Comprehensive Recovery Test of Valuable Metals from a Silver, Gold and Copper Bearing Sulfide Concentrate

-

摘要:

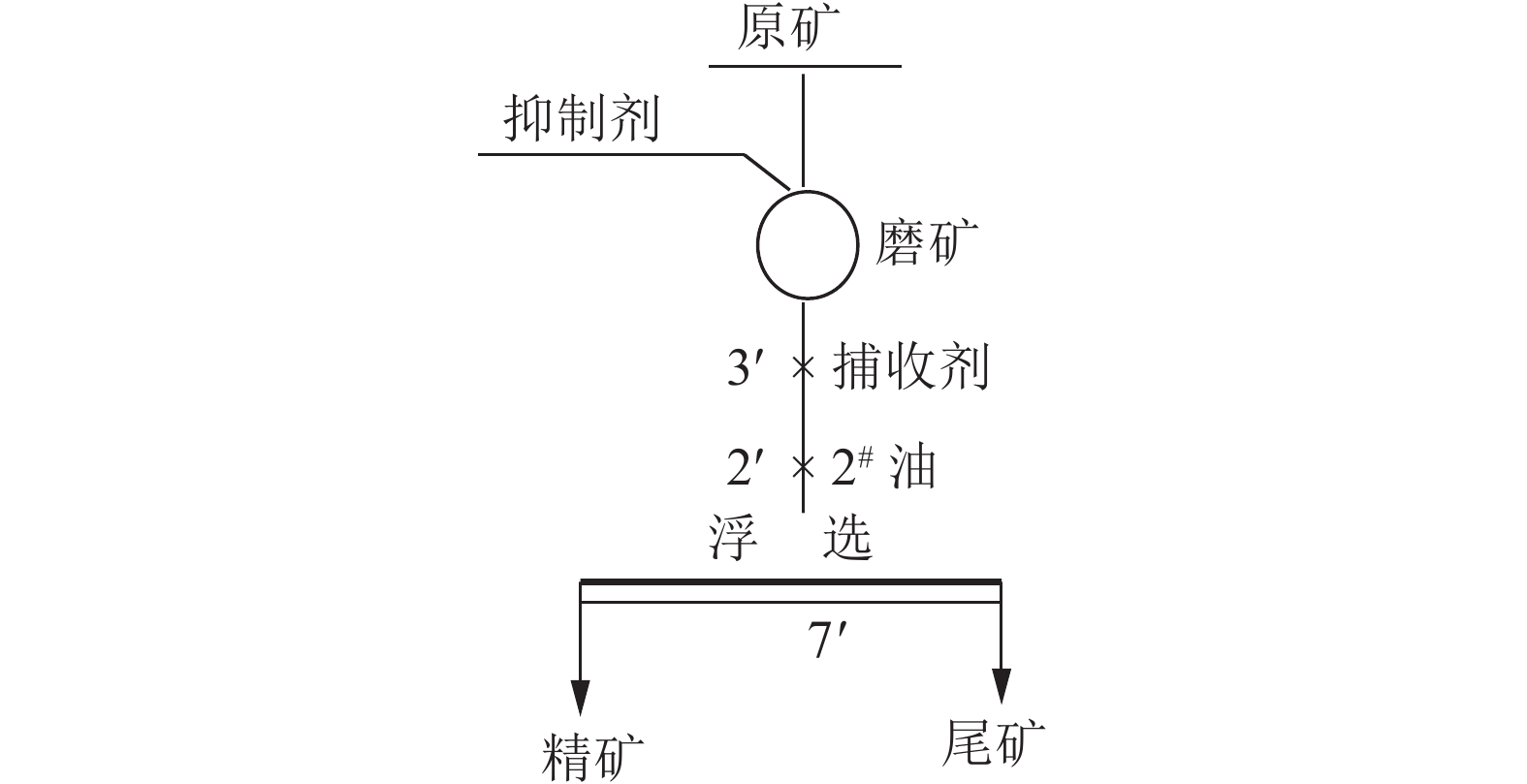

这是一篇矿物加工工程领域的论文。对某含铜金银硫精矿进行了选矿综合回收实验研究,实验结果表明,采用异丁基黄药+乙硫氮组合捕收剂,氧化钙做抑制剂,2#油做起泡剂,经过一次粗选-三次精选-二次扫选的浮选工艺流程,最终可得到铜品位为16.66%、回收率为86.96%,金品位为278.95 g/t,回收率为75.56%;银品位为1848.74 g/t,回收率为78.55%的精矿产品,有效地实现了硫精矿中铜的综合回收,同时使金、银很好地富集在铜精矿中,便于回收利用,选矿指标理想。

Abstract:This is an article in the field of mineral processing engineering. The comprehensive recovery test of silver, gold and copper bearing sulfide concentrate was carried out. With isobutyl xanthate and sodium diethyl dithiocarbamate as a combined collector, calcium oxide as the depressant, 2# oil as a frother, which produced a concentrate approaching 16.66% Cu grade at 86.96% recovery, Au content of 278.95 g/t at 75.56% Au recovery and Ag content of 1848.74 g/t at 78.55% Ag recovery by a flotation process consisting of one stage of roughing, three stages of cleaning and two stages of scavenging was used to collect lead minerals. The comprehensive recovery of copper from sulfur concentrate has been effectively realized. At the same time, gold and silver are well enriched in copper concentrate, which is convenient for recovery and utilization, and the mineral processing index is ideal.

-

Key words:

- Mineral processing engineering /

- Flotation /

- Sulfur concentrate /

- Comprehensive recovery /

- Chalcopyrite /

- Gold /

- Silver

-

-

表 1 样品化学多元素分析/%

Table 1. Chemical multi-element analysis of samples

TFe S Cu Pb Zn Au* Ag* SiO2 31.30 39.20 1.29 0.27 0.22 24.61 158.00 14.60 CaO MgO Al2O3 Na2O K2O C As 2.40 2.00 2.95 0.01 0.60 0.97 0.0011 *单位为g/t. 表 2 金物相分析结果

Table 2. Gold physical phase analysis results

名称 裸露+

半裸露Au碳酸

盐中Au褐铁

矿中Au硫化

物中Au硅酸

盐中Au合计 含量/(g/t) 1.12 0.20 0.18 22.11 0.41 24.02 占有率% 4.66 0.83 0.75 92.05 1.71 100.00 表 3 铜物相分析结果

Table 3. Copper physical phase analysis results

名称 氧化相 硫化相 结合相 合计 含量/% 0.008 1.09 0.18 1.278 占有率/% 0.63 85.29 14.08 100.00 表 4 磨矿细度实验结果

Table 4. Test results of grinding fineness

-0.037 mm

含量/%产物

名称产率/% 品位/% 回收率/% Cu Au* Cu Au 65 精矿 25.00 3.93 68.97 78.44 70.44 尾矿 75.00 0.36 9.65 21.56 29.56 原矿 100.00 1.25 24.48 100.00 100.00 75 精矿 25.90 3.97 69.37 80.32 73.57 尾矿 74.10 0.34 8.71 19.68 26.43 原矿 100.00 1.28 24.42 100.00 100.00 85 精矿 30.10 3.42 64.13 83.55 77.82 尾矿 69.90 0.29 7.87 16.45 22.18 原矿 100.00 1.23 24.80 100.00 100.00 90 精矿 30.25 3.77 64.65 89.10 78.98 尾矿 69.75 0.20 7.46 10.90 21.02 原矿 100.00 1.28 24.76 100.00 100.00 95 精矿 31.90 3.51 60.58 88.67 78.40 尾矿 68.10 0.21 7.82 11.33 21.60 原矿 100.00 1.26 24.65 100.00 100.00 *单位为g/t 表 5 抑制剂种类对比实验结果

Table 5. Test results of inhibitor type comparison

抑制剂种类

及用量/(g/t)产物

名称产率/% 品位/% 回收率/% Cu Au* Cu Au 氧化钙:6000 精矿 34.30 3.12 53.50 87.16 75.04 尾矿 65.70 0.24 9.29 12.84 24.96 原矿 100.00 1.23 24.45 100.00 100.00 单宁酸:600 精矿 60.70 1.46 27.03 73.10 67.83 尾矿 39.30 0.83 19.80 26.90 32.17 原矿 100.00 1.21 24.19 100.00 100.00 焦性没食子酸:600 精矿 44.87 2.12 26.30 76.84 48.54 尾矿 55.13 0.52 22.69 23.16 51.46 原矿 100.00 1.24 24.31 100.00 100.00 *单位为g/t 表 6 捕收剂种类对比实验结果

Table 6. Test results of trapping agent type comparison

捕收剂种类

及用量/(g/t)产物

名称产率/% 品位/% 回收率/% Cu Au* Cu Au 异丁黄:80

黑药:40精矿 33.20 3.34 51.55 87.37 69.24 尾矿 66.80 0.24 11.38 12.63 30.76 原矿 100.00 1.27 24.72 100.00 100.00 丁黄:80

乙硫氮:40精矿 28.00 3.75 58.52 83.41 66.35 尾矿 72.00 0.59 11.54 16.59 33.65 原矿 100.00 1.25 24.69 100.00 100.00 异丁黄:80

乙硫氮:40精矿 35.20 3.23 55.09 89.31 77.94 尾矿 64.80 0.21 8.47 10.69 22.06 原矿 100.00 1.27 24.82 100.00 100.00 Z-200:50 精矿 39.87 2.51 37.78 78.21 60.59 尾矿 60.13 0.46 16.29 21.79 39.41 原矿 100.00 1.28 24.86 100.00 100.00 *单位为g/t 表 7 氧化钙用量实验结果

Table 7. Test results of calcium oxide dosage

氧化钙

用量/(g/t)产物名称 产率/% 品位/% 回收率/% Cu Au* Cu Au 6000 精矿 32.30 3.44 55.48 87.71 73.69 尾矿 67.70 0.23 9.45 12.29 26.31 原矿 100.00 1.27 24.32 100.00 100.00 8000 精矿 29.80 3.64 61.10 88.54 73.92 尾矿 70.20 0.20 9.15 11.46 26.08 原矿 100.00 1.23 24.63 100.00 100.00 10000 精矿 29.25 3.90 67.83 88.96 78.74 尾矿 70.75 0.20 7.46 11.04 21.26 原矿 100.00 1.28 24.83 100.00 100.00 12000 精矿 28.30 3.95 57.96 88.63 66.28 尾矿 71.70 0.20 11.64 11.37 33.72 原矿 100.00 1.26 24.75 100.00 100.00 *单位为g/t 表 8 捕收剂用量实验流程结果

Table 8. Results of test flow of trapping agent dosage

捕收剂用

量/(g/t)产物名称 产率/% 品位/% 回收率/% Cu Au* Cu Au 60+30 精矿 25.42 4.20 69.91 82.16 71.03 尾矿 74.58 0.31 9.72 17.84 28.97 原矿 100.00 1.30 25.02 100.00 100.00 70+35 精矿 25.16 4.39 75.07 86.25 74.83 尾矿 74.84 0.24 8.49 13.75 25.17 原矿 100.00 1.28 25.24 100.00 100.00 80+40 精矿 27.07 4.21 73.43 88.28 79.10 尾矿 72.93 0.21 7.20 11.72 20.90 原矿 100.00 1.29 25.13 100.00 100.00 90+45 精矿 28.50 3.94 69.79 88.36 79.05 尾矿 71.50 0.21 7.37 11.64 20.95 原矿 100.00 1.27 25.16 100.00 100.00 *单位为g/t 表 9 开路实验结果

Table 9. Results of open-circuit tests

产物名称 产率/% 品位/% 回收率/% Cu Au* Cu Au 精矿 4.70 18.82 266.20 70.40 51.24 中5 1.28 5.25 64.23 5.35 3.37 中4 2.88 3.11 52.19 7.13 6.16 中3 8.32 1.44 36.25 9.54 12.35 中2 2.05 0.97 83.52 1.58 7.01 中1 1.23 0.81 54.33 0.79 2.74 尾矿 79.54 0.10 5.26 6.33 17.13 原矿 100.00 1.27 24.42 100.00 100.00 *单位为g/t 表 10 闭路实验结果

Table 10. Test results of closed circuit

产物名称 产率/% 品位/% 回收率/% Cu Au* Ag* Cu Au Ag 精矿 6.72 16.66 278.95 1848.74 86.96 75.56 78.55 尾矿 93.28 0.18 6.50 36.36 13.04 24.44 21.45 原矿 100.00 1.29 24.81 158.15 100.00 100.00 100.00 *单位为g/t -

[1] 聂光华, 邱廷省, 刘志红. 某浮选铜精矿中铜、金浸出实验研究[J]. 黄金, 2009, 30(8):37-40.NIE G H, QIU T S, LIU Z H. Experimental study on copper and gold leaching from copper concentrate[J]. Gold, 2009, 30(8):37-40.

NIE G H, QIU T S, LIU Z H. Experimental study on copper and gold leaching from copper concentrate[J]. Gold, 2009, 30(8):37-40.

[2] 王宝胜, 张振平, 刘万志, 等. 改善含高铜、铅金精矿氰化浸出指标的实验研究[J]. 黄金科学技术, 2008(5):44-45.WANG B S, ZHANG Z P, LIU W Z, et al. Improve the gold leaching rate of gold concentrate which bears the higher copper and lead[J]. Gold Science and Technology, 2008(5):44-45.

WANG B S, ZHANG Z P, LIU W Z, et al. Improve the gold leaching rate of gold concentrate which bears the higher copper and lead[J]. Gold Science and Technology, 2008(5):44-45.

[3] 温 凯, 陈建华. 某含银复杂铜铅锌多金属硫化矿浮选试验[J]. 矿产综合利用, 2019(6):28-32.WEN K, CHEN J H. Experimental study on flotation of copper, lead and zinc polymetallic sulfide ore containing silver[J]. Multipurpose Utilization of Mineral Resources, 2019(6):28-32.

WEN K, CHEN J H. Experimental study on flotation of copper, lead and zinc polymetallic sulfide ore containing silver[J]. Multipurpose Utilization of Mineral Resources, 2019(6):28-32.

[4] 胡真, 邹坚坚, 李汉文. 从云南某硫精矿中回收铜铋的选矿实验[J]. 金属矿山, 2017(2):60-65.HU Z, ZOU J J, LI H W. Beneficiation on recovery of copper and bismuth from a sulphur concentrate in Yunnan[J]. Mental Mine, 2017(2):60-65.

HU Z, ZOU J J, LI H W. Beneficiation on recovery of copper and bismuth from a sulphur concentrate in Yunnan[J]. Mental Mine, 2017(2):60-65.

[5] 张磊, 戴惠新, 杜五星. 铜锌硫化矿分离工艺现状[J]. 矿产综合利用, 2019(1):1-6.ZHANG L, DAI H X, DU W X. Research progress of copper-zinc sulfide ore separation technology[J]. Multipurpose Utilization of Mineral Resources, 2019(1):1-6. doi: 10.3969/j.issn.1000-6532.2019.01.001

ZHANG L, DAI H X, DU W X. Research progress of copper-zinc sulfide ore separation technology[J]. Multipurpose Utilization of Mineral Resources, 2019(1):1-6. doi: 10.3969/j.issn.1000-6532.2019.01.001

[6] Córdoba E M, Muñoz J A, Blázquez M L, et al. Leaching of chalcopyrite with ferric ion. Part I: General aspects[J]. Hydrometallurgy, 2008, 93(3-4):81-87. doi: 10.1016/j.hydromet.2008.04.015

[7] 万丽, 周少珍, 曾克文, 等. 安徽某铜硫矿选矿工艺优化试验[J]. 矿产综合利用, 2019(6):41-44.WAN L, ZHOU S Z, ZENG K W, et al. Experimental research on beneficiation technology of a copper-sulfur ore from Anhui[J]. Multipurpose Utilization of Mineral Resources, 2019(6):41-44.

WAN L, ZHOU S Z, ZENG K W, et al. Experimental research on beneficiation technology of a copper-sulfur ore from Anhui[J]. Multipurpose Utilization of Mineral Resources, 2019(6):41-44.

[8] 沈旭. 从某硫精矿中回收铜的实验研究[J]. 有色金属(选矿部分), 2016(5):13-17.SHEN X. Study on recovery of copper from sulphur concentrate[J]. Nonferrous Metals(Mineral Processing Section ), 2016(5):13-17.

SHEN X. Study on recovery of copper from sulphur concentrate[J]. Nonferrous Metals(Mineral Processing Section ), 2016(5):13-17.

[9] 熊道陵, 张辉, 汪杨, 等. 一种新型有机抑制剂的铜硫分离效果[J]. 金属矿山, 2015(6): 59-64.XIONG D L, ZHANG H, WANG Y, et al. Effects of a new organic inhibitor on separation of pyrite from chalcopyrite [J]. Mental Mine 2015(6): 59-64.

XIONG D L, ZHANG H, WANG Y, et al. Effects of a new organic inhibitor on separation of pyrite from chalcopyrite [J]. Mental Mine 2015(6): 59-64.

-

下载:

下载: