Preparation of High-purity Quartz Sand by Purifying a White Pegmatite in Inner Mongolia

-

摘要:

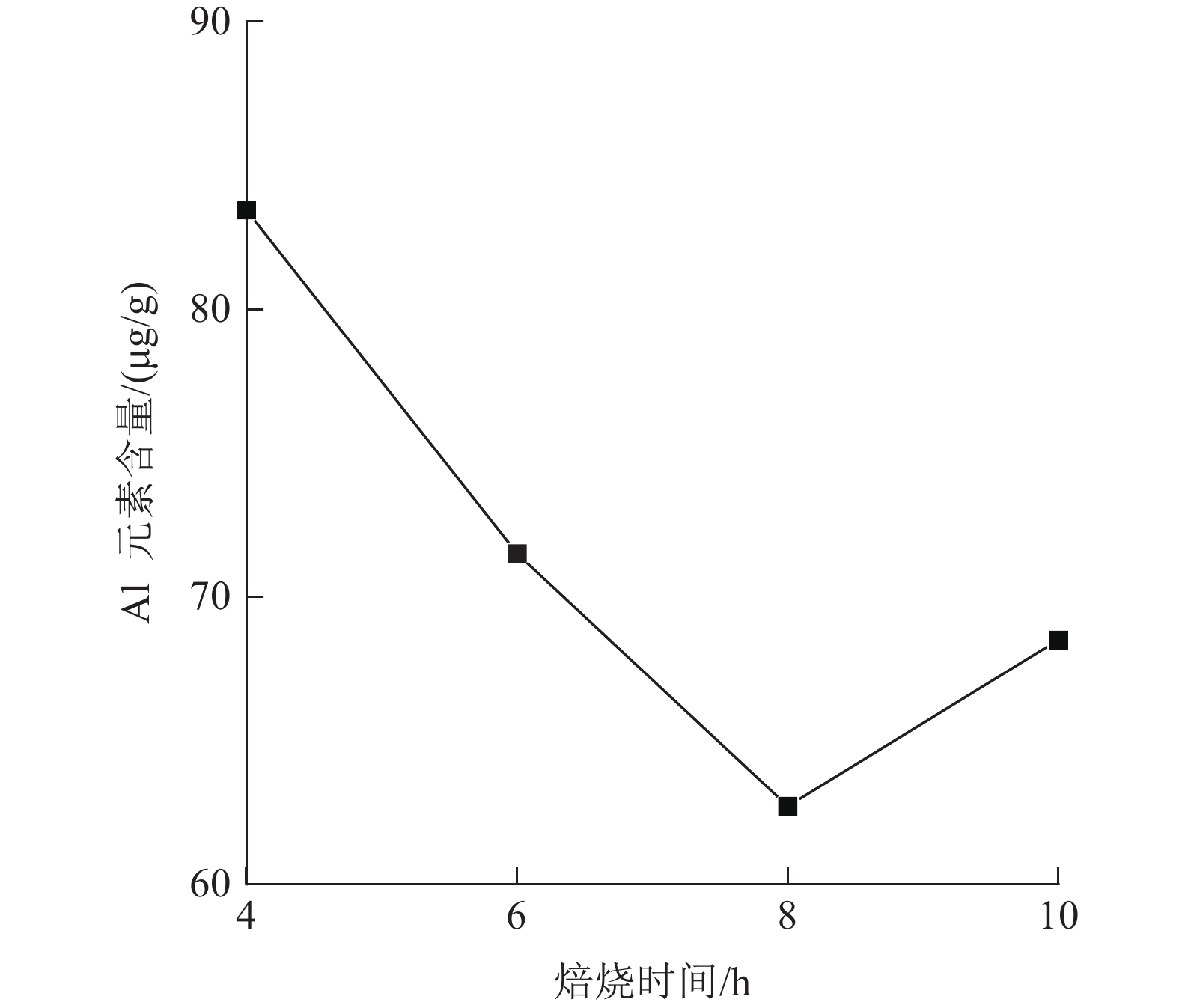

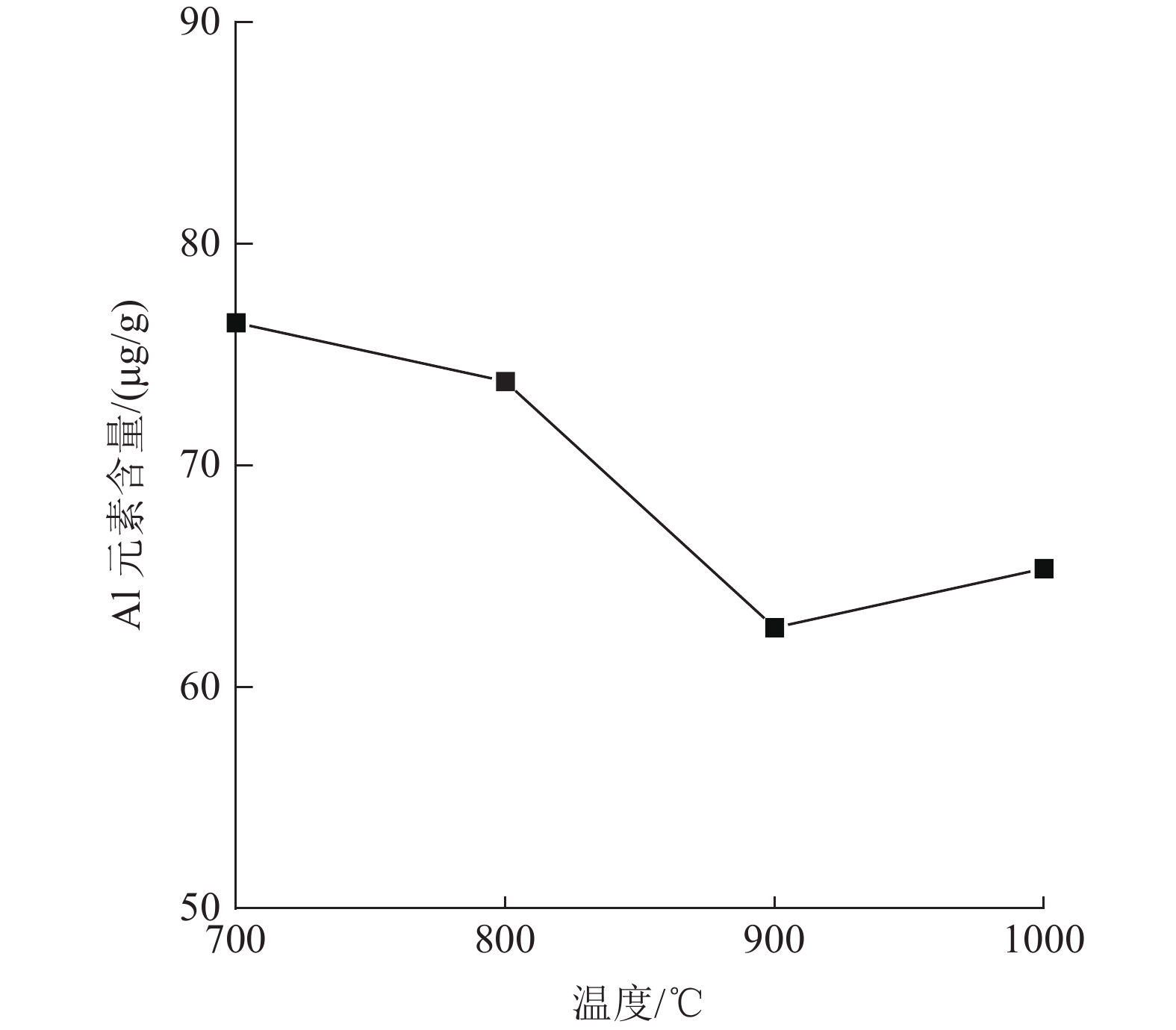

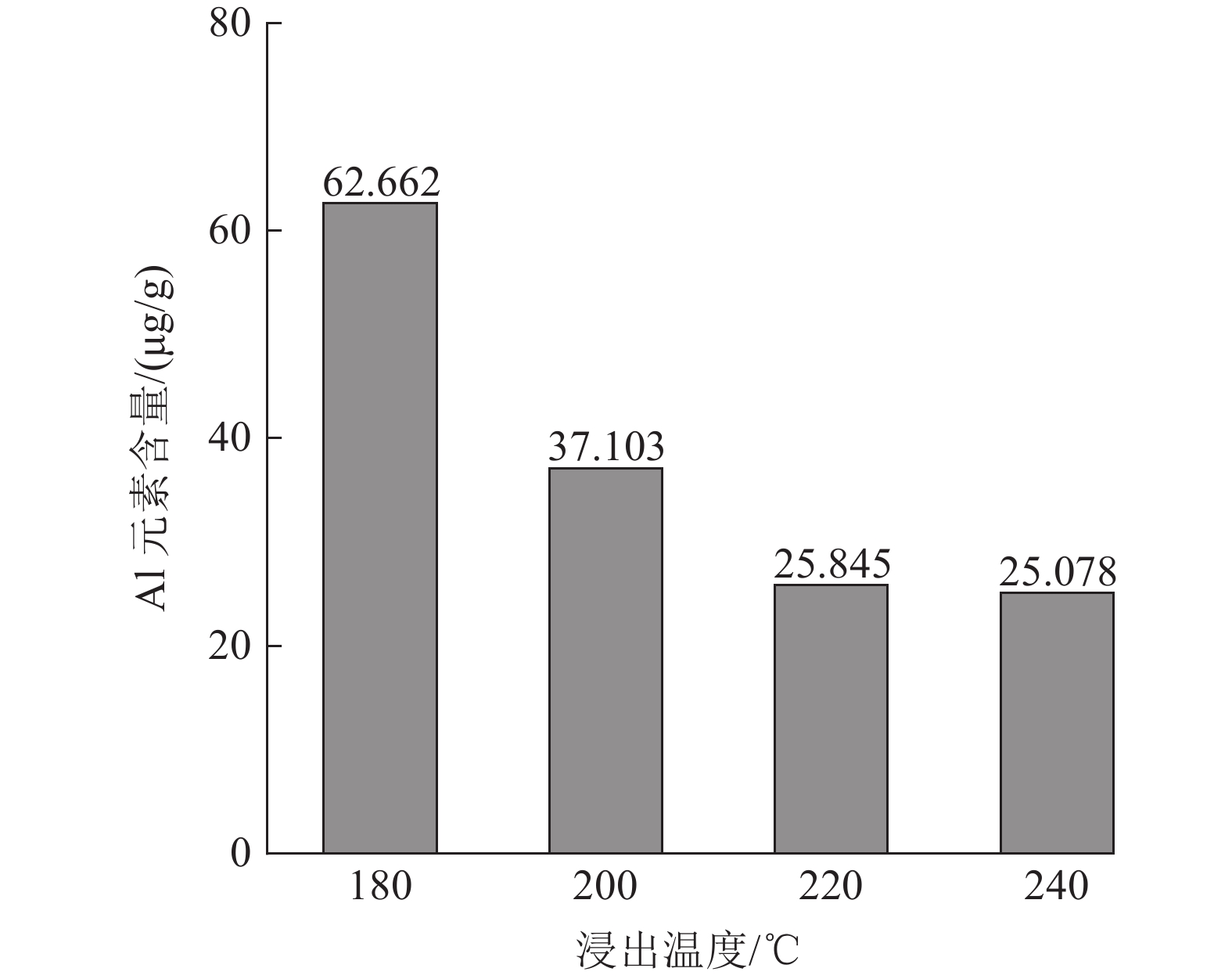

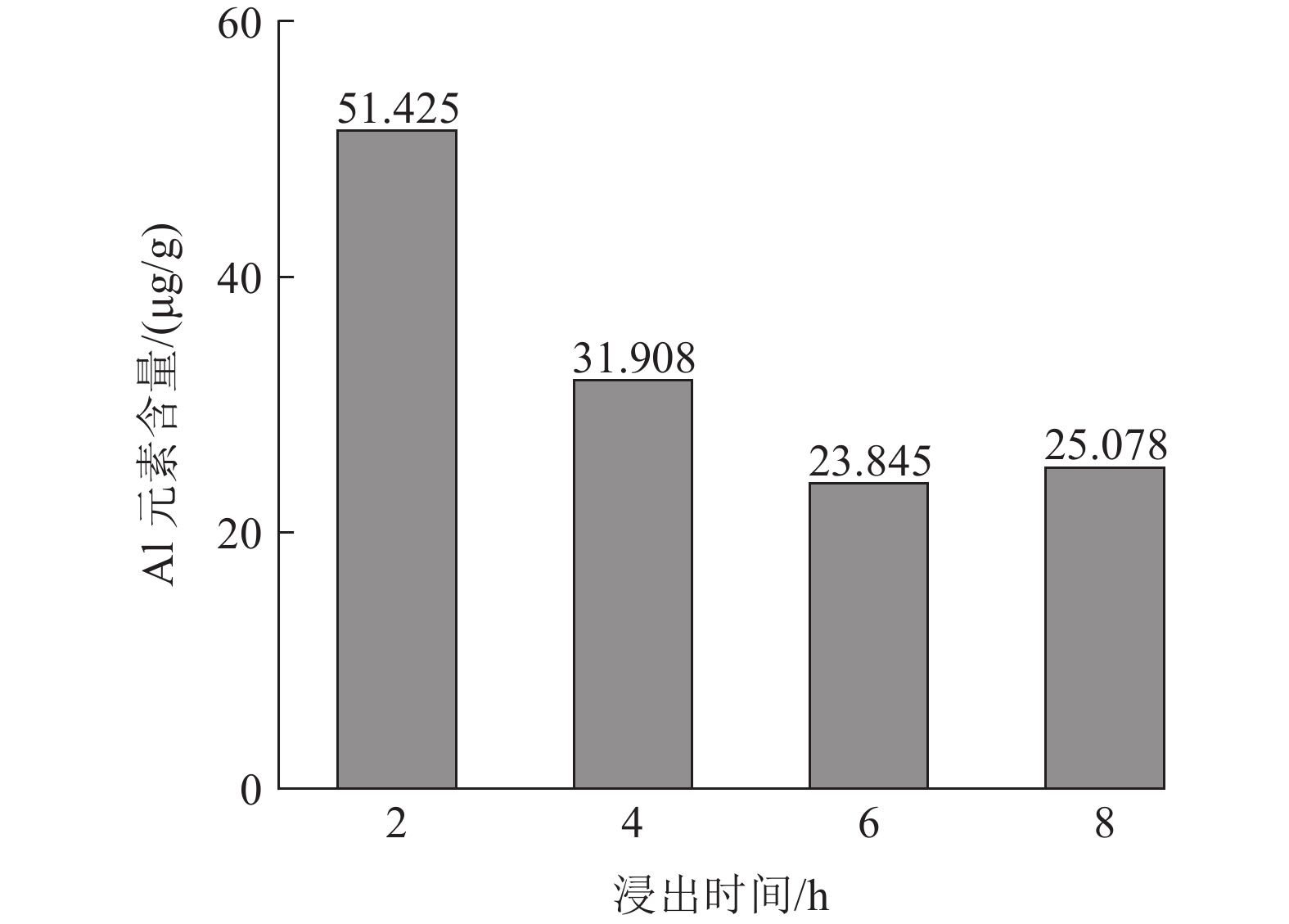

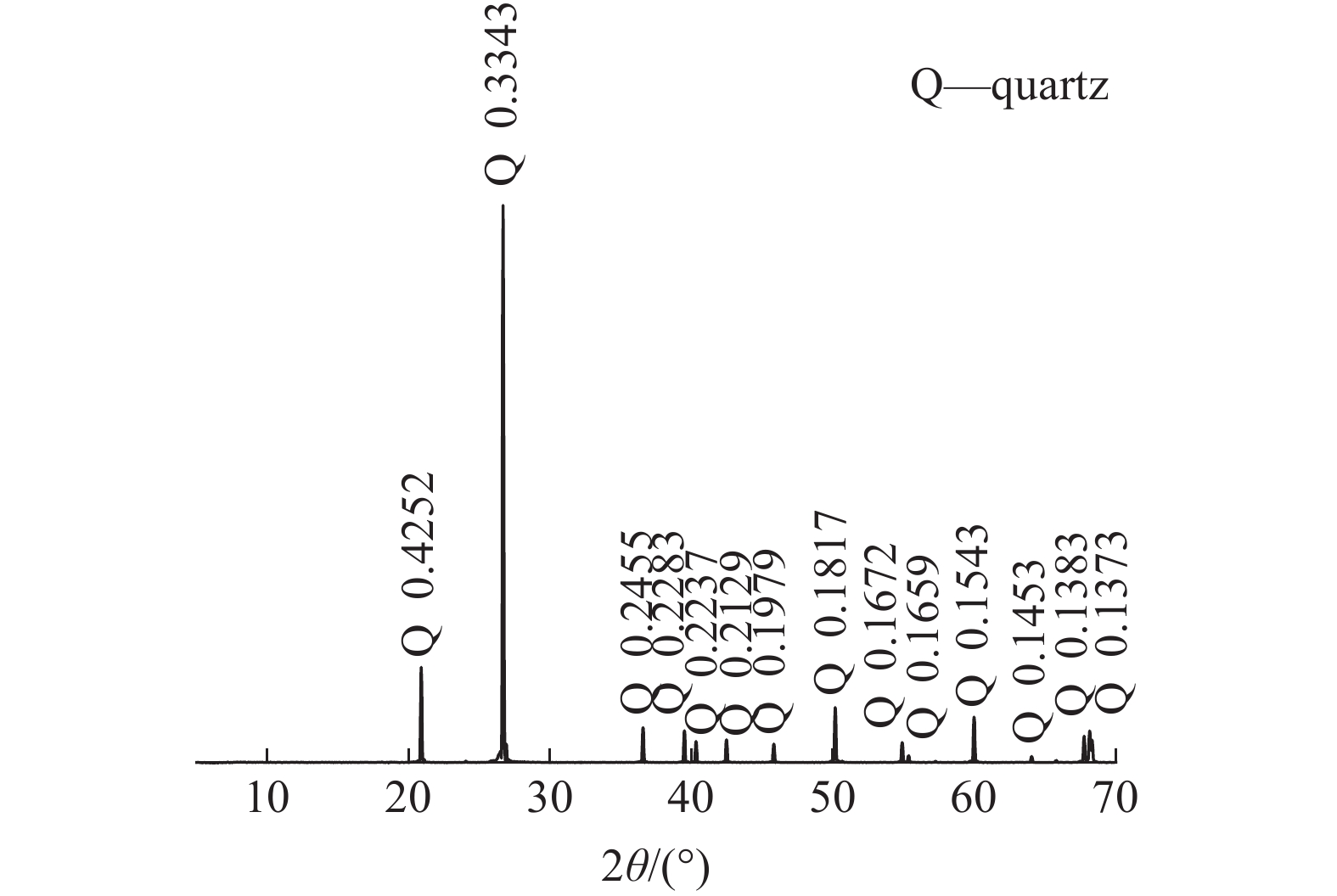

这是一篇矿物加工工程领域的文章。针对内蒙古某白伟晶岩样品进行工艺矿物学研究,采用“焙烧水淬-热压混合酸浸”实验工艺流程对内蒙古某地白伟晶岩进行选矿实验研究。通过条件实验研究得到较佳工艺条件,高纯石英砂中SiO2含量由99.917%提高到99.994%,杂质元素总含量从419.9 g/t下降到54.79 g/t,总去除率达86.95%;主要杂质元素Al含量从250.9 g/t下降到26.09 g/t,Al元素去除率达到了89.60%,取得了较好的纯化效果。

Abstract:This is an essay in the field of mineral processing engineering. Based on the process mineralogy, a mixed process containing roasting-water quenching-hot pressure leaching was applied to purify a white pegmatite ore from Inner Mongolia. The optimum condition was obtained via various tests. The content of SiO2 in the final product was increased from 99.917% to 99.994%, while the total impurity content was decreased from 419.9 to 54.79 g/t, with a total removal of 86.95%. The main impurity element of Al was decreased from 250.9 g/t to 26.09 g/t, with a removal of 89.60%. Therefore, this study provides a good purification approach for high-purity quart preparation.

-

-

表 1 白伟晶岩石英砂中主要杂质元素含量/(g/t)

Table 1. Contents of main impurity elements in white pegmatite quartz

Al B Fe Li Ti K Na S 总量 SiO2/% 250.90 37.90 14.00 34.40 6.60 15.80 42.30 18.00 419.90 99.917 表 2 精矿元素含量/(g/t)

Table 2. Chemical composition of concentrate

名称 Al B Fe Li Ti K Na S 总量 SiO2含量/% 含量 23.85 1.30 2.20 6.70 3.20 5.80 8.60 0.90 52.55 99.994 热压酸浸去除率/% 90.50 96.60 84.30 80.50 51.50 63.30 79.70 95.00 87.46 -

[1] 刘泽伟, 邹玄, 赵阳, 等. 某石英砂矿制取高纯石英工艺的研究[J]. 矿产综合利用, 2020(4):111-115. LIU Z W, ZOU X, ZHAO Y, et al. Study on the process of producing high-purity quartz from a quartz sand mine[J]. Multipurpose Utilization of Mineral Resources, 2020(4):111-115. doi: 10.3969/j.issn.1000-6532.2020.04.018

LIU Z W, ZOU X, ZHAO Y, et al. Study on the process of producing high-purity quartz from a quartz sand mine[J]. Multipurpose Utilization of Mineral Resources, 2020(4): 111-115. doi: 10.3969/j.issn.1000-6532.2020.04.018

[2] 汪灵, 党陈萍, 李彩侠, 等. 中国高纯石英技术发展现状与发展前景[J]. 地学前缘, 2014, 21(5):267-273. WANG L, DANG C P, LI C X, et al. Technology of high-purity quartz in China: Status quo and prospect[J]. Earth Science Frontiers, 2014, 21(5):267-273.

WANG L, DANG C P, LI C X, et al. Technology of high-purity quartz in China: Status quo and prospect[J]. Earth Science Frontiers, 2014, 21(5): 267-273.

[3] 林敏, 裴振宇, 熊康, 等. 我国高纯石英制备技术现状[J]. 矿产综合利用, 2017(5):18-21. LIN M, PEI Z Y, XIONG K, et al. Situation of High-purity Quartz Preparation in China[J]. Multipurpose Utilization of Mineral Resources, 2017(5):18-21. doi: 10.3969/j.issn.1000-6532.2017.05.004

LIN M, PEI Z Y, XIONG K, et al. Situation of High-purity Quartz Preparation in China[J]. Multipurpose Utilization of Mineral Resources, 2017(5): 18-21. doi: 10.3969/j.issn.1000-6532.2017.05.004

[4] 徐鹏金. 光伏玻璃用低铁石英砂的生产与市场概况[J]. 中国粉体工业, 2021(5):18-23. XU P J. Production and market overview of low iron quartz sand for photovoltaic glass[J]. China Powder Industry, 2021(5):18-23.

XU P J. Production and market overview of low iron quartz sand for photovoltaic glass[J]. China Powder Industry, 2021, (5): 18-23.

[5] 钟乐乐. 超高纯石英纯化制备及机理研究[D]. 武汉: 武汉理工大学, 2015.

ZHONG L L. Study on purifying preparationand mechanism of ultra-pure quartz[D]. Wuhan: Wuhan University of Technology, 2015.

[6] HAUS R. High demands on high purity[J]. Industrial Minerals, 2005, 10:62-67.

[7] 王九一. 全球高纯石英原料矿的资源分布与开发现状[J]. 岩石矿物学杂质, 2021, 40(1):131-141. WANG J Y. Global high purity quartz deposits: Resources distribution and exploitation status[J]. Acta Petrologica et Mineralogica, 2021, 40(1):131-141.

WANG J Y. Global high purity quartz deposits: Resources distribution and exploitation status[J]. Acta Petrologica et Mineralogica, 2021, 40(1): 131-141.

[8] 陈坤, 李育彪, 王志杰, 等. 内蒙古某脉石英提纯实验研究[J]. 非金属矿, 2022, 45(1):59-62. CHEN K, LI Y B, WANG Z J, et al. Experimental study on purification of a vein quartz from Inner Mongolia[J]. Non-Metallic Mines, 2022, 45(1):59-62.

CHEN K, LI Y B, WANG Z J, et al. Experimental study on purification of a vein quartz from Inner Mongolia[J]. Non-Metallic Mines, 2022, 45(1): 59-62.

[9] 熊康. 湖北蕲春脉石英纯化及机理研究[D]. 武汉: 武汉理工大学, 2017.

XIONG K. Research on purication and mechanism of Vein quartz in Qichun Hubei[D]. Wuhan: Wuhan University of Technology, 2017.

[10] 臧芳芳, 雷绍民, 钟乐乐, 等. 混合酸热压浸出纯化脉石英及机理[J]. 中国矿业, 2016, 25(5):106-110. ZANG F F, LEI S M, ZHONG L L, et al. Purification of vein quartz by mixed acid thermal pressure leaching and it’s mechanism[J]. China Mining Magazine, 2016, 25(5):106-110.

ZANG F F, LEI S M, ZHONG L L, et al. Purification of vein quartz by mixed acid thermal pressure leaching and it’s mechanism[J]. China Mining Magazine, 2016, 25(5): 106-110.

-

下载:

下载: