Research on FeO Content of Sinter Used in Shagang's 5800 m3 Blast Furnace

-

摘要:

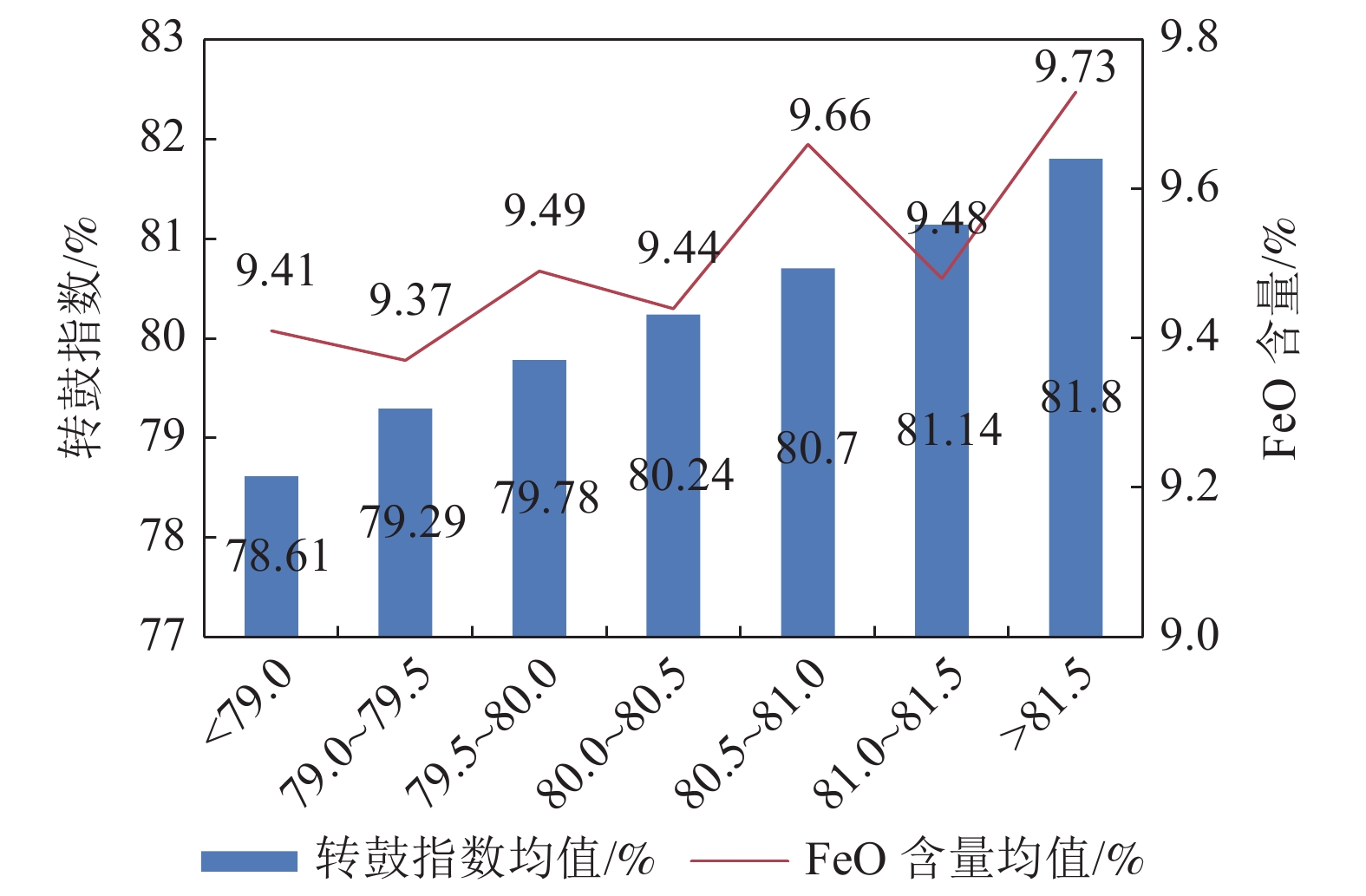

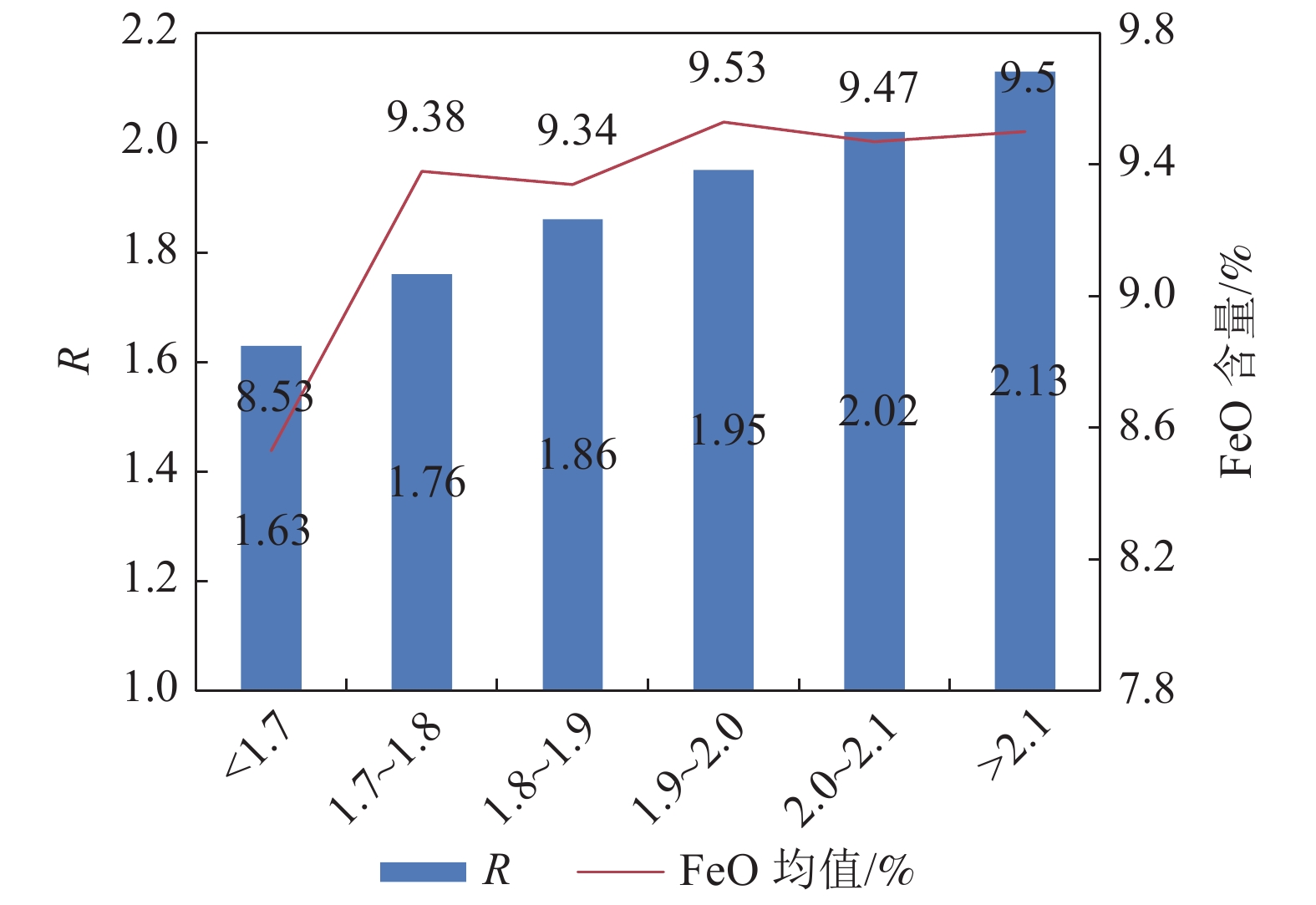

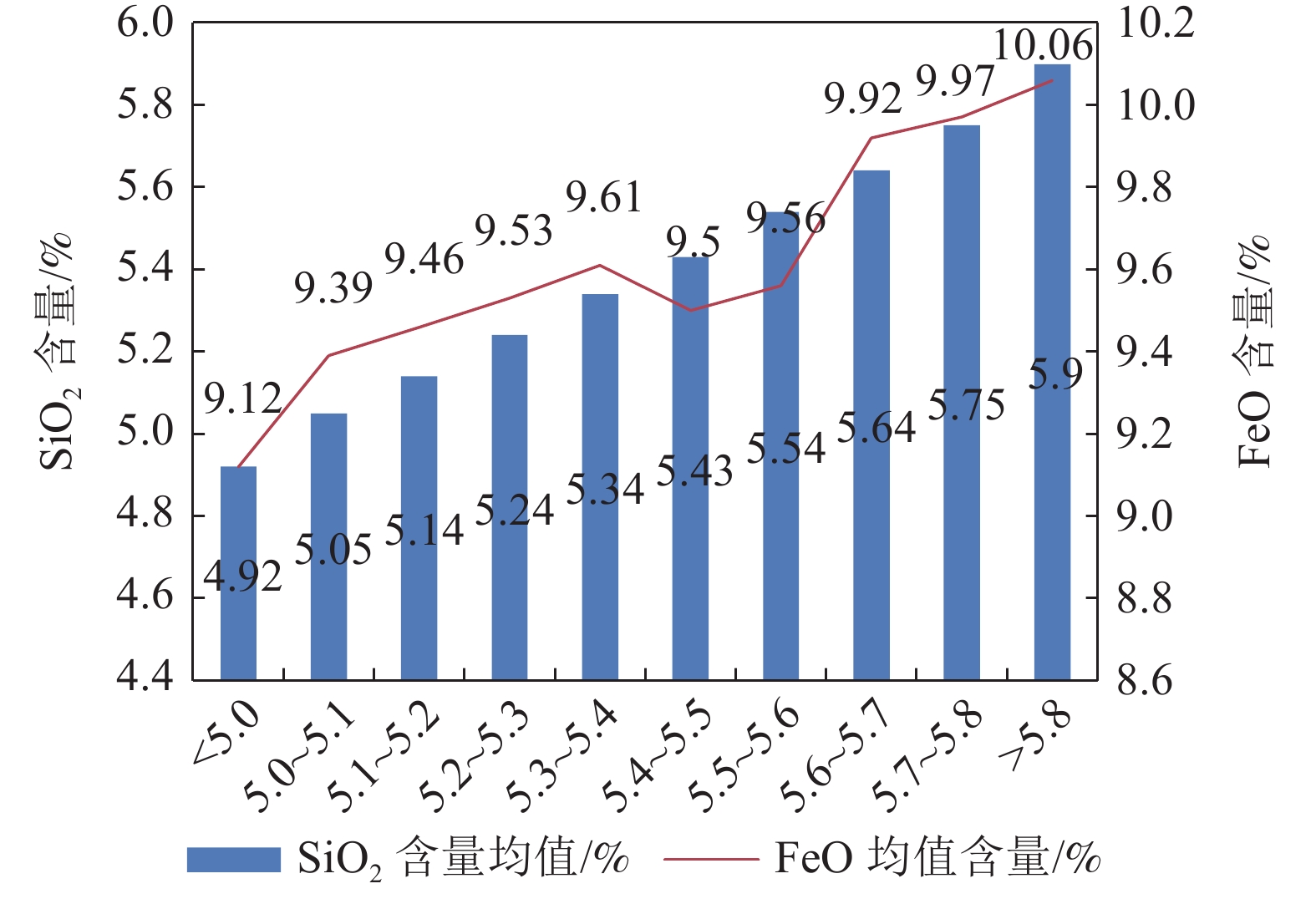

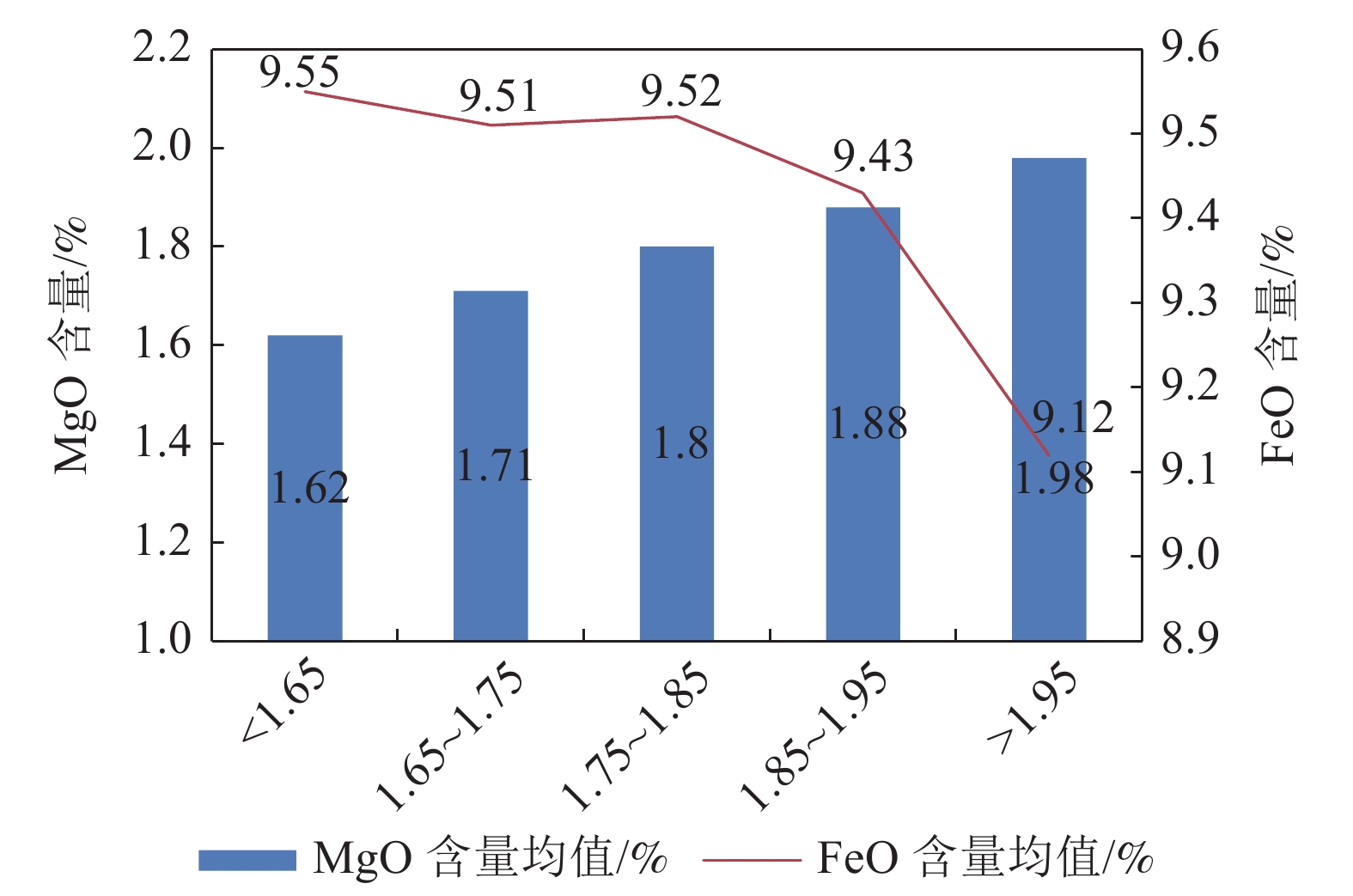

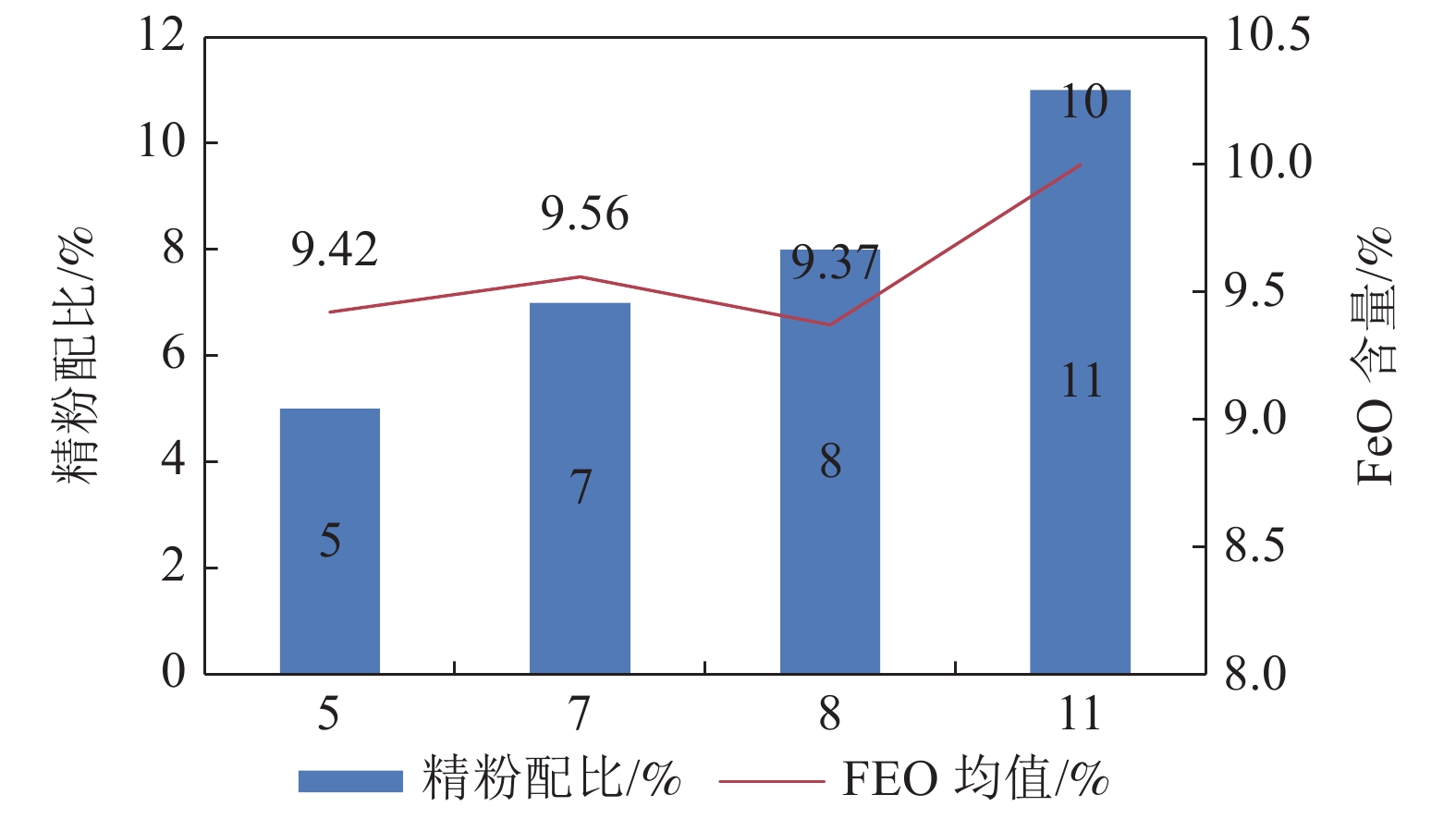

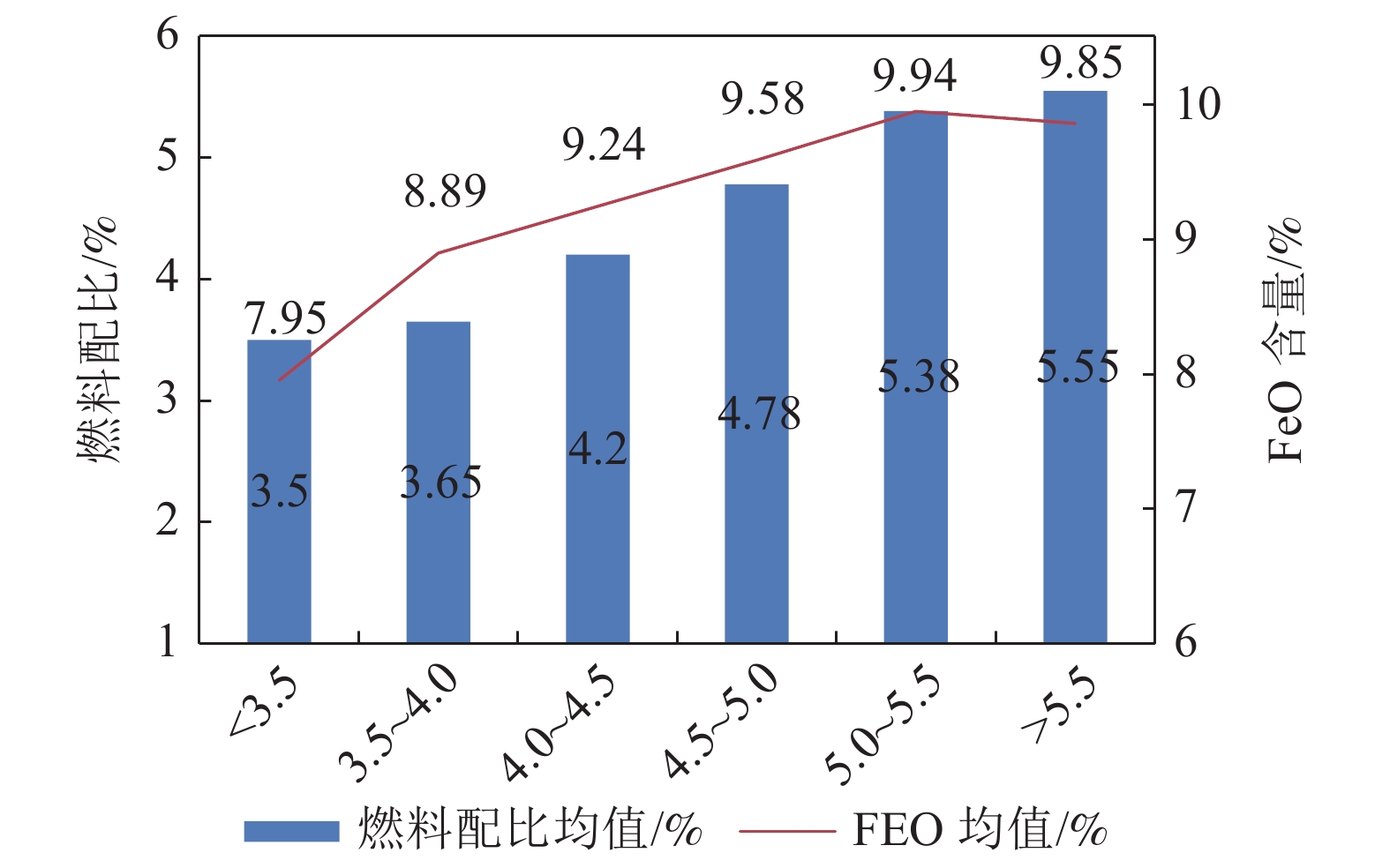

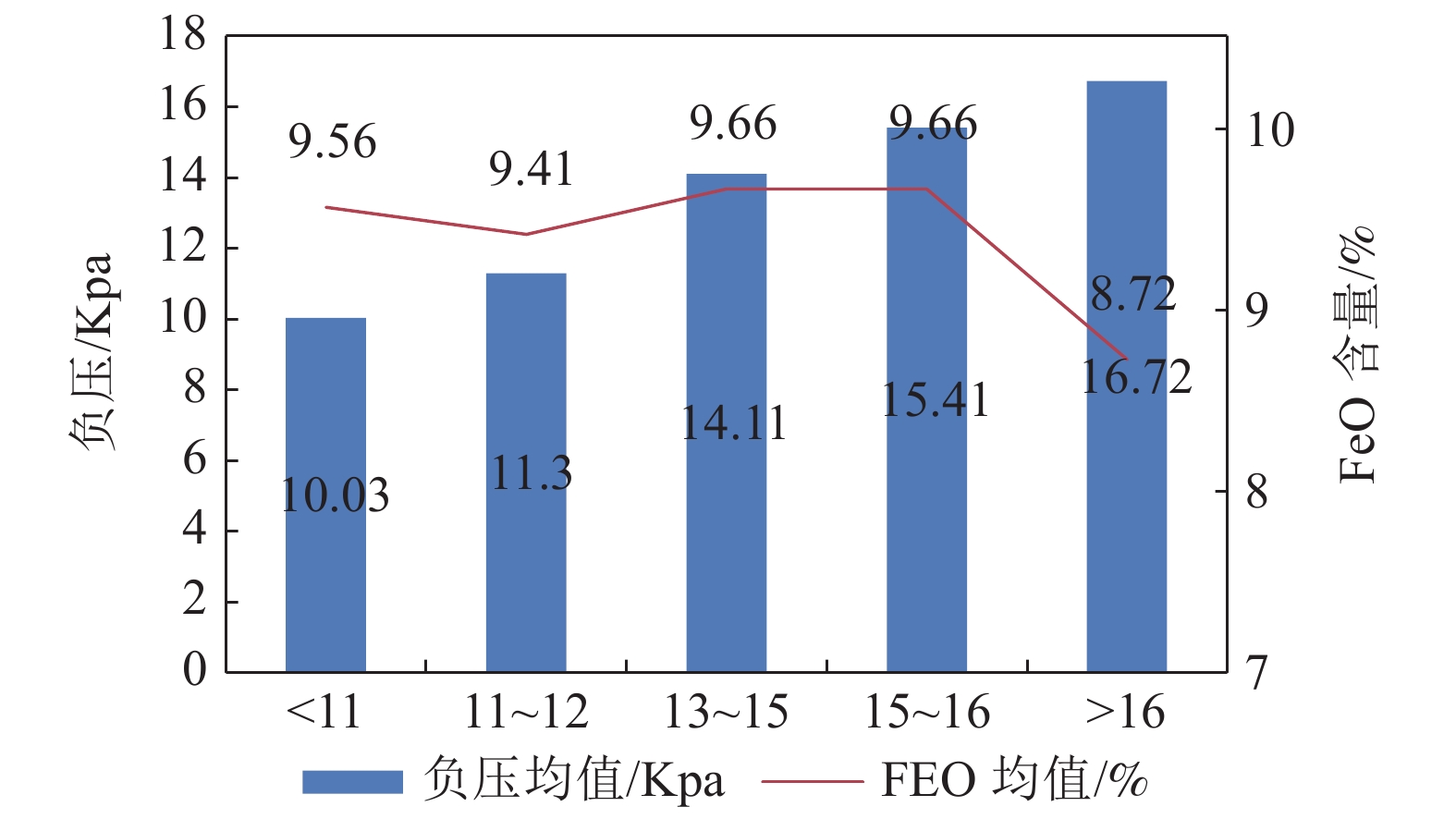

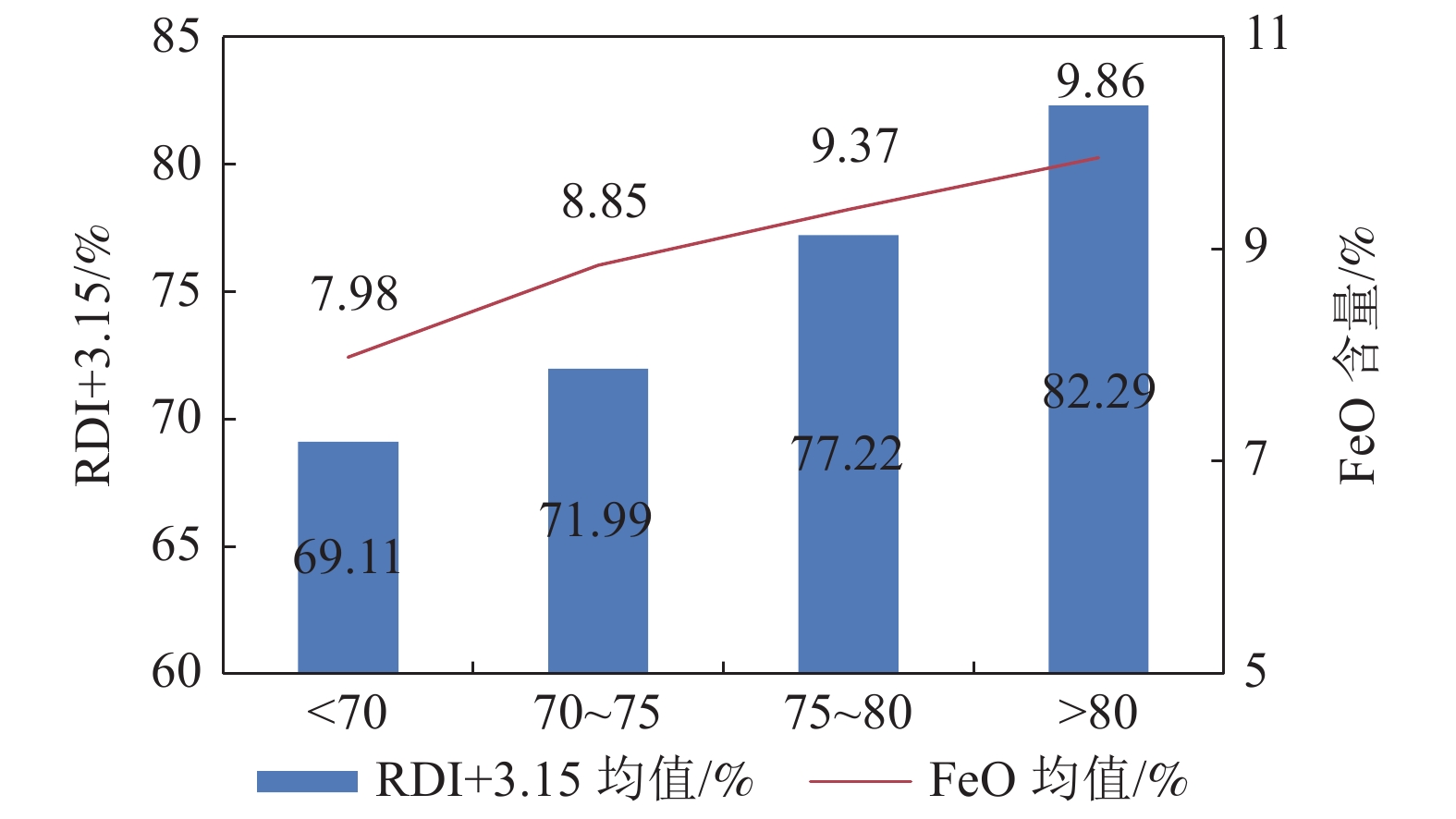

这是一篇冶金工程领域的文章。为给烧结矿FeO成分控制、质量优化提供理论依据,考查了沙钢5800 m3高炉所用烧结矿转鼓强度、低温还原粉化、中温还原性等冶金性能,并通过统计数据分析探究了FeO含量对烧结矿冶金性能的影响以及影响FeO含量的因素,结果表明:基于沙钢现行原料质量、配矿结构以及工艺操作条件下:FeO含量增加可提升烧结矿转鼓指数、RDI+3.15及RI,当RI大于85%时,FeO含量才成为制约RI因素,FeO含量适宜值为9.5%左右;R、SiO2含量、精粉及燃料配比增加会导致FeO含量升高,提升MgO含量,负压会造成FeO含量下降;数据分析表明:控制R为1.9,SiO2、MgO含量分别为5.2%、1.8%左右,精粉配比在11%以内,燃料配比在4.5%~5%之间,负压为16 KPa以内,可使烧结矿FeO含量均值维持在9.5%左右,对应转鼓指数均值为80%左右,RDI+3.15、RI均值分别为75%、80%以上。

Abstract:This is an article in the field of metallurgical engineering. To provide a theoretical basis for FeO composition control and quality optimization of sinter, the metallurgical properties of sinter ore used in 5800 m3 blast furnace of Shagang, such as drum strength, low-temperature reduction pulverization, medium-temperature reducibility were investigated. The effect of FeO content on the performance of sinter and the factors affecting FeO content were explored through statistical data analysis. The results show that based on Shagang's current raw material quality, ore blending structure and process operating conditions, the increase of FeO content can improve the drum index and RDI+3.15 of sinter. When RI is more than 85%, the FeO content becomes the limiting factor of RI, and the appropriate value of FeO content is about 9.5%. The increase of R, SiO2 content, fine powder and fuel ratio will cause the increase of FeO content, MgO content and negative pressure will cause the decrease of FeO content. Data analysis shows if R is 1.9, the contents of SiO2 and MgO are about 5.2% and 1.8%, respectively. The ratio of fine powder is less than 11%, the ratio of fuel is between 4.5 and 5%, and the negative pressure is below 16 KPa, the average FeO content of sinter is about 9.5%, the corresponding drum index is about 80%. The average values of RDI+3.15 and RI are above 75% and 80%, respectively.

-

Key words:

- Metallurgical engineering /

- FeO content /

- Sinter /

- Strength /

- Metallurgical properties /

- Influencing factors

-

-

表 1 烧结混匀矿配料结构/%

Table 1. Distribution ratio of each group of sintering raw materials

巴西粉 澳洲粉 精粉 杂料 卡粉 BRBF S FHT 扬迪 纽曼 PB 哈扬 澳精 英美精 智利精 英美资源 氧化铁皮 返矿 7~25 7~25 0~5 20~36 6~29 6~33 10~14 5~11 7~8 0~8 7~8 0~5 5~10 表 2 配矿结构及工艺参数

Table 2. Ore blending structure and process parameters

卡粉/% BRBF/% 杨迪/% 纽曼/% PB/% 精粉/% 燃料/% 负压/ kPa 15 16 32 13 16 8 4.8 14 表 3 烧结矿化学成分及冶金性能/%

Table 3. Sinter chemical composition and metallurgical properties

CaO SiO2 MgO Al2O3 FeO P2O5 TiO2 TFe RDI+3.15 RI T 10.16 5.22 1.82 1.78 9.47 0.06 0.11 56.87 78.32 79.9 80.33 -

[1] 罗桂娟, 付志军, 张水菊. 铁料中氧化亚铁测定的影响因素分析[J]. 化学分析计量, 2011, 20(5):86-88.LUO G J, FU Z J, ZHANG S J. Analysis of factors affecting the determination of ferrous oxide in iron materials[J]. Chemical Analysis and Metrology, 2011, 20(5):86-88. doi: 10.3969/j.issn.1008-6145.2011.05.026

LUO G J, FU Z J, ZHANG S J. Analysis of factors affecting the determination of ferrous oxide in iron materials[J]. Chemical Analysis and Metrology, 2011, 20(5):86-88. doi: 10.3969/j.issn.1008-6145.2011.05.026

[2] 吉训生, 荆田田, 熊年昀. 烧结矿FeO含量预测研究[J]. 计算机仿真, 2015, 32(10):318-322.JI X S, JING T T, XIONG N J. Research on the prediction of FeO content of sintered ore[J]. Computer Simulation, 2015, 32(10):318-322. doi: 10.3969/j.issn.1006-9348.2015.10.069

JI X S, JING T T, XIONG N J. Research on the prediction of FeO content of sintered ore[J]. Computer Simulation, 2015, 32(10):318-322. doi: 10.3969/j.issn.1006-9348.2015.10.069

[3] 张朝晖, 徐凯强, 邢相栋, 等. 烧结矿低温还原粉化影响因素研究进展[J]. 钢铁研究学报, 2021, 33(6):453-460.ZHANG Z H, XU K Q, XING X D, et al. Progress in the study of factors affecting low-temperature reduction pulverization of sintered ore[J]. Journal of Iron and Steel Research, 2021, 33(6):453-460.

ZHANG Z H, XU K Q, XING X D, et al. Progress in the study of factors affecting low-temperature reduction pulverization of sintered ore[J]. Journal of Iron and Steel Research, 2021, 33(6):453-460.

[4] 秦鹏, 毛志祥, 李琳, 等. 烧结矿低温还原粉化(RDI)影响因素的研究[A]. 中国金属学会. 2012年全国炼铁生产技术会议暨炼铁学术年会文集(上)[C]. 中国金属学会: 中国金属学会, 2012: 9.QIN P, MAO Z X, LI L, et al. Research on the influencing factors of low temperature reduction pulverization (RDI) of sintered ore[A]. China Society for Metals. 2012 National Conference on Ironmaking Production Technology and Ironmaking Academic Annual Meeting Proceedings (Upper)[C]. China Society for Metals: China Society for Metals, 2012: 9.

QIN P, MAO Z X, LI L, et al. Research on the influencing factors of low temperature reduction pulverization (RDI) of sintered ore[A]. China Society for Metals. 2012 National Conference on Ironmaking Production Technology and Ironmaking Academic Annual Meeting Proceedings (Upper)[C]. China Society for Metals: China Society for Metals, 2012: 9.

[5] 赵佐军. 基于六西格玛精益管理提高烧结矿还原性实践[J]. 烧结球团, 2019, 44(5):32-37.ZHAO Z J. Improvement of sinter ore reducibility practice based on Six Sigma lean management[J]. Sinter Pellet, 2019, 44(5):32-37.

ZHAO Z J. Improvement of sinter ore reducibility practice based on Six Sigma lean management[J]. Sinter Pellet, 2019, 44(5):32-37.

[6] 刘丽娜. 碱度对石钢烧结矿矿相结构及冶金性能的影响[J]. 钢铁钒钛, 2021, 42(3):125-129.LIU L N. Influence of alkalinity on the phase structure and metallurgical properties of sinter ore from Shigang[J]. Iron and Steel Vanadium and Titanium, 2021, 42(3):125-129. doi: 10.7513/j.issn.1004-7638.2021.03.019

LIU L N. Influence of alkalinity on the phase structure and metallurgical properties of sinter ore from Shigang[J]. Iron and Steel Vanadium and Titanium, 2021, 42(3):125-129. doi: 10.7513/j.issn.1004-7638.2021.03.019

[7] 庞建明, 汪志全. SiO2对烧结矿矿相组成的影响[J]. 安徽工业大学学报(自然科学版), 2005(4):338-340.PANG J M, WANG Z Q. Effect of SiO2 on the composition of sintered ore phase[J]. Journal of Anhui University of Technology (Natural Science Edition), 2005(4):338-340.

PANG J M, WANG Z Q. Effect of SiO2 on the composition of sintered ore phase[J]. Journal of Anhui University of Technology (Natural Science Edition), 2005(4):338-340.

[8] 贾树仟, 李建伟, 彭树成, 等. MgO含量对烧结矿性能的影响[J]. 河北冶金, 2020(8):7-10+73.JIA S Q, LI J W, PENG S C, et al. Effect of MgO content on the properties of sintered ore[J]. Hebei Metallurgy, 2020(8):7-10+73.

JIA S Q, LI J W, PENG S C, et al. Effect of MgO content on the properties of sintered ore[J]. Hebei Metallurgy, 2020(8):7-10+73.

[9] 王自学, 冯帅. 钒钛烧结矿性能及矿物组成和结构的研究[J]. 矿产综合利用, 2020(1):71-75.WANG Z X, FENG S. Study on metallurgical properties and phase of vanadium titanium sinter[J]. Multipurpose Utilization of Mineral Resources, 2020(1):71-75. doi: 10.3969/j.issn.1000-6532.2020.01.015

WANG Z X, FENG S. Study on metallurgical properties and phase of vanadium titanium sinter[J]. Multipurpose Utilization of Mineral Resources, 2020(1):71-75. doi: 10.3969/j.issn.1000-6532.2020.01.015

[10] 孟利建, 董复明, 刘金涛, 等. 加拿大精粉的烧结性能研究[J]. 矿产综合利用, 2021(1):130-133.MENG L J, DONG F M, LIU J T, et al. Experimental study on sintering of Canada iron ore fines[J]. Multipurpose Utilization of Mineral Resources, 2021(1):130-133. doi: 10.3969/j.issn.1000-6532.2021.01.022

MENG L J, DONG F M, LIU J T, et al. Experimental study on sintering of Canada iron ore fines[J]. Multipurpose Utilization of Mineral Resources, 2021(1):130-133. doi: 10.3969/j.issn.1000-6532.2021.01.022

-

下载:

下载: