属矿物:钛磁铁矿94%左右,磁黄铁矿<2%;

非金属矿物:<4%钛磁铁矿:95%以上为单体,5%左右为连生体;与脉石矿物连生的连生体占50%左右,与磁黄铁矿连生的连生体占50%左右。

磁黄铁矿:70%左右为单体,30%左右为连生体;与钛磁铁矿连生的连生体占90%以上,与脉石连生的连生体占10%左右。

脉石:80%左右为单体,20%左右为连生体,连生体多为与钛磁铁矿连生,少量与磁黄铁矿连生。-0.10+0.074 金属矿物:钛磁铁矿95%左右,磁黄铁矿<2%;

非金属矿物:<3%钛磁铁矿:95%以上为单体,5%左右为连生体;与脉石矿物连生的连生体占50%左右,与磁黄铁矿连生的连生体占50%左右。

磁黄铁矿:90%左右为单体,10%左右为连生体;与钛磁铁矿连生连生体约占90%,与脉石连生连生体约占10%。

脉石:80%左右为单体,20%左右为连生体;连生体多为与钛磁铁矿连生,少量与磁黄铁矿连生。-0.074+0.038 金属矿物:钛磁铁矿96%左右,磁黄铁矿<2%;

非金属矿物:<2%钛磁铁矿和脉石:基本都为单体,连生体极少;

磁黄铁矿:95%以上为单体。-0.038 金属矿物:钛磁铁矿96%左右,磁黄铁矿<3%;

非金属矿物:<1%钛磁铁矿、磁黄铁矿、脉石基本都为单体,连生体极少。 表 6 提质实验结果

Table 6. Beneficiation test results of inproving the quality of the sample

磨矿细度 产品

名称产率/% 品位/% 回收率/% TFe TiO2 V2O5 SiO2 Al2O3 MgO S TFe TiO2 V2O5 SiO2 Al2O3 MgO S -0.074 mm

82.62%精矿 94.41 55.75 12.64 0.582 2.43 3.73 2.72 0.59 97.43 94.72 98.47 63.20 86.49 84.59 84.77 尾矿 5.59 24.88 11.89 0.153 23.90 9.84 8.37 1.79 2.57 5.28 1.53 36.80 13.51 15.41 15.23 原矿 100.00 54.02 12.60 0.558 3.63 4.07 3.04 0.66 100.00 100.00 100.00 100.00 100.00 100.00 100.00 -0.074 mm

92.88%精矿 93.22 56.25 12.63 0.588 2.36 3.83 2.55 0.58 96.88 93.71 98.13 57.63 83.77 80.49 81.67 尾矿 6.78 24.88 11.66 0.154 23.86 10.20 8.50 1.79 3.12 6.29 1.87 42.37 16.23 19.51 18.33 原矿 100.00 54.12 12.56 0.559 3.82 4.26 2.95 0.66 100.00 100.00 100.00 100.00 100.00 100.00 100.00 -0.074 mm

97.40%精矿 92.93 56.50 12.75 0.577 1.86 3.52 2.42 0.58 96.96 93.39 98.28 49.86 81.13 77.83 80.99 尾矿 7.07 23.25 11.87 0.133 24.59 10.76 9.06 1.79 3.04 6.61 1.72 50.14 18.87 22.17 19.01 原矿 100.00 54.15 12.69 0.546 3.47 4.03 2.89 0.67 100.00 100.00 100.00 100.00 100.00 100.00 100.00 -0.045 mm

90.10%精矿 92.03 56.56 12.67 0.597 1.74 3.45 2.36 0.58 96.40 92.46 97.75 46.19 78.89 75.55 79.28 尾矿 7.97 24.38 11.93 0.159 23.41 10.66 8.82 1.75 3.60 7.54 2.25 53.81 21.11 24.45 20.72 原矿 100.00 54.00 12.61 0.562 3.47 4.02 2.87 0.67 100.00 100.00 100.00 100.00 100.00 100.00 100.00 -0.045 mm

94.00%精矿 91.40 57.00 12.66 0.598 1.71 3.48 2.33 0.57 96.00 91.79 97.45 44.06 77.56 72.89 77.38 尾矿 8.60 25.25 12.04 0.166 23.07 10.70 9.21 1.78 4.00 8.21 2.55 55.94 22.44 27.11 22.62 原矿 100.00 54.27 12.61 0.561 3.55 4.10 2.92 0.68 100.00 100.00 100.00 100.00 100.00 100.00 100.00 -

[1] 陈福林, 杨晓军, 蔡先炎, 等. 攀西地区白马辉长岩型超低品位钒钛磁铁矿选铁实验研究[J]. 矿产综合利用, 2020(6):26-30. CHEN F L, YANG X J, CAI X Y, et al. Experimental study on iron separation of Baima Gabbro-type ultra-low-grade vanadium-titanomagnetite in Panxi Area[J]. Multipurpose Utilization of Mineral Resources, 2020(6):26-30.

CHEN F L, YANG X J, CAI X Y, et al. Experimental study on iron separation of Baima Gabbro-type ultra-low-grade vanadium-titanomagnetite in Panxi Area[J]. Multipurpose Utilization of Mineral Resources, 2020(6): 26-30.

[2] 陈福林, 杨晓军, 杨道广, 等. 甘肃某低品位钒钛磁铁矿工艺矿物学研究[J]. 矿产综合利用, 2020(6):64-68. CHEN F L, YANG X J, YANG D G, et al. Research on process mineralogy for a low grade vanadium titano-magnetite in Gansu province[J]. Multipurpose Utilization of Mineral Resources, 2020(6):64-68.

CHEN F L, YANG X J, YANG D G, et al. Research on process mineralogy for a low grade vanadium titano-magnetite in Gansu province[J]. Multipurpose Utilization of Mineral Resources, 2020(6): 64-68.

[3] 黑色金属矿产资源强国战略研究专题组. 黑色金属矿产资源强国战略研究[M]. 北京: 科学出版社, 2019.

Research Group on the Strategy of a Powerful Country in Ferrous Metal Mineral Resources. Research on a Strategy of a Powerful Country in Ferrous Metal Mineral Resources[M]. Beijing:Science Press, 2019.

[4] 《现代铁矿石选矿》编委会. 现代铁矿石选矿(上册)[M].合肥: 中国科学技术大学出版社, 2009.

Editorial Board of "Modern Iron Ore Beneficiation". Modern iron ore beneficiation (Volume One) [M]. Hefei:University of Science and Technology of China Press, 2009.

[5] 陈超, 张裕书, 李潇雨, 等. 钛磁铁矿选矿技术研究进展[J]. 矿产综合利用, 2021(3):99-105. CHEN C, ZHANG Y S, LI X Y, et al. Research progress in titanium-magnetite beneficiation technology[J]. Multipurpose Utilization of Mineral Resources, 2021(3):99-105.

CHEN C, ZHANG Y S, LI X Y, et al. Research progress in titanium-magnetite beneficiation technology [J]. Multipurpose Utilization of Mineral Resources, 2021(3): 99-105.

[6] 邹锋, 殷志刚, 陈思竹. 攀枝花白马选铁尾矿综合回收利用研究[J]. 矿产综合利用, 2020(6):19-25. ZOU F, YIN Z G, CHEN S Z. Research on comprehensive utilization of iron tailings from Baima, Panzhihua[J]. Multipurpose Utilization of Mineral Resources, 2020(6):19-25.

ZOU F, YIN Z G, CHEN S Z. Research on comprehensive utilization of iron tailings from Baima, Panzhihua[J]. Multipurpose Utilization of Mineral Resources, 2020(6): 19-25.

[7] 池冬瑞, 顾畔, 严伟平, 等. 红格钒铁精矿提质降杂新技术研究[J]. 矿产综合利用, 2020(6):91-95. CHI D R, GU P, YAN W P, et al. Study on quality improvement and impurities reduction new technology of vanadium-iron concentrate in Hongge[J]. Multipurpose Utilization of Mineral Resources, 2020(6):91-95.

CHI D R, GU P, YAN W P, et al. Study on quality improvement and impurities reduction new technology of vanadium-iron concentrate in Hongge[J]. Multipurpose Utilization of Mineral Resources, 2020(6): 91-95.

[8] 周政, 赵华伦, 李兵荣, 等. 红格某钒钛磁铁矿选矿试验研究[J]. 矿产综合利用, 2018(1):32-35. ZHOU Z, ZHAO H L, LI B R, et al. Experimental study on beneficiation of a vanadium-titanium magnetite in Hongge[J]. Multipurpose Utilization of Mineral Resources, 2018(1):32-35.

ZHOU Z, ZHAO H L, LI B R, et al. Experimental study on beneficiation of a vanadium-titanium magnetite in Hongge[J]. Multipurpose Utilization of Mineral Resources, 2018(1): 32-35.

-

下载:

下载: