Preparation and Properties of Fly Ash Based Porous Ceramics Modified by Al2O3

-

摘要:

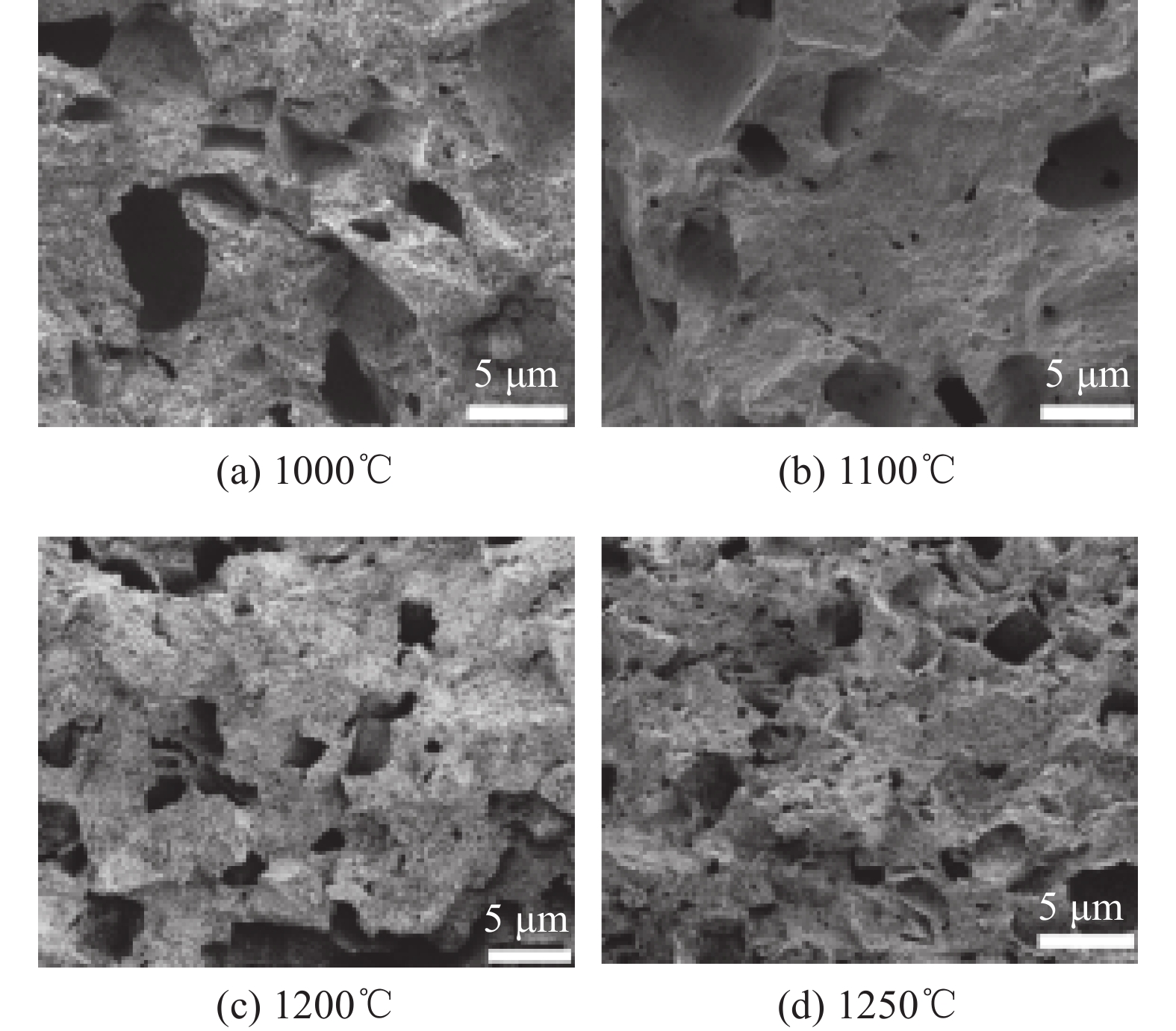

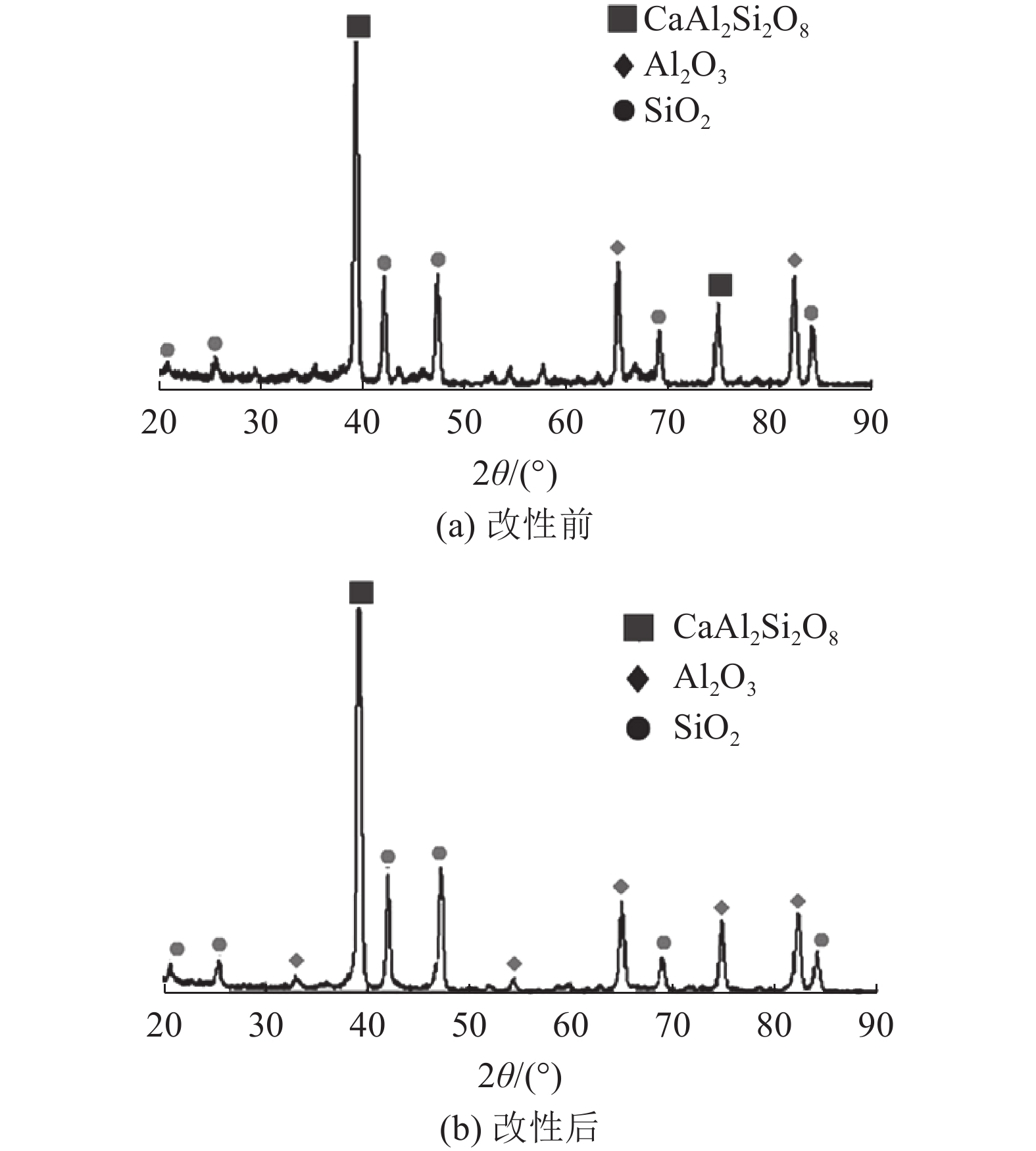

这是一篇陶瓷及复合材料领域的论文。为了提高粉煤灰基多孔陶瓷材料的性能,利用Al2O3修饰液对样品进行表面处理,并对其开展物理、力学性能、吸附效果和微观实验。结果表明:烧结温度越高,多孔陶瓷的气孔率与吸水率越小,强度和表观密度越大,在1100 ℃的温度条件下,多孔结构烧结成型的效果较佳;当修饰液的浓度从0增至50 mol/L,多孔陶瓷的饱和吸附率增加了4.5倍左右,同时密实度和强度也显著提高;氧化铝修饰液的表面改性效应对钙长石晶体的形成起到促进作用,使得孔陶瓷的强度与吸附性能显著提升。

Abstract:This is an article in the field of ceramics and composites. In order to improve the performance of fly ash-based porous ceramic materials, the samples were surface-treated using Al2O3 modifying liquid, and physical and mechanical properties, adsorption effects and microscopic experiments were carried out on them. The results showed that the higher the sintering temperature, the smaller the porosity and water absorption of the porous ceramics, and the greater the strength and apparent density. Optimal sintering and molding of porous structures at a temperature of 1100 °C. When the concentration of Al2O3 modifying liquid was increased from 0 to 50 mol/L, the saturated adsorption rate of the porous ceramics increased about 6 times, and at the same time, the densities and strengths were also significantly increased. The surface modification effect of the Al2O3 modifying liquid promotes the formation of the caliche feldspar crystals, which results in a significant increase in the strength and adsorption properties of the porous ceramics. strength and adsorption performance were significantly improved.

-

Key words:

- Ceramics and composites /

- Porous ceramics /

- Fly ash /

- Al2O3 modification /

- Adsorption performance /

- Microstructure

-

-

表 1 粉煤灰化学组分 /%

Table 1. Chemical components of fly ash

SiO2 Al2O3 CaO Fe2O3 MgO 其他 56.4 8.5 21.7 3.2 3.9 6.3 表 2 多孔陶瓷的配比

Table 2. Proportion of porous ceramics

名称 粉煤灰 造孔剂 黏结剂 助溶剂 质量占比/% 55 25 8 12 -

[1] 孙进兴, 陈 斌, 刘培生. 轻质多孔陶瓷的制备及吸声性能研究[J]. 无机材料学报, 2016, 31(8):860-864.SUN J X, CHEN B, LIU P S. Preparation and sound absorption properties of lightweight porous ceramics[J]. Journal of Inorganic Materials, 2016, 31(8):860-864. doi: 10.15541/jim20150654

SUN J X, CHEN B, LIU P S. Preparation and sound absorption properties of lightweight porous ceramics[J]. Journal of Inorganic Materials, 2016, 31(8):860-864. doi: 10.15541/jim20150654

[2] 王闯, 张快, 严红燕, 等. 锌窑渣再利用以烧制铁基金属陶瓷及其展望[J]. 矿产综合利用, 2020(4):8-12.WANG C, ZHANG K, YAN H Y, et al. Reuse of zinc kiln slag for firing iron-based cermet and its prospect[J]. Multipurpose Utilization of Mineral Resources, 2020(4):8-12.

WANG C, ZHANG K, YAN H Y, et al. Reuse of zinc kiln slag for firing iron-based cermet and its prospect[J]. Multipurpose Utilization of Mineral Resources, 2020(4):8-12.

[3] 井强山, 唐旖天, 田永尚, 等. 烧结助剂对多孔吸音陶瓷结构和性能的影响[J]. 非金属矿, 2018, 41(5):50-53.JING Q S, TANG Y T, TIAN Y S, et al. Effects of sintering aids on the structure and properties of porous sound-absorbing ceramics[J]. Non-metallic Minerals, 2018, 41(5):50-53.

JING Q S, TANG Y T, TIAN Y S, et al. Effects of sintering aids on the structure and properties of porous sound-absorbing ceramics[J]. Non-metallic Minerals, 2018, 41(5):50-53.

[4] 卢志华, 李呈顺, 马育栋. 多孔氧化铝陶瓷制备技术研究进展[J]. 中国陶瓷, 2018, 54(2):1-7.LU Z H, LI C S, MA Y D. Research progress on preparation technology of porous alumina ceramics[J]. China Ceramics, 2018, 54(2):1-7.

LU Z H, LI C S, MA Y D. Research progress on preparation technology of porous alumina ceramics[J]. China Ceramics, 2018, 54(2):1-7.

[5] Ukwatta A, Mohajerani A. Characterisation of fired-clay bricks incorporating biosolids and the effect of heating rate on properties of bricks[J]. Construction and Building Materials, 2017, 142:11-22. doi: 10.1016/j.conbuildmat.2017.03.047

[6] GOLLAKOTA A R K, VOLLI V, SHU C. Progressive utilisation prospects of coal fly ash: a review[J]. Science of The Total Environment, 2019, 672:951-989. doi: 10.1016/j.scitotenv.2019.03.337

[7] FU M, LIU J, DONG X F, et al. Waste recycling of coal fly ash for design of highly porous whisker-structured mullite ceramic membranes[J]. Journal of the European Ceramic Society, 2019, 39(16):5320-5331. doi: 10.1016/j.jeurceramsoc.2019.08.042

[8] 于成龙, 熊楠, 宋杰, 等. 近20年来中国利用粉煤灰合成分子筛研究进展[J]. 矿产综合利用, 2020(4):26-35.YU C L, XIONG N, SONG J, et al. Research progress on the synthesis of molecular sieves from fly ash in China in the past 20 years[J]. Multipurpose Utilization of Mineral Resources, 2020(4):26-35.

YU C L, XIONG N, SONG J, et al. Research progress on the synthesis of molecular sieves from fly ash in China in the past 20 years[J]. Multipurpose Utilization of Mineral Resources, 2020(4):26-35.

[9] HUO W L, ZHANG X Y, CHEN Y G, et al. Mechanical strength of highly porous ceramic foams with thin and lamellate cell wall from particle stabilized foams[J]. Ceramics International, 2018, 44(5):5780-5784. doi: 10.1016/j.ceramint.2017.11.202

[10] 谷玲钰, 刘振英, 刘银. 利用煤矸石制备多孔陶瓷的及力学性能研究[J]. 矿产综合利用, 2018(5):135-137.GU L Y, LIU Z Y, LIU Y. Preparation and mechanical properties of porous ceramics from coal gangue[J]. Multipurpose Utilization of Mineral Resources, 2018(5):135-137.

GU L Y, LIU Z Y, LIU Y. Preparation and mechanical properties of porous ceramics from coal gangue[J]. Multipurpose Utilization of Mineral Resources, 2018(5):135-137.

[11] LIU R P, XU T T, WANG C A. A review of fabrication strategies and applications of porous ceramics prepared by freeze-casting method[J]. Ceramics International, 2016, 42(2):2907-2925. doi: 10.1016/j.ceramint.2015.10.148

[12] 王杰,邓伟超,麻永林,等.La负载赤泥-粉煤灰基多孔陶瓷制备研究[J].矿冶工程, 2019, 39(5):123-128.WANG J, DENG W C, MA Y L, et al. Preparation of La-loaded red mud-fly ash-based porous ceramics[J]. Mining and Metallurgical Engineering, 2019, 39(5):123-128.

WANG J, DENG W C, MA Y L, et al. Preparation of La-loaded red mud-fly ash-based porous ceramics[J]. Mining and Metallurgical Engineering, 2019, 39(5):123-128.

[13] 冉岚, 刘少友, 兰琳琳. 工业废渣制备多孔陶瓷及性能研究[J]. 非金属矿, 2020, 43(2):92-94.RAN L, LIU S Y, LAN L L. Preparation of porous ceramics from industrial waste residues and their properties[J]. Nonmetallic Minerals, 2020, 43(2):92-94.

RAN L, LIU S Y, LAN L L. Preparation of porous ceramics from industrial waste residues and their properties[J]. Nonmetallic Minerals, 2020, 43(2):92-94.

[14] ZHANG R B, YE C S, ZHANG Y Y. Strengthening of porous TiB2-SiC ceramics by pre-oxidation and crack-healing[J]. Applied Surface Science, 2016, 360:1036-1040 doi: 10.1016/j.apsusc.2015.11.125

[15] 施云芬, 魏冬雪. 改性粉煤灰陶粒的制备及其吸附 SO2性能研究[J]. 硅酸盐通报, 2012, 31(3):567-570.SHI Y F, WEI D X. Preparation of modified fly ash ceramsite and its adsorption performance of SO2[J]. Bulletin of Silicate, 2012, 31(3):567-570.

SHI Y F, WEI D X. Preparation of modified fly ash ceramsite and its adsorption performance of SO2[J]. Bulletin of Silicate, 2012, 31(3):567-570.

[16] 梁昌金, 林少敏, 刘桂文. 基于陶瓷废料的改性泡沫陶瓷对Cd2+的吸附研究[J]. 中国陶瓷, 2021, 57(9):52-57.LIANG C J, LIN S M, LIU G W. Study on Cd2+ adsorption of modified foam ceramics based on ceramic waste[J]. China Ceramics, 2021, 57(9):52-57.

LIANG C J, LIN S M, LIU G W. Study on Cd2+ adsorption of modified foam ceramics based on ceramic waste[J]. China Ceramics, 2021, 57(9):52-57.

[17] 张宏泉, 文进, 沈海燕. 添加剂对轻质多孔陶瓷材料制备与性能的影响[J]. 武汉理工大学学报, 2021, 43(10):1-5.ZHANG H Q, WEN J, SHEN H Y. Effects of additives on the preparation and properties of lightweight porous ceramic materials[J]. Journal of Wuhan University of Technology, 2021, 43(10):1-5.

ZHANG H Q, WEN J, SHEN H Y. Effects of additives on the preparation and properties of lightweight porous ceramic materials[J]. Journal of Wuhan University of Technology, 2021, 43(10):1-5.

[18] 范益群, 漆虹, 徐南平. 多孔陶瓷膜制备技术研究进展[J]. 化工学报, 2013, 64(1):107-115.FAN Y Q, QI H, XU N P. Research progress on the preparation technology of porous ceramic membranes[J]. Acta Chemical Industry, 2013, 64(1):107-115.

FAN Y Q, QI H, XU N P. Research progress on the preparation technology of porous ceramic membranes[J]. Acta Chemical Industry, 2013, 64(1):107-115.

[19] 肖汉宁, 熊敏, 郭文明, 等. 多孔陶瓷膜及其在液固和气固分离中的应用[J]. 陶瓷学报, 2017, 38(6):791-798.XIAO H N, XIONG M, GUO W M, et al. Porous ceramic membrane and its application in liquid-solid and gas-solid separation[J]. Chinese Journal of Ceramics, 2017, 38(6):791-798.

XIAO H N, XIONG M, GUO W M, et al. Porous ceramic membrane and its application in liquid-solid and gas-solid separation[J]. Chinese Journal of Ceramics, 2017, 38(6):791-798.

-

下载:

下载: