Recovery of Ilmenite from an Ultrafine Fine Particle Material in Panxi

-

摘要:

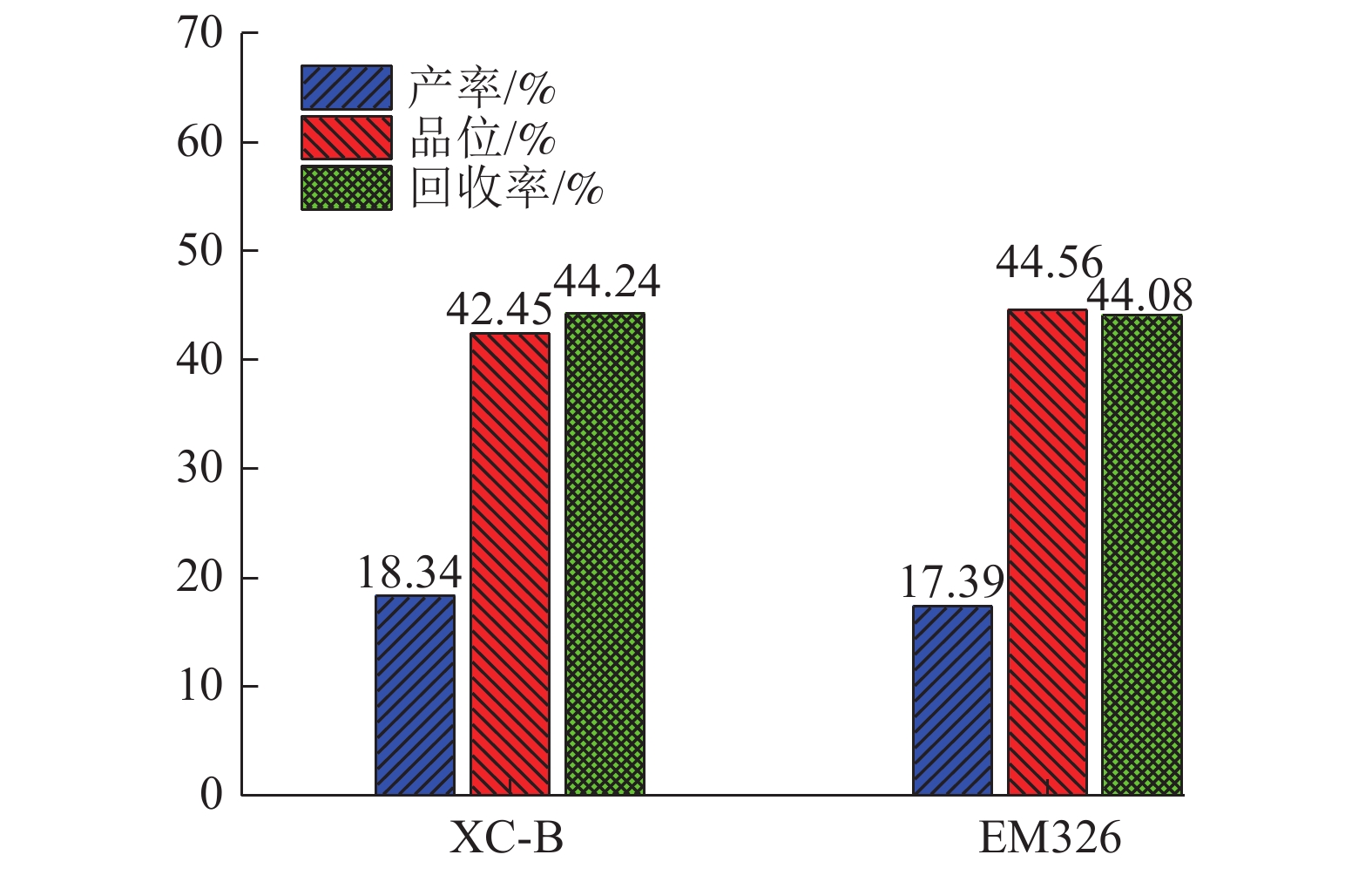

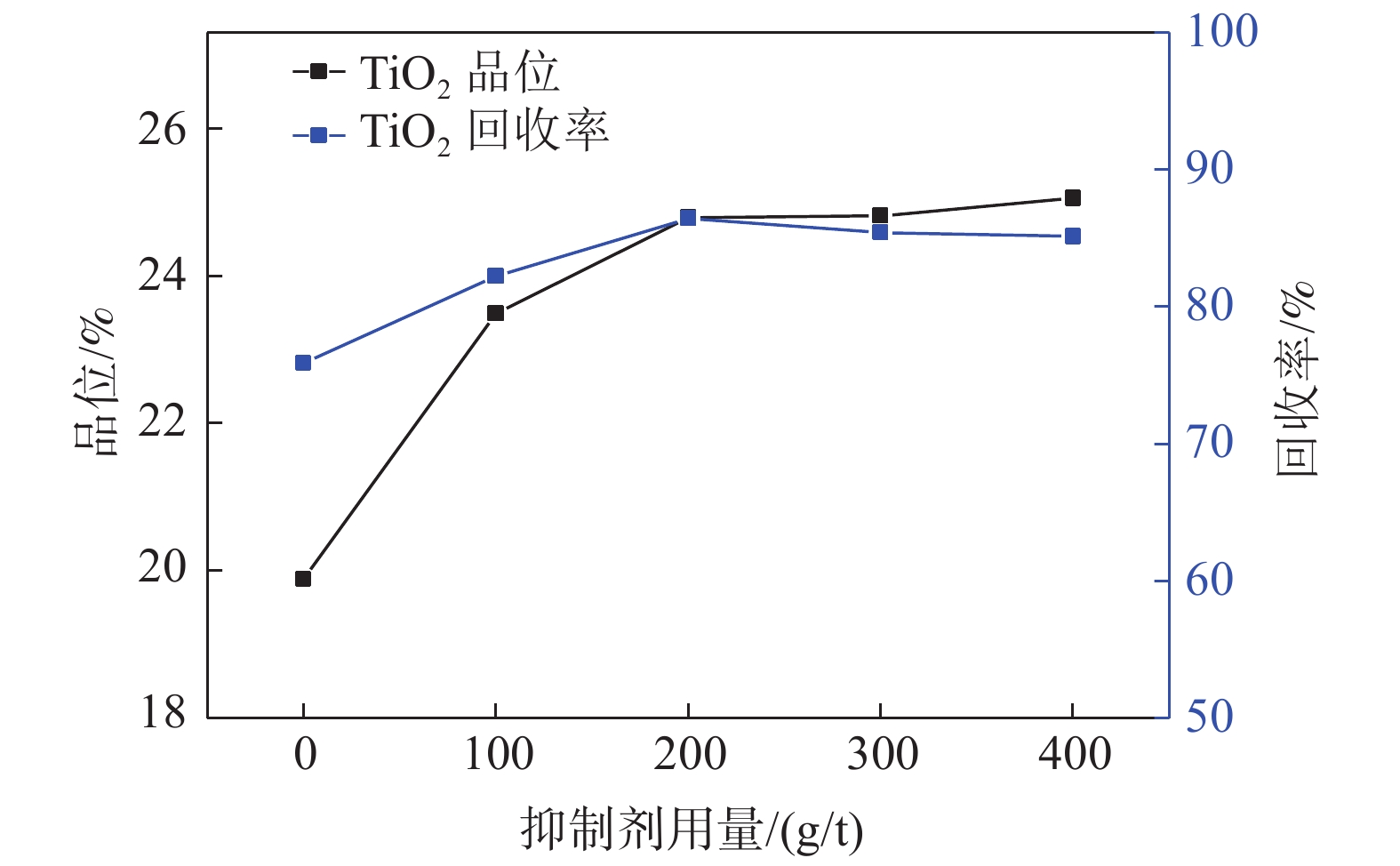

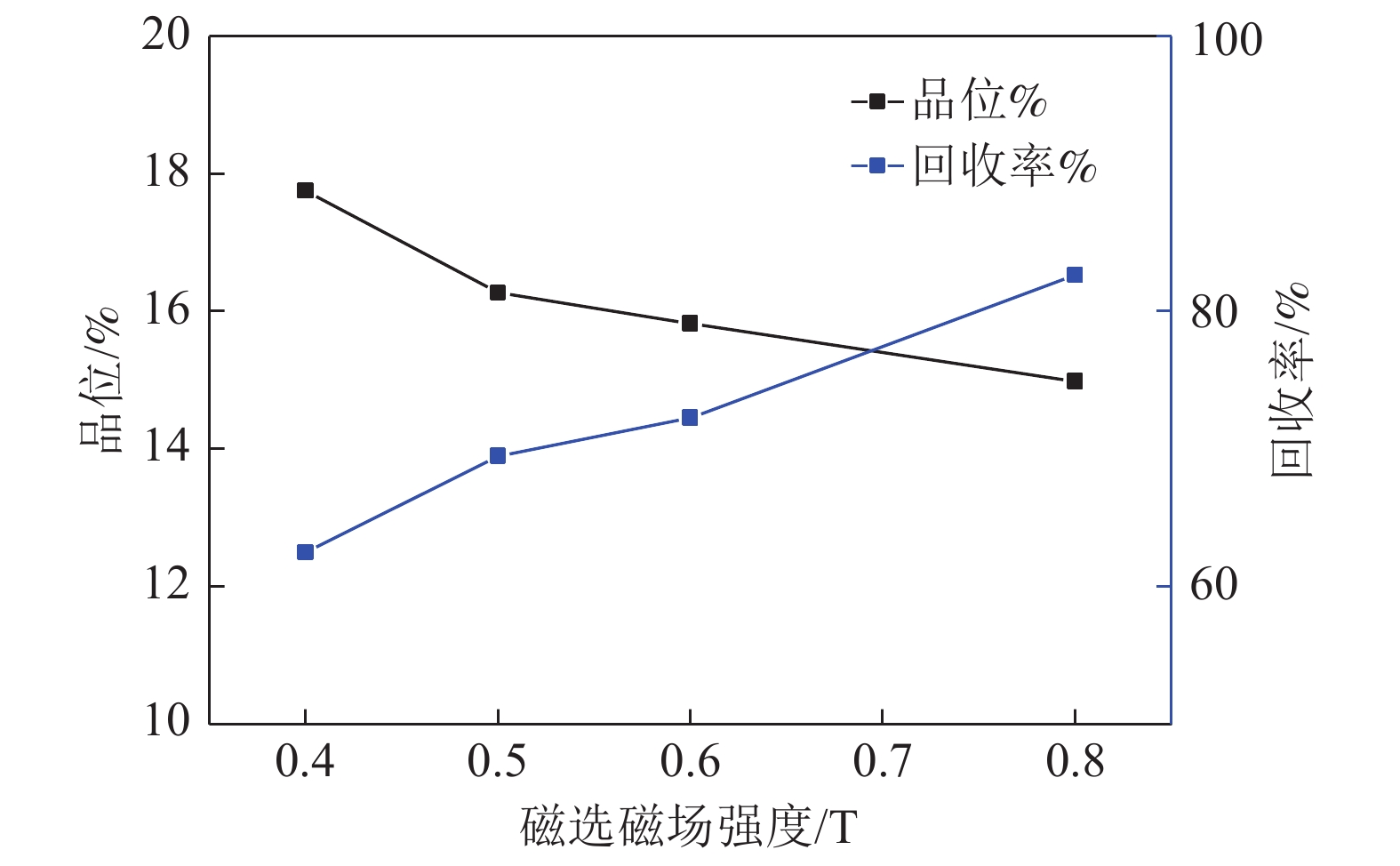

这是一篇矿物加工工程领域的论文。本研究针对攀西某选厂超微细粒物料进行了超微细粒钛铁矿选矿回收实验研究,确定了强磁预富集-浮选的整体工艺流程,获得了优化的选矿回收工艺流程及条件参数,应用了适用于该类超微细粒钛铁矿回收的浮选药剂EM-A和EM326。结果表明,通过强磁预富集-浮选脱硫+浮选脱泥+一粗一扫五次精选中矿再选返回的选钛流程,最终可获得钛精矿产品TiO2品位45.56%,回收率47.10%的良好指标,为该类超微细粒物料中钛铁矿资源回收提供了技术参考。

Abstract:This is an essay in the field of mineral processing engineering. This study conducted a test study on the recovery of Ilmenite from an Ultrafine Fine Particle Material in Panxi, determined the overall process flow of strong magnetic preconcentration flotation, obtained the optimized beneficiation and recovery process flow and condition parameters, and applied the flotation reagents EM-A and EM326 suitable for the recovery of this type of ultrafine ilmenite. Results show that through the titanium separation process of strong magnetic preconcentration flotation desulfurization + flotation desliming + one roughing and one sweeping five times of cleaning middlings in the beneficiation and return, the titanium concentrate product TiO2 grade of 45.56% and the recovery rate of 47.10% can finally be obtained, which provides a technical reference for the recycling of titanium ilmenite in this kind of ultrafine materials.

-

Key words:

- Mineral processing engineering /

- Ultrafine particle material /

- Ilmenite /

- Recovery

-

-

表 1 选钛给料X荧光光谱分析结果/%

Table 1. X-ray fluorescence spectrum analysis results of titanium mixture

TiO2 Fe MgO SiO2 Al2O3 P2O5 SO3 K2O CaO Na2O NiO Co3O4 Cr2O3 MnO Nb2O5 SrO 12.37 21.38 15.86 32.08 7.08 0.27 0.66 0.20 8.33 0.53 0.15 0.079 0.096 0.32 0.004 0.026 表 2 选钛给料粒度分析结果

Table 2. Particle size analysis results of titanium separation mixture

产品名称/mm 产率/% TiO2品位/% 分布率/% +0.015 8.39 11.21 7.60 -0.015+0.074 17.47 12.74 17.98 -0.074+0.038 8.70 11.36 7.98 -0.038+0.019 12.24 13.05 12.90 -0.019 53.20 12.46 53.54 给 料 100.00 12.38 100.00 表 3 入浮给料粒度组成及金属分布情况

Table 3. Particle size composition and metal distribution of floating feed

粒级/mm 产率/% TiO2

品位/%TiO2

分布率/%个别 累积 +0.074 4.92 4.92 13.73 3.83 -0.074+0.038 12.78 17.70 14.84 10.74 -0.038+0.030 10.98 28.68 16.58 10.31 -0.030+0.019 21.22 49.90 16.94 20.36 -0.019+0.010 15.63 65.53 17.75 15.72 -0.010 34.47 100.00 20.00 39.04 合计 100.00 17.66 100.00 表 4 浮选闭路实验结果

Table 4. Results of closed circuit flotation test

产品名称 中矿再选/% 顺序返回/% 产率 品位 回收率 产率 品位 回收率 钛精矿 25.79 45.56 67.12 28.32 43.65 69.82 泥 8.57 17.42 8.53 8.38 17.84 8.44 硫精矿 8.86 16.76 8.48 9.09 16.58 8.51 尾矿1 41.76 4.72 11.26 54.21 4.32 13.23 尾矿2 15.02 5.37 4.61 原矿 100.00 17.50 100.00 100.00 17.70 100.00 表 5 钛精矿化学多项分析结果/%

Table 5. Chemical multiple analysis results of titanium concentrate

TFe FeO Fe2O3 TiO2 V2O5 Cu Co Ni SiO2 Al2O3 CaO MgO S P2O5 K2O Na2O 33.45 38.16 44.60 45.56 0.121 0.034 0.026 0.124 6.403 1.726 1.860 4.771 0.162 0.078 0.036 0.101 表 6 钛精矿粒度组成及金属分布情况

Table 6. Particle size composition and metal distribution of titanium concentrate

粒级/mm 产率/% 品位/% 分布率/% +0.038 3.76 45.53 3.76 -0.038+0.030 8.05 46.81 8.27 -0.030+0.019 17.47 46.89 17.99 -0.019+0.010 22.17 45.32 22.07 -0.010 48.55 44.92 47.91 合计 100.00 45.53 100.00 -

[1] 邓建, 杨耀辉, 王洪彬, 等. 攀西某选铁尾矿中钛铁矿浮选药剂优化实验研究[J]. 钢铁钒钛, 2022, 43(3):77-83. DENG J, YANG Y H, WANG H B, et al. Experimental study on optimization of flotation reagents for ilmenite from an iron dressing tailing in Panxi area[J]. Iron Steel Vanadium Titanium, 2022, 43(3):77-83. doi: 10.7513/j.issn.1004-7638.2022.03.013

DENG J, YANG Y H, WANG H B, et al. Experimental study on optimization of flotation reagents for ilmenite from an iron dressing tailing in Panxi area[J]. Iron Steel Vanadium Titanium, 2022, 43(3): 77-83. doi: 10.7513/j.issn.1004-7638.2022.03.013

[2] 王丰雨, 徐晓衣, 梁焘茂, 等. 攀枝花超细粒级钛铁矿磁选富集方法[J]. 钢铁钒钛, 2021, 42(2):79-85. WANG F Y, XU X Y, LIANG T M, et al. Magnetic separation and enrichment method for Panzhihua ultrafine ilmenite[J]. Iron and Steel Vanadium and Titanium, 2021, 42(2):79-85. doi: 10.7513/j.issn.1004-7638.2021.02.014

WANG F Y, XU X Y, LIANG T M, et al. Magnetic separation and enrichment method for Panzhihua ultrafine ilmenite[J]. Iron and Steel Vanadium and Titanium, 2021, 42 (2): 79-85. doi: 10.7513/j.issn.1004-7638.2021.02.014

[3] 吴贤, 张健. 中国的钛资源分布及特点[J]. 钛工业进展, 2006(6):8-12. WU X, ZHANG J. Distribution and characteristics of titanium resources in China[J]. Progress in Titanium Industry, 2006(6):8-12. doi: 10.3969/j.issn.1009-9964.2006.06.004

WU X, ZHANG J. Distribution and characteristics of titanium resources in China[J]. Progress in Titanium Industry, 2006 (6): 8-12. doi: 10.3969/j.issn.1009-9964.2006.06.004

[4] 朱福兴, 焦钰, 李亮, 等. 攀西钒钛磁铁矿的选矿技术现状及发展趋势[J]. 矿冶, 2021, 30(4):26-32+40. ZHU F X, JIAO Y, LI L, et al. Current situation and development trend of mineral processing technology for Panxi vanadium titanomagnetite[J]. Mining and Metallurgy, 2021, 30(4):26-32+40. doi: 10.3969/j.issn.1005-7854.2021.04.005

ZHU F X, JIAO Y, LI L, et al. Current situation and development trend of mineral processing technology for Panxi vanadium titanomagnetite[J]. Mining and Metallurgy, 2021, 30 (4): 26-32+40. doi: 10.3969/j.issn.1005-7854.2021.04.005

[5] 谭世国, 樊学赛, 蒋仁东, 等. 攀西某选厂选钛浮选动力学特性研究[J]. 钢铁钒钛, 2022, 43(2):21-24. TAN S G, FAN X S, JIANG R D, et al. Study on the kinetic characteristics of titanium flotation in a concentrator in Panxi[J]. Steel and Vanadium Titanium, 2022, 43(2):21-24. doi: 10.7513/j.issn.1004-7638.2022.02.004

TAN S G, FAN X S, JIANG R D, et al. Study on the kinetic characteristics of titanium flotation in a concentrator in Panxi[J]. Steel and Vanadium Titanium, 2022, 43 (2): 21-24. doi: 10.7513/j.issn.1004-7638.2022.02.004

[6] 申帅平, 袁致涛, 马龙秋, 等. 攀西微细粒钛铁矿工艺矿物学特征[J]. 东北大学学报(自然科学版), 2019, 40(4):580-584. SHEN S P, YUAN Z T, MA L Q, et al. Process mineralogy characteristics of panxi fine grained ilmenite[J]. Journal of Northeast University (Natural Science Edition), 2019, 40(4):580-584. doi: 10.12068/j.issn.1005-3026.2019.04.024

SHEN S P, YUAN Z T, MA L Q, et al. Process mineralogy characteristics of panxi fine grained ilmenite[J]. Journal of Northeast University (Natural Science Edition), 2019, 40 (4): 580-584. doi: 10.12068/j.issn.1005-3026.2019.04.024

[7] 崔毅琦, 王凯, 童雄, 等. 难选微细粒钛铁矿资源的回收利用研究概述[J]. 矿冶, 2014, 23(6):14-17+21. CUI Y Q, WANG K, TONG X, et al. Overview of research on the recovery and utilization of refractory fine grained ilmenite resources[J]. Mining and Metallurgy, 2014, 23(6):14-17+21. doi: 10.3969/j.issn.1005-7854.2014.06.004

CUI Y Q, WANG K, TONG X, MENG Q, et al. Overview of research on the recovery and utilization of refractory fine grained ilmenite resources[J]. Mining and Metallurgy, 2014, 23 (6): 14-17+21. doi: 10.3969/j.issn.1005-7854.2014.06.004

[8] 杨耀辉, 惠博, 严伟平, 等. 攀西微细粒钛铁矿工艺矿物学研究[J]. 矿产综合利用, 2020(3):131-135. YANG Y H, HUI B, YAN W P, et al. Study on the process mineralogy of Panxi fine grained ilmenite[J]. Multipurpose Utilization of Mineral Resources, 2020(3):131-135. doi: 10.3969/j.issn.1000-6532.2020.03.022

YANG Y H, HUI B, YAN W P, et al. Study on the process mineralogy of Panxi fine grained ilmenite[J]. Multipurpose Utilization of Mineral Resources, 2020 (3): 131-135. doi: 10.3969/j.issn.1000-6532.2020.03.022

[9] 李丽匣, 申帅平, 袁致涛, 等. 微细粒钛铁矿磁选回收率低原因分析[J]. 中国矿业, 2018, 27(11):138-144. LI L X, SHEN S P, YUAN Z T, et al. Analysis of the reasons for low magnetic separation recovery of fine ilmenite[J]. China Mining, 2018, 27(11):138-144.

LI L Z, SHEN S P, YUAN Z T, et al. Analysis of the reasons for low magnetic separation recovery of fine ilmenite[J]. China Mining, 2018, 27 (11): 138-144.

[10] 陈攀, 翟计划, 王洪彬, 等. 微细粒钛铁矿浮选捕收剂改性实验研究[J]. 稀有金属, 2018, 42(2):205-212. CHEN P, ZHAI J H, WANG H B, et al. Experimental study on modification of flotation collectors for ultrafine ilmenite[J]. Rare Metals, 2018, 42(2):205-212.

CHEN P, ZHAI J H, WANG H B, et al. Experimental study on modification of flotation collectors for ultrafine ilmenite[J]. Rare Metals, 2018, 42 (2): 205-212.

[11] 李维斯, 陈攀, 杨耀辉, 等. 新型捕收剂TZ-1浮选微细粒钛铁矿实验研究[J]. 矿产综合利用, 2022(2):86-91. LI W S, CHEN P, YANG Y H, et al. Experimental study on flotation of fine ilmenite with a new collector TZ-1[J]. Multipurpose Utilization of Mineral Resources, 2022(2):86-91. doi: 10.3969/j.issn.1000-6532.2022.02.016

LI W S, CHEN P, YANG Y H, et al. Experimental study on flotation of fine ilmenite with a new collector TZ-1[J]. Multipurpose Utilization of Mineral Resources, 2022 (2): 86-91. doi: 10.3969/j.issn.1000-6532.2022.02.016

[12] 马龙秋, 杜雨生, 孟庆有, 等. 钛铁矿浮选药剂及其作用机理研究进展[J]. 金属矿山, 2018(3):7-12. MA L Q, DU Y S, MENG Q Y, et al. Research progress in ilmenite flotation reagents and their action mechanism[J]. Metal Mines, 2018(3):7-12. doi: 10.19614/j.cnki.jsks.201803002

MA L Q, DU Y S , MENG Q Y , et al. Research progress in ilmenite flotation reagents and their action mechanism[J]. Metal Mines, 2018 (3): 7-12. doi: 10.19614/j.cnki.jsks.201803002

-

下载:

下载: